Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

D8LC TS en

Caricato da

pricopdanielTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

D8LC TS en

Caricato da

pricopdanielCopyright:

Formati disponibili

Air heater D 8 L C

and Repair Instructions

These troubleshooting and repair in,tRlctions are valid

for the following heater versions:

DalC

251890 00 00 00 -12 V

25 1891 00 00 00 - 24 V

Contents Page

Sectional view.... ............ ................ ... ......... .... ...... 2

Description of operation ................................ ....... 3

Arst check the following if faults occur ................. 4

Function and fault test ...... ... .... ................. ............ 4, 5

Wiring diagrams. ............ ........ .............................. 6 - 9

Repair Instructions . ........ ...... .......... ...................... 10- 14

Fuel quantity measurement ............... .. .. ............... 15

Use attest adapter ... .................................. ... ...... 16

25 1766 95 0922 08.1995 Subject to alterations. Printed In Germany.

Eberspacher

Copyright J . Eberspticher

J . Eberspache!

GmbH & Co.

Eberspi!lcherstr. 24

073730 Esslingen

Telelon (zen Ira I)

(071 1)939 - 00

Telelax

(0711) 939 - 0500

C33

Sectional view of Dale

UST OF PARTS

1 Hot air Impeller

2 Combustion air Impeller

3 Glow plug

4 Safety thermal cutout switch

5 Combustion chamber

6 Flame sensor

7 Heat exchanger

12

8 Outer casing

9 Exhaust pipe seal

10 Fuel line

11 Blower motor

3 16

13

12 Combustion air solenoid valve

13 Exhaust pipe

14 Fuel metering pump

17 18

97 8 20 21

15 Fuel screen

16 Control relay

17 Glow plug relay

18 Control unit

19 Temperature limiter

20 Operating device

21 Heater timer

6)

I

@I[j)(!)@[B

F = Fresh air

V = Combustion air

B = Fuel

W = Hot air

A = Exhaust gas

22 Extemal room temperature sensor

2

. ....,

J

22

Description of operation

Control elements

1. Operating device

2. Heater timer

A heater timer can be installed in addition to the operating

device. The heater timer can be used to switch on the

heater immediately or preset a switch-on time from 24

hours to 7 days depending on the version.

Mode of operation

Sequence after switch-on

Switch-on: Green pilot light on operating device

comes "ON"

Glow coil of glow plug comes "ON".

(A timing relay ensures that the voltage

of the glow plug does not exceed the

permissible range.) Blower comes "ON"

at max. speed.

After about 25 sec: Fuel metering pump comes 'ON"

(with fuel feed rate for "High" heat flow.)

Once a stable flame forms, the glow plug is switched off after

a delay of approx. 10 sec. The heater is then forced to

operate for at least another 30 sec in the "High" setting. Only

then can heat controller begin to operate.

Heat flow/room temperature control

Heat flow and room temperature are regulated by interaction

of the external temperature sensor installed in the room to be

heated, by the operating device, the control unit and a

temperature limiter fitted in the air outlet.

The heater operates in either the "High" setting or between

the "High" and "Low" settings until the room temperature set

at the operating device (approx. 10C to 30 0c) is reached.

Fuel feed and, after a 2-second delay, combustion air feed are

reduced in the "Low" setting.

If the room temperature continues to increase despite the fact

that the heater is in the "Low" setting, the heater switches to

the "Off" setting and the blower continues to run for 3

minutes. The heater then switches to standby mode (green

pilot light comes on).

After the room temperature has dropped below the set value,

the heater is restarted and runs for 80 seconds in the "High"

setting.

The outlet temperature is limited by the temperature limiter to

125C to 150 C regardless of the room temperature.

Switch-off

When the heater is finally switched off, the green pilot light

goes out. The blower then continues to operate at high

blower speed to cool the heater down. This is stopped

automatically after 3 minutes.

3

Control and safety functions

The flame is monitored by the flame sensor, and the max.

permissible temperature by the safety thermal cutout switch

(4). Both the flame sensor and the safety thermal cutout

switch influence the control unit (18), which switches off the

heater in the event of a fault.

1. If the heater fails to ignite within 90 seconds after fuel feed

has started, start-up is repeated as described above.

If the heater repeatedly fails to ignite within 90 seconds

after fuel feed has started, a fault cutout is triggered.

2. If the flame goes out by itself during operation, a restart is

first performed.

If the heater repeatedly fails to ignite within 90 seconds

after fuel feed has started or if it ignites but goes out again

within 10 minutes, a fault cutout is triggered.

A fault cutout can be cancelled by briefly switching the

heater on and off again.

3. In the event of an overheat, the safety thermal cutout

switch is triggered (4), fuel feed is interrupted and a fault

cutout is then triggered.

If an overheat is the cause of a fault putout, the switch-on

pilot light (green) on the operating device flashes at a

steady rate.

Other fault display signals can be called using auxiliary

equipment.

4. If the voltage drops below approx. 1 0.5V or 21V or if it

rises above approx. 15V or 30V, a fault cutout is triggered

after 20 sec. Voltage undershoots or overshoots of shorter

duration do not have any effect.

5. When the heater is started up, the blower motor undergoes

a functional check. If it fails to start, the heater switches to

fault mode.

The blower motor is monitored cyclically (every 4 min.)

during operation. If the motor speed is below the

permissible limit, a fault cutout is triggered ..

Please note:

If electrical welding work is to be carried out on the vehicle,

disconnect the positive terminal from the battery and connect

it to ground in order to protect the control unit.

For a functional check of the heater, turn the rotary knob at

the operating device right round to the "High" setting.

First check the following if faults occur

Fuel in tank?

Fuses OK?

Electrical leads and connections OK?

Combustion air and exhaust piping free?

When combustion generates soot, check the following:

Combustion air pipe or exhaust pipe clogged? ........ Clear obstruction.

Fuel metering pump feeding too much? ........ Measure fuel quantity, replace fuel metering pump if necessary.

Deposits inside heat exchanger? ........ Clean heat exchanger, replace if necessary.

Function and fault test

Call diagnostic signals

Insert a strap between terminals 6 (yellow) and 4 (black &

white) on the back of the operating device for 0.5 to 5 sec.

or

Place a jumper to plug 8 between connection 89 (yellow) and

811 (black & white) on the control unit for 0.5 to 5 sec (see

wiring diagram).

To do this, unscrew the cover from the electronics box on the

heater and unclip the control unit from the holder. The green

pilot light on the operating device flashes and emits diagnostic

signals (listed on page 5).

Rectify the fault as described under "Remarks/Remedial

Action".

Check values

Speed of blower motor (at set voltage)

High: 3400 rpm 10 %

Low: 3200 rpm 10 %

After-ventilation: 3400 rpm 10 %

Flame sensor: 1 060 to 1 090 (when heater is cold)

Check safety thermal cutout switch for continuity.

Extemal room temperature sensor: 1800 to 2200 at 20C

Air outlet temperature limiter: 550 to 570 at 20 C

4

;.

.'

Diagnostic signals

0

1 T Y 1 Y ? T ~

sec.

Remark/Remedial Action

Operation

Overvoltage/undervoltage warning

1---

Check controller, charge battery

Check controller, if necessary check

Overvoltage cutout

--

battery charger. Heater must be

connected directly to the battery

Undervoltage cutout

-

Charge battery, check controller

Check glow plug

Glow plug interruption

----

Check leads and connections

Check glow plug relay

Burner motor not turning, Check motor speed, Replace blower if necessary

speed changeover relay defective Check speed changeover

Short -circuit in glow plug relay

.-

Replace glow plug relay

contacts

Safety time exceeded

---

Check fuel supply

Non-start Check glow plug, replace if necessary

Check heating air piping, inlet and outlet,

for clogging,. and if necessary clear any obstruction.

Overheat

1---------

Check electrical leads and contacts to fuel metering

pump. Check safety thermal cutout switch and if

necessary check air outlet temperature limiter

Fuel metering pump

---

Check metering pump and

short circuit supply lines, replace if necessary

Plug connection to external temperature sensor in

External room temperature

cable harness plugged in?

monitor defective

--

Check external temperature sensor directl

Check connection of operating device

(tester for operating device)

Flame sensor defective

1--

-

Check flame sensor or connections

Check PCB using test adapter

Check fuel line for leaks, Check fuel filter

Flame loss in "Low" setting

--

Check fuel quantity

Heater goes out by itself Check blower speed

Check function of solenoid valve

Check fuel line for leaks,Check fuel filter

Flame loss in "High" setting

~

Check fuel quantity

Heater goes out by itself Check blower speed

Check function of solenoid valve

Control unit defective Replace control unit

External interference voltages

-

--

Eliminate cause

Check solenoid valve for short-circuit

Air outlet temperature limiter No flashing code Effect of short-circuit:

is not monitored by Heater still operates in "High" setting.

diagnostic unit and has Effect of interruption:

to be checked manually. Heater now operates only in "Low setting.

Display if provided

.--------

5

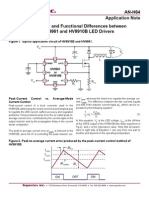

Wiring diagram - 251890 -12 V Design up to model year mid-1995

251891-24 V

/

i

/

l I

I 2

a::o CI:D CJTI

I rw----lllTTIl-rrU-rr-D :--1 -----

I

,

(1- '

(ill]][!) I ---:] I mn

-

--- f-=f:: -- - --

I! !

8

Q Q

In-o,

\\

1 ___ .1

I "1-'\

\

\

12 II

\

a::IT)

<Iill

/

r---f

i CID

I

j

I

ICC]])

I .

i

L ___ ,

<>

L-

t-

I

5 !II_S

I . S Dr

-

rni]

,84

- / /I /

l

CI:D

\CIJD

r-------------------,

\

! 8 A

Gill

1lT

I I) II 9 7 5 1 I

TT I

[ITTITn-ITTITnrln-ITI

'-I -l-J-.s61-BTiOIII2ili"i, i-i2-'J4

1

1--- ----- -----1 ----

r ( -r= Jt 1\' mil

- run

1. 0 C1I

1. 0 . 5

1. 5 IS

1. 0 .,so

1. 0 Dr

1.5 It

I . G ... 1

1"--

1 .. \ 5.

I, Qii]

;

1. 5 Dr

/

I. I. I

1. 5 " 111 .l:m

I. 0 Ir

i

\. CIID

\ 1.5 5'QI1

1. 5 Sns

I J;llf-

/

L_J.::

OJD :C:

1. 0 \)1"$ /

'N') r-

i . ,.:::;..."

1. 0 fII'

\\.----a"

/

.. _-----

- 1-1- -I- -1----- ---------_.1

CID CID

I

rt

E

'"

J

il

!o

!I! I: !

11 L a .

A. .. B = L posijive

<> .. .... <>

13 .1 N"'; C ... D = L negative

IT

H - 1--1-

-r

,

L pos, + L neg. = L total

85 86

\

\

84

v v

f-J- -f--

v

+-

g

---

rl Dr

-

..

- ,., 1.0 Ir.s

C +11.0 cr

2. 5 rl

2.5 Dr

111108 6

IJ \I 9 7 5 J I

....l-

87

86

85

- f-

JO

':'.t=I

____________________

1.0 rt

'[

1. 05"5

1. 09".

1. 5 flO 1.0 \ll'rt

I. S 'lI' 1. 0 DrYS

1.0 bl .,

Parts list

1.1 Burner motor 2.1 Control Length AS + length CD

-I

i

i

I

I

i

I

,.

-'

1.1 ,1 Resistor for burner motor (partial load)

1.2 Glow plug 2.2 Fuel metering pump

< 5 m, cross-section 4 mm

2

> 5 m < 8 m, cross-section 6 mm

2

l.5 Safety thermal cutout switch

1.7 PCB

1.B.5 Varistor

1.12 Flame sensor

1.13 Temperature sensor

2,3 Air solenoid valve (for combustion air)

2.5.1 Glow plug relay

2.5.5 Control relay

2.7 12V1S0A main fuse

24V125A

2,15.1 Room temperature sensor

2.15.9 Outside temperature sensor

6

BI SI

<D

_

___ --Ti'('""T"'1 rl ,----=->

r-

Q) Ie ':

CD

I i oe

I 1-

, IIr ,

bl

IlTt i

:::::J

'<II

i

i

I

i

<D W;L

-

!

B2

r--r---"""'25.---r=

CD ----ji-<l=

1+...:: -"<-+--

I I.

.1

dl

81

I 1-

r-F

II

I

,

I

I :

B3

3.1 .11 Operating device

3.1 .12 Fault code enquiry

3.2.5 Timer, rectangular, 7 -day

-

-=

3.2.7 Timer, rectangular, surface-mounted

5.1 Battery

a)

b)

c)

d)

e)

BI SI

... ,., ...

..,."

ID"" ......

(I::::; I]l

I

U

aWI!1IWlIlIla

u

BZ

83

Test (garage) digital timer

When connecting timer

cut wil9 here x

Vehicle light terminal 58

Terminal 15

Terminal 31 (battery-)

7

Plug housing and socket housing aI9 shown

from the conductor entry side

Wiring diagram -- 25 1890 - 12 V Design up to model year mid-1995

251891-24 V

85

..1

11

51

15

t- t-

30 I

CIDCIIJ CID

i iJJ

- IID_UJ U_U I

-----',.6'

\ UI 2-:iil

I -01

ammJ IIDl

L- _--1

21 -_

It l!

25 til'

/11

I 2 2. S .. ....

0::0

;'it-II

a.ID

illI)

,----:=:=1

COD

I B .

t 13 1/ 9 7 5 l 1 2 T

TTT!JJ_LI I' . 'rlD:

1 1

II 2 3 4 5 5 7 I , 10 II 12 13 '"

J: ,,87

85

.: r\

I: I

f.-H 1m]

I

Jl

L.-..

f-

I

1011

2511

10...,

T 1 I 0 til'

15 .. .-

10_1

I

II II

15_

CITIDI

I

C>

I 5 til'

I.S e.

&1h1i

I 5 til'

J

.1.

I 0 til'

1. 5 BIIrI 1:1

1.5 BIIrI

15_

If

CIJI) I 0 tII'n

r=--'

IOcr

____ I

\---:..

'7"'-

-

"'"

- --_.

-

J

lit

I"

8 Is II !.&-r

Cil) OJ::)

:;;

13 14 ::::

..

... on .rt

NN

-t

86 87 II I

-)

a ______ 1

4 3

\I "

...

(fJ

2 I

II

-

I B

on o til'

lOtii'm

1

1

_

21

r=- r 1(1=1-110 cr

o rt

;-

::: ......

til'

.LULU.LL!_!!.aill!l!j

6

I 0 rt

.11

10_

10 ..

15 CII 1 0 crrt.

Ltl

I 5 CII 10 ln8

lObI ..

I

________________________________________________________

Parts list

1 .1 Burner motor

1 .1 .1 Resistor for burner motor (partial load)

1 .2 Glow plug

1.5 Safety themlal cutout switch

1.7 PCB

1.8.5 Varistor

1 .12 Flame sensor

1.13 Temperature sensor

2.1 Control unit

2.2 Fuel metering pump

2.3 Air solenoid valve (for combustion air)

2.5.1 Glow plug relay

2.5.5 Control relay

2.7 12V/30A main fuse

24V125A

2.15.1 Room temperature sensor

2.15.9 Outside temperature sensor

8

Length AB + length CD

< 5 m, cross-section 4 mm'

> 5 m < 8 m. cross-section 6 mm'

"

1

. /

)

.J

B3 S2

dl--++---+Cj

B4

3.1.11 Operating device

3.1.12 Fault code enquiry

3.2.5 Timer. rectangular, 7-day

3.2.7 Timer, rectangular, surface-mounted

5.1 Battery

1-

I

I

'-

a)

b)

c)

d)

e)

COL

UI!III!I !ill 12!1 11111 aU

o . : ~ t .

TT

I

-

84

Test (garage) digital timer

When connecting timer

cut wire here x

Vehicle light terminal 58

Terminal 15

Terminal 31 (battery-)

9

Plug housing and socket housing are shown

from the conductor entry side

Repair instructions

For designation and

Cat. No. of spare parts,

see spare parts list

10

Repair steps

Remove / Install

1. Cover

2. Glow plug

3. Solenoid valve

4. PCB

5. Control unit

6. Safety thermal cutout switch

7. Temperature limiter

8. Flame sensor

Overall view of heater

11

9. Preparations for removal

of outer casing

10. Brackets, reducing pieces

11 . Outer casing

12. Heat exchanger with blower, remove

from outer casing

13. Blower and heat exchanger

14. Blower impeller

15. Combustion chamber lining

Remove I install

1. Cover 4. PCB

2. Glow plug 6. Control unit

3. Solenoid valve 6. Safety thermal cutout switch

12

7. Temperature limiter

8. Flame sensor

9. Preparations for removal of outer casing

13

10. Brackets, reducing pieces

11. Outer casing

When inserting the screws along the longitudinal

seam, draw together the casing using tightening strips.

12. Heat exchanger with blower, remove from outer casing

-.,

13. Blower and heat exchanger

14. Blower impeller

15. Combustion chamber lining

14

30

ml 25

20

Fuel quantity measurement

CAUTIONI Only measure the fuel when the battery is

sufficiently charged. At least 11/22V and max. 13/26V as

appropriate must be applied to the control unit during

measurement.

1. Preparation

Detach the fuel line from the heater and place it In a

measuring glass.

Connect a voltmeter to terminals 3 (+) and 4 (-) on the control

unit.

Switch on the heater. When fuel is fed smoothly (about 25 to

55 seconds after switch-on), the fuel line is filled and bled.

Switch off the heater and empty the measuring glass.

2. Measurement

Switch on the heater.

Fuel pumping starts about 25 to 55 seconds after switch-on.

Keep the measuring glass at the level of the plug during

measurement.

Read off the voltage at the voltmeter.

About 90 seconds of pumping it is switched off automatically.

Switch off the heater.

Measure the fuel quantity in the measuring glass.

DalC (12V)

Fuel consumption in ml/90 sec.

Fuel consumption In (mV90 sec.)

~ o

---

---

29.0

..--

..--

I ~

~

--

-

--

~

--

--

11 11,5 12 12,5 13

Operating voltage in (V)

3. Evaluation

Plot the readings onto the diagram.

Fuel consumption is OK when the intersection of the two

values is inside the limit curve.

If they intersect outside the curve, the fuel metering pump

must be replaced.

DalC (24V)

Fuel consumption in mV90 sec.

Fuel consumption in (mV90 sec.)

30

~ o

---

---

28.0

---

..--

~

~

I---"

ml 25

.---

--

~

--

~

-n;-

20

I .

22 23 24 25 26

Operating voltage In (V)

15

Tester for operating device

Disconnect the plug from the operating device.

Connect the tester to the operating device.

Connect the operating voltage.

Set the switch on the operating device to the "Ventilation and

Heating" setting. The appropriate lights must come on.

The pilot light in the switch must also come on:

* This test is not necessary during operation with heater timer.

Tester for operating deviceg

Set the operating device to the "0" setting.

Call the light.

Press key 1 and also key 2.

Pilot light must change from red to green.

Connect the ohmmeter. Turn the rotary knob right round.

The set value of 1800 to 2200 must be sustained without

interruption.

In the event of a fault, replace the operating device.

--------

1800- 2200

4.>-+----(

5 > - ~ - - - - - - - - - - - - - - - - - - - - ~ - - ~ ~

Heating

6

'9

----- - - - - - - - - - - - . ~

16

+

sw

Key 2

Green LED

Key 1

Red LED

. ~

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Location ComponentDocumento12 pagineLocation ComponentpricopdanielNessuna valutazione finora

- Technical Data Sheet: Opus A3 Standard BasicDocumento9 pagineTechnical Data Sheet: Opus A3 Standard BasicNicole SmithNessuna valutazione finora

- Alaska Eng 11.2019Documento115 pagineAlaska Eng 11.2019pricopdanielNessuna valutazione finora

- Catalog 2011Documento113 pagineCatalog 2011pricopdanielNessuna valutazione finora

- Repair Ecas2 Ecas3 ConversionDocumento2 pagineRepair Ecas2 Ecas3 ConversionpricopdanielNessuna valutazione finora

- Inspection Ecas3 lf45lf55 PDFDocumento1 paginaInspection Ecas3 lf45lf55 PDFpricopdanielNessuna valutazione finora

- BA - UGE - 04-15 - en - GB - PDF UNIMOG U5000 PDFDocumento384 pagineBA - UGE - 04-15 - en - GB - PDF UNIMOG U5000 PDFFelipe GlauserNessuna valutazione finora

- SW 10 16 Ta Ma EnglDocumento64 pagineSW 10 16 Ta Ma Englpricopdaniel100% (2)

- Meritor ManualDocumento192 pagineMeritor ManualJanisse B. Padilla100% (1)

- Dealer Response Form: Only For LF45 Vehicles Mentioned in PSFA 0090001Documento1 paginaDealer Response Form: Only For LF45 Vehicles Mentioned in PSFA 0090001pricopdanielNessuna valutazione finora

- 730a Motoconformadora PDFDocumento262 pagine730a Motoconformadora PDFHilton Herrera83% (6)

- Libro de Instrucciones LE LT LF 2003Documento72 pagineLibro de Instrucciones LE LT LF 2003Alfonso CasemaNessuna valutazione finora

- Inspection Astronic Cf75cf85xf95 12tdDocumento1 paginaInspection Astronic Cf75cf85xf95 12tdWaldek KozlowskiNessuna valutazione finora

- 17 - BremsachseDocumento2 pagine17 - BremsachsepricopdanielNessuna valutazione finora

- Trailer ABS: 000 700 022/01.99./redditchDocumento20 pagineTrailer ABS: 000 700 022/01.99./redditchpricopdanielNessuna valutazione finora

- Haldex Brake Products LTDDocumento30 pagineHaldex Brake Products LTDpricopdanielNessuna valutazione finora

- Deutz Emr4 Tier4f CanDocumento47 pagineDeutz Emr4 Tier4f CanMircea Gilca100% (1)

- K1 12 AS Mid OD/TO: (Incr) (Incr) (Incr) (Incr)Documento1 paginaK1 12 AS Mid OD/TO: (Incr) (Incr) (Incr) (Incr)pricopdanielNessuna valutazione finora

- en WHB Hatz W35 PDFDocumento76 pagineen WHB Hatz W35 PDFpricopdaniel100% (3)

- ZF 3 WG 94 PDFDocumento106 pagineZF 3 WG 94 PDFpricopdaniel100% (4)

- Culori Ral UtilajeDocumento10 pagineCulori Ral UtilajepricopdanielNessuna valutazione finora

- v8+ Electrical Error Fault Codes v1-07Documento2 paginev8+ Electrical Error Fault Codes v1-07Rajan Mullappilly100% (9)

- Man Fault-Messages-TGA PDFDocumento203 pagineMan Fault-Messages-TGA PDFNadeem Mohd100% (9)

- GHH PDFDocumento14 pagineGHH PDFpricopdanielNessuna valutazione finora

- v8+ Electrical Error Fault Codes v1-07Documento2 paginev8+ Electrical Error Fault Codes v1-07Rajan Mullappilly100% (9)

- ManDocumento1 paginaManpricopdanielNessuna valutazione finora

- Meritor ManualDocumento192 pagineMeritor ManualJanisse B. Padilla100% (1)

- Liebherr LTM 1040-2.1 Mobile Crane - 40t - InformationDocumento16 pagineLiebherr LTM 1040-2.1 Mobile Crane - 40t - InformationCallumWoodward50% (2)

- GHH PDFDocumento14 pagineGHH PDFpricopdanielNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- STATCOMDocumento17 pagineSTATCOMAbdel-Rahman Saifedin ArandasNessuna valutazione finora

- Chapter5 Low Noise AmplifiersDocumento104 pagineChapter5 Low Noise AmplifiersNikunj ShahNessuna valutazione finora

- Is - 2026Documento7 pagineIs - 2026Qadri FaizanNessuna valutazione finora

- 2SK4085LS - 500V, 16aDocumento5 pagine2SK4085LS - 500V, 16aRenatoMaiaNessuna valutazione finora

- DeviceNet Drop 2x24 AWG + 2x22 AWG SFTP FR-PVC - 982VD14101 - V - 1 - R - 2 PDFDocumento2 pagineDeviceNet Drop 2x24 AWG + 2x22 AWG SFTP FR-PVC - 982VD14101 - V - 1 - R - 2 PDFᕱᕱᗋᖇᓾᗅ ᙍᕠNessuna valutazione finora

- DC Motor Control Using Arduino: 1) IntroductionDocumento10 pagineDC Motor Control Using Arduino: 1) IntroductionSoeAyeNessuna valutazione finora

- Superbar Final 2019Documento32 pagineSuperbar Final 2019Firoj Al HasanNessuna valutazione finora

- New Construction FIRE ALARM ChecklistDocumento2 pagineNew Construction FIRE ALARM ChecklistThein TunNessuna valutazione finora

- 11kV GIS Specification PDFDocumento44 pagine11kV GIS Specification PDFRiyazNessuna valutazione finora

- An H64Documento4 pagineAn H64Hugo RojasNessuna valutazione finora

- Lead Acid Battery Training by EnerSys at IEEE 02-21-13 PDFDocumento134 pagineLead Acid Battery Training by EnerSys at IEEE 02-21-13 PDFDanny NjomanNessuna valutazione finora

- Analog Electronics Module-2Documento15 pagineAnalog Electronics Module-2Sourabh HalagekarNessuna valutazione finora

- MKS MV HV CapacitorsDocumento12 pagineMKS MV HV Capacitorsjoydeep_d3232Nessuna valutazione finora

- Setting Co-Ordination Chart & Graph Relay Setting Calculation 0.415 KV Panel - Ecr-2Documento90 pagineSetting Co-Ordination Chart & Graph Relay Setting Calculation 0.415 KV Panel - Ecr-2susovan bIswasNessuna valutazione finora

- Color Monitor: Service ManualDocumento34 pagineColor Monitor: Service ManualCristian LeizzaNessuna valutazione finora

- Electrical ConstructionDocumento41 pagineElectrical ConstructionJayam Harinatha Guptha100% (2)

- MAJORDocumento30 pagineMAJORcholleti sriramNessuna valutazione finora

- bc337 PDFDocumento4 paginebc337 PDFgerluccioniNessuna valutazione finora

- Sensor de Marca Lx-100Documento16 pagineSensor de Marca Lx-100ElinplastNessuna valutazione finora

- Aimur Professional Outdoor Decorations Magic Christmas 2021-22Documento114 pagineAimur Professional Outdoor Decorations Magic Christmas 2021-22VEMATELNessuna valutazione finora

- MAX803/MAX809/MAX810 3-Pin Microprocessor Reset Circuits: General Description - FeaturesDocumento8 pagineMAX803/MAX809/MAX810 3-Pin Microprocessor Reset Circuits: General Description - FeaturesStefania FerrarioNessuna valutazione finora

- 220kV Thaltej Substation 220 132 33kV, 250MVA ICT-3 HV (BAY-206) 206Documento134 pagine220kV Thaltej Substation 220 132 33kV, 250MVA ICT-3 HV (BAY-206) 206Ragul VNessuna valutazione finora

- Electronics Fundamentals: Circuits, Devices, and ApplicationsDocumento40 pagineElectronics Fundamentals: Circuits, Devices, and ApplicationsCece SolihinNessuna valutazione finora

- AC Practice ExerciseDocumento3 pagineAC Practice ExercisesumitNessuna valutazione finora

- PSI AP Physics C - Gauss's Law Multiple Choice QuestionsDocumento7 paginePSI AP Physics C - Gauss's Law Multiple Choice Questionsanthony solorzanoNessuna valutazione finora

- Sr. RF Design EngineerDocumento2 pagineSr. RF Design Engineerapi-121655558Nessuna valutazione finora

- Brushless DC MotorDocumento14 pagineBrushless DC Motorir_yusriNessuna valutazione finora

- Product Specifications Product Specifications: DB411 DB411 - BBDocumento2 pagineProduct Specifications Product Specifications: DB411 DB411 - BBCesar LopezNessuna valutazione finora

- Blinking LED Project FinalDocumento16 pagineBlinking LED Project FinalGauravNarkhede60% (15)

- Transformer PolarityDocumento10 pagineTransformer PolarityMizhar GerardoNessuna valutazione finora