Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Saep 324

Caricato da

brecht1980100%(3)Il 100% ha trovato utile questo documento (3 voti)

3K visualizzazioni8 pagineThis Engineering Procedure specifies the minimum requirements for certification review and registration of contractor welders and brazers working on In-Kingdom construction, fabrication and Maintenance projects. The term welder shall also mean welding operator or brazer. When industry codes and standards, or Saudi Aramco standards are required for use by project specification they shall become a part of this Engineering Procedure.

Descrizione originale:

Titolo originale

SAEP-324

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis Engineering Procedure specifies the minimum requirements for certification review and registration of contractor welders and brazers working on In-Kingdom construction, fabrication and Maintenance projects. The term welder shall also mean welding operator or brazer. When industry codes and standards, or Saudi Aramco standards are required for use by project specification they shall become a part of this Engineering Procedure.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

100%(3)Il 100% ha trovato utile questo documento (3 voti)

3K visualizzazioni8 pagineSaep 324

Caricato da

brecht1980This Engineering Procedure specifies the minimum requirements for certification review and registration of contractor welders and brazers working on In-Kingdom construction, fabrication and Maintenance projects. The term welder shall also mean welding operator or brazer. When industry codes and standards, or Saudi Aramco standards are required for use by project specification they shall become a part of this Engineering Procedure.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 8

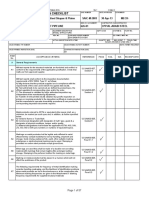

Engineering Procedure

SAEP-324 1 J uly 2008

Certification Review and Registration

of Project Welders and Brazers

Document Responsibility: Inspection Department

Saudi Aramco DeskTop Standards

Table of Contents

1 Scope............................................................. 2

2 Conflicts and Deviations................................. 2

3 Applicable Documents................................... 2

4 Definitions and Acronyms.............................. 3

5 Responsibilities.............................................. 4

6 Instructions..................................................... 5

Previous Issue: 30 June 2003 Next Planned Update: 1 July 2013

Page 1 of 8

Primary contact: Supervisor, IEU on 874-6604

CopyrightSaudi Aramco 2008. All rights reserved.

Document Responsibility: Inspection Department SAEP-324

Issue Date: 1 J uly 2008 Certification Review and Registration

Next Planned Update: 1 J uly 2013 of Project Welders and Brazers

Page 2 of 8

1 Scope

1.1 This Engineering Procedure specifies the minimum requirements for

certification review and registration of contractor welders and brazers working

on In-Kingdom construction, fabrication and Maintenance projects.

1.2 Unless specifically noted otherwise the term welder shall also mean welding

operator or brazer.

2 Conflicts and Deviations

Conflicts between this Engineering Procedure and any other Saudi Aramco Standard

shall be resolved by the Operations Inspection Division of the Inspection Department in

writing.

3 Applicable Documents

Unless stated otherwise, all codes and standards referenced shall be the latest issue

(including Revisions and Addenda). When industry codes and standards, or Saudi

Aramco standards are required for use by project specification they shall become a part

of this Engineering Procedure.

3.1 Saudi Aramco References

Saudi Aramco Engineering Procedures

SAEP-321 Performance Qualification Testing and

Certification of Saudi Aramco Welders

SAEP-322 Performance Qualification Testing and

Certification of Saudi Aramco Brazers

Saudi Aramco Engineering Standard

SAES-W-013 Welding Requirements for Offshore Structures

Saudi Aramco Forms

SA 4758-ENG Job Clearance Card

3.2 Industry Codes and Standards

American Petroleum Institute

API STD 1104 Welding of Pipelines & Related Facilities

Document Responsibility: Inspection Department SAEP-324

Issue Date: 1 J uly 2008 Certification Review and Registration

Next Planned Update: 1 J uly 2013 of Project Welders and Brazers

Page 3 of 8

American Society of Mechanical Engineers/Boiler & Pressure Vessels Code

ASME SEC IIC Welding Rods, Electrodes and Filler Metals

ASME SEC V Nondestructive Examination

ASME SEC IX Welding and Brazing Qualifications

American Welding Association

AWS D1.1 Structural Welding Code - Steel

4 Definitions and Acronyms

Certified Welder: A welder that has a valid welder certification. A certified welder is

only qualified to weld with those welding processes, and within the essential variables,

of the valid certification.

Contractor Welder: A welder working directly for, and under the supervision of, a

contractor.

Fabrication Shop: A building used for the fabrication and/or assembly of equipment

and structures such as pipe spools, pressure vessels, etc.

Fabrication Yard: A large open outdoor area used for the fabrication and/or assembly

of very large structures such as offshore platforms, large pressure vessels, etc.

Field Fabrication Shop: A temporary fabrication shop set up in the field near a

construction project by a contractor to fabricate piping, fittings and/or structural

components.

JCC: J ob Clearance Card (Form SA 4758-ENG):

Job Clearance Card (JCC): A identification card issued by Saudi Aramco Inspection

to contractor welders registered on field fabrication projects. The J CC lists

certifications held, description of the job, and the welders name and symbol.

Maintenance Project: A project to perform maintenance work under a short form

contract with the Maintenance Department as the proponent.

OIU: Operations Inspection Unit.

Qualification: See preferred term Welder Performance Qualification.

Qualification Card: A photo identity card issued by a welder testing agency or

contractor to a welder passing a certification test that lists all the certifications held by

the welder. Qualification Cards must be carried at all times by the welder, and must be

presented for review upon request.

Document Responsibility: Inspection Department SAEP-324

Issue Date: 1 J uly 2008 Certification Review and Registration

Next Planned Update: 1 J uly 2013 of Project Welders and Brazers

Page 4 of 8

Qualified Welder: See preferred term Certified Welder.

Registered Welder: A welder whose certification has been reviewed, found to be

acceptable, and is on file with the project inspector.

Registration: The act of registering a welder certification, or a photostatic copy

thereof. Registration is performed after certification review and approval. Current lists

of approved welders and/or J ob Clearance Cards are examples of registration.

Uncertified Welder: A welder that does not have a valid welder certification.

Unqualified Welder: See preferred term Uncertified Welder.

Welder Certification: Certification in writing that a welder has produced a test weld

meeting a defined standard.

Welder Performance Qualification: The demonstration of a welders ability to

produce a test weld meeting a defined standard.

WPS: Welding Procedure Specification.

WTC: Welder Test Center.

WTS: Welder Tracking System.

5 Responsibilities

5.1 The Project Inspector or is responsible for:

a) Reviewing contractor welder certifications prior to the start of welding;

b) Registering contractor welders with valid welder certifications;

c) Monitoring the initial production work of contract welders to determine

their ability to make sound welds.

d) Monitoring the contractors quality control program to ensure contractor

welder certifications are being maintained in accordance with the

governing codes and standards of the job or project.

e) Issuing and controlling J ob Clearance Cards on the job.

Commentary Note:

If inspection of small, single job maintenance contracts or other non BI/JO

work is handled by OIU, OIU Inspector is responsible for the above.

5.2 The Welder Test Center is responsible for the testing of contractor welders when

Document Responsibility: Inspection Department SAEP-324

Issue Date: 1 J uly 2008 Certification Review and Registration

Next Planned Update: 1 J uly 2013 of Project Welders and Brazers

Page 5 of 8

there is insufficient time for the contractor to have welders tested by an

independent welder testing agency (only applies to Maintenance projects).

5.3 The Welder Tracking System Administrator is responsible for tracking all

withdrawn J CC's for a period of at least three years.

6 Instructions

6.1 General Requirements

6.1.1 Contractors, fabricators and vendors are responsible for the testing and

certification of welders working under their supervision in accordance

with the governing Codes, standards, and or specifications of each

project.

6.1.2 The project inspector shall have the right to require the removal or retest

of any welder at any time due to unsatisfactory work.

6.1.3 Performance qualification testing of welders strictly for tack welding is

prohibited.

6.1.4 For SMAW performance qualification testing welders shall be qualified

for all passes and the full thickness of the test coupon.

6.2 Field Fabrication Work

6.2.1 Contractor welders shall be tested in accordance with either ASME SEC

IX, AWS D1.1, or API STD 1104 as required, for all types of welding

(includes tack, repair and temporary).

6.2.2 Contractor welders working on In Kingdom field construction projects

(includes field fabrication shops also) shall be tested and certified by an

independent welder testing agency approved by the Saudi Aramco

Inspection Department prior to the start of work. Established contractors

and fabricators with extensive experience and a proven ability in welder

testing shall be permitted to test their own welders through written

approval of the Saudi Aramco Inspection Department.

6.2.3 Certifications of contractor welders shall be reviewed by the project

inspector prior to the start of work.

6.2.4 Contractor welders that have not been properly certified shall not be

permitted to weld.

Document Responsibility: Inspection Department SAEP-324

Issue Date: 1 J uly 2008 Certification Review and Registration

Next Planned Update: 1 J uly 2013 of Project Welders and Brazers

Page 6 of 8

6.2.5 All properly certified contractor welders shall be registered by the

project inspector and issued a J ob Clearance Card (J CC) prior to the start

of work.

6.2.6 The initial production work of contractor welders shall be monitored by

the project inspector to determine their ability to make sound welds.

6.2.7 The project inspector shall monitor the contractors quality control

program to determine whether contractor welder certifications are being

maintained in accordance with the governing Codes and standards of the

job or project. Contractor welders that do not maintain valid

certifications shall have their J CC withdrawn. Once withdrawn, J CC's

will only be reinstated upon receipt of written proof of training, and the

successful completion of a recertification test. All withdrawn J CC's shall

be sent to the WTS Administrator for tracking, where they will be kept

on file for a period of at least three years.

6.2.8 For offshore pipelines and structures all welders welding primary joints

(refer to SAES-W-013, Table 4, Note 7) shall be requalified if the

original performance qualification test was not witnessed by a third party

inspection agency. Requalification testing shall be witnessed by a third

party inspection agency or the project inspector.

6.2.9 For offshore pipelines and structures all welders welding joints other

than primary joints shall be retested on a 10% random basis, as selected

by the project inspector unless the original performance qualification test

was witnessed by a third party welder testing agency. Requalification

testing shall be witnessed by a third party inspection agency or project

inspector. If the requalification failure rate exceeds 20%, all welders

shall be retested.

6.3 Fabrication Yard Work

6.3.1 The fabricator shall maintain a welder identification system acceptable to

the project inspector. Welders shall carry an identification card that

includes a photo, welders name, company identification number, and

welders symbol.

6.3.2 A list of all welders shall be submitted to the project inspector prior to

the start of work. This list shall be maintained up to date by the

fabricator. The list shall include the welders name, symbol, processes

qualified and all other important essential variables as well as

certification issue dates.

Document Responsibility: Inspection Department SAEP-324

Issue Date: 1 J uly 2008 Certification Review and Registration

Next Planned Update: 1 J uly 2013 of Project Welders and Brazers

Page 7 of 8

6.3.3 The project inspector shall audit welder certifications to ensure fabricator

compliance with the Codes, standards and approved Quality Plan.

6.4 Maintenance Projects

6.4.1 Contractor welders working on small single job Maintenance projects

(short form contracts) shall be properly certified by a Saudi Aramco

approved In-Kingdom independent welder testing agency prior to the

start of work.

6.4.2 Certifications shall be submitted to the project inspector prior to the start

of work for review. Contractor welders with acceptable certifications

shall be registered by the project inspector.

6.4.3 Welders that are not properly certified shall not be registered and shall

not be permitted to work.

6.4.4 For critical work, where time is of the essence, contractor welders may

be tested by the Welder Testing Center in accordance with either SAEP-

321 (or SAEP-322 if required) in lieu of testing by an independent third

party welder testing agency(except that retests are not permitted). This is

not intended to be used as a substitute for proper planning by the

proponent organization and shall only be permitted when there are no

other feasible options. Upon completion of testing the WTC shall issue a

letter to the proponent inspection authority summarizing the results of

the testing.

6.5 J ob Clearance Cards (J CC)

6.5.1 Contractor welders working on field fabrication projects such as BI and

J O work, and who are properly certified, shall be registered and issued a

J ob Clearance Card (Form SA 4758-ENG) by the project inspector prior

to the start of work.

6.5.2 The issuance of J ob Clearance Cards to contractor welders on small,

single job maintenance contracts or other non BI/J O work, is optional

and shall be determined by the project inspector.

6.5.3 J ob Clearance Cards are only valid for the job or project for which they

are issued.

6.5.4 J ob Clearance Cards can be withdrawn by the project inspector at any

time for cause if the contractor welder is not producing work of

acceptable quality. Once withdrawn, J CC's will only be reinstated upon

receipt of written proof of training, and the successful completion of a

recertification test.

Document Responsibility: Inspection Department SAEP-324

Issue Date: 1 J uly 2008 Certification Review and Registration

Next Planned Update: 1 J uly 2013 of Project Welders and Brazers

Page 8 of 8

6.5.5 J ob Clearance Cards shall be returned to the project inspector when the

contractor welder goes on home leave or is terminated from the project.

Contractor welders that return to work within three months from home

leave (to the same project) may be reinstated without retesting.

Revision Summary

1 July 2008 Revised the "Next Planned Update. Reaffirmed the contents of the document, and reissued

with no other changes.

Potrebbero piacerti anche

- Saep 321Documento28 pagineSaep 321brecht1980Nessuna valutazione finora

- Saep 323Documento8 pagineSaep 323brecht1980100% (1)

- Saep 322Documento18 pagineSaep 322brecht1980100% (1)

- Saep 324 PDFDocumento13 pagineSaep 324 PDFArvind ShakyaNessuna valutazione finora

- Saep 324Documento13 pagineSaep 324Hansel Francis100% (4)

- Saep-324 2018 PDFDocumento23 pagineSaep-324 2018 PDFAdnan Rafiq100% (1)

- Saep-1160 (NDT - Tracking and Reporting of Welding, NDT and Pressure Testing For Capital ProjectsDocumento12 pagineSaep-1160 (NDT - Tracking and Reporting of Welding, NDT and Pressure Testing For Capital ProjectsShajin Mohammed Shamsudhin88% (8)

- SAEP-352 - Welding Procedures Review and Approval PDFDocumento14 pagineSAEP-352 - Welding Procedures Review and Approval PDFsilvrsurfr637Nessuna valutazione finora

- Saep 1142Documento11 pagineSaep 1142shaban100% (2)

- Saep 352 PDFDocumento15 pagineSaep 352 PDFRami ElloumiNessuna valutazione finora

- SAES-W-012 - Google Search3Documento1 paginaSAES-W-012 - Google Search3fayceal0% (1)

- Saep 1145Documento20 pagineSaep 1145Amit shah100% (1)

- 2019 - Saep-1160Documento24 pagine2019 - Saep-1160smdriyazbashaNessuna valutazione finora

- Saep 1151Documento13 pagineSaep 1151fero67% (3)

- 01 Samss 044 PDFDocumento11 pagine01 Samss 044 PDFAbdul Rahim ShaikhNessuna valutazione finora

- Saep 347Documento27 pagineSaep 347Qaiser Mahmood100% (2)

- 01 Saip 01Documento17 pagine01 Saip 01Kuppan Srinivasan100% (2)

- 1 SATIP-L-350-01 On-Plot Piping - Rev 01Documento4 pagine1 SATIP-L-350-01 On-Plot Piping - Rev 01zooplado75% (4)

- Saep 1160Documento13 pagineSaep 1160Durga Jagan Puppala100% (1)

- Materials System SpecificationDocumento21 pagineMaterials System Specificationnadeem shaikhNessuna valutazione finora

- SAIC-M-2003 Rev 7Documento57 pagineSAIC-M-2003 Rev 7yugandhar100% (1)

- 175 320300Documento1 pagina175 320300sridhar100% (1)

- SAEP-1150 Inspection Coverage On ProjectsDocumento55 pagineSAEP-1150 Inspection Coverage On ProjectsAbdul Rahim Shaikh100% (5)

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldDocumento19 pagineSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldIrshad IqbalNessuna valutazione finora

- Saep 1146Documento8 pagineSaep 1146Ronanki RaviNessuna valutazione finora

- Saudi Aramco Typical Inspection PlanDocumento11 pagineSaudi Aramco Typical Inspection PlanAhdal NoushadNessuna valutazione finora

- Saudi Aramco Inspection ChecklistDocumento15 pagineSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Saudi Aramco piping inspection planDocumento2 pagineSaudi Aramco piping inspection planMuhammad Farukh ManzoorNessuna valutazione finora

- Saep-352, 01.01.2018 PDFDocumento15 pagineSaep-352, 01.01.2018 PDFRami ELLOUMI100% (2)

- SAIC-L-2035 Rev 6Documento2 pagineSAIC-L-2035 Rev 6biplabpal2009Nessuna valutazione finora

- Saep 381 PDFDocumento17 pagineSaep 381 PDFRami Elloumi100% (2)

- Saudi Aramco Typical Inspection Plan: Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MechanicalDocumento5 pagineSaudi Aramco Typical Inspection Plan: Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MechanicalpravinNessuna valutazione finora

- 01 Samss 035Documento28 pagine01 Samss 035Cherukunnon Jubu100% (2)

- SAEP-35-N - Valves Handling, Hauling, Receipt Tests and StorageDocumento8 pagineSAEP-35-N - Valves Handling, Hauling, Receipt Tests and StorageMuhammad Farukh Manzoor0% (1)

- SAES-L-150 PDF Download - Pressure Testing of Plant Pipelines - PDFYARDocumento7 pagineSAES-L-150 PDF Download - Pressure Testing of Plant Pipelines - PDFYARZahidRafiqueNessuna valutazione finora

- SatipDocumento5 pagineSatipMuhammad Abdul Kadher100% (3)

- Saep 1140Documento15 pagineSaep 1140shaban100% (1)

- Manual Ultrasonic Thickness Testing ProcedureDocumento8 pagineManual Ultrasonic Thickness Testing ProcedureAmit shahNessuna valutazione finora

- SAEP-379 Quality Issues Notification 2-MAR-2016Documento4 pagineSAEP-379 Quality Issues Notification 2-MAR-2016asiqna100% (1)

- Obtaining Waivers for Mandatory Engineering RequirementsDocumento8 pagineObtaining Waivers for Mandatory Engineering Requirementsxiongweijun100% (1)

- Saudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 WeldDocumento2 pagineSaudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 Weldm4metz100% (1)

- Saudi Aramco PMI checklist ensures alloy purityDocumento5 pagineSaudi Aramco PMI checklist ensures alloy puritykarioke mohaNessuna valutazione finora

- Saic L 2007 PDFDocumento7 pagineSaic L 2007 PDFHesham HelalNessuna valutazione finora

- Saep 1141Documento71 pagineSaep 1141omar santos100% (3)

- Saudi Aramco Typical Inspection PlanDocumento10 pagineSaudi Aramco Typical Inspection Plankarthi51289Nessuna valutazione finora

- 175 000003Documento1 pagina175 000003zhangNessuna valutazione finora

- 01 Samss 010 PDFDocumento11 pagine01 Samss 010 PDFAnonymous ZxJZoU0% (1)

- Saep 1144Documento22 pagineSaep 1144shaban100% (1)

- Saep 316 2016 PDFDocumento25 pagineSaep 316 2016 PDFAllan LindoNessuna valutazione finora

- SAUDI ARAMCO LPT INSPECTION PLANDocumento3 pagineSAUDI ARAMCO LPT INSPECTION PLANDurga Jagan PuppalaNessuna valutazione finora

- SAIC W 2069 in Process Welding InspectionDocumento8 pagineSAIC W 2069 in Process Welding InspectionAbdul Gafoor ShaikhNessuna valutazione finora

- QMISDocumento14 pagineQMISLopez Gardo0% (1)

- Schedule Q and Its AttachmentsDocumento32 pagineSchedule Q and Its Attachmentssajeevismail50% (2)

- 00 Saip 13Documento12 pagine00 Saip 13immuNessuna valutazione finora

- Saep 1154Documento5 pagineSaep 1154IRFAN NAZIR0% (1)

- 09 Samss 069Documento10 pagine09 Samss 069Selvakpm06Nessuna valutazione finora

- Saep 323 PDFDocumento8 pagineSaep 323 PDFthanga balanNessuna valutazione finora

- Saep 323Documento8 pagineSaep 323paul cafeNessuna valutazione finora

- 100-YER-PM-PPM-0550 (Welders & Brazers)Documento11 pagine100-YER-PM-PPM-0550 (Welders & Brazers)Armando AballeNessuna valutazione finora

- Well Testing Project Management: Onshore and Offshore OperationsDa EverandWell Testing Project Management: Onshore and Offshore OperationsNessuna valutazione finora

- AirLine Respirator MSA PDFDocumento8 pagineAirLine Respirator MSA PDFbrecht1980Nessuna valutazione finora

- Purchasing Process in Prep For ISODocumento4 paginePurchasing Process in Prep For ISObrecht1980Nessuna valutazione finora

- Saep 333Documento39 pagineSaep 333brecht1980100% (1)

- Saep 327Documento11 pagineSaep 327brecht1980100% (2)

- Saep 317Documento22 pagineSaep 317brecht1980100% (1)

- Saep 329Documento20 pagineSaep 329brecht1980100% (2)

- Saep 332Documento15 pagineSaep 332abidch143100% (1)

- Engineering Procedure: SAEP-310 13 January 2008 Piping and Pipeline Repair Piping Standards Committee MembersDocumento39 pagineEngineering Procedure: SAEP-310 13 January 2008 Piping and Pipeline Repair Piping Standards Committee Membersbrecht1980100% (4)

- Saep 318Documento28 pagineSaep 318brecht1980Nessuna valutazione finora

- Saep 250Documento32 pagineSaep 250brecht198075% (4)

- Saep 311Documento31 pagineSaep 311brecht1980Nessuna valutazione finora

- Saep 309Documento22 pagineSaep 309brecht1980Nessuna valutazione finora

- Saep 303Documento60 pagineSaep 303brecht1980100% (2)

- Saep 316Documento20 pagineSaep 316brecht1980100% (17)

- Saep 305Documento5 pagineSaep 305brecht1980Nessuna valutazione finora

- Saep 308Documento19 pagineSaep 308brecht1980Nessuna valutazione finora

- Saep 306Documento13 pagineSaep 306brecht1980Nessuna valutazione finora

- Saep 201Documento5 pagineSaep 201brecht1980Nessuna valutazione finora

- Saep 140Documento10 pagineSaep 140brecht1980Nessuna valutazione finora

- Saep 134Documento5 pagineSaep 134brecht1980100% (1)

- Saep 135Documento47 pagineSaep 135brecht1980Nessuna valutazione finora

- Saep 136Documento20 pagineSaep 136brecht1980Nessuna valutazione finora

- Saep 127Documento9 pagineSaep 127brecht1980Nessuna valutazione finora

- Saep 125Documento9 pagineSaep 125brecht1980Nessuna valutazione finora

- Saep 133Documento10 pagineSaep 133abidch143100% (1)

- Engineering Procedure: SAEP-122 31 July, 2005 Project Records Document Responsibility: Project Support and Controls DeptDocumento11 pagineEngineering Procedure: SAEP-122 31 July, 2005 Project Records Document Responsibility: Project Support and Controls Deptbrecht1980100% (3)

- Study Guide For HKIA Professional Assessment Paper 5 Building Materials and TechnologyDocumento202 pagineStudy Guide For HKIA Professional Assessment Paper 5 Building Materials and TechnologykiddhoNessuna valutazione finora

- Catalogo de Tuberías TenarisDocumento134 pagineCatalogo de Tuberías TenarisErwin Jeronimo GarciaNessuna valutazione finora

- Is.13349.1992 0Documento21 pagineIs.13349.1992 0tharaka.me2018Nessuna valutazione finora

- Oracle Nca ProtocolDocumento23 pagineOracle Nca ProtocoldivyaNessuna valutazione finora

- M E LAB 3 Experiment 4 Heat Losses From Pipes 3Documento20 pagineM E LAB 3 Experiment 4 Heat Losses From Pipes 3Alister Mae ZafraNessuna valutazione finora

- PVDGIntegration BarkerDocumento41 paginePVDGIntegration BarkerEliNessuna valutazione finora

- PPTP Tunneling - DD-WRTDocumento5 paginePPTP Tunneling - DD-WRTsys2uNessuna valutazione finora

- Data StructureDocumento12 pagineData StructureAnkit KomarNessuna valutazione finora

- Mathv1v2 With AnswerdocxDocumento4 pagineMathv1v2 With AnswerdocxCharles FollmarNessuna valutazione finora

- Slovenski Standard SIST EN 14066:2013: 01-Junij-2013Documento4 pagineSlovenski Standard SIST EN 14066:2013: 01-Junij-2013Bac Thac LeNessuna valutazione finora

- Aerial Access PlatformDocumento18 pagineAerial Access PlatformMANDAR DHANDENessuna valutazione finora

- SAP HCP Cloud ConnectorDocumento22 pagineSAP HCP Cloud ConnectorAmrinder Singh0% (1)

- LEVAC Slings Instruction Manual ENGLISHDocumento20 pagineLEVAC Slings Instruction Manual ENGLISHpeachykristaNessuna valutazione finora

- E4-E4 Sanchar SoftDocumento19 pagineE4-E4 Sanchar SoftAGM PHONE UjjainNessuna valutazione finora

- Part S16 Cast in Place Concrete Piles (2008)Documento3 paginePart S16 Cast in Place Concrete Piles (2008)CK TangNessuna valutazione finora

- New Product Development Process For HyundaiDocumento33 pagineNew Product Development Process For HyundaiDheeraj Kumar100% (1)

- Skim Akreditasi Makmal Malaysia (SAMM)Documento5 pagineSkim Akreditasi Makmal Malaysia (SAMM)milobengNessuna valutazione finora

- 6.2.2.2 Advanced Problems and Solutions For Network ConnectionsDocumento2 pagine6.2.2.2 Advanced Problems and Solutions For Network Connectionstaufiqur rahman100% (1)

- High DPI Support in Windows Forms PDFDocumento4 pagineHigh DPI Support in Windows Forms PDFmbianchettoNessuna valutazione finora

- Wireless Site SurveyDocumento52 pagineWireless Site SurveyMSA Systems100% (1)

- Bluecoat Training-24.2.2012Documento55 pagineBluecoat Training-24.2.2012dhui12183% (6)

- OH - DisconnectorDocumento4 pagineOH - DisconnectorTaQuangDucNessuna valutazione finora

- PackfenseDocumento96 paginePackfenseIldrich Elizandro Reyes NúñezNessuna valutazione finora

- ABB-Alen King - PDF - Adobe ReaderDocumento39 pagineABB-Alen King - PDF - Adobe ReaderFrancisco ParedesNessuna valutazione finora

- Axiom: Owner's ManualDocumento16 pagineAxiom: Owner's ManualĐứcThọNessuna valutazione finora

- j1939 ProtocolDocumento2 paginej1939 ProtocolFaraz ElectronicNessuna valutazione finora

- 122 Keralastic GBDocumento4 pagine122 Keralastic GBRaman IyerNessuna valutazione finora

- LogDocumento132 pagineLogjamesNessuna valutazione finora

- 2010 Mitsubishi Endeavor 36843 PDFDocumento514 pagine2010 Mitsubishi Endeavor 36843 PDFbarcelonetaNessuna valutazione finora

- CR3000 Student WorkbookDocumento538 pagineCR3000 Student WorkbookdyaNessuna valutazione finora