Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Gerador Kipor Kde19 Sta

Caricato da

antoniomecptDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Gerador Kipor Kde19 Sta

Caricato da

antoniomecptCopyright:

Formati disponibili

DIESEL

GENERATING SET

R

WUXI KIPOR POWER CO., LTD.

R

KDE16EA K DE16STA

KDE19EA K DE19STA

KDE16EA3 K DE16STA3

KDE19EA3 K DE19STA3

Si ngl e- phase:

Three- phase:

PREFACE

Thank you for purchasing a our generating set.

This manual covers the operation and maintenance of our generating

sets KDE16STA/KED19EA/KED19STA/ 3/KDE16STA3/

KED19EA3/KED19STA3 generating set. All information in this manual is based on

the latest product information available at the time of printing.

Read all labels and the owner's manual before operating this generator.

Operate only in well ventilated areas. Exhaust gas contains poisonous carbon

monoxide, and can be deadly. Always stop engine before refueling. Wait 5 minutes

before restarting.

Check for spilled fuel or leaks. Clean and/or repair before use.

Keep any sources of ignition away from engine.

KDE16EA/ KDE16EA

We reserves the right to make changes at any time without notice and without

incurring any obligation.

No part of this publication may be reproduced without written permission.

This manual should be considered an important part of the generating set, and

it must stay with the generating set if resold.

Check local laws and regulations before operating the generating set. If you

have any questions about compliance with local requirements governing

generating set use, consult a qualified electrician, electrical inspector, or licensed

contractor.

Read this manual careful. Pay special attention to these symbols and anyinst-

ruction that follow:

Failure to properly follow these precautions can result in

property damage, serious injury or DEATH!

If a problem should arise, or if you have any questions about your generating

set, consult our company or an authorized our agent.

Indicates a strong possibility of severe personal injury or

death if instructions are not followed.

Indicates that the equipment damage will result if the

instructgions are not followed.

Indicates that helpful information is provided.

To ensure the safety and durability, be sure to obey to this

manual. To ensure the safety of the operator and others, be

sure to correctly operate and carefully manage your

generating set.

Indicates that there is potential danger of severe personal

injury or death if carelessly operate or misuse the generat-ing

set. Be sure to read this manual before operation.

If a problem should arise, or if you have any questions about

your generating set, consult our company or an authorized

our agent.

[OPERATION NOTICE]

39

1. Safety Information

2. Parts Name and Control Unit

2.1 Generator fig

2.2 Control Panel

2.3 Breaker

2.4 Fuel Meter

2.5

2.6 AC Three-phase and Single-phase Output Terminals

3. Pre-running Check

3.1 Engine Oil

3.2 Fuel

3.3 Coolant

3.4 Fuel-water Separator

3.5 Battery

4. Start and shut off the engine

4.1 Break-in Period (initial 50 hours)

4.2 Start the Engine

4.3 Stop the Engine

The functions of the digital panel

1

2

2

3

4

4

5

6

7

8

9

11

12

13

14

14

14

16

CONTENTS

38

The conditions of generator rated output:

Altitude: 0 m Ambient temperature: 25 Relative humidity: 30%

Ambient modified coefficient: C (Relative humidity 30%)

Note: When the relative humidity is 60%, the modified coefficient is C-0.01

When the relative humidity is 80%, the modified coefficient is C-0.02

When the relative humidity is 90%, the modified coefficient is C-0.03

When the relative humidity is 100%, the modified coefficient is C-0.04

Counting example:

When the rated power of generator is P =5KW, altitude is 1000m, ambient

N

temperature is 35 , relative humidity is 80%, the rated power of generator is:

P=P (C-0.02) = 5 (0.82-0.02) = 4KW

N

2. Modified coefficient table of ambient condition power

Ambient temperature ( )

Altitude

(m)

0

500

1000

2000

3000

4000

25

1

0.93

0.87

0.75

0.64

0.54

30

0.98

0.91

0.85

0.73

0.62

0.52

35

0.96

0.89

0.82

0.71

0.6

0.5

40

0.93

0.87

0.80

0.69

0.58

0.48

45

0.90

0.84

0.78

0.66

0.56

0.46

5. Handling the Generating Set

5.1 Connecting to a Building's Power Supply System

5.2 AC Application

5.3 Usage of the Receptacles and Terminals

6. Maintenance

6.1 Maintenance schedule

6.2 Replace Engine Oil

6.3 Service the Air Cleaner

6.4 Clean the Battery

6.5 Replace the Fuse

7. Transporting and Storage

7.1 Transporting

7.2 Storage

8. Troubleshooting

9. Technical Specifications and Data

10. Electrical wiring diagram

11. Appendix

17

17

18

22

23

23

24

25

26

27

28

28

29

30

31

33

37

37

The choice of the electric cable depends on the allowable current of the cable

and the distance between the load and the generator. And the cable section

should be big enough.

If the current in the cable is bigger than the allowable current, it will become over

hot and the cable will be burnt. If the cable is long and thin, the input voltage of

the electric appliance will be not enough, causing that the generator doesn't start.

In the following formula, you can calculate the value of the potential "e".

The relations among of the allowable current, and length, section of the Insulating

cable (single core, multi-core) are as follow:

(Presume that the use voltage is 220V and the potential is below 10V.

2

The application of the single-core insulating cable section mm

2

The application of the multi-core insulating cable section mm

1. The choice of the electric cable

Potential (v) = Current (A) 3

Length

Section area

1

58

50A

100A

200A

300A

Current

Lengt h

beneath

75m 125m 200m 150m 50m 100m

8

22

60

100

14

30

60

100

38

60

125

200

22

38

60

100

22

50

80

125

30

50

100

150

50A

100A

200A

300A

Current

75m 125m 200m 150m 50m 100m

14

38

38 2

60 2

14

38

38 2

60 2

22

38

38 2

60 2

22

50

50 2

60 2

30

50

50 2

80 2

38

60

50 2

100 2

Lengt h

beneath

Electrical equipment (including electrical lines and plugs connection) could not be

defective. By the effect of mechanical stress, make sure to use the rubber sheathed

flexible cable or analog.

Limit length of electric line when using the extension line or distributed network is: less

than 60m for cables of 1.5mm2, and less than 100m for cables of 2.5mm2

Caution: !

10

11. PPENDIX

1

Carbon monoxide hazards

Exhaust contains poisonous carbon monoxide, a colorless and odorless

gas.Inhaling exhaust can cause loss of consciousness and lead to death.

If you run the generating set in unventilated or confined place, the air you

breathe could contain a dangerous amount of exhaust gas. So, be sure to

keep the good ventilation to prevent the exhaust gas from building up.

Operator

Responsibility:

For the safety of the operator and others, be sure to operate the

generating set carefully.

Know how to stop the generating set quickly in case of emergency. Master

the usage and connection procedures of all generating set controllers,

output receptacles. Be sure that the operator must receive proper

instruction. The children or the pets are forbidden to close to the generator.

The operation including installation, running and maintenance should be

done by professional people who know well about the feature of generator.

Fire and burn hazards

The exhaust gets hot enough to ignite some materials. The gen-erating set

must be kept at least 1 meter away from buildings and other equipments.

Keep flammable materials away from the generating set. Be sure to service or

store the generating set in doors after the engine cooled.

The fuel is flammable and fuel vapor can explode. Refuel in a well-ventilated

place with the engine stopped. Keep the flames and sparks away, and do not

smoke in the area.

Fuel may spill and ignite if the generating set is tilted or overturned. Place the

generating set on a firm, level surface. Avoid loose sand or snow.

It is limited to use the generator in the high-hazard risk area.

Some parts of the explosive motor are very hot. Failure to operate could lead

to burn. Please note the warning stickers on the generator.

Operators should have self-protection awareness when operating generator,

please wear sound-proof ear shield, insulating boot and insulating gloves.

The key of door lock and electric door accessories for meter door and

maintenance door should be well kept by operators. Please lock the doors of

generator tightly to prevent somebody to operate (the children can not realize

the danger).

WARNING

WARNING

Electric shock hazards

The generating set will produce enough electric current to cause a serious

shock or electrocution if misused. Running the generating set in the wet

places such as rain, snow, swimming pool or sprinkler system, or when your

hands are wet, could result in electrocution. Do not connect to the building's

power system without installation of the isolation switch performed by a

qualified electrician.

WARNING

1. SAFETY INFORMATION

4. KDE16EA3, KDE19EA3 Electrical wiring diagram of

36

Coolant drain outlet

2

2. PATS NAME AND CONTROL UNIT

2.1 Generator fig.

Cooling air outlet Exhaust outlet

Lifting hook

Fuel filler cap

Emergent stop button

Operation panel

Grounding bolt

Connection pole

Fuel drain outlet

Engine oil drain outlet

Overflow pot

Engine oil drain bolt

Battery

Air filter

35

3. KDE16EA, KDE19EA Electrical wiring diagram of

3

2.2 Control panel

Fuel Meter Fuse Breaker

Smart Display

Starter Switch

Starter switch

starter

starter

34

2. KDE16STA3, KDE19STA3 Electrical wiring diagram of

4

Breaker can prevent the electric shock. If need to replace , please replace one

that has equal degree and performance.

Fuel

2.4 Fuel Meter

2.3 Circuit Breaker

Indicator

Fuel meter

33

1. Electrical wiring diagram of KDE16STA, KDE19STA

10

10. ELECTRICAL WIRING DIAGRAM

5

Knob function:

Screen Option: Switch the content of display, the content including: battery voltage,

running time, output frequency, output current, generator voltage.

Phase Sequence Switch: Switch the three-phase voltage and current.

Start/Back: Start the generator, press the knob for two minutes after the generator

started, the generator current specification will display automatically.

Stop/Clear: Stop the generator, it can stop the annunciator, trouble indicator light.

Indicator function:

Battery Voltage: Indicating battery voltage.

Running Time: Indicating generator total running time.

Frequency: Indicating generator frequency.

2.5 The functions of the digital panel

Voltage Current Frequency Running time Battery voltage

Generator running

Running trouble

Voltage Current Frequency Running time Battery voltage

Generator running

Running trouble

Code map list:

P-01 Low oil pressure

P-02 Underfrequency

P-03 Undervoltage

P-04 Generator overload

P-05 Start trouble

P-06 Emergency indicator

P-07 Charging trouble

P-08 Generator overheating

PRE-H Preheating indicator

START Start indicator

Code map list:

P-01 Low oil pressure

P-02 Underfrequency

P-03 Undervoltage

P-04 Generator overload

P-05 Start trouble

P-06 Emergency indicator

P-07 Charging trouble

P-08 Generator overheating

PRE-H Preheating indicator

START Start indicator

Screen option Phase sequence

switching

Start/Back Stop/Clear Screen option Phase sequence

switching

Start/Back Stop/Clear

PVC Lable (Three-phase) PVC Lable (Single-phase)

32

Generating Set Model

E

n

g

i

n

e

Model

Type

Displacement(L)

BoreXStroke(mm)

Fuel

startomg system

lubricating system

Engine oil capacity(L)

Rated output (kW)

Rated frequency (Hz)

Rated voltage(V)

Rated current(A)

Max. output (kVA)

Phase

Power factor

Excitation method

Fuel tank capacity(L)

Structure

LxWxH(mm)

Net weight (kg)

U

n

i

t

Fuel consumption (g/kWh)

G

e

n

e

r

a

t

o

r

u

n

i

t

KM376AG KM376AG KM376AG KM376AG

Calibration power kw/r(r/min)

1.048

76X73

1.048

76X77

1.048

76X77

1.048

76X77

13.5/3000 15.5/3600 15.3/3000 17.5/3600 17.5/3600 17.5/3600 15.3/3000 15.3/3000

Light diesel oil

295 295 295 295

12V DC electric starter

Pressure and splashing

4.8

12

50

13

14 15.5KVA 13.5KVA

230/115

52.2/104.4

17 14.4 19.0KVA 16.25KVA

60 60 60 60 50 50 50

240/120

58.3/116.6

15 16.7 18.7

400/230

19.5

416/240

21.5

230/115

62.6/125

240/120

70.8/142 23.5 26.4

Single phase Three phase Single phase Three phase

1.0 0.9(Lag) 1.0

Self-excited stabilivolt (AVR)

38

Ultra silent generator

1210 800 855

400/230 416/240

300 300 320 320

0.9(Lag)

KDE16EA KDE16EA3 KDE19EA KDE19EA3

15kVA 17kVA 18.75kVA 21kVA

6

Three-phase current: Indicating generator current.

Single phase power: Indicating generator power.

Generator voltage: Indicating generator voltage.

Generator running: Indicating the existence of electrical power.

Running trouble: Indicating running trouble, check it according to the code map list.

The indication lamp function of Code map list :

P-01 Low oil pressure: Indicating low oil pressure, the generator will self-braking.

P-02 Underfrequency: Indicating frequency higher (lower), the generator will self-

braking.

P-03 Undervoltage: Indicating voltage higher (lower), the generator will self-

braking.

P-04 Generator overload: indicate overload, the generator will self-braking.

P-05 Start trouble: Indicating failure start

P-06 Emergency indicator: Indicating stop generator according to emergency

measure.

P-07 Charging trouble: Charging system trouble.

P-08 Generator overheating: Water temperature of generator is overheated, the

engine will self-braking.

2.6 AC Three-phase and Single-phase Output Terminals

31

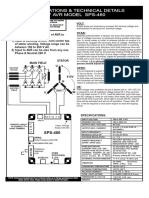

Specifications and technical of Ultra-silent generating set

the noise list indicates the noise emission level while not the safe working noise

level. Although the noise emission level is related to the sound exposure level, it is

not the judging standard for whether applying noise protection. Factors affect the

practical noise level include: the ambient condition and other noise source, such as

the quantity of working machine or the working hours in noisy condition. Furthermore,

the sound exposure level varies among different countries.

INSTRUCTION !

Generating Set Model

E

n

g

i

n

e

Model

Type

Displacement(L)

BoreXStroke(mm)

Fuel

startomg system

lubricating system

Engine oil capacity(L)

Rated output (kW)

Rated frequency (Hz)

Rated voltage(V)

Rated current(A)

Max. output (kVA)

Phase

Power factor

Excitation method

Fuel tank capacity(L)

Structure

LxWxH(mm)

Net weight (kg)

U

n

i

t

Fuel consumption (g/kWh)

G

e

n

e

r

a

t

o

r

u

n

i

t

KDE16STA KDE16STA3 KDE19STA KDE19STA3

KM376AG KM376AG KM376AG KM376AG

Calibration power kw/r(r/min)

1.047

76X77

1.047

76X77

1.047

76X77

1.047

76X77

15.3/3000 17.2/3600 15.3/3000 17.2/3600 17.5/3600 17.5/3900 15.3/3000 15.3/3000

Light diesel oil

320 320 320 320

12V DC electric starter

Pressure and splashing

5.2

12

50

13

14 15.5KVA 13.5KVA

230/115

52.2/104.4

17 14.4 19.0KVA 16.25KVA

60 60 60 60 50 50 50

240/120

58.3/116.6

15 15 17 16.7 18.7 18.7 21

400/230

19.5

416/240

21.5

230/115

62.6/125

240/120

70.8/142 23.5 26.4

Single phase Three phase Single phase Three phase

1.0 0.9(Lag) 1.0

Self-excited stabilivolt (AVR)

38

Ultra silent generator

1540X845X925

9. TECHNICAL SPECIFICATIONS AND DATA

400/230 416/240

420 420 442 442

0.9(Lag)

7

3. PRE-RUNNING CHECK

Maintenance door

30

Is the electric door lock on? Turn the electric door lock on?

8. TROUBLESHOOTING

ing.

agent.

8

3.1 Engine Oil

29

7.2 Storage

1. Clean each generating set component.

2.Check each part according to the maintenance schedule and repair/service the faulty

parts.

3. Replace the engine oil with fresh oil before operating the generating set after storage.

4.Fill the fuel tank with fresh diesel fuel.

5.Disconnect the battery ground cable from the terminal and tape it. While storing the

battery, fully charge teh battery once a month.

6.Cover the generating set and place it in a well ventilated and dry area. If the

generating set is still hot, wait until it cools down cover.

consult our authorized agent.

9

.

3.2 Fuel

28

7. TRANSPORTING AND STORAGE

7.1 Transporting

Handle

Handle

Lifting hook

10

The waste oil and water processing

Don't pour waste oil into the sewer or the river to prevent environment pollution.

The exhaust oil from generator must be stored in container. To deal with bad

matter, such as fuel, oil cooling water, solvent, filter and battery, according to the

law.

27

agent.

6.5 Replace the Fuse

Turn the key of electric door lock to OFF position and remove the key before

checking and replacing the fuses to prevent accidental short circuit.

20A

30A

11

Wait until the engine is cold, turn the radiator cap counterclockwise until stops.

Do not press down while turning the cap. After any remaining pressure has been

relieved, remove the cap by pressing down and again turning it counterclockwise.

Add enough coolant to fill the radiator, and reinstall the cap. Be sure to tighten it

securely. Fill the r up to the MAX mark with the engine cold. overflow pot

3. If there is no in the , check whether the cooling system has

leadage and service it if necessary. Be sure that there is coolant in the radiator

and the .

coolant overflow pot

overflow pot

3.3 Coolant

1. Open the maintenance

2. Check the level while the engine has the normal wording temperature. If

the level is approaching the "MIN" mark, refill to "MAX" mark.

door.

water

coolant

Filling coolant liquid outler

Radiator

26

6.4 Clean the Battery

Negative terninal (-)

Battery set plate

Battery

12

3.4 Fuel-water Separator

Drain water: there is water mixed in oil usually, the fuel-water separator can

separate the water, and settled the cup base. So need to change regularly. Loose

the drain water bolt, the water will drain form the rubber conduit and drain it up,

then tighten the bolt.

25

6.3 Service the Air Cleaner

13

3.5 Battery

The generator uses battery which dose not need maintenance and filling liquid.

Observe the status displays of battery:

Blue: the battery is in good condition

White: the electricity is not enough, need to charge.

Red: the electrolyte is not enough, need to change.

24

Oil drain bolt

6.2 Replace Engine Oil

14

2. Insert the key to electric door lock and turn to START position, the unit is

preheating and starting, then hands off , the key will back to ON position

automatically

3. Smart panel control can preheat automatically when start, the time can be set.

4. START AND SHUTOFF THE ENGINE

4.1 Break-in Period (initial 50 hours)

4.2 Start the Engine

OFF

ON

Breaker

23

The electric eye color of battery electric

6. MAINTENANCE

6.1 Maintenance schedule

our authorized agent unless the owner

15

OFF

ON

START

Electric Starter Key

When displays PRE-H, the unit is preheating. After preheat, the unit will back to

START automatically. When displays START, the unit is starting.

22

T

h

e

m

a

x

i

m

u

m

l

a

d

o

f

e

a

c

h

r

e

c

e

p

-

t

a

c

l

e

o

r

t

e

r

m

i

n

a

l

(

k

V

A

)

Frequ-

ency (Hz)

Three phase

Terminal

KDE19STA3 Model KDE16STA3

50 60 50 60

Three phase

Terminal

Three phase

Terminal

Three phase

Terminal

Recep-

tacle

Recep-

tacle

Recep-

tacle

Recep-

tacle

13.5

10

8

6

4

0

1.1

1.8

2.5

3.1

15.5

12

10

8

6

4

0

1.2

1.8

2.5

3.2

3.8

16.25

15

12

10

8

6

4

0

0.4

1.4

2.0

2.7

3.4

4.0

19

15

12

10

8

6

4

0

1.3

2.3

3

3.7

4.3

5

Apply load to single-phase receptacles equally to prevent voltage fluctuation.

The receptacle should not have default

5.3 Usages of Receptacles and Terminals

16

To restore the emergency button, screw it by clockwise.

1.Turn off the electrical appliance switch.

2.Close the breaker(Turn the breaker to "OFF")

3.Close the electric door lock(Turn the key of electric door lock to "OFF")

4.3 Shutoff the Engine

Electric

Start Key

OFF

ON

START

21

Model

Frequency (Hz)

One circuit (kVA)

Two circuit used (kVA)

Three circuit used (kVA)

50

4.5

9.0

10.8

60

5.2

10.3

12.4

50

5.4

10.8

13

60

6.3

12.6

15.2

KDE19STA3 KDE16STA3

17

5. HANDLING THE GENERATING SET

5.1 Connecting to a Buildings Power Supply System

20

Model

Frequency (Hz)

One circuit (kVA)

Two circuit used (kVA)

Three circuit used (kVA)

50

7.2

10.8

10.8

60

8.3

12.4

12.4

50

8.7

13

13

60

10.1

15.2

15.2

KDE19STA3 KDE16STA3

18

5.2 AC Application

If there are some electric motors loading in appliance, please start the high-

power motor first, then start the low-power.

Be sure to start the electrical motor at zero load, after that connect the load.

19

AC Application (three-phase 400V)

1. Open the connection wiring box cover and connet the cable to terminal U,V and

W.(Using terminals)

U

V

W

N

2. Close the connecting box cover and tighten the bolts.

3. Start engine

Examine the generator three-phase voltage and frequency by smart display.

4. Connect the appliance. (single-phase 220V)

To prevent overload, each receptacle load and terminal load is equal, especially

when the generator been used in communicator and sensor to voltage.

Turn the AC breaker to ON position.

Potrebbero piacerti anche

- Kipor - Kde19sta 19eaDocumento24 pagineKipor - Kde19sta 19eaManuel Guillermo Smidt Garcia100% (11)

- KDE19EA SERVICE MANUAlDocumento73 pagineKDE19EA SERVICE MANUAlAntonio Martin100% (5)

- Dse 701 Dse 702 Auto Manual Start Control Modules PDFDocumento2 pagineDse 701 Dse 702 Auto Manual Start Control Modules PDFOdy Christian ViryaNessuna valutazione finora

- Manual de Instalacion de GeneracDocumento142 pagineManual de Instalacion de Generacsolounsiervo100% (2)

- Engine Interface ModuleDocumento3 pagineEngine Interface ModuleLuis Curipoma100% (1)

- Rear Panel Layout: Description ItemDocumento4 pagineRear Panel Layout: Description ItemHector CabreraNessuna valutazione finora

- Kipor GeneratorDocumento39 pagineKipor GeneratorWebdesign Webmasters87% (15)

- F24 60 en (A4) V1.2Documento2 pagineF24 60 en (A4) V1.2dozer_kamilNessuna valutazione finora

- Kipor Diesel Gen Service ManualDocumento44 pagineKipor Diesel Gen Service ManualSteven J Baynes86% (28)

- Engine Cranks But Does Not StartDocumento5 pagineEngine Cranks But Does Not StartNay Soe100% (1)

- DYNS 30000 CalibratorDocumento4 pagineDYNS 30000 Calibratorgolu201100% (2)

- Access2000 PanelDocumento2 pagineAccess2000 PanelSayed Younis Sadaat100% (4)

- Kipor - KDE7000T Generator-EnDocumento20 pagineKipor - KDE7000T Generator-EnEzzadin Baban50% (4)

- Sx440 Automatic Voltage Regulator (Avr) : Specification, Installation and AdjustmentsDocumento4 pagineSx440 Automatic Voltage Regulator (Avr) : Specification, Installation and AdjustmentsJose PirulliNessuna valutazione finora

- Dse720 ManualDocumento25 pagineDse720 ManualSandeep Saikia100% (7)

- GCM01 Mu GB 12.2Documento33 pagineGCM01 Mu GB 12.2carrettiNessuna valutazione finora

- Dse704 Manual PDFDocumento15 pagineDse704 Manual PDFJulio Hinostroza AlarconNessuna valutazione finora

- Instruction: Electronic GovernorDocumento28 pagineInstruction: Electronic GovernorAung MhNessuna valutazione finora

- Kipor KDE2200,3500,5000,6500,6700E, X, T, TA Service ManualDocumento44 pagineKipor KDE2200,3500,5000,6500,6700E, X, T, TA Service Manualmenderman100% (4)

- Woodward ATS Module Spec Easy Gen 350Documento4 pagineWoodward ATS Module Spec Easy Gen 350nooruddinkhan1Nessuna valutazione finora

- Denyo Dca ModelsDocumento12 pagineDenyo Dca ModelsKhaled Kamel100% (2)

- Specifications of Avr - Uvr7Documento4 pagineSpecifications of Avr - Uvr7Александр ЩеблыкинNessuna valutazione finora

- SDG25S-100S 3A Series Service Manual PDFDocumento78 pagineSDG25S-100S 3A Series Service Manual PDFSomadbsiNessuna valutazione finora

- SDG25S-150S-6A Series Service ManualDocumento109 pagineSDG25S-150S-6A Series Service ManualGoolshan BhugalooNessuna valutazione finora

- Especificaciones Tecnicas AVR Stamford SX440Documento4 pagineEspecificaciones Tecnicas AVR Stamford SX440MH..2023Nessuna valutazione finora

- LS 800 Inverter Err CodeDocumento135 pagineLS 800 Inverter Err CodeDedy100% (2)

- BA Generator PMG10 2 E PDFDocumento30 pagineBA Generator PMG10 2 E PDFJuan Domingo OrlandiniNessuna valutazione finora

- R448 Leroy Somer Manual enDocumento4 pagineR448 Leroy Somer Manual enJohn GarnetNessuna valutazione finora

- Sps 460Documento1 paginaSps 460BrianHazeNessuna valutazione finora

- 2001 FG Wilson P100 Generator (UEQ110907 - 150997)Documento3 pagine2001 FG Wilson P100 Generator (UEQ110907 - 150997)John NottyNessuna valutazione finora

- Dca 20spk2Documento10 pagineDca 20spk2John GarnetNessuna valutazione finora

- SV-Is5 Manual (English)Documento205 pagineSV-Is5 Manual (English)sunhuynhNessuna valutazione finora

- GU620ADocumento62 pagineGU620AEric JohnNessuna valutazione finora

- Deep Sea 5310 Manual PDFDocumento65 pagineDeep Sea 5310 Manual PDFMario Emilio Castro TineoNessuna valutazione finora

- Dse7320 Installation InstDocumento2 pagineDse7320 Installation InstNgười Chờ Thời100% (7)

- FDMDocumento4 pagineFDMKrishna PardeshiNessuna valutazione finora

- DC20D MKII Genset Controller Upgrade Version For Diesel - Gasoline Engine - EbayDocumento2 pagineDC20D MKII Genset Controller Upgrade Version For Diesel - Gasoline Engine - EbayAliNessuna valutazione finora

- Dse 710-720Documento2 pagineDse 710-720Christian Nicolasora0% (1)

- Manual Book Genset Denyo DCA-70, - 125, & - 180ESEIDocumento65 pagineManual Book Genset Denyo DCA-70, - 125, & - 180ESEIDadung PrakosoNessuna valutazione finora

- Kipor Kde16sta3 pdf1 PDFDocumento24 pagineKipor Kde16sta3 pdf1 PDFابو عمر الغزي100% (2)

- SV-iP5A Manual (English)Documento207 pagineSV-iP5A Manual (English)Wesam Wesam100% (1)

- Mitsubishi Freqrol FR S500 ManualDocumento191 pagineMitsubishi Freqrol FR S500 Manualzodiakastro75Nessuna valutazione finora

- 61169Documento28 pagine61169Junior Gatbunton100% (1)

- GENERAC 5000 Watt GeneratorDocumento16 pagineGENERAC 5000 Watt GeneratorDana Milner100% (1)

- Chestoten Invertor Sv150is5!4!380vac Upravlenie Na Trifazen Elektrodvigatel 15kw 1Documento213 pagineChestoten Invertor Sv150is5!4!380vac Upravlenie Na Trifazen Elektrodvigatel 15kw 1jbarroyetaNessuna valutazione finora

- Mitsubishi D700 Installation GuideDocumento28 pagineMitsubishi D700 Installation Guideawong_911374Nessuna valutazione finora

- Sinus K r03.1 ManualDocumento219 pagineSinus K r03.1 ManualVIJAYKAGRENessuna valutazione finora

- Operation Manual: Mist CollectorDocumento40 pagineOperation Manual: Mist CollectorYing Kei ChanNessuna valutazione finora

- Titan GS Series User ManualDocumento182 pagineTitan GS Series User Manualsibtainasghar1100% (1)

- Sinus M PDFDocumento198 pagineSinus M PDFJuan Santiago RojasNessuna valutazione finora

- Mitsubishi S500E VFD Basic ManualDocumento79 pagineMitsubishi S500E VFD Basic ManualPuvan80Nessuna valutazione finora

- Manual L510Documento102 pagineManual L510JoseManuelNuñezNessuna valutazione finora

- 12k Service ManualDocumento68 pagine12k Service ManualJ C Quality Woodstoves67% (3)

- Mep 802a TM9 6115 641 10Documento152 pagineMep 802a TM9 6115 641 10GreenMountainGenerators50% (2)

- MitsubishiDocumento300 pagineMitsubishijuan_oliva_41Nessuna valutazione finora

- EEEAAWEL650Documento239 pagineEEEAAWEL650elecompinnNessuna valutazione finora

- FR-S500 Inverter PDFDocumento192 pagineFR-S500 Inverter PDFJose OrtegaNessuna valutazione finora

- NGK Generator Honda EngineDocumento31 pagineNGK Generator Honda Enginerajkrsingh988Nessuna valutazione finora

- IufenDocumento8 pagineIufensalemhanafiNessuna valutazione finora

- IV5 ManualDocumento247 pagineIV5 ManualRobert AguilarNessuna valutazione finora

- Material FiatDocumento1 paginaMaterial FiatantoniomecptNessuna valutazione finora

- AaaaaaaaaaaDocumento4 pagineAaaaaaaaaaaantoniomecptNessuna valutazione finora

- KDE5000E T ServiceDocumento38 pagineKDE5000E T Serviceantoniomecpt100% (1)

- Diagrama Hiace 2kd 5le PDFDocumento48 pagineDiagrama Hiace 2kd 5le PDFantoniomecptNessuna valutazione finora

- QQQQQQQQQQQQQQQDocumento2 pagineQQQQQQQQQQQQQQQantoniomecptNessuna valutazione finora

- Ehvs PDFDocumento24 pagineEhvs PDFantoniomecptNessuna valutazione finora

- YTDocumento1 paginaYTantoniomecpt100% (1)

- 2015 SKFDocumento972 pagine2015 SKFantoniomecptNessuna valutazione finora

- Boarding Pass BA0514 LHR MAD 027Documento1 paginaBoarding Pass BA0514 LHR MAD 027antoniomecptNessuna valutazione finora

- Boarding Pass BA0076 LAD LHR 022Documento1 paginaBoarding Pass BA0076 LAD LHR 022antoniomecptNessuna valutazione finora

- GM 4L80 Caixa AutomaticaDocumento3 pagineGM 4L80 Caixa AutomaticaantoniomecptNessuna valutazione finora

- Perkins CatalogueDocumento24 paginePerkins Catalogueantoniomecpt90% (20)

- Operation and Mantenance Manual Perkins 1103 and 1104c Engines SystemsDocumento92 pagineOperation and Mantenance Manual Perkins 1103 and 1104c Engines SystemsDiego Barbas83% (6)

- Inteliats NT Datasheet 2010-03 CpleiantDocumento4 pagineInteliats NT Datasheet 2010-03 CpleiantThao Nguyen XuanNessuna valutazione finora

- BB Series User Manual V0 (2) .0Documento28 pagineBB Series User Manual V0 (2) .0a.elwahabNessuna valutazione finora

- Akai S5000 and S6000 Owners ManualDocumento292 pagineAkai S5000 and S6000 Owners ManualdodNessuna valutazione finora

- Preventive MaintenanceDocumento31 paginePreventive MaintenanceNeeraj Singh100% (1)

- MANUAL Silka MatrixDocumento35 pagineMANUAL Silka MatrixPepeNessuna valutazione finora

- Texecom InstallDocumento44 pagineTexecom InstallGary SmythNessuna valutazione finora

- KBCH CortecDocumento9 pagineKBCH CortechakimsalimiNessuna valutazione finora

- PEC Meter Wiring SpecsDocumento11 paginePEC Meter Wiring Specsdentron2Nessuna valutazione finora

- NPS-MRI-0070E - NSM-S15P PRE Manual - EN V1.3Documento81 pagineNPS-MRI-0070E - NSM-S15P PRE Manual - EN V1.3ьшчNessuna valutazione finora

- Siemens Dry TransformerDocumento30 pagineSiemens Dry TransformerMahmoud_Eldeek100% (1)

- 220 VDC80 AHChargerswith DCDBDocumento20 pagine220 VDC80 AHChargerswith DCDBRAPRATSINNessuna valutazione finora

- Deep Sea Electronics PLC: DSE4310 & DSE4320 Operator ManualDocumento92 pagineDeep Sea Electronics PLC: DSE4310 & DSE4320 Operator ManualMostafa ShannaNessuna valutazione finora

- Hyperion I24319 EN 2nd Rev EditionDocumento116 pagineHyperion I24319 EN 2nd Rev EditionaaaasassNessuna valutazione finora

- HS50 HS60 User Manual Vol1 EngDocumento230 pagineHS50 HS60 User Manual Vol1 Engtecnifrios50% (2)

- Jackson DW Avenger HT LT Service ManualDocumento68 pagineJackson DW Avenger HT LT Service Manualdan themanNessuna valutazione finora

- Marshall MG100DFX Manual (English - 6 Pages)Documento2 pagineMarshall MG100DFX Manual (English - 6 Pages)Oscar Chonchin Hernandez VillegasNessuna valutazione finora

- Epoch LT: User's ManualDocumento142 pagineEpoch LT: User's ManualWalter SuarezNessuna valutazione finora

- Uninterruptible Power Supply UPS Protect 5. 31/xxx-S05 10 kVA - 120 kVADocumento56 pagineUninterruptible Power Supply UPS Protect 5. 31/xxx-S05 10 kVA - 120 kVAMohamedHussein MohamedHusseinNessuna valutazione finora

- Manual Yamaha RX-V363Documento77 pagineManual Yamaha RX-V363Alberto Gonzalez de CanalesNessuna valutazione finora

- Manual PVPMDocumento62 pagineManual PVPMMenthor555Nessuna valutazione finora

- C10547058 PDFDocumento28 pagineC10547058 PDFParinyaNessuna valutazione finora

- AEG AC Motor AMME 80Z BA2Documento14 pagineAEG AC Motor AMME 80Z BA2TonyNessuna valutazione finora

- Sumitomo hf320Documento103 pagineSumitomo hf320moshik99100% (8)

- Owner's Manual For 1/6 HP Series SR Flexible Shaft Power ToolsDocumento20 pagineOwner's Manual For 1/6 HP Series SR Flexible Shaft Power ToolsFazenda ItaNessuna valutazione finora

- VoCALL Installation & Commissioning Guide Rev 2aDocumento20 pagineVoCALL Installation & Commissioning Guide Rev 2aAlan SpencerNessuna valutazione finora

- Manual de Servicio Ultraview 2202Documento156 pagineManual de Servicio Ultraview 2202Yohn FaizerNessuna valutazione finora

- Specification 11kV VCB Panel - IndoorDocumento29 pagineSpecification 11kV VCB Panel - Indoormayur100% (1)

- GC-1 AmfDocumento8 pagineGC-1 Amfnandomata100% (1)

- Class 8Documento45 pagineClass 8ASHFAQNessuna valutazione finora

- 02 - Power PlugDocumento12 pagine02 - Power Plugzizou.rengokuNessuna valutazione finora