Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Loads Acting On Crane Structure During Travel

Caricato da

aiyubi2Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Loads Acting On Crane Structure During Travel

Caricato da

aiyubi2Copyright:

Formati disponibili

Testing of Elements and Assemblies

MMM4035L

Laboratory Handout

Loads acting on crane structure during travel

by

Eugeniusz Grabowski, PhD, MSc. (Mech. Eng.)

Wrocaw 2009

All rights reserved

1

1. Introduction

Loads acting on the structure of cranes vary substantially, depending on their source,

magnitude and type, frequency and duration, which has been reflected in their classification

according to international and european standards covering crane design.

The main sources of loads applied to the structures of the cranes are:

- masses of elements and parts of these structures (including those which either change or

not change their position relatively to other elements and parts),

- masses of payloads,

- accelerations and decelerations in the periods of unsteady work movements of cranes,

- dynamic reactions due to cranes own masses and carried payloads,

- dynamical reactions of crane runway rails and buffers,

- elastic deformations crane structures caused by deviations in manufacturing tolerances

and differences in characteristics of parallel drives,

- wind pressure.

Depending on frequency and duration, loads acting on the structure of of overhead tra-

velling cranes are classified into:

- regular loads, which occur in normal exploitation and arise from gravity, accelerations and

decelerations during start ups and breaking of the crane work movements,

- irregular loads, which also occur in the normal exploitation and arise from wind pressure

(in seviere wind condition), temperature effects or by the so-called crane skewing a phe-

nomenon occurring during the crane travel,

- exceptional loads, which occur occasionally in conditions other then normal exploitation

and are caused by very high wind pressure (so-called out of service wind conditions),

seismic effects, failure of working mechanisms or sudden crane impact on fenders.

Loads acting on crane structures during travel, qualify into all the above categories and

are those whose proper evaluation is especially significant for safe strength design dimension-

ing, particularly for crane structures characterised by large spans (distance between the rails

of the crane runway) in relation to the distance of the cranes wheels (on the same rail of the

crane runway).

Amongst the loads, which are more important from the point of view of (already men-

tioned) safe strength design/dimensioning of crane structures, and which occur during or as a

consequence of crane travel, it is necessary to distinguish between:

- loads caused by crane skewing on the crane runway,

- loads caused by travelling on an uneven surfaces of the crane runway,

2

- loads caused by crane impact into fenders or by impact into another crane on the same

crane runway.

These irregular loads, which all do not occur at the same time, are accounted for in the

design calculations by the so-called co-incidental systems of combined loads, which by acting

simultaneously in vertical and horizontal planes in different parts of the crane structure cause

its effort which is checked by design calculations according to the codes of practice (stan-

dards) ISO or EN.

2. Theoretical and codes of practice bases for defining loads acting on crane structure

during travel loads caused by crane skewing

Skewing, understood to be a deviation of the crane from its ideal, or intended alignment

(in which the longitudinal axis of the crane bridge is perpendicular to the crane runway axis),

is an external symptom of the crane skewing process during travel. During skewing, the load-

carrying structure of the crane undergoes rotations relative to the crane runway (within the

gaps between the rail and flanges of the cranes wheels or crane guiding elements) and simul-

taneously experiences elastic deformations in the horizontal plane [1].

External loads acting on the crane structure, in the horizontal plane are balanced by the

forces in contact points of the runway rails and tracks of the cranes wheels (forces of fric-

tional contact), flanges of these wheels or side guide rolls (forces of rigid contact).

Such a crane structure, treated as a non-deformable frame in the horizontal plane and

moving in a plane , is subjected to longitudinal and transverse (relative to the rail axis) com-

ponents of skewing force F

x1i

, F

y1i

, F

x2i

, F

y2i

(tangential forces). These forces arise from the

rotation of the system about the so-called instant slide pole (Fig.1) and are balanced by one,

largest in magnitude, guiding force F

y

, occurring at the interface between the rail and just one

element guiding the crane along the runway. It is a case of traveling with one guiding force,

which amongst other cases (traveling with a number of guiding forces) is the most undesirable

from the point of view of the magnitude of horizontal loads that it generates.

3

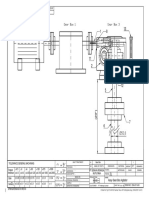

Fig.1 Forces on the load-carrying structure of the crane caused by skewing

The magnitudes of the aforementioned forces are determined according to the standards

[2] and [3], depending on the features of the travel mechanism (with central or individual

drives), the method of wheel attachment (with or without possibility of lateral movement), as

well as the basic dimensional ratios of the crane structure (the crane bridge span to the wheel

distance on the same rail).

The magnitude of the guiding force F

y

is determined according to the aforementioned

standards as

F

y

= f m g (1)

while components of mentioned skewing forces (tangential forces) are given as

F

x1i

=

1i

f m g (2)

F

y1i

=

1 1 1 1

f m g (3)

F

x2i

=

2i

f m g (4)

F

y2i

=

2 2 2 2

f m g (5)

where

4

f is a coefficient of rolling friction, dependent on the angle of skewing , given by:

f= 0,3[1-exp( -250 )] (for < 0,15 rad) (6)

m g the gravitational force due to the mass of the crane,

1i

,

2i

parameters dependent on the location of the instant slide pole (determined by , , h

see fig 1), crane span l, the number n of the crane wheel pairs and type of crane travel drives

(

1i

=

2i

=0 for individually powered travel mechanisms),

1i

,

2i

parameters dependent on the location of the instant slide pole ( , , h), the distance

d

i

and the number n of the crane wheel pairs.

3. Methodology of measurement of selected loads acting on crane structure

Measurements of the loads discussed above, which act on real structures, are carried out

mostly by employing strain gauge methods, which, compared to other methods, produce the

most accurate results, provided the measurement procedures described below are followed.

The methodology of such measurements uses one to one relationships (usually capable of be-

ing expressed analytically) between the experimental readings at selected strain gauge points

and the loads acting at those points. Thus strain gauge measurements are indirect methods

and the only useful methods of measurement (with the exception of loads due to the trans-

ported payloads) in situations where installation of appropriate load converters would be im-

possible or would require significant changes to the construction of the crane structure.

Strain gauge measuring points employ rosette strain gauges or single strain gauges con-

nected into Wheatstones bridge (whenever possible), ensuring temperature compensation and

signal magnification (even four-fold), compared to the signal obtained from an individual

strain gauge. Both types of strain gauges are oriented along the direction of main stresses

(strains) caused by the measured loads.

The results of the strain gauge measurements, expressed non-dimensionally (usually in

promils ) are linearly dependent on the relative strains

i

associated with the normal stresses

i on a surface of the given structural element (plane stress state), where

i

=

i

E or

i

=

i

E/(1+ ) (E Youngs modulus, - Poissons ratio). The values of determined in this

way can be used to find the measured values of forces F

i

, using the relationship F

i

=F

i

(

i

),

known form the strength of materials.

The most accurate measurement of loads using the strain gauge method is achieved

through calibration of the measuring points readings in units of forces placed externally at the

exact locations of the measured loads. As a result of the direct experimental measurement of

the relationship between the strain gauge readings and the loads, other effects, such as manu-

5

facturing imperfections of the crane structure, variations in strain gauge parameters (resis-

tance, strain gauge constant k) and effects of varying cable lengths (between the strain gauge

points and measuring amplifier) are all compensated for.

4. Example of implementation of strain gauge measurements of selected loads acting on

crane structure during travel

Measured loads (guiding forces) F

H1i

, F

H2i

, acting at the points of contact with the rails of

the side rolls guiding the crane along its runway in the laboratory (Fig.2) are, in fact, the reac-

tions to the forces mentioned above, occurring at the time of crane skewing during travel

(more precisely component tangential forces F

y1i

, F

y2i

, according to Fig. 1).

4.1. Location of strain gauge points for measurement of forces F

H1i

, F

H2i

These points (accordingly to their name) are groups of two pairs of strain gauges bonded

to especially constructed measuring pins in brackets of guiding rolls placed at the ends of both

crane end beams (Fig.2). These pins work in shear caused by the forces S

H1i

, S

H2i

due to the

measured forces F

H1i

, F

H2i

.

Fig.2 Location of strain gauge points PT

H1i

, PT

H2i

for the purpose of measurement of se-

lected horizontal loads F

H1i

, F

H2i

acting on the crane structure during travel

6

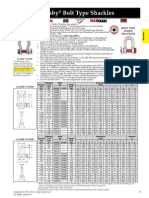

4.2. Strain gauge arrangement for measurement of horizontal forces F

H1

, F

H2i

The system comprises four measuring points PT

H11

, PT

H12,

PT

H21

, PT

H22

(pins for measur-

ing of the horizontal loads acting on the crane structure), each of which consists of four active

strain gauges joined into a complete Wheatstons bridge (Fig. 3)

Fig.3 Strain gauge arrangement for measurement of horizontal loads F

H22

All strain gauge points are connected to a multi-channel measuring amplifier. To each of

these points, to one diagonal of its Wheatstons bridge, voltage [V] (DC or AC - depending on

the type of the measuring amplifier) is supplied with one pair of cables. From the second di-

agonal of the bridge, a measurement power signal is received [mV], which is appropriately

processed in the amplifier ( e.g. amplified and cleaned from interference), and then is written

by the multi-channel register (numerical acquisition of data written into a computer disc).

Fig.4 shows a monitor in the measurement system enabling an observation of the changes of

measured loads. A similar function can be performed by a register using a paper tape.

Fig. 4 Schematic arrangement of strain gauge system for measurement of horizontal loads

F

H1i

, F

H2i

acting on the crane structure

7

4.3. Basic requirements regarding the measurement procedure applied to loads F

H1i

,

F

H2i

The correctness and accuracy of the measurement of loads mentioned above depend,

most of all, on:

- establishing and adopting the appropriate zero level of the measurement signal at strain

gauge points PT

H1i

, PT

H2i

,

- appropriate selection and setting of the measurement range in the amplifier for the individual

measuring channels,

- calibration of the strain gauge readings at measurement points.

In order to satisfy the above conditions, it is necessary to:

1) Determine and set a zero level of the measurement signal from points PT

H1i

, PT

H2i

for the

case of completely unloaded side rolls guiding the crane. In order to achieve that, the

crane can be moved short distances in opposite directions so that the successive pairs of

guiding rolls (of the first or second crane end beam) do not come into contact with the

sides of rails of the crane runway. In cases where it is impossible to achieve such an un-

loaded state, the zero level of the measurement signal for points PT

H1i

, PT

H2i

can be estab-

lished as an arithmetic mean of at least 60 readings, taken after stopping the crane travel

(in alternative, opposing directions) and releasing crane brakes in 3 different places on the

most used section of the crane runway, or near its ends and centre.

2) Set up the same measurement range on all measurement channels (that is the same range

for F

H1i

and F

H2i

) to facilitate later analysis of results. The magnitude of the range should

be slightly larger than the maximum values of the measured forces (then, the need to ampl-

ify the strain gauge signals is smaller, which reduces the effect of external interference).

3) Load each pair of the guiding rolls (those which are not in contact with the rail) with hori-

zontal and perpendicular to the rail force, using at least three different values in order to

check the linearity of strain gauge readings at the measurement points as a function of this

calibrating force. As mentioned in section III it is an activity that ensures the highest poss-

ible accuracy of load measurement possible in the given conditions and given accuracy

class of measuring equipment used in the strain gauge measurement system.

5. Program of the laboratory exercise

1. Safety training.

2. Preparation of the crane and measuring equipment.

8

2.1. Determination of zero reading for the individual measurement points (guiding

rolls without contact with the sides of the tops of the rails).

2.2. Determination of the measurement range for the all measurement channels (trial

movements of the crane).

2.3. Calibration of readings of the measurement points ( loading of rolls with horizon-

tal forces of known magnitude).

3. Measurement of forces F

H1i

and F

H2i

registration of strain gauge readings at points

PT

H1i

and PT

H2i

4. Analysis of results

4.1. Determination of the largest guiding force.

4.2. Determination of the calculated value of the leading force according to the stan-

dards [2] or [3].

4.3. Comparative assessment of the values of the measured forces conclusions

5. Report

ad.1. The convener (leading laboratory exercise) familiarizes all participants with the ba-

sic principles of safety in the area of the working crane and safe conduct of all the

tasks associated with the preparation of the crane and measuring equipment.

ad.2. All tasks are to be carried out in the manner that would ensure satisfaction of the re-

quirements presented in point 4.3. In order to establish adequate level of zero read-

ing of measurement signal from points PT

H1i

and PT

H2i

, it is possible to achieve

(other than by methods described in point 1, section 4.3) a complete relaxation of

the guiding rolls through forcing a transverse displacement of the wheels of the un-

loaded crane end beam that is when unloaded hoist trolley stands by the second

crane end beam. In order to establish the same measurement range for the individ-

ual channels, it is necessary to carry out trial runs of the crane over short distances,

in each direction and at full speed.

The largest values registered at the strain gauge points PT

H1i

and PT

H2i

sets the

base for the measurement range. During calibration of the individual measurement

points, the largest values of the calibrating force should be so chosen as to ensure

that the corresponding readings at these points were close to the set measurement

range (equal to all channels).

ad.3. In the measurements, depending on the number of the available measurement chan-

nels and possibility of simultaneous recording of their signals, it is necessary to reg-

9

ister readings of at least two measurement points located at the same ends of oppo-

site crane end beam.

ad.4. The analysis includes parts (within the scope of work described in p 4.1) which are

to be carried out by the students immediately after completing the measurements of

guiding forces F

H1i

, F

H2i

, and the remaining parts (within the scope of work de-

scribed in pp. 4.2, 4.3) carried out by the students individually, after the laboratory

session.

The largest absolute value of the measured loads, F

H1i

, or F

H2i

is to be determined

after studying all the changes in the strain gauge recordings at points PT

H1i

and

PT

H2i

(noted on the channels of the same measurement range).

The value of the guiding force F

y,

calculated according to the standards [2] and [3],

is to be determined from equations(1), (6), (7), (8) using the following data (Fig. 5):

l=5,17 m; e

k

=1,25 m; e

r

=1,58 m; m g=85 kN; d

1

=0,165; d

2

=1,415 m; n=2;

p=0; =0,36; =0.015 rad

h =

2 1

2 1

2 2

d d

d d

+

+

(7)

=

h n

d d

2 1

1 (8)

Fig.5 Scheme of the crane and data for calculating the guiding force according to the

standards [2] and[3].

10

When comparing the extreme values of the measured guiding forces F

H1i

, or F

H2i

it

is necessary to check the relationship between the direction of crane travel and the

occurrence of the largest guiding force F

y

on one of the ends of the crane end

beams (in accordance with Fig.1). Subsequently, it is necessary to compare the

largest value of the measured force F

H1i

, or F

H2i

(previously determined in accor-

dance with p. 4.1) with the value of the calculated force F

y

(determined in accor-

dance with p. 4.2) and formulate conclusions from all the comparisons.

ad.5. The report on the completed laboratory exercise (in accordance with points 1 - 4)

ought to contain a brief description of the measurements that were carried out, pres-

entation of the results from the measurements and calculations, and conclusions

from the analysis of the results and comparative assessments.

Literature

[1]. Grabowski E: Limiting of cranes skewing. Transport Przemyslowy nr 2/2001

[2]. International Standard ISO 8686-1: Cranes Design principles for loads and load com-

binations Part 1: General.

[3] European Standard EN 13001-2: Cranes. General Design Part 2: Load effects. CEN B-

1050

Potrebbero piacerti anche

- FEM9.311 EnglDocumento6 pagineFEM9.311 EnglPınar SunNessuna valutazione finora

- Assy Gear Box AgitatorDocumento1 paginaAssy Gear Box Agitatorer_winwibowoNessuna valutazione finora

- Book Chapter 10Documento24 pagineBook Chapter 10Camilo Ponce PerezNessuna valutazione finora

- Carbon Steel Tee Rails: Standard Specification ForDocumento7 pagineCarbon Steel Tee Rails: Standard Specification ForAAYNessuna valutazione finora

- Brugg Catalog enDocumento28 pagineBrugg Catalog enSinoj V AntonyNessuna valutazione finora

- Guias Lineares HIWIN PDFDocumento95 pagineGuias Lineares HIWIN PDFEdmar S JNessuna valutazione finora

- Md-17 Shaft Design StepsDocumento12 pagineMd-17 Shaft Design StepsRamji RaoNessuna valutazione finora

- Isis DriveDocumento18 pagineIsis DriveTms ArnNessuna valutazione finora

- Crane Guide Chap-1Documento1 paginaCrane Guide Chap-1Jayadev PalaiNessuna valutazione finora

- Design of Bearings & Miscellaneous ElementsDocumento14 pagineDesign of Bearings & Miscellaneous ElementsjvanandhNessuna valutazione finora

- Eot Crane During SeismicDocumento12 pagineEot Crane During SeismicboyzesNessuna valutazione finora

- Service Factor RatingsDocumento4 pagineService Factor Ratingschu42Nessuna valutazione finora

- Cálculo de EngranajesDocumento18 pagineCálculo de EngranajesJose Luis HernandezNessuna valutazione finora

- Experimental stress analysis improves gondola wagon designDocumento2 pagineExperimental stress analysis improves gondola wagon designrentizahariaNessuna valutazione finora

- Engineering Inspiration - Brake System Design CalculationsDocumento17 pagineEngineering Inspiration - Brake System Design CalculationsManjeet SinghNessuna valutazione finora

- Design and Analysis of Crane Hook With Different MaterialsDocumento6 pagineDesign and Analysis of Crane Hook With Different MaterialsEditor IJTSRDNessuna valutazione finora

- 059 062 PDFDocumento4 pagine059 062 PDFMario MereniNessuna valutazione finora

- 02 Mechanical BasicsDocumento29 pagine02 Mechanical BasicsVLADIMIR YOLVIS CHOQUEHUANCA GALINDONessuna valutazione finora

- Mdesign 2016 Gears Verzahnungen en PDFDocumento86 pagineMdesign 2016 Gears Verzahnungen en PDFmgualdiNessuna valutazione finora

- Bushman C HookDocumento2 pagineBushman C Hookperdhana2000100% (1)

- Gear DesignDocumento83 pagineGear DesignmuhammadaminjamalmutNessuna valutazione finora

- Dynamic Factor FormulaeDocumento15 pagineDynamic Factor FormulaeShubham More0% (1)

- Calculations - Trolley&BaseDocumento10 pagineCalculations - Trolley&BaseShree SalunkheNessuna valutazione finora

- Wheel Model 6 CatalogDocumento40 pagineWheel Model 6 CatalogHernan LopezNessuna valutazione finora

- C HookDocumento11 pagineC HookPradip SitaparaNessuna valutazione finora

- Swapnil (2016) - Design of Components Used in Hoisting Mechanism of An EOTDocumento5 pagineSwapnil (2016) - Design of Components Used in Hoisting Mechanism of An EOTGogyNessuna valutazione finora

- Spiral Springs PDFDocumento18 pagineSpiral Springs PDFEngr Eze Chuklet ChukwumaNessuna valutazione finora

- A Kinematic Analysis of Meshing Polymer Gear TeethDocumento16 pagineA Kinematic Analysis of Meshing Polymer Gear TeethsandeepNessuna valutazione finora

- Brochure 2010Documento20 pagineBrochure 2010shankarsreekumarNessuna valutazione finora

- GB/T 10095.2-2008 Cylindrical Gears Accuracy StandardDocumento5 pagineGB/T 10095.2-2008 Cylindrical Gears Accuracy StandardtaghdirimNessuna valutazione finora

- Wire Ropes Drive Mechanism For Reciprocating Linear MotionDocumento5 pagineWire Ropes Drive Mechanism For Reciprocating Linear MotionSachin KumawatNessuna valutazione finora

- KBK Classic and KBK Ergo Crane Construction Kits GuideDocumento12 pagineKBK Classic and KBK Ergo Crane Construction Kits GuideMahendran KuppusamyNessuna valutazione finora

- Kisssoft Tut 003 E KeyDocumento11 pagineKisssoft Tut 003 E KeyJorge Ronald Cabrera ÑaupaNessuna valutazione finora

- Worm DriveDocumento6 pagineWorm DriveRavi Kiran MeesalaNessuna valutazione finora

- Flender - Ejes ParalelosDocumento49 pagineFlender - Ejes ParalelosYenny LaraNessuna valutazione finora

- Dynamic Force Analysis ProblemsDocumento8 pagineDynamic Force Analysis Problemsa c s KumarNessuna valutazione finora

- Chassis MechanicsDocumento37 pagineChassis Mechanicsneerajsingh000007Nessuna valutazione finora

- Austenitic Cast IronDocumento2 pagineAustenitic Cast Ironkatchani123Nessuna valutazione finora

- CMAA 70 2000 Structure DesignDocumento19 pagineCMAA 70 2000 Structure DesignmishikhanNessuna valutazione finora

- Alform 700 MCDocumento9 pagineAlform 700 MCCarlos Nombela PalaciosNessuna valutazione finora

- Hardened steel pins and weightsDocumento1 paginaHardened steel pins and weightsSachin JawaleNessuna valutazione finora

- Cone Tolerance PDFDocumento21 pagineCone Tolerance PDFPopoaia MarianNessuna valutazione finora

- Loading Factors Within The Strength Calculation Procedure For Involute Marine Gears With Parallel AxesDocumento12 pagineLoading Factors Within The Strength Calculation Procedure For Involute Marine Gears With Parallel AxesNenad VulićNessuna valutazione finora

- A Comparison of The AGMA Gear Design Stresses, The LewisDocumento41 pagineA Comparison of The AGMA Gear Design Stresses, The LewisJulendra AriatedjaNessuna valutazione finora

- Altair Simsolid: 2020 Verification ManualDocumento107 pagineAltair Simsolid: 2020 Verification ManualAnonymous 1rLNlqUNessuna valutazione finora

- Goliath CraneDocumento2 pagineGoliath CraneZankar R ParikhNessuna valutazione finora

- ISO Standardisation of Bevel Gears: Overview and Ideas On Method A"Documento28 pagineISO Standardisation of Bevel Gears: Overview and Ideas On Method A"vincemugnaioNessuna valutazione finora

- Synchronous Belt Drives - Automotive PulleysDocumento14 pagineSynchronous Belt Drives - Automotive Pulleystv-locNessuna valutazione finora

- Samyang Gear ReducerDocumento6 pagineSamyang Gear Reducerjuliyanto88Nessuna valutazione finora

- HVATACDocumento2 pagineHVATACHrvatski strelicarski savezNessuna valutazione finora

- ISO Gear Standards GuideDocumento6 pagineISO Gear Standards GuideEslam YehiaNessuna valutazione finora

- Load Sharing Methods of Backstops 2004 01Documento10 pagineLoad Sharing Methods of Backstops 2004 01Ruben SalgadoNessuna valutazione finora

- Gear ForcesDocumento7 pagineGear ForcesSahil Kumar100% (1)

- Emm 3506 - Group 3Documento132 pagineEmm 3506 - Group 3Griffin ThomasNessuna valutazione finora

- Universal Joint and Theory-Basic PDFDocumento17 pagineUniversal Joint and Theory-Basic PDFPrasadNessuna valutazione finora

- Bonfiglioli Geared MotorDocumento584 pagineBonfiglioli Geared MotorProdip SarkarNessuna valutazione finora

- KranDocumento7 pagineKranMarioNessuna valutazione finora

- GS52Documento3 pagineGS52S.Hasan MirasadiNessuna valutazione finora

- Structural Health MonitoringDa EverandStructural Health MonitoringDaniel BalageasNessuna valutazione finora

- Kukmc 0378 UsDocumento2 pagineKukmc 0378 Usaiyubi2Nessuna valutazione finora

- Kukmc 0377 UsDocumento2 pagineKukmc 0377 Usaiyubi2Nessuna valutazione finora

- Kukmc 0375 UsDocumento4 pagineKukmc 0375 Usaiyubi2Nessuna valutazione finora

- Kukmc 0328 UsDocumento8 pagineKukmc 0328 Usaiyubi2Nessuna valutazione finora

- Fifthwheel - JOST JSK 38CDocumento2 pagineFifthwheel - JOST JSK 38Caiyubi2100% (2)

- Hose Clamps and Ferrules for Assembly of Different FittingsDocumento6 pagineHose Clamps and Ferrules for Assembly of Different Fittingsaiyubi2Nessuna valutazione finora

- MS100-00 (M-MA Series Meter Specs)Documento6 pagineMS100-00 (M-MA Series Meter Specs)aiyubi2Nessuna valutazione finora

- Kukmc 0376 UsDocumento12 pagineKukmc 0376 Usaiyubi2Nessuna valutazione finora

- Kukmc 0328 UsDocumento8 pagineKukmc 0328 Usaiyubi2Nessuna valutazione finora

- Kukmc 0258 UsDocumento2 pagineKukmc 0258 Usaiyubi2Nessuna valutazione finora

- Heavy duty fifth wheel couplings JSK 38 C-1-2Documento2 pagineHeavy duty fifth wheel couplings JSK 38 C-1-2aiyubi2Nessuna valutazione finora

- DODGE Torque-Arm Speed Reducer Feature BenefitDocumento4 pagineDODGE Torque-Arm Speed Reducer Feature Benefitaiyubi2Nessuna valutazione finora

- 400-20 (Meter Manual)Documento28 pagine400-20 (Meter Manual)edwinramonNessuna valutazione finora

- Repair Manual JSK 38Documento38 pagineRepair Manual JSK 38aiyubi2Nessuna valutazione finora

- 200 60 IndustrialDocumento8 pagine200 60 Industrialaiyubi2Nessuna valutazione finora

- Coel Catalogue 2006 1Documento58 pagineCoel Catalogue 2006 1Danilo MontesanoNessuna valutazione finora

- Acf Fastener HandbookDocumento84 pagineAcf Fastener Handbookninjanear2012100% (2)

- C-Line - Front & Back CoversDocumento4 pagineC-Line - Front & Back Coversaiyubi2Nessuna valutazione finora

- DRIV-LOK Press Fit FastenersDocumento28 pagineDRIV-LOK Press Fit Fastenersaiyubi2Nessuna valutazione finora

- Crosby Mckissick Sheaves CatalogDocumento29 pagineCrosby Mckissick Sheaves Catalogaiyubi2Nessuna valutazione finora

- Crosby G-2130Documento1 paginaCrosby G-2130AekJayNessuna valutazione finora

- Blind FastenersDocumento7 pagineBlind Fastenersaiyubi2Nessuna valutazione finora

- CROSBY Master Link & Shackles - MetricDocumento2 pagineCROSBY Master Link & Shackles - Metricaiyubi2Nessuna valutazione finora

- Wire Rope ThimblesDocumento1 paginaWire Rope Thimblesaiyubi2Nessuna valutazione finora

- Tranz Couplings CatalogDocumento4 pagineTranz Couplings Catalogaiyubi2Nessuna valutazione finora

- A-344 & A347 Welded Master Link - ImperialDocumento1 paginaA-344 & A347 Welded Master Link - Imperialaiyubi2Nessuna valutazione finora

- CROSBY Master Link & Shackles - MetricDocumento2 pagineCROSBY Master Link & Shackles - Metricaiyubi2Nessuna valutazione finora

- A-344, A-347 Master LinkDocumento1 paginaA-344, A-347 Master LinkAekJayNessuna valutazione finora

- Universal JointsDocumento10 pagineUniversal JointsshashanksekharNessuna valutazione finora

- APEX U-Joint CatalogDocumento28 pagineAPEX U-Joint Catalogaiyubi2Nessuna valutazione finora

- LNG JettyDocumento17 pagineLNG Jettywilliam pasamonteNessuna valutazione finora

- Pat Lmi Manual - Ds150Documento15 paginePat Lmi Manual - Ds150Anonymous yjK3peI7100% (1)

- Monorail Beam Design Q&ADocumento33 pagineMonorail Beam Design Q&Aabdulloh_99Nessuna valutazione finora

- Altec Lmap CalibrationDocumento17 pagineAltec Lmap Calibrationwilliam ortizNessuna valutazione finora

- 50 Years of Crane Component ExcellenceDocumento32 pagine50 Years of Crane Component ExcellenceMahnooshNessuna valutazione finora

- OSHA - 29CFR - Construction StandardsDocumento22 pagineOSHA - 29CFR - Construction Standardshasan_676489616100% (1)

- Manual enDocumento194 pagineManual enJohnNessuna valutazione finora

- English Translate 1 - 质量证明书Documento12 pagineEnglish Translate 1 - 质量证明书Kiki Kiko KikoNessuna valutazione finora

- Safety in Erection and Dismantling of Constructions: Submitted by Saravana Kumar Saravanan ShilpaDocumento13 pagineSafety in Erection and Dismantling of Constructions: Submitted by Saravana Kumar Saravanan ShilpaMageshwarNessuna valutazione finora

- Function 2Documento78 pagineFunction 2AdiiNessuna valutazione finora

- GR-900EX-4: Hydraulic Rough Terrain CraneDocumento16 pagineGR-900EX-4: Hydraulic Rough Terrain CraneboooNessuna valutazione finora

- 6200 - 1 Superstructure MalfunctionsDocumento82 pagine6200 - 1 Superstructure Malfunctionsrenat100% (1)

- SEVAN LOUISIANA OFFSHORE DRILLING RIG SPECSDocumento1 paginaSEVAN LOUISIANA OFFSHORE DRILLING RIG SPECSfahad mullaNessuna valutazione finora

- TEMPORARY POWER PROJECT PANEL INSTALLATIONDocumento18 pagineTEMPORARY POWER PROJECT PANEL INSTALLATIONNurdin Sudrajat SasrabahuNessuna valutazione finora

- 36x48 Poster of Big Blue Crane Collapse v8Documento1 pagina36x48 Poster of Big Blue Crane Collapse v8Zakaria DinataNessuna valutazione finora

- QUY180 EnglishDocumento22 pagineQUY180 EnglishDarma HermawanNessuna valutazione finora

- Racking Systems Guide for Any Storage DemandDocumento18 pagineRacking Systems Guide for Any Storage DemandSheel JhaNessuna valutazione finora

- Algorithm Crane SelectionDocumento10 pagineAlgorithm Crane SelectionZafr O'ConnellNessuna valutazione finora

- 2018 Product CatalogDocumento23 pagine2018 Product CatalogKien Trung NguyenNessuna valutazione finora

- Crane Chart - Tadano AR-2000MDocumento16 pagineCrane Chart - Tadano AR-2000Mdamnaged100% (2)

- Petroleum Development Oman Lift Plan for Lifting Turbine RotorDocumento7 paginePetroleum Development Oman Lift Plan for Lifting Turbine RotorVuthpalachaitanya KrishnaNessuna valutazione finora

- Girder Installation MethodologyDocumento4 pagineGirder Installation MethodologyRolly EscamillanNessuna valutazione finora

- Lifting+Matters+Q4+2019 Final WEB LRDocumento44 pagineLifting+Matters+Q4+2019 Final WEB LRMeleti Meleti MeletiouNessuna valutazione finora

- Method Statement For The, Gulf Eagle Project: Installation, Commissioning & Load Testing of CraneDocumento14 pagineMethod Statement For The, Gulf Eagle Project: Installation, Commissioning & Load Testing of CraneFAYIZNessuna valutazione finora

- Hansson - Servin - Semi-Autonomous Shared Control For Redundant Forwarder CranesDocumento107 pagineHansson - Servin - Semi-Autonomous Shared Control For Redundant Forwarder CranesHugo SilvaNessuna valutazione finora

- Crosby Mckissick Sheaves CatalogDocumento29 pagineCrosby Mckissick Sheaves Catalogaiyubi2Nessuna valutazione finora

- 1125-003-07Y Cap 7 Mantenimiento Grua QY70V 532Documento25 pagine1125-003-07Y Cap 7 Mantenimiento Grua QY70V 532IAN GRUPNessuna valutazione finora

- View 55-Ton Mobile Crane Specs and Features on FreeCraneSpecs.comDocumento8 pagineView 55-Ton Mobile Crane Specs and Features on FreeCraneSpecs.comPodnosniki dźwigi KielceNessuna valutazione finora

- Industrial Visit Jadhav GearsDocumento11 pagineIndustrial Visit Jadhav GearsDIPAK VINAYAK SHIRBHATE75% (4)

- T05 - Palfinger ATaşman KataloğuDocumento24 pagineT05 - Palfinger ATaşman KataloğusmylmrNessuna valutazione finora