Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

07 - LO525 - Lot Sizing Procedures

Caricato da

vviiniDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

07 - LO525 - Lot Sizing Procedures

Caricato da

vviiniCopyright:

Formati disponibili

SAP AG

R

Chapter 6 Lot-Sizing Procedures

Static lot-sizing procedures

Period lot-sizing procedures

Optimum lot-sizing procedures

SAP AG

R

Chapter 6 Objectives

you will know the lot-sizing procedures available in

the R/ System and the options you have !or detailed

control

"y the end o! this chapter#

SAP AG

R

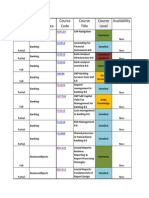

Lot-Sizing Procedures# Overview

Static Static

procedures procedures

Lot-!or-lot order $uantity

Replenishment up to

ma%imum stock level

&i%ed lot size

Period Period

procedures procedures

'aily lot size

(onthly lot size

)eekly lot size

Planning calendar

Optimum Optimum

procedures procedures

Least unit cost procedure

Part period procedure

*ro!! reorder procedure

Lot-sizing procedures Lot-sizing procedures

'ynamic +ost Planning

When maintaining the material master record, you can define additional restrictions for the lot-sizing

procedure:

minimum lot size

maximum lot size

rounding value

SAP AG

R

Static Lot-Sizing Procedures

,uantity

-.me

Lot-!or-lot order $uantity

Replenishment up to

ma%imum stock level

&i%ed lot size

Receipts

.ssues

In static lot-sizing procedures, future shortages are not taken into account, that is, if a shortage exists, an order

proposal is created for the amount defined for the static lot size. The system does not check to see when a future

shortage exists.

If you select the lot-for-lot order uantity, an order proposal is created for the shortage uantity. If several issues

exist on one day that cannot !e covered, the system still only creates one order proposal covering the total

shortage uantity on this particular day.

If you select the fixed lot size, the system creates an order proposal for the fixed lot size if a material shortage

occurs. If this is not sufficient to cover the shortage uantity, then the system creates several order proposals for

the same date until the shortage is covered.

If you select replenishment up to maximum stock level, when a material shortage occurs, the system creates an

order proposal for the amount reuired to !ring the stock level up to the maximum stock level recorded in the

material master record.

SAP AG

R

Period Lot-Sizing Procedures

,uantity

-ime

Period length Period length

Receipts

.ssues

In period lot-sizing procedures, reuirements that lie within the predefined period lengths are grouped together

into one lot.

The period length is !ased on the gregorian calendar "day, week, month# where!y the num!er of periods can !e

determined additionally.

SAP AG

R

Paris

Paris

Lot Size /ccording to Planning +alendar

(O -0 )1 -2 &R S/ S0

3

4

35

63

64

6

7

38

66

67

39

3:

6

9

;

33

34

6;

3

5

36

37

65

8

3

69

68

:

3;

63

6:

/ugust 3778

"erlin

"erlin

$ou can use the planning calendar to detemine period lengths of your choice.

SAP AG

R

Optimum Lot-Sizing Procedures

/ lot o! deliveries/

2igh order costs

(inimal stockkeeping/

(inimal storage costs

&ew deliveries /

Low order costs

(ore e%tensive stockkeeping/

2igher storage costs

%ptimum lot-sizing procedures optimize the total costs incurred for order costs and storage costs.

The principle of the optimum lot-sizing procedure is to keep grouping reuirements together into one lot until

the total costs are optimized - using various cost criteria.

SAP AG

R

Part Period "alancing

Re$mts % Price % Storage costs <age % Storage time

)arehse costs =

399 % 85

Price # 69 >

Lot size !i%ed costs# 399 >

Storage costs percentage # 39 <

Re$mts date Re$mts

$uantity

Lot size &i%ed

costs

Storage

costs

-otal storage

costs

9:?98?377; 3999 3999 399 9 9

9:?3?377; 3999 6999 4?8 4?8

9:?69?377; 3999 999 :8?:3 335?9:

9:?6:?377; 3999 ;999 335?9: 374?:4

Optimum

&earching for point of intersection.

'euirements grouped together into one lot until the total warehouse costs exceed the lot size fixed costs.

In this example, the optimum lot size is ())) pieces as if the lot size is set to *))) pieces, the total

warehouse costs "++,.)-# would !e greater than the lot size fixed costs "+))#.

SAP AG

R

Least 0nit +ost Procedure

Re$mts % Price % Storage costs <age % Storage time

)arehse costs =

399 % 85

Price # 69 >

Lot size !i%ed costs# 399 >

Storage costs percentage # 39 <

Re$mts date Re$mts

$uantity

Lot size &i%ed

costs

Storage

costs

-otal

costs

0nit

costs

9:?98?377; 3999 3999 399 9 399 9?39

9:?3?377; 3999 6999 4?8 34?8 9?9:

9:?69?377; 3999 999 :8?:3 635?9: 9?33

9:69:?377; 3999 ;999 335?9: 9?3; 9?94

Optimum

&earch for minimum.

'euirements are grouped into one lot until the total costs per unit reach a minimum level.

The optimum lot size in this example is ())) pieces as here the minimum cost per unit ").)-# is achieved.

SAP AG

R

*ro!! Reorder Procedure

Re$mts % Price % Storage costs <age

/dditional storage costs =

399 % 85 % 6

Lot size !i%ed costs

Saving on ordering costs =

Storage time % @Storage time A 3B

Price # 69 '(

Lot size !i%ed costs # 399 '(

Storage costs percentage # 39 <

Re$mts date Re$mts

$uantity

Lot size &i%ed

costs

Saving on

ordering costs

/dditional

storage costs

9:?98?377; 3999 3999 399 9 9

9:?3?377; 3999 6999 3?:7 6?:;

9:?69?377; 3999 999

9:?6:?377; 3999 ;999

Optimum

&earch for increase.

'euirements are grouped into one lot until the additional storage costs per period are greater than the

savings on ordering costs per period.

In this example, the optimum lot size is +))) pieces as if one more reuirement is added, the additional

storage costs "(.-.# are greater than the saving on ordering costs "+.-/#.

SAP AG

R

'ynamic Lot Size +reation

Re$mts % Price % Storage costs <age % Storage time

Storage costs =

399 % 85

Price # 69 >

Lot size !i%ed costs# 399 >

Storage costs percentage # 39 <

Re$mts date Re$mts

$uantity

Lot size &i%ed

costs

Storage costs

9:?98?377; 3999 3999 399 9

9:?3?377; 3999 6999 4?8

9:?69?377; 3999 999 :8?:3

9:?6:?377; 3999 ;999 335?9:

Optimum

'emts are grouped into one lot until the additional storage costs are less than the lot size fixed costs.

The additional storage costs are greater than the lot size fixed costs with a lot size of .))) pieces.

Therefore, the optimum lot size is *))) pieces.

SAP AG

R

Chapter 6 Review

.n the static proceduresC !uture shortages are not taken

into account? -hese procedures are based on each

shortage?

-he !i%ed order $uantity or the procedure entitledC

Dreplenishment up to ma%imum stock levelE are both

recommended !or reorder point planning?

.n the period lot-sizing proceduresC re$uirements within a

prede!ined period are grouped together#

- Period according to the gregorian calendar

- Period according to the planning calendar

.n optimum proceduresC the system optimizes the sum o!

order costs and storage costs?

Potrebbero piacerti anche

- 35 Lot Size CalculationDocumento9 pagine35 Lot Size CalculationlymacsauokNessuna valutazione finora

- Appendix: Special G/L Transactions (Optional) Periodic Processing (Optional)Documento39 pagineAppendix: Special G/L Transactions (Optional) Periodic Processing (Optional)fab10moura32Nessuna valutazione finora

- Lot-Size Calculation: PurposeDocumento1 paginaLot-Size Calculation: PurposeBhattahcarjee RupakNessuna valutazione finora

- Business Examples On Different Replenishment MethodsDocumento4 pagineBusiness Examples On Different Replenishment MethodsbaluanneNessuna valutazione finora

- Risk Based Gas Mapping WorkflowDocumento11 pagineRisk Based Gas Mapping Workflowfredo405Nessuna valutazione finora

- Purchase Assignment: ContentsDocumento17 paginePurchase Assignment: ContentsmkumarshahiNessuna valutazione finora

- MM 1 010 Lot Size CalculationDocumento4 pagineMM 1 010 Lot Size Calculationaudi404Nessuna valutazione finora

- SCM244 ProductionPlanningPartII (SAPR3 MRP)Documento315 pagineSCM244 ProductionPlanningPartII (SAPR3 MRP)krushi123Nessuna valutazione finora

- Warehouse AutomationDocumento4 pagineWarehouse Automationdeepakverma1981Nessuna valutazione finora

- Sage ERP X3: Processes For Year End Simulation and Fiscal Year End.Documento3 pagineSage ERP X3: Processes For Year End Simulation and Fiscal Year End.SagePartnerNessuna valutazione finora

- AC305 AssetAccountingDocumento248 pagineAC305 AssetAccountingfungayingorima100% (1)

- Tuning Mappings For Better PerformanceDocumento12 pagineTuning Mappings For Better PerformanceNaveen ShettyNessuna valutazione finora

- 2011 What's New at CMG Event in Perth - Automated History-Matching & Optimization Using CMOSTDocumento48 pagine2011 What's New at CMG Event in Perth - Automated History-Matching & Optimization Using CMOSTtsar_philip2010Nessuna valutazione finora

- Period-End Postings in CO: Unit ContentsDocumento9 paginePeriod-End Postings in CO: Unit Contentsfab10moura32Nessuna valutazione finora

- Batch Specific Units of MasureDocumento11 pagineBatch Specific Units of MasureAmit AggarwalNessuna valutazione finora

- Transtutors002 25922 HomeworkDocumento5 pagineTranstutors002 25922 HomeworkПĀßΞΞŁ KhalidNessuna valutazione finora

- 06 - LO525 - Quota ArrangementsDocumento10 pagine06 - LO525 - Quota ArrangementsvviiniNessuna valutazione finora

- Strategic Capacity Planning: ©the Mcgraw-Hill Companies, Inc., 2004Documento26 pagineStrategic Capacity Planning: ©the Mcgraw-Hill Companies, Inc., 2004recoil25Nessuna valutazione finora

- Warehouse ManagementDocumento139 pagineWarehouse ManagementcvkrajNessuna valutazione finora

- What Is SAP MM Module? An OverviewDocumento34 pagineWhat Is SAP MM Module? An OverviewPrudhvikrishna GurramNessuna valutazione finora

- Schema Design For Time Series Data in BigtableDocumento6 pagineSchema Design For Time Series Data in BigtableJo bookingNessuna valutazione finora

- 02 - LO525 - General InformationDocumento23 pagine02 - LO525 - General InformationvviiniNessuna valutazione finora

- Daily Processing: Unit ContentsDocumento37 pagineDaily Processing: Unit Contentsfab10moura32Nessuna valutazione finora

- Dynamic Safety Stock Calculation and Integration With PlanningDocumento18 pagineDynamic Safety Stock Calculation and Integration With PlanningKathula VenkateswararaoNessuna valutazione finora

- SCM - Case Assin Group 2 Sec - BDocumento8 pagineSCM - Case Assin Group 2 Sec - BHarmeet kapoorNessuna valutazione finora

- MIT6 172F10 Lec03Documento75 pagineMIT6 172F10 Lec03printesoiNessuna valutazione finora

- AC305Documento242 pagineAC305harish402100% (2)

- Lean MpsDocumento7 pagineLean MpsMichael ThompsonNessuna valutazione finora

- Consumption Based Planning in Sap MMDocumento6 pagineConsumption Based Planning in Sap MMnbhaskar bhaskarNessuna valutazione finora

- Revision Part 1: WWW - Bradford.ac - Uk/managem EntDocumento18 pagineRevision Part 1: WWW - Bradford.ac - Uk/managem EntHappy AdelaNessuna valutazione finora

- En - SodaPop Game - Teaching NoteDocumento7 pagineEn - SodaPop Game - Teaching NoteFrancisco Antonio Suarez Salas100% (2)

- Fabric UtilizationDocumento8 pagineFabric Utilizationranjann349Nessuna valutazione finora

- MBA Ops MGT Assignemnt Updated JULY 2013Documento4 pagineMBA Ops MGT Assignemnt Updated JULY 2013reshmee1234Nessuna valutazione finora

- Critical Analysis: Titus WanjalaDocumento3 pagineCritical Analysis: Titus WanjalaTitus wanjalaNessuna valutazione finora

- Chapter 3 Target Costing: 1. ObjectivesDocumento9 pagineChapter 3 Target Costing: 1. ObjectivesMevika MerchantNessuna valutazione finora

- SCAP Session 9 Cut Order PlanDocumento30 pagineSCAP Session 9 Cut Order PlanReena VermaNessuna valutazione finora

- Plan Safety Stock Levels with Standard MethodsDocumento8 paginePlan Safety Stock Levels with Standard MethodsjeevanNessuna valutazione finora

- Safety Stock Calculation in SAPDocumento3 pagineSafety Stock Calculation in SAPashish sawantNessuna valutazione finora

- Oracle E Business Suite R12 BOM and WIPDocumento27 pagineOracle E Business Suite R12 BOM and WIPSenthil KumarNessuna valutazione finora

- Pricing Appendix - Calculating Price Elasticity and Profit-Maximizing PriceDocumento23 paginePricing Appendix - Calculating Price Elasticity and Profit-Maximizing PriceShane Camille AbuegNessuna valutazione finora

- Benchmark and optimize costs for plasma cutting operationsDocumento3 pagineBenchmark and optimize costs for plasma cutting operationswentropremNessuna valutazione finora

- Monitor and optimize SAP APO performanceDocumento16 pagineMonitor and optimize SAP APO performanceRitam NandyNessuna valutazione finora

- I. Executive Summary: at Garmin, You Never Know How The Next Great Idea Will Be BornDocumento9 pagineI. Executive Summary: at Garmin, You Never Know How The Next Great Idea Will Be BornRobert BrownNessuna valutazione finora

- Sport ObermeyerDocumento3 pagineSport ObermeyerAshutosh Mishra100% (2)

- Six Sigma ThesisDocumento13 pagineSix Sigma ThesisNikhil MehtaNessuna valutazione finora

- Aggregate Planning PPTsDocumento41 pagineAggregate Planning PPTsSahil ChaudharyNessuna valutazione finora

- Reducing Costs at Complete Hardware SupplyDocumento3 pagineReducing Costs at Complete Hardware SupplyJavier SotomayorNessuna valutazione finora

- 036 APO SizingDocumento20 pagine036 APO SizingmyvroomNessuna valutazione finora

- Advantages of ForecastingDocumento3 pagineAdvantages of ForecastingCaleb MunyairiNessuna valutazione finora

- Gv8 Tutorial Manual-5Documento60 pagineGv8 Tutorial Manual-5Pedro JaraNessuna valutazione finora

- How to use Smart RoundingDocumento23 pagineHow to use Smart Roundingpjanssen2306Nessuna valutazione finora

- Littlefield Technologies ReportDocumento1 paginaLittlefield Technologies ReportHardik RupareliaNessuna valutazione finora

- P25 Img Consumption Based PlanningDocumento23 pagineP25 Img Consumption Based PlanninglymacsauokNessuna valutazione finora

- Mmfieldviewrevised ALLDocumento62 pagineMmfieldviewrevised ALLzramuk3Nessuna valutazione finora

- Thesis Reservoir SimulationDocumento8 pagineThesis Reservoir Simulationfjdxfc4v100% (1)

- How To Improve The Performance in Nested LoopsDocumento6 pagineHow To Improve The Performance in Nested LoopssushipiggieNessuna valutazione finora

- The Official Supply Chain Dictionary: 8000 Researched Definitions for Industry Best-Practice GloballyDa EverandThe Official Supply Chain Dictionary: 8000 Researched Definitions for Industry Best-Practice GloballyValutazione: 4 su 5 stelle4/5 (4)

- TIME SERIES FORECASTING. ARIMAX, ARCH AND GARCH MODELS FOR UNIVARIATE TIME SERIES ANALYSIS. Examples with MatlabDa EverandTIME SERIES FORECASTING. ARIMAX, ARCH AND GARCH MODELS FOR UNIVARIATE TIME SERIES ANALYSIS. Examples with MatlabNessuna valutazione finora

- CISA EXAM-Testing Concept-Recovery Time Objective (RTO) & Recovery Point Objective (RPO)Da EverandCISA EXAM-Testing Concept-Recovery Time Objective (RTO) & Recovery Point Objective (RPO)Valutazione: 1 su 5 stelle1/5 (2)

- LO540 Gerenciamento de Servicos Externos4Documento15 pagineLO540 Gerenciamento de Servicos Externos4vviiniNessuna valutazione finora

- LO540 Gerenciamento de Servicos Externos2 PDFDocumento15 pagineLO540 Gerenciamento de Servicos Externos2 PDFvviiniNessuna valutazione finora

- LO540 Gerenciamento de Servicos Externos5Documento15 pagineLO540 Gerenciamento de Servicos Externos5vviiniNessuna valutazione finora

- LO540 Gerenciamento de Servicos Externos3 PDFDocumento15 pagineLO540 Gerenciamento de Servicos Externos3 PDFvviiniNessuna valutazione finora

- LO540 Gerenciamento de Servicos Externos1 PDFDocumento15 pagineLO540 Gerenciamento de Servicos Externos1 PDFvviiniNessuna valutazione finora

- LO540 Gerenciamento de Servicos Externos5Documento15 pagineLO540 Gerenciamento de Servicos Externos5vviiniNessuna valutazione finora

- LO540 Gerenciamento de Servicos Externos5Documento15 pagineLO540 Gerenciamento de Servicos Externos5vviiniNessuna valutazione finora

- LO540 Gerenciamento de Servicos Externos4Documento15 pagineLO540 Gerenciamento de Servicos Externos4vviiniNessuna valutazione finora

- LO540 Gerenciamento de Servicos Externos4Documento15 pagineLO540 Gerenciamento de Servicos Externos4vviiniNessuna valutazione finora

- 03 - LO525 - Reorder Point and Store Location PlanningDocumento18 pagine03 - LO525 - Reorder Point and Store Location PlanningvviiniNessuna valutazione finora

- LO540 Gerenciamento de Servicos Externos3 PDFDocumento15 pagineLO540 Gerenciamento de Servicos Externos3 PDFvviiniNessuna valutazione finora

- Hub001 PDFDocumento12 pagineHub001 PDFvviiniNessuna valutazione finora

- 02 - LO525 - General InformationDocumento23 pagine02 - LO525 - General InformationvviiniNessuna valutazione finora

- 06 - LO525 - Quota ArrangementsDocumento10 pagine06 - LO525 - Quota ArrangementsvviiniNessuna valutazione finora

- 08 - LO525 - Controlling The Total Planning RunDocumento7 pagine08 - LO525 - Controlling The Total Planning RunvviiniNessuna valutazione finora

- Sappress Sap Netweaver BW 7x ReportingDocumento60 pagineSappress Sap Netweaver BW 7x ReportingdiitrisNessuna valutazione finora

- Chap 3Documento46 pagineChap 3Tharani21Nessuna valutazione finora

- Инструкция терминала IND310Documento52 pagineИнструкция терминала IND310ДенисNessuna valutazione finora

- Planos Electricos. Gruas NuevasDocumento122 paginePlanos Electricos. Gruas NuevasSebastian Segovia100% (1)

- Irrigation Canal Longitudinal & Cross Section Drawing and Quantity Offtake PackageDocumento16 pagineIrrigation Canal Longitudinal & Cross Section Drawing and Quantity Offtake Packageram singhNessuna valutazione finora

- Splunk 4.2.3 AdminDocumento426 pagineSplunk 4.2.3 AdminjazzymoonNessuna valutazione finora

- Recurdyn Solver - Theoretical ManualDocumento325 pagineRecurdyn Solver - Theoretical ManualsawamurNessuna valutazione finora

- Department of Computer ScienceDocumento2 pagineDepartment of Computer ScienceAnonymous XZZ6j8NONessuna valutazione finora

- Dijkstra's, Kruskals and Floyd-Warshall AlgorithmsDocumento38 pagineDijkstra's, Kruskals and Floyd-Warshall AlgorithmsRajan JaiprakashNessuna valutazione finora

- Assignment ProblemDocumento11 pagineAssignment ProblemSwasti SinghNessuna valutazione finora

- Prediction of Aircraft Lost of Control in The Flight by Continuation, Bifurcation, and Catastrophe Theory MethodsDocumento10 paginePrediction of Aircraft Lost of Control in The Flight by Continuation, Bifurcation, and Catastrophe Theory MethodsAnonymous mE6MEje0Nessuna valutazione finora

- 82 - 90 Optimasi Rekonfigurasi Jaringan Distribusi Tegangan MenengahDocumento9 pagine82 - 90 Optimasi Rekonfigurasi Jaringan Distribusi Tegangan MenengahYoakim MoraNessuna valutazione finora

- nnsd691s Panasonic Service ManualDocumento9 paginennsd691s Panasonic Service Manualrafael rincon100% (1)

- OJT AtTRACK - On The Job Trainee Remote Attendance Monitoring System Using Face Recognition SystemDocumento6 pagineOJT AtTRACK - On The Job Trainee Remote Attendance Monitoring System Using Face Recognition SystemIOER International Multidisciplinary Research Journal ( IIMRJ)Nessuna valutazione finora

- Wooldridge 2002 Rudiments of StataDocumento11 pagineWooldridge 2002 Rudiments of StataDineshNessuna valutazione finora

- EUBIS SOP-Master Version 1 0Documento4 pagineEUBIS SOP-Master Version 1 0iman8869Nessuna valutazione finora

- Modelman PDFDocumento72 pagineModelman PDFCarlos CamachoNessuna valutazione finora

- Context Diagram DFD For (Existing) Billing SystemDocumento3 pagineContext Diagram DFD For (Existing) Billing SystemDanna ClaireNessuna valutazione finora

- Data Sheet: FeaturesDocumento16 pagineData Sheet: FeatureschristianNessuna valutazione finora

- How to Register for Smart Prepaid Innovation Generation FAQsDocumento12 pagineHow to Register for Smart Prepaid Innovation Generation FAQsKELLY CAMILLE GALIT ALAIRNessuna valutazione finora

- Measurement, Diagnostic, and Analysis Technology: For Monitoring of Hydraulic and Lubrication FluidsDocumento16 pagineMeasurement, Diagnostic, and Analysis Technology: For Monitoring of Hydraulic and Lubrication FluidsMiguel VlntìnNessuna valutazione finora

- RTD Temperature Transmitter DatasheetDocumento1 paginaRTD Temperature Transmitter DatasheetMohan BabuNessuna valutazione finora

- nRF52832 NFC Antenna Tuning: White PaperDocumento15 paginenRF52832 NFC Antenna Tuning: White PaperCanNessuna valutazione finora

- NOS AdminGuide v411 PDFDocumento748 pagineNOS AdminGuide v411 PDFMaeckol Segura PeñaNessuna valutazione finora

- Wimax System Performance StudiesDocumento10 pagineWimax System Performance StudiesFelix GatambiaNessuna valutazione finora

- SentryGuide75 10sept2015Documento204 pagineSentryGuide75 10sept2015Adrian Calin RigoNessuna valutazione finora

- Taiwan Semiconductor Manufacturing Company: Competitor AnalysisDocumento36 pagineTaiwan Semiconductor Manufacturing Company: Competitor Analysisjingning2929Nessuna valutazione finora

- Building Boats - A Kanban GameDocumento9 pagineBuilding Boats - A Kanban GameTim WiseNessuna valutazione finora

- Create Table PlayerDocumento8 pagineCreate Table PlayerMr MittalNessuna valutazione finora

- OTC 21070 Fluid-Structure Interaction Simulations of A Pipeline Span Exposed To Sea Bottom CurrentsDocumento12 pagineOTC 21070 Fluid-Structure Interaction Simulations of A Pipeline Span Exposed To Sea Bottom CurrentsRasheed YusufNessuna valutazione finora

- 10ME64 FEM Lesson Plan (Student)Documento9 pagine10ME64 FEM Lesson Plan (Student)PavanKumarNNessuna valutazione finora

- Inventory Management System UML Diagram - CompleteDocumento15 pagineInventory Management System UML Diagram - CompleteHuda Al-Shuhayeb100% (1)