Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Graphyt Crystals in Blast Furnace Coke

Caricato da

Rizal Ahmad MubarokDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Graphyt Crystals in Blast Furnace Coke

Caricato da

Rizal Ahmad MubarokCopyright:

Formati disponibili

Graphite crystals in blast furnace coke

Stanislav S. Gornostayev

*

, Jouko J. Harkki

Laboratory of Process Metallurgy, University of Oulu, P.O. Box 4300, 90014 Oulu, Finland

Received 15 November 2006; accepted 26 February 2007

Available online 4 March 2007

Abstract

Graphite was found at several spots on the porous surface of a sample of blast furnace (BF) coke in association with droplets of Si-

bearing iron and other inorganic compounds. It occurred in foliated intergrowths and rose-like aggregates of euhedral to subhedral crys-

tals of various size (10 lm0.7 mm) and morphologies, the generic forms that can be seen in the crystals being basal pinacoid, hexagonal

prism and hexagonal dipyramid. The largest crystals have a ake-like habit and are represented by a combination of a basal pinacoid and

a hexagonal prism. Graphite crystals that have an ideal hexagonal prism in their cross-section are rarer than distorted forms. There are

twins on the dypiramidal composition planes and twins produced by rotation on [0001]. The major deformations in the crystals, i.e.

detaching, bending and rolling of (0001) planes, may be referred to exfoliation phenomena caused by potassium and sodium from cir-

culating BF gases and enforced by the BF gas ows. The formation of graphite crystals on a surface of BF coke, especially those of ake-

like morphology with an undeveloped hexagonal prism, possibly decreases its reactivity and can be accompanied by the generation of

nes. The graphitic coating on a surface of BF coke can act as a lubricant to facilitate coke pieces sliding over each other thus aecting

the mechanical stability of the coke cone in a BF.

2007 Elsevier Ltd. All rights reserved.

1. Introduction

Coke is a key material for blast furnace (BF) operation,

acting as (1) a fuel; (2) a reductant, to generate reducing

gases, including CO; (3) a carburisation agent for the hot

metal, to give it the required properties, and (4) a structural

support to provide permeability for liquid phase drainage

and upward ow of the blast furnace gases [1]. It is charged

into the BF along with the iron ores and various uxes.

Metallurgical coke is made from a mix of several coals,

preferably of low inorganic content, by heating the mix

to 1100 C in coke batteries (ovens) that consist of two

heated walls spaced about 4045 cm apart. Reactivity and

strength are the most important parameters that character-

ize the quality of the coke, and these are in turn dependent

on the amounts and properties of organic (maceral-

derived) carbon-based components [14] and inorganic

matter (minerals) [59] inherited from the primary coals

and serve to determine the behaviour of the coke in the

BF. The evolution of the carbon structure of coke at tem-

peratures comparable to those in the upper parts of a BF

have been discussed recently based on the results of exper-

iments carried out in a horizontal laboratory-scale tube

furnace [10].

The conditions of formation and subsequent degrada-

tion and deformation of graphite crystals can be reected

in their size and morphology, as documented in a number

of studies of natural [1120] and synthetic [2123] graphite.

It is mentioned that well formed natural and laboratory-

grown graphite crystals are uncommon and that they rarely

exceed a few millimetres in size [24]. Conventional graphite

forms hexagonal (dihexagonaldipyramidal class 6/m2/

m2/m) crystals, with weak bonding between the graphite

layers. The hexagonal nature of the crystal arises because

graphite exists as a stack of sheets of carbon atoms par-

allel to {0001}, each sheet having a hexagonal arrange-

ment of atoms. Graphite crystals in the natural

environment usually possess a scaly (ake-like), platy, tab-

ular or columnar habit [1120]. In addition to its unique

0008-6223/$ - see front matter 2007 Elsevier Ltd. All rights reserved.

doi:10.1016/j.carbon.2007.02.033

*

Corresponding author. Fax: +358 8 553 2339.

E-mail address: ssg@cc.oulu. (S.S. Gornostayev).

www.elsevier.com/locate/carbon

Carbon 45 (2007) 11451151

technological properties, graphite is also known as one of

the few single-mineral geothermometers [25], a feature that

could make it useful for temperature estimations in systems

and processes where direct measurements are not possible.

Growing energy demands and shortage of resources

require new approaches and methods for production of

highly eective cokes. The latest is impossible without an

understanding of fundamentals of coking and coke con-

sumption processes, which includes detailed observation,

documentation and careful interpretations of various phe-

nomena that occur in materials taken from dierent stages

of these processes and comparable laboratory-scale exper-

iments. Very little is known as yet about carbon behaviour

in a coke after it is charged into a BF (such coke is often

referred to as BF coke), where it exposed to high tempera-

ture and takes part in various solid-to-solid, solid-to-melt

and solid-to-gas reactions that occur inside the BF. The

scarcity of data on BF coke in general and on the appear-

ance of graphite in it in particular [26], is mostly due to the

obvious diculties encountered in obtaining samples from

inside a working BF. This paper represents the description

of the mode of occurrence and morphological features of

graphite crystals in sample of coke taken from inside a

working BF, from the tuyere zone, where air ows into

the BF and where temperature exceeds 2000 C.

2. Materials and methods

The sample was selected from a drill core obtained from the tuyere

zone of an operating BF at the Ruukki Steel Works in Raahe, Finland,

using a mobile tuyere rig. The original location of the piece of BF coke

was 35 cm from the tuyere level. The details of the tuyere drilling were sim-

ilar to those reported by Kerkkonen [27]. A piece about 30 mm long,

23 mm wide and 57 mm thick was cut from the sample under dry condi-

tions (no cooling water was used in sawing), preserving one original sur-

face. The piece was then xed to a glass plate of 28 48 mm that ts

into the specimen holder of a scanning electron microscope (SEM). A

few particles were also selected from the sample surface for the prepara-

tion of polished sections. The dry-cut section and the polished sections

were examined preliminarily under a stereo microscope and optical micro-

scope and then with a JEOL JSM-6400 SEM equipped with an energy dis-

persive spectrometer (EDS) and operated with the INCA and SemAfore

analytical and image processing software packages.

3. Results and discussion

Investigations of the dry-cut section with a stereomicro-

scope have shown that the porous surface of the sample

hosts numerous particles of dierent size, shape and optical

properties (Figs. 14). There are relatively large segrega-

tions of slag phases (qualitative EDS data), which were

met in a few locations (Fig. 1C). The most abundant parti-

cles, which can be observed by stereomicroscope, are of

0.10.4 mm in diameter (Fig. 1A). They have a rounded

or drop-like shape and possess a dull metallic luster. The

particles often have a sharp contact with the coke matrix

and look submersed into the matrix (Fig. 1A). The sur-

face of these particles has geometric facets bounded by

ridges of triangular cross section (Fig. 1B). These carbon

(EDS-data) facets look similar to the graphitic shells syn-

thesized on top of millimeter-sized spherical transition

metal cores in high vacuum [28]. Some of these particles

also carry occasional graphite crystals on their surface.

In order to investigate the composition of such particles,

a few of them (35 mm in size) were detached from the

sample and used for the preparation of polished sections.

EDS analyses (Table 1) have shown that they are com-

posed of Si-bearing (4.017.30 wt.%) iron with traces of

Mn, V and P. So, these rounded particles seem to be drops

Fig. 1. Appearance, size and morphology of various particles on the

surface of the BF coke. A and C stereomicroscope; B SEM Jeol JSM-

6400. See text for details.

1146 S.S. Gornostayev, J.J. Ha rkki / Carbon 45 (2007) 11451151

of molten iron descending from the cohesive zone of the BF

and they are external in respect of BF coke.

There are larger particles (25 mm) surrounded by a

contact zone (0.51.5 mm), which is full of graphite crys-

tals. Such particles were observed in several separate places

(spots) located a few millimetres apart in dierent parts of

the sample. Two of them (Fig. 2A and B) located 910 mm

apart are discussed below. These particles have no geomet-

ric facets, but their surface in many places is covered by the

inorganic shells containing Ca, Al and Si (qualitative EDS

data on an unpolished surface). A clear oxygen peak was

also detected in the EDS spectrum. The particles also look

submersed into the coke matrix and host occasional graph-

ite crystals on their surface (Fig. 2A and B).

The graphite in the contact zone occurs in foliated

(Fig. 3C) intergrowths and rose-like aggregates (Fig. 2A

and B) of euhedral to subhedral crystals of varying size

and morphology (Fig. 2CK). The crystals themselves were

found on the coke matrix in close association with various

inorganic compounds, which were located in interstices

between the crystals (Fig. 5). X-ray mapping (Fig. 5) has

revealed that the interstitial phase can be presented either

by Fe (Fig. 5A) or by a complex CaFeSiO phase

(Fig. 5B). The later also contains traces of Al and K (qual-

Fig. 2. Appearance, size and morphology of graphite crystals. SEM Jeol JSM-6400. See text for details.

S.S. Gornostayev, J.J. Ha rkki / Carbon 45 (2007) 11451151 1147

itative EDS data). One of the EDS analyses on an unpol-

ished surface on the top of one particle (Fig. 2B) gave

the following concentrations (wt.%, normalized, carbon

was not measured): Fe 97.07, Ca 0.24, Si 0.15, O

2.53. So, the particles surrounded by the reaction zone

composed of graphite crystals, seem to be also droplets

of molten iron, but they were probably mixed with (cov-

ered by) the spatially associated mineral compounds from

the coke matrix.

There are also other small particles, which were

observed attached to the coke surface and to the graphite

crystals. These particles can be seen under high magnica-

tions with a SEM (Figs. 2CK, 3 and 4). Qualitative EDS

analyses has indicated that they composed of aluminosili-

cate (Ca, K and Na) phases. The nature and the compo-

sition of various inorganic compounds in the BF coke and

on its surface have been also discussed in our earlier studies

[69].

The generic forms that can be clearly seen in the crystals

from the contact zone are basal pinacoid {0001} (Fig. 2C

K; Fig. 3, Fig. 4A and B), hexagonal prism f10

10g

Fig. 3. Twinning in graphite crystals. Fig. 4. Deformations in graphite crystals.

Table 1

EDS analysis of some particles from the BF coke surface

a

Si P V Mn Fe Sum

1 4.74 0.56 0.81 94.55 100.66

2 7.30 0.32 1.24 0.58 89.79 99.22

3 4.01 0.35 0.70 94.81 99.88

a

Note: JEOL JSM-6400. Particle index: 1 30424109-35b2; 2

30424109-35b3; 3 30424109-35b4.

1148 S.S. Gornostayev, J.J. Ha rkki / Carbon 45 (2007) 11451151

(Fig. 2FK) and hexagonal dipyramid f10

11g. The dipyr-

amid can be seen in a twinned crystal (Fig. 3A), which is

discussed below. The combination of basal pinacoid and

hexagonal prism (Figs. 2C and 4A) seems to be more fre-

quent than any other combination and it was observed in

crystals of varying size (from 10 lm to 0.7 mm), although

the hexagonal prism in many crystals is not well developed

(Fig. 2C). The crystals which combine basal pinacoid and

hexagonal prism have a ake-like (Fig. 2C), platy

(Fig. 4A) or tabular habit. The ake-like crystals, which

are about 0.50.7 mm in their greatest dimension, along

the basal pinacoid, greatly exceed all the other forms in

size. The combination of basal pinacoid and hexagonal

dipyramid (Fig. 2D and E) is present in crystals which mea-

sure about 5070 lm along the (0001) plane. They have a

platy (Fig. 2D) or in rare cases an elongated-columnar

habit (Fig. 2E), which has been observed to be a rare mor-

phology in natural graphite [13,16]. The combination of

basal pinacoid, hexagonal prism and hexagonal dipyramid

is found in crystals with a platy (Fig. 2F and G) or tabular

(Fig. 2IK) habit, while graphite crystals that have an equi-

dimensional hexagonal prism in their cross-section

(Fig. 2FH) are much rarer than the distorted forms

(Fig. 2C,E and IK). In the latest forms some faces are sub-

ordinate or even missing, reecting less-than-ideal growth

conditions.

It seems likely that the crystals of ake-like morphology

with undeveloped hexagonal prism (Fig. 2C) and their foli-

ated intergrowths (Fig. 3C), which have larger surface area

than the columnar crystals (Fig. 2E), can form graphitic

cover (shield) on a surface of BF coke. The fact that

The carbon structure of coke. . . have a signicant inu-

ence on the coke behavior in a BF such that highly ordered

coke displayed lower reactivity. . . [10] combined with

these data may suggest, that in the case of favourable con-

ditions for graphite crystallization, the graphitic shield can

cover larger area of surface of BF coke (Fig. 6) thus pre-

venting it from reactions with gases circulating in a BF.

Fig. 5. X-ray maps for Fe (A: no elements other than Fe were detected) and Ca, Fe and Si (B) of two separate areas in graphite-bearing spots. SEM Jeol

JSM-6400. Scale bars: A 40 lm; B 100 lm.

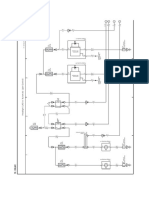

Fig. 6. Generalized scheme for occurrence of graphitic coating on a

surface of BF coke (cross-section). (1) A rounded particles of Si-bearing

iron covered by graphitic shells; B particles of Si-bearing iron

surrounded by zones of graphite crystals; (2) graphite crystals and their

aggregates; (3) segregations of slag phases; (4) Internal pores (white) in a

coke matrix (black).

S.S. Gornostayev, J.J. Ha rkki / Carbon 45 (2007) 11451151 1149

One consequence of the symmetry of the internal struc-

ture of crystals is the possibility of formation of twins.

Twinned crystals have two or more parts, in which the

crystal lattice of one part is dierently but symmetrically

oriented to that of the next. The mechanisms by which

twinned crystals can be formed include growth (for pene-

tration and contact twins), transformation and deforma-

tion [29]. The following types of twins have been

identied in the graphite-bearing spots studied here: one

formed on fh0

hlg dypiramidal composition planes

(Fig. 3A and B), yielding twinned crystals (contact twins)

of size about 100 lm and 1520 lm, respectively, and the

other related to rotation on [0001] (Fig. 3C), producing

contact twins, as observed in large ake-like or plate-like

crystals.

It should be mentioned, that the intensity of coke graph-

itization with temperature was found to depend on iron

content of a coke [10]. The assessment of the mechanism

for the graphite crystallization in the BF coke based on

the experiments with the feed coke and almost 100% pure

iron was made by Wang et al. [26] including data of other

investigators [30,31] on the molten iron and vanadium car-

bide catalyzed graphitization process. It was summarized

that The iron melt at rst penetrates the surrounding car-

bon matrix through carbon dissolutionprecipitation

sequences leaving behind the well ordered graphitic car-

bons. As the penetration front moves further into the car-

bon the coke sample transforms into well ordered graphitic

carbon. Since the penetration of iron melt follows the

graphitization front, the precipitated small graphite crys-

tals would be transformed in later recrystallization steps

into large akes [26]. The last referred paper contains

no details on the graphite morphology and has no discus-

sion on possible inuence of graphite on the processes in

the BF, but among many other interesting data it reports

that the synthetic graphite has been formed in the feed coke

samples at temperatures ca. 1500 C that is well below nor-

mal graphitization temperatures due to the catalytic eect

of molten iron.

It seems, that the model proposed for the graphite crys-

tallization in the experiment [26], can be applied, at least

partly (Fig. 5A, iron-catalyzed graphite crystallization),

to the sample from the real process discussed in this study.

Nevertheless, further research will be needed in order to

explain the reason for the graphite appearance near certain

particles of molten iron and lack of it around the others as

well as the graphite association with the CaFeSiO phase

(Fig. 5B). We suggest, that one of the possible explanations

could be related to the properties of the coke matrix them-

selves, i.e. various maceral-derived components inherited

from the coking coal may have reacted dierently with

the iron droplets and other inorganic compounds. The rea-

son for the graphite appearance near the CaFeSiO

phase (Fig. 5B) can be explained by the presence of Fe in

the phase and, probably, by the impurities of other metals,

i.e., Ni and Mn, which also have catalytic eect for graph-

ite crystallization [32]. These metals (Ni and Mn) were not

detected by the X-ray mapping (Fig. 5B) probably due to

low sensitivity of the method, but they are common constit-

uents of the mineral phases of the BF coke samples from

the tuyere drillings at Ruukki Steel Works analyzed by

CAMECA SX-50 electron microprobe (WDS-method)

[33].

Graphite has low modulus of elasticity, but its high

lubricity [34] allows easy sliding of the graphene layers

across one another. For that reason, the graphitic coating

on a surface of BF coke can act as a lubricant to facilitate

the coke pieces sliding over each other thus aecting

mechanical stability of the coke cone in a BF. Further-

more, crystallization of graphite in a tuyere level can be

accompanied by the generation of coke-related nes in this

area. This suggestion can be supported by data from exper-

iments on coke annealing carried out in a horizontal labo-

ratory-scale tube furnace, which established that a higher

ordered carbon structure provided a greater amount of

nes. . . [10], where the coke nes are attributed to the par-

ticles (fractions from 63 to +450 lm were discussed) origi-

nated from coke, which were found in the BF exhaust dust.

The major deformations found in the crystals are

detaching, bending and rolling of the (0001) planes

(Fig. 4AC). Such deformations in graphite may be attrib-

uted to exfoliation, and are considered to be the result of a

phase transition involving vaporization of the intercalate in

the graphite [19,20]. The major intercalates in the BF

graphite were probably potassium and sodium, which are

abundant in BF gases. The process of exfoliation has prob-

ably caused the dismembering of the crystals to micro and

nanosheets [20] and, then, the fragile graphite crystals may

have been deformed by the BF gas ows. In some of the

crystals this concerns only tiny, submicron-thick sheets

(Fig. 4A and B), as noted elsewhere [20], while in others

a whole graphite crystal can be dismembered into several

parts (yielding a stack of sheets) and then they can be bent

(Fig. 4C). The dismembering of the crystals can be behind

the generation of the smallest fraction (comparable to the

crystal size) of nes, when particles of graphite, especially

those of ake-like morphology detached from the larger

crystals, can be easy captured by the circulating BF gas

ows thus contributing the total amount of the BF-gener-

ated dust.

4. Concluding remarks

The BF coke on tuyere level contains graphite crystals of

various size and morphologies. They occur in randomly

distributed spots and are associated with droplets of iron

with varying Si content and other inorganic compounds.

Alkali, which circulate in a BF gases, may have causes sub-

sequent exfoliation of the crystals enforced by the BF gas

ows. The formation of graphite crystals on a surface of

BF coke, especially those of ake-like morphology with

undeveloped hexagonal prism probably decreases its reac-

tivity and can be accompanied by nes generation in a

tuyere level. The graphitic cover on a surface of BF coke

1150 S.S. Gornostayev, J.J. Ha rkki / Carbon 45 (2007) 11451151

can act as a lubricant to facilitate the coke pieces to slide

along each other and thus aect mechanical stability of

coke cone in a BF.

The data presented in this study can be useful for assess-

ing coke behaviour in a BF. It will be essential to perform

further detailed investigations on graphite formation and

its evolution in a coke as well as on the nature and behav-

iour of associated inorganic compounds. This is needed for

better understanding of major reactions in a BF and for

revealing typomorphic features of graphite crystals that

can serve as an indicator of particular coke composition

and BF environment.

Acknowledgements

This research was funded by the Academy of Finland. Mr.

T. Kokkonen is thanked for the samples preparation. Anon-

ymous referees have provided valuable comments which

greatly improved clarity and quality of the manuscript.

References

[1] Andriopoulos N, Loo CE, Dukino R, McGuire SJ. Micro-properties

of Australian coking coals. ISIJ Int 2003;3:152837.

[2] Yamaoka H, Suyama S. Prediction model of coke strength after

gasication reaction. ISIJ Int 2003;43:33847.

[3] Kawakami M, Karato T, Takenaka T, Yokoyama S. Structure

analysis of coke, wood charcoal and bamboo charcoal by Raman

spectroscopy and their reaction rate with CO

2

. ISIJ Int

2005;45:102734.

[4] Sharma R, Dash PS, Banerjee PK, Kumar D. Eect of coke micro-

textural and coal petrographic properties on coke strength charac-

teristics. ISIJ Int 2005;45:18207.

[5] Todoschuk TW, Price JP, Gransden JF. Development of coke

strength after reaction (CSR) at Dofasco. Iron Steel Technol

2004;March:7384.

[6] Gornostayev S, Harkki J. Spinel crystals in tuyere coke. Metall Mater

Trans 2005;36B-2:3035.

[7] Gornostayev S, Harkki J. Mineral matter crystallization and crack

formation in tuyere coke. Fuel 2006;85:104751.

[8] Gornostayev SS, Kerkkonen O, Harkki JJ. Importance of mineral-

ogical data for inuencing properties of coke: a reference on SiO

2

polymorphs. Steel Res Int 2006;77:7703.

[9] Gornostayev S, Harkki J. Mechanism of physical transformations of

mineral matter in the blast furnace coke with reference to its reactivity

and strength. Energy Fuels 2006;20:26325.

[10] Gupta S, Sahajwalla V, Burgo J, Chaubal P, Youmans T. Carbon

structure of coke at high temperatures and its inuence on coke nes

in blast furnace dust. Metall Mater Trans 2005;36B:38594.

[11] Palache C. Graphite. Am Miner 1941;26:70917.

[12] Freise EJ, Kelly A. Twinning in graphite. Proc R Soc London

1961;64-A:26976.

[13] Jaszczak JA. Famous graphite crystals from Sterling Hill, New Jersey.

The Picking Table 1994;35:611.

[14] Jaszczak JA. Unusual graphite crystals from the lime crest quarry,

Sparta New Jersey. Rocks Miner 1997;72:3304.

[15] Luque FJ, Pasteris JD, Wopenka B, Rodas M, Barrenechea JF.

Natural uid-deposited graphite: mineralogical characteristics and

mechanisms of formation. Am J Sci 1998;298:47198.

[16] Kvasnitsa VN, Yatsenko VG, Jaszczak JA. Disclinations in unusual

graphite crystals from anorthosites of Ukraine. Can Mineral

1999;37:95160.

[17] Rakovan J, Jaszczak JA. Multiple length scale growth spirals on

metamorphic graphite {001} surfaces studied by atomic force

microscopy. Am Miner 2002;87:1724.

[18] Jaszczak JA, Robinson GW, Dimovski S, Gogotsi Y. Naturally

occurring graphite cones. Carbon 2003;41:208592.

[19] Anderson SH, Chung DDL. Exfoliation of intercalated graphite.

Carbon 1984;22:25363.

[20] Chen G, Wu D, Weng W, Wu C. Exfoliation of graphite ake and its

nanocomposites. Carbon 2003;41:579625.

[21] Gogotsi Y, Dimovski S, Libera JA. Conical crystals of graphite.

Carbon 2002;40:22637.

[22] Dimovski S, Nikitin A, Ye H, Gogotsi Y. Synthesis of graphite by

chlorination of iron carbide at moderate temperatures. J Mater Chem

2004;14:23843.

[23] Okuno H, Palnichenko A, Despres J-F, Issi J-P, Charlier J-C.

Synthesis of graphite polyhedral crystals using a combustion ame

method. Carbon 2005;43:6927.

[24] Rotkin S, Gogotsi Y. Analysis of non-planar graphitic structures:

from arched edge planes of graphite crystals to nanotubes. Mat Res

Innov 2002;5:191200.

[25] Luque FJ, Barrenechea JF, Rodas M. Graphite geothermometry in

low and high temperature regimes; two case studies. Geol Mag

1993;130:50111.

[26] Wang W, Thomas KM, Poultney RM, Willmers RR. Iron catalysed

graphitisation in the blast furnace. Carbon 1995;33:152535.

[27] Kerkkonen O. Tuyere Drilling Coke Sample Data from Rau-

taruukkis Blast Furnaces No. 1 and 2. AISTech 2004; Iron & Steel

Technology Conference Proceedings, Nashville, TN, USA, September

1517, 2004;I:46981.

[28] Winder SM, Liu D, Bender JW. Synthesis and characterization of

compound-curved graphite. Carbon 2006;44:303742.

[29] Nesse WD. Introduction to mineralogy. New York: Oxford Univer-

sity Press; 2000. p. 442.

[30] Fitzer E, Kegel B. The reaction of vanadium carbide melt with

ordered and disordered carbon. Carbon 1968;6:4336.

[31] Weisweiler W, Subramanian N, Terwiesch B. Catalytic inuence of

metal melts on the graphitization of monolithic glasslike carbon.

Carbon 1971;9:7558.

[32] Sevilla M, Fuertes AB. Catalytic graphitization of templated meso-

porous carbons. Carbon 2006;44:46874.

[33] Gornostayev S, Kerkkonen O, Harkki J. Occurrence and composition

of some mineral phases in the tuyere coke. ISIJ Int 2005;45:17.

[34] Dienwiebel M, Verhoeven GS, Pradeep N, Frenken JWM, Heimberg

JA, Zandbergen HW. Superlubricity of graphite. Phys Rev Lett

2004;92:126101-14.

S.S. Gornostayev, J.J. Ha rkki / Carbon 45 (2007) 11451151 1151

Potrebbero piacerti anche

- Carbon Tubular Morphologies in Blast Furnace CokeDocumento4 pagineCarbon Tubular Morphologies in Blast Furnace CokeInezukyNessuna valutazione finora

- 184 Chunky GraphiteDocumento10 pagine184 Chunky GraphiteIPSITNessuna valutazione finora

- Effect of Welding On Microstructure and Mechanical Properties of An Industrial Low Carbon SteelDocumento5 pagineEffect of Welding On Microstructure and Mechanical Properties of An Industrial Low Carbon Steelmalika_00Nessuna valutazione finora

- Toz Boyut AnaliziDocumento14 pagineToz Boyut AnaliziMustafa CeyhanNessuna valutazione finora

- Production and Characterization of The Nanostructured Hollow Iron Oxide Spheres and Nanoparticles by Aerosol RouteDocumento5 pagineProduction and Characterization of The Nanostructured Hollow Iron Oxide Spheres and Nanoparticles by Aerosol RoutePpa Gpat AmitNessuna valutazione finora

- Bokov Et Al. - 2021 - Interplay Between Decarburization, Oxide Segregation, and DensificationDocumento12 pagineBokov Et Al. - 2021 - Interplay Between Decarburization, Oxide Segregation, and DensificationAnna ShelyugNessuna valutazione finora

- 59 - Isijint 2018 613Documento8 pagine59 - Isijint 2018 613Satadal GhoraiNessuna valutazione finora

- Corrosion Behavior of Plain Carbon Steels Under Different Heat Treatment Conditions in Freely Aerated 3.5% NaCl SolutionDocumento62 pagineCorrosion Behavior of Plain Carbon Steels Under Different Heat Treatment Conditions in Freely Aerated 3.5% NaCl SolutionDra. Nelly Abigail Rodríguez RosalesNessuna valutazione finora

- 133 XiaoDocumento12 pagine133 XiaoRaju KumarNessuna valutazione finora

- Regordosa-Llorca-Isern2016 Article ChemicalAndStructuralCharacterDocumento15 pagineRegordosa-Llorca-Isern2016 Article ChemicalAndStructuralCharactersanjeev singhNessuna valutazione finora

- Corrosion Science: Q. Zhu, H.T. Zhu, A.K. Tieu, C. KongDocumento9 pagineCorrosion Science: Q. Zhu, H.T. Zhu, A.K. Tieu, C. KongDavid Rincon CamargoNessuna valutazione finora

- Aspects of Saf Smelting of FerrochromeDocumento14 pagineAspects of Saf Smelting of FerrochromeSradha SumanNessuna valutazione finora

- Journal of Nuclear MaterialsDocumento6 pagineJournal of Nuclear Materialsehagar60Nessuna valutazione finora

- Gradient Transition Zone Structure in Steel-CopperDocumento16 pagineGradient Transition Zone Structure in Steel-CopperdhairyasheelNessuna valutazione finora

- Ledeburite: Solidification of Cast IronsDocumento14 pagineLedeburite: Solidification of Cast IronsFauzul ImanNessuna valutazione finora

- Carbon-An Old But New MaterialDocumento28 pagineCarbon-An Old But New MaterialinorgsanthoshalNessuna valutazione finora

- (18657109 - Zeitschrift Für Naturforschung A) Specimen Geometry Effect On The Mechanical Properties of AISI 1040 SteelDocumento5 pagine(18657109 - Zeitschrift Für Naturforschung A) Specimen Geometry Effect On The Mechanical Properties of AISI 1040 SteelR JNessuna valutazione finora

- Co Paper White LabelDocumento9 pagineCo Paper White LabelJayjeet BhoiteNessuna valutazione finora

- Metals: Effects of Rare Earth (Ce and La) On Steel Corrosion Behaviors Under Wet-Dry Cycle Immersion ConditionsDocumento14 pagineMetals: Effects of Rare Earth (Ce and La) On Steel Corrosion Behaviors Under Wet-Dry Cycle Immersion ConditionsThanhluan NguyenNessuna valutazione finora

- Formation of Two-Dimensional Nanomaterials of Boron CarbidesDocumento5 pagineFormation of Two-Dimensional Nanomaterials of Boron CarbidesGirish GuptaNessuna valutazione finora

- Research Article: Characterization of Ladle Furnace Slag From Carbon Steel Production As A Potential AdsorbentDocumento7 pagineResearch Article: Characterization of Ladle Furnace Slag From Carbon Steel Production As A Potential Adsorbentheinz wieduwiltNessuna valutazione finora

- Industrial & Manufacturing Engineering Systems: Fall 2021-22Documento19 pagineIndustrial & Manufacturing Engineering Systems: Fall 2021-22Saleh AlgdaryNessuna valutazione finora

- Microstructural Comparison of Spray-Formed and Conventionally Cast 2.5C-19Cr High-Chromium White Iron PDFDocumento12 pagineMicrostructural Comparison of Spray-Formed and Conventionally Cast 2.5C-19Cr High-Chromium White Iron PDFFàtí ĐCNessuna valutazione finora

- Powder Metallurgy: Report For IE228Documento20 paginePowder Metallurgy: Report For IE228صالح القداريNessuna valutazione finora

- Paper Decarburization in Spring SteelDocumento7 paginePaper Decarburization in Spring SteelMauricio RodriguezNessuna valutazione finora

- A Study of The Microstructure of Continuously Cast Iron PDFDocumento4 pagineA Study of The Microstructure of Continuously Cast Iron PDFFARID MIFTAHUL ANWARNessuna valutazione finora

- Rheology and Metal Forming of Fire-Refined CopperDocumento6 pagineRheology and Metal Forming of Fire-Refined CoppervitordeleteNessuna valutazione finora

- Reaction Mechanisms of Charcoal and Coke in The SiDocumento15 pagineReaction Mechanisms of Charcoal and Coke in The Siivan galassiNessuna valutazione finora

- Fractography of Steam Treated Sintered Steel Compacts: PARVIN Nader, HASHEMI Zahra, NAEIMI MohammadDocumento6 pagineFractography of Steam Treated Sintered Steel Compacts: PARVIN Nader, HASHEMI Zahra, NAEIMI MohammadanshuNessuna valutazione finora

- Synth and Prop of Novel Structural BinderDocumento10 pagineSynth and Prop of Novel Structural BinderMaximiliano ZarateNessuna valutazione finora

- Crystallographic Characterizations of Eutectic and Secondary Carbides in A Fe-12Cr-2.5Mo-1.5W-3V-1.25C AlloyDocumento7 pagineCrystallographic Characterizations of Eutectic and Secondary Carbides in A Fe-12Cr-2.5Mo-1.5W-3V-1.25C AlloyCHONKARN CHIABLAMNessuna valutazione finora

- Tribological Study of Gray Cast Iron With Automotive Brake Linings: The Effect of Rotor MicrostructureDocumento9 pagineTribological Study of Gray Cast Iron With Automotive Brake Linings: The Effect of Rotor MicrostructureJasna GlisovicNessuna valutazione finora

- Microstructure and Properties of Electrotechnical Porcelain: Studia Universitatis Babes-Bolyai Chemia January 2011Documento13 pagineMicrostructure and Properties of Electrotechnical Porcelain: Studia Universitatis Babes-Bolyai Chemia January 2011samar209Nessuna valutazione finora

- High Temperature CorrosionDocumento16 pagineHigh Temperature CorrosionBubai111Nessuna valutazione finora

- Effect of Processing Paramters On Metal Matrix Composites: Stir Casting ProcessDocumento5 pagineEffect of Processing Paramters On Metal Matrix Composites: Stir Casting Processchethan kumarNessuna valutazione finora

- Modelling The Behaviour of Oxide Scale in Hot Rolling: ReviewDocumento15 pagineModelling The Behaviour of Oxide Scale in Hot Rolling: ReviewsosoNessuna valutazione finora

- 75.sundar RajuDocumento5 pagine75.sundar RajuTrishul SampathNessuna valutazione finora

- Solid State Reactions of SiC With Co, Ni, and PTDocumento14 pagineSolid State Reactions of SiC With Co, Ni, and PTAntonio CamaranoNessuna valutazione finora

- Thpuniversity Ofbritish ColumbiaDocumento0 pagineThpuniversity Ofbritish ColumbiasaeedhoseinitazikNessuna valutazione finora

- (Advances in Materials Science) Assessment of Fitness For Service of Cr-Mo Steel Tubes in Catalytic Reforming Charge HeatersDocumento10 pagine(Advances in Materials Science) Assessment of Fitness For Service of Cr-Mo Steel Tubes in Catalytic Reforming Charge HeatersM ANessuna valutazione finora

- Review Article Barium HexaferriteDocumento11 pagineReview Article Barium HexaferriteIngrid Bena RiaNessuna valutazione finora

- Flyash Geopolymer Concrete As Future Concrete: Authors:-Rachit Ghosh, Anil Kumar and Sanjay KumarDocumento12 pagineFlyash Geopolymer Concrete As Future Concrete: Authors:-Rachit Ghosh, Anil Kumar and Sanjay KumarWalter Jimmy Flores AlcocerNessuna valutazione finora

- Corrosion Behavior of Pipeline Carbon Steel Under Different Iron Oxide Deposits in The District Heating SystemDocumento20 pagineCorrosion Behavior of Pipeline Carbon Steel Under Different Iron Oxide Deposits in The District Heating SystemHimanshu SharmaNessuna valutazione finora

- A Review of Zeolite-Like Porous Materials PDFDocumento10 pagineA Review of Zeolite-Like Porous Materials PDFMatchem BensafiNessuna valutazione finora

- SintefDocumento14 pagineSintefRodrigo RamosNessuna valutazione finora

- Mesophase State and Coke StructureDocumento11 pagineMesophase State and Coke StructureJorge AncheytaNessuna valutazione finora

- Dordrecht, NL, Pp. 239-255 (2001) : Nanostructured Carbon Coatings On Silicon Carbide: Experimental and Theoretical StudyDocumento17 pagineDordrecht, NL, Pp. 239-255 (2001) : Nanostructured Carbon Coatings On Silicon Carbide: Experimental and Theoretical StudyHimani Gaur JainNessuna valutazione finora

- Chemical Composition and Morphology of M C Eutectic Carbide in High Chromium White Cast Iron Alloyed With VanadiumDocumento5 pagineChemical Composition and Morphology of M C Eutectic Carbide in High Chromium White Cast Iron Alloyed With VanadiumMario SitorusNessuna valutazione finora

- CuproneyiteDocumento19 pagineCuproneyitesirdrinkalotNessuna valutazione finora

- Cast Iron OxidationDocumento8 pagineCast Iron OxidationRamon BrownNessuna valutazione finora

- 10 1007@bf00543728 PDFDocumento9 pagine10 1007@bf00543728 PDFJHON WILMAR CARDENAS PULIDONessuna valutazione finora

- Soft Magnetic Properties of Bulk Nanocrystalline Fe-Co-B-Si-Nb-Cu Alloy With High Saturated Magnetization of 1.35 TDocumento4 pagineSoft Magnetic Properties of Bulk Nanocrystalline Fe-Co-B-Si-Nb-Cu Alloy With High Saturated Magnetization of 1.35 TFaisal RazzaqNessuna valutazione finora

- Microstructure and Ablation Mechanism of C C ZRC SiC Composites in A Plasma Flame - 2017 - Ceramics InternationalDocumento7 pagineMicrostructure and Ablation Mechanism of C C ZRC SiC Composites in A Plasma Flame - 2017 - Ceramics InternationalLucas CaraffiniNessuna valutazione finora

- Corrosion Science: Pengpeng Bai, Shuqi Zheng, Hui Zhao, Yu Ding, Jian Wu, Changfeng ChenDocumento10 pagineCorrosion Science: Pengpeng Bai, Shuqi Zheng, Hui Zhao, Yu Ding, Jian Wu, Changfeng ChenArturo CervantesNessuna valutazione finora

- Porous ElectrodeDocumento34 paginePorous ElectrodeMirghani MohamedNessuna valutazione finora

- Ch17 Powder MetallurgyDocumento22 pagineCh17 Powder MetallurgyRudi SiswantoNessuna valutazione finora

- 1 s2.0 S0022024823002622 MainDocumento12 pagine1 s2.0 S0022024823002622 MainHanane Mohammed BirkudarNessuna valutazione finora

- Effect of Steel Composition and Slag ProDocumento5 pagineEffect of Steel Composition and Slag ProAbhinandan ChatterjeeNessuna valutazione finora

- Fastshapes - Sprocket: Typical ApplicationsDocumento23 pagineFastshapes - Sprocket: Typical ApplicationsJimmy MyNessuna valutazione finora

- 20a-Esp8266 Rtos SDK Programming Guide enDocumento41 pagine20a-Esp8266 Rtos SDK Programming Guide enkellisgfNessuna valutazione finora

- The Oredigger Issue 24 - April 26, 2010Documento12 pagineThe Oredigger Issue 24 - April 26, 2010The OrediggerNessuna valutazione finora

- Overhead Design Manua Section 8 - Cable DataDocumento18 pagineOverhead Design Manua Section 8 - Cable DataIVAN TURCONessuna valutazione finora

- Fertilizer Industry Wastewater TreatmentDocumento1 paginaFertilizer Industry Wastewater TreatmentAnmol UpadhyayNessuna valutazione finora

- Pipe and Tube Operations - DaytonaDocumento123 paginePipe and Tube Operations - Daytonaramon nava0% (1)

- Print PDFDocumento11 paginePrint PDFFe CasarolliNessuna valutazione finora

- Lab 11.4.1: Using The Scandisk and Defrag Utilities: Estimated Time: 30 Minutes ObjectiveDocumento2 pagineLab 11.4.1: Using The Scandisk and Defrag Utilities: Estimated Time: 30 Minutes ObjectiveHamzaSpahijaNessuna valutazione finora

- Termostato Temporizable Honeywell-Pro-2000-Manual-De-UsuarioDocumento72 pagineTermostato Temporizable Honeywell-Pro-2000-Manual-De-UsuariocostainmueblessasNessuna valutazione finora

- BITS Herald Summer Issue 2013Documento23 pagineBITS Herald Summer Issue 2013Bits Herald100% (1)

- Health Care Facilities and Medical Gas and VacuumDocumento27 pagineHealth Care Facilities and Medical Gas and VacuumStephen TabiarNessuna valutazione finora

- Synchronous ManufacturingDocumento18 pagineSynchronous ManufacturingPatricia Romero100% (1)

- Assessment 1 - Questioning - Written Assessment: Satisfactory or Not Yet SatisfactoryDocumento35 pagineAssessment 1 - Questioning - Written Assessment: Satisfactory or Not Yet SatisfactorySonal Awasthi MishraNessuna valutazione finora

- LiliaGutnik Resume 2013Documento2 pagineLiliaGutnik Resume 2013Lilia GutnikNessuna valutazione finora

- Deception & Detection-On Amazon Reviews DatasetDocumento9 pagineDeception & Detection-On Amazon Reviews Datasetyavar khanNessuna valutazione finora

- Overall EWD Vehicle Exterior Rear Fog LightDocumento10 pagineOverall EWD Vehicle Exterior Rear Fog Lightgabrielzinho43Nessuna valutazione finora

- Implementation Steps For Oracle Alert ModuleDocumento12 pagineImplementation Steps For Oracle Alert Modulemzee1981Nessuna valutazione finora

- C-Zone SDN BHD: Price List Effective 10 AUG 2019Documento2 pagineC-Zone SDN BHD: Price List Effective 10 AUG 2019Cikgu AlNessuna valutazione finora

- BX 3010 (0C)Documento362 pagineBX 3010 (0C)Lâm Hồ Ngọc HãnNessuna valutazione finora

- (Task Specific Risk Assessment) : No Name Signature Position Date N Name Signature Position DateDocumento5 pagine(Task Specific Risk Assessment) : No Name Signature Position Date N Name Signature Position DateRavi Shankar TurlapatiNessuna valutazione finora

- Alien Legacy-Manual PDFDocumento93 pagineAlien Legacy-Manual PDFMark BallingerNessuna valutazione finora

- Foreword by Brett Queener - Agile Product Management With Scrum - Creating Products That Customers LoveDocumento3 pagineForeword by Brett Queener - Agile Product Management With Scrum - Creating Products That Customers LoveJoao Paulo MouraNessuna valutazione finora

- 3 Drill StringDocumento43 pagine3 Drill StringShabaz HazharNessuna valutazione finora

- Office Automation & Attendance System Using IoTDocumento4 pagineOffice Automation & Attendance System Using IoTAnonymous kw8Yrp0R5rNessuna valutazione finora

- Klauke - Bi-Metal Lugs & ConnectorsDocumento6 pagineKlauke - Bi-Metal Lugs & ConnectorsBiplab PaulNessuna valutazione finora

- Rac MCQDocumento10 pagineRac MCQnimish lambatNessuna valutazione finora

- Is 13935 2009 PDFDocumento33 pagineIs 13935 2009 PDFManojKumawatRjNessuna valutazione finora

- Ansi Asabe S261.7 Feb1989 (R2011)Documento5 pagineAnsi Asabe S261.7 Feb1989 (R2011)StephanNessuna valutazione finora

- AdClient SDK For Android 4.3.0 PDFDocumento48 pagineAdClient SDK For Android 4.3.0 PDFOscarGomezNessuna valutazione finora

- Blockchain Technology in AdvertisingDocumento20 pagineBlockchain Technology in AdvertisingKittuNessuna valutazione finora