Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Watergel or Emulsions Which Is The Better Bulk Explosive?

Caricato da

Brent BuffhamTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Watergel or Emulsions Which Is The Better Bulk Explosive?

Caricato da

Brent BuffhamCopyright:

Formati disponibili

20 Quarry August 2012

T

he history of commercial explosives

is relatively short. Only 140 years

ago, the world was restricted to black

powder and nitro-glycerine based explosives.

In todays world of resource extraction, there

is an explosive for the majority of situations

and applications. However, what does this

mean for the user? It means choice, and

with choice comes compromise - between

explosive performance and cost. Is there a

perfect explosive for your needs?

The explosive supply and manufacturing

industry is the same as any other commercial

entity that provides something for sale. The

saleability of a product is based on the raw

materials cost, its availability, the technology

available, manufacturing costs as well as

transport versus the possible returns from the

sale of the product. Consider if the price of

corn was raised to the same value as that of

gold; we as consumers would see corn flakes

disappear from our supermarket shelves

overnight. The cost of manufacturing corn

flakes would negate the returns achievable.

The same is true for explosives, as is the adage

of getting what you pay for. We all want a

bargain but at what cost? With explosives, that

cost is available useable energy!

Many companies in the explosive industry

tailor their products to suit their resources and

their market. Traditionally Maxam supplies to

the quarry and smaller mines in Australia and

Rioflex produces exceptional results for these

consumers. This robust and reliable product

has seen Maxams quarry market share grow.

Rioflex, Maxams bulk variable density

product, is placed in the category of an

ammonium nitrate suspension gel. This

essentially means that Rioflex is a watergel in

the traditional sense. However, the watergels

of yesteryear are not the same as the Rioflex

matrixes of today. Emulsions, when they

first arrived on the market were hailed as

the future of explosives, and statements

and papers were produced to support the

technology change. The use of electron

microscopes to show the intimacy between

oxidiser and fuel produced undeniably great

imagery. The measurements of oxidisers in a

100 per cent emulsion phase were compared

to the size of oxidisers in slurries (watergels)

from the 1990s. Various companies used this

as evidence that the product would have a

higher velocity of detonation and therefore be

a better and more advanced technology.

However, the situation in the early days

of emulsion development is likely not to be

as relevant to how emulsions are made in

todays market. Cost, as mentioned before,

is the driving force in how products are made

and marketed. Emulsions are traditionally

aimed at large diameter blast hole markets

in large scale mines where single blasts can

consume 500 plus tonnes of bulk explosives.

Although clientele now want the best deal,

they remain oblivious to the rising cost of

production and development of blasting

products. Thus, the key for an emulsion

supplier is to make the emulsion based

explosive cheaper, which is likely the reverse

of the reason for their development in the

first place. To do this water may be added,

resulting in less energy.

Slurries or watergels get their name from

being partially composed of water and

containing long carbon chain molecules that

are cross-linked to a gelled, semi-solid state.

Thus the name watergel. Emulsions were

derived to take the energy thief water out

of the gel. With the expanding oil market,

copious oil derivatives were produced and

emulsions became cheaper to manufacture.

Then the emulsion phase needed the addition

of explosive grade ammonium nitrate prill

(PPAN), this process is called doping. The

most common and cheapest water resistant

bulk explosive is a 70 per cent emulsion

with a 30 per cent ammonium nitrate dope.

What the explosive suppliers realised is that

emulsions needed to be made with water

as well to make them more cost-effective,

as water is a low cost additive. The gain

of liquidising the oxidisers for intimacy is

soon reduced by the addition of ammonium

nitrate prill and the introduction of water to

the emulsion phase. The ultimate energy thief

for an explosive is water! Therefore, to make

high energy explosives, water content must

be reduced. Water provides no energy to

In the battle between water gels and emulsions for the perfect bulk explosive, Brent Buffham

explains that Maxams Rioex variable density product is the best compromise.

WATERGEL OR EMULSION:

WHICH IS THE BETTER BULK EXPLOSIVE?

SPECIAL REPORT - DRILL & BLAST

Figure 1. Sensitised Rioex. Figure 2. Unsensitised Rioex.

08 Q AUG 12_revised pgs.indd 20 16/07/12 9:52 AM

Our rental eet includes the latest equipment

from the worlds leading manufacturers.

The Right gear in the Right

place at the Right time

Delta Rent Pty. Ltd.

577 Plummer Street Port Melbourne Victoria 3207

Ofce: 1300 793 071

Warren Colbert, General Manager Mobile: 0413 201 448

David Hoyle, Territory Manager East Coast - Mobile: 0423 571 081

Wayne Stone, Southern Region Territory Manager - Mobile: 0412 651 227

www.deltagroup.com.au

Hydraulic Excavators

Hitachi and Komatsu

30 to 90 tonnes

Articulated

Dump Trucks

Figure 3. HDAN at 20x magnication.

Figure 4. HDAN at 360x magnication, showing smooth edge of the prill.

Figure 6. PPAN at 360x magnication, showing the rough edge of the prill.

Figure 5. PPAN at 19x magnication.

08 Q AUG 12_revised pgs.indd 21 16/07/12 9:52 AM

WARRANTY

The main focus for Hycons new

Sydney location will be the

replacement supply and service of

Kawasaki Pumps and motors to the

construction equipment market.

Hycon have an exhaustive testing facility. This facility is managed in accordance

withtheir Q.A. accreditationinorder toensurebothontime andreliableservice.

1300 142 236

sales@hyconhydraulic.com.au

www.hyconhydraulic.com.au

C

M

Y

CM

MY

CY

CMY

K

n

Manganese & alloy steel wear parts

n

Bowl, mantle and jaw liners

n

Concave segments

n

Blow bars & hammers

n

Auxiliary wear parts

n

Mining & Quarrying spares

n

Mill liners

n

AUD$5 million manganese in stock

www.crushingequip.com.au

Quality Assurance Standard AS/NZS ISO 9001:2008 covered wear parts for all popular crushers in stock.

Assuring you of our careful attention at all times

n

Premium grade 12 14 % manganese

n

Mn18% HC manganese

n

23% XAlloy manganese

n

Alloy steels

MELBOURNE

7 Beverage Drive

Tullamarine VIC 3043

F 03 9338 0680

P 03 9338 0200

PERTH

88 Barberry Way

Bibra Lake WA 6163

F 08 9434 5515

P 08 9434 5552

BRISBANE

Unit 1/38 Computer Road

Yatala Qld 4207

F 07 3382 0098

P 07 3801 8153

Quality assured alternative wear

parts for all crushing equipment

lift jaw

& cone

liners with

SPECIAL REPORT - DRILL & BLAST

the bulk explosive when detonated. Waters

vaporisation essentially steals energy. In order

to heat one kilogram of water to vaporisation,

a whopping 2256 kilojoules per kilogram

of energy is required. Well, now we are

completely confused! Watergels have water

and emulsions have water, so how is one

better than the other?

Rioflex is not your usual watergel. It is

made with high grade and refined short

carbon chain fuels. This fuel is nitrated and

normalised and along with this, ammonium

nitrate is dissolved into the solution making

the base suspension media of the matrix.

Contrary to popular articles on watergels,

water content amounts to less than 13 per

cent of the final mix. The suspension media

has more ammonium nitrate prill, either

high density prill or porous explosive grade,

added. However, not before it is crushed

and made angular. This crushing process

takes the previously round ammonium nitrate

and increases the surface to mass ratio and

therefore drastically increases the reaction

speed and in turn the velocity of detonation

of the bulk product. At this point, a very

small percentage of water has been added,

so where does this watergel get its name?

Maybe its the same as when horses used to

roam the streets? They werent called streets,

they were called carriageways. Now we

have dual carriageways but no horses and

carts! We have watergels with less water

than emulsions.

This is where the water plays its part in

protecting and stabilising the product. The

carbon chains used in gelling are long and

they are all ravelled up into a little ball. They

require a medium to be suspended in so that

they can unravel, this is through hydration.

In order to do this Maxam uses a small

amount of water to suspend the fuel and

oxidiser, and that is it. Of all the explosive

phases or matrixes on the Australian

explosive market, Rioflex has the least water

content. Other manufacturers in the Australian

market may add up to 23 per cent water to

the emulsion phases of their bulk products.

It is important to understand that emulsions

Figure 7. HDAN post crushing at 21x magnication. Figure 8. HDAN at 360x magnication post-crushing.

08 Q AUG 12_revised pgs.indd 22 16/07/12 9:52 AM

Our crushing plant consists of a full range

of primary, secondary and tertiary mobile

crushing & screening equipment.

The Right gear in the Right

place at the Right time

Delta Group

Contract Crushing and Concrete Recycling

577 Plummer Street Port Melbourne Victoria 3207

Contact Paul Matson

Mob: 0413 388 426 E-mail: paulm@deltagroup.com.au

www.deltagroup.com.au

Production capabilities for full product range:

Asphalt & concrete aggregates

High specifcation roadbase

Ballast, drainage medium

Lower sub base products

Concrete recycling

Pegson 1300 Maxicones

Kawasaki Cones

Track Mounted

Jaw Crushers with

capacity up to 500TPH

Kawasaki 1885

Cone Crusher

Mobile Jaw Crushers

Aggregate capability

AW110817.indd 1 29/08/11 2:42 PM

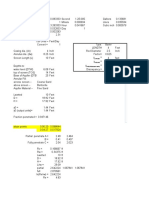

RIOFLEX MATRIX EMULSION PHASES

Highly angular and suspended

oxidisers. Increases the reaction speed.

Liquid oxidisers in a solution of

water. Requires doping which

reduces reaction speed.

Perfectly fuelled. Over fuelled.

Excellent velocity of detonation.

4600m/s to 6000m/s. *

Very good velocity of detonation.

3800m/s to 5600m/s. *

Viscosity in excess of 35,000

centipoise. Reduced product migration.

Lower viscosity.

Migration possible.

Less than 14% water content.

Less energy thieves.

Less than 23% water content.

More explosive energy thieves.

Can be doped if required with either

PPAN or HDAN.

Can only be doped

with PPAN.

Has naturally inhibited qualities

for use in reactive ground.

Only suitable in reactive ground

when additional urea is added and

the cost on-charged.

Mechanically or chemically sensitised. Must be chemically sensitised.

Gelled Rioex resists migration in the

blast-hole and foreign water ingression.

Gassed Emulsion has no links between

suspended particles allowing for migration.

Optimal product for reduced loss

of precious minerals, such as gold.

No long hydrocarbon fuels,

Rioex spills dont consume

extractive chemicals.

Composed of waxes and oils.

Spills may consume precious metal

extractive chemicals, such as those in

a gold otation tank.

Maximum density 1.53g/cc Maximum density 1.35g/cc

Excellent pattern expansion

capabilities when working with

optimised emulsion patterns.

Reduced expansion possibilities in

comparison to Rioex.

=| AESIG HOT AND REACTIVE GROUND CODE OF PRACTICE must be

followed prior to implementing in reactive or hot ground.

* Ideal Theoretical VODs that are effected by geological conditions, water,

hole diameter and others.

The above densities are not inhole critical densities, above values

equate to the limiting density of the base matrix/emulsion formulations.

of any type, explosives or not, use a chemical (emulsifier) to

blend two or more immiscible (non-blendable) liquids together.

As emulsions in terms of explosives are waxes, oils and oxidisers

in water, they have to be over-fuelled in general terms to reduce

noxious fumes of nitrous oxide when doped with ammonium nitrate.

Rioflex is perfectly formulated to ensure a near neutral oxygen-fuel

balance that, along with the intimate encapsulation of highly angular

ammonium nitrate, produces the optimal base matrix.

The gain that the industry achieves with emulsion phase

explosives creates a false economy, robbing Peter (energy) to pay

Paul (procurement). What many explosive users understand is what

you spend on drill and blast results in improved production in the

pit as well as through the crusher or mill in orders of magnitudes.

So to answer a question that was posed earlier: Is there a perfect

explosive for your needs? The answer is yes!

Brent Buffham is the technical manager for Maxam.

08 Q AUG 12_revised pgs.indd 23 16/07/12 9:52 AM

Potrebbero piacerti anche

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesDa EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNessuna valutazione finora

- Non Explosive Rock Breaking TechniquesDocumento7 pagineNon Explosive Rock Breaking Techniquescontenido100% (2)

- Development of Natm: Principles of Observational MethodDocumento14 pagineDevelopment of Natm: Principles of Observational MethodChin Thau WuiNessuna valutazione finora

- Three-Dimensional Face Stability Analysis of Pressurized Tunnels Driven in A Multilayered Purely Frictional MediumDocumento17 pagineThree-Dimensional Face Stability Analysis of Pressurized Tunnels Driven in A Multilayered Purely Frictional MediumChin Thau WuiNessuna valutazione finora

- 9 TBM Boreability I Hard BergmasseDocumento43 pagine9 TBM Boreability I Hard BergmassepabulumzengNessuna valutazione finora

- Magnum Anchoring CatalogDocumento177 pagineMagnum Anchoring CatalogTom HortonNessuna valutazione finora

- 02 Slurry Kovari Addition enDocumento8 pagine02 Slurry Kovari Addition enJinChongNessuna valutazione finora

- 107 818-PropDocumento17 pagine107 818-Propp_ignatiusNessuna valutazione finora

- Production Estimating Techniques For Underground Mining Using RoadheadersDocumento11 pagineProduction Estimating Techniques For Underground Mining Using RoadheadersAmbarr SutantiNessuna valutazione finora

- Supporting Action of Anchors BoltsDocumento8 pagineSupporting Action of Anchors BoltsMohamed MostafaNessuna valutazione finora

- Kellaway Taylor Keyter Ingula Power CavernsDocumento23 pagineKellaway Taylor Keyter Ingula Power Cavernstiyok10Nessuna valutazione finora

- R C Q B S E F P R: Mohd For Mohd Amin, Chan Sook Huei, Abdul Ghani MD RafikDocumento13 pagineR C Q B S E F P R: Mohd For Mohd Amin, Chan Sook Huei, Abdul Ghani MD RafikjimmyNessuna valutazione finora

- Face Stability Design and Face CounterpressureDocumento6 pagineFace Stability Design and Face CounterpressurenumspyNessuna valutazione finora

- Raisebore Brochure 2014 PDFDocumento19 pagineRaisebore Brochure 2014 PDFIng del PeleNessuna valutazione finora

- B.4a Surface Mining MethodsDocumento29 pagineB.4a Surface Mining MethodsYocky Fidra100% (1)

- Crenshaw/LAX Line Contract ReportDocumento28 pagineCrenshaw/LAX Line Contract ReportMetro Los AngelesNessuna valutazione finora

- Fly Rock Range 1979Documento97 pagineFly Rock Range 1979Roman DamanikNessuna valutazione finora

- Barton-High Pressure Pre-Grouting. TTI Sept 2004 p28-30 PART IDocumento3 pagineBarton-High Pressure Pre-Grouting. TTI Sept 2004 p28-30 PART Icastille1956Nessuna valutazione finora

- Especific EnergyDocumento13 pagineEspecific Energyvictorba3Nessuna valutazione finora

- TheStability of A Laminated Voussoir Beam PDFDocumento17 pagineTheStability of A Laminated Voussoir Beam PDFDaniel SantanaNessuna valutazione finora

- Bheri Babai RFPDocumento107 pagineBheri Babai RFPDEBASIS BARMANNessuna valutazione finora

- Pr9788 - Specification For Horizontal Directional DrillingDocumento38 paginePr9788 - Specification For Horizontal Directional Drilling仲达Nessuna valutazione finora

- Pre-Excavation Grouting in Hard Rock Tunnelling PDFDocumento58 paginePre-Excavation Grouting in Hard Rock Tunnelling PDFTony ChanNessuna valutazione finora

- Plan de Voladuras: General InformationDocumento4 paginePlan de Voladuras: General InformationCarlos Andrés Santacruz SantacruzNessuna valutazione finora

- Grouting Article Tti Oct 2004 P33-35part II 2Documento3 pagineGrouting Article Tti Oct 2004 P33-35part II 2Rajnish Bahuguna0% (1)

- Regional Connector Design Build Contract RecommendationDocumento21 pagineRegional Connector Design Build Contract RecommendationMetro Los AngelesNessuna valutazione finora

- AZDOT EXAMPLE SUBSTRUCTURE Appendix - A - Example - 2 - 2 PDFDocumento76 pagineAZDOT EXAMPLE SUBSTRUCTURE Appendix - A - Example - 2 - 2 PDFMike2322Nessuna valutazione finora

- EASY PIPE - A New Technology For Trenchless Installation of Large Diameter Steel PipelinesDocumento13 pagineEASY PIPE - A New Technology For Trenchless Installation of Large Diameter Steel PipelinesrameshkaaNessuna valutazione finora

- Herrenknecht Gripper Illustration enDocumento1 paginaHerrenknecht Gripper Illustration enantoniusnoroNessuna valutazione finora

- Isee Performance Specifications For Blasting Seismographs 2017Documento16 pagineIsee Performance Specifications For Blasting Seismographs 2017Kiim Yiiom DeeNessuna valutazione finora

- Pile Top Drill Rigs - en 1Documento16 paginePile Top Drill Rigs - en 1aminoNessuna valutazione finora

- Roadheader6 PDFDocumento6 pagineRoadheader6 PDFMika PrameswariNessuna valutazione finora

- Dosco Introduction - Civils (NDCO)Documento60 pagineDosco Introduction - Civils (NDCO)beekay01Nessuna valutazione finora

- 11analysis of Shield TunnelDocumento35 pagine11analysis of Shield Tunnelnguyen tuanNessuna valutazione finora

- Hktunnel CatDocumento58 pagineHktunnel CatThaungMyintNessuna valutazione finora

- Limitations of Rock Mass Classification SystemsDocumento11 pagineLimitations of Rock Mass Classification SystemsScott DownsNessuna valutazione finora

- Surface Mining Products Services and Reference Guide 2016Documento56 pagineSurface Mining Products Services and Reference Guide 2016serge.pungweNessuna valutazione finora

- Shotcrete For Rock Support ITA-AITES Part A PDFDocumento8 pagineShotcrete For Rock Support ITA-AITES Part A PDFwjzabalaNessuna valutazione finora

- Drill and Blast Manuals EkatiDocumento49 pagineDrill and Blast Manuals EkatiElías Bravo CortésNessuna valutazione finora

- B.3 Blast Layouts Initiation and Timing of BlastsDocumento37 pagineB.3 Blast Layouts Initiation and Timing of BlastsYocky Fidra100% (2)

- Boyce Shaft and Portal DesignDocumento120 pagineBoyce Shaft and Portal DesignSérgio BernardesNessuna valutazione finora

- Hollmann2013 PDFDocumento11 pagineHollmann2013 PDFSérgio BernardesNessuna valutazione finora

- Bored Cast in PlaceDocumento12 pagineBored Cast in PlaceJJNessuna valutazione finora

- 9406 G WorkmanDocumento15 pagine9406 G WorkmanJose RojasNessuna valutazione finora

- Explosives Manufacturing and Processing Guideline To Safety TrainingDocumento16 pagineExplosives Manufacturing and Processing Guideline To Safety TrainingCuesta AndresNessuna valutazione finora

- Raiseboring RSADocumento26 pagineRaiseboring RSAsijuaNessuna valutazione finora

- Ischebeck - Lizzi Lecture - Design of Direct Drilled and Continuous Flush Grouted Micropiles TITANDocumento40 pagineIschebeck - Lizzi Lecture - Design of Direct Drilled and Continuous Flush Grouted Micropiles TITANDaniel Rioja GarciaNessuna valutazione finora

- Rock Burst Mechanisms: BY: Saqib Ahmad Saki Eg Grad Colloquium Ms - Cv/EsDocumento21 pagineRock Burst Mechanisms: BY: Saqib Ahmad Saki Eg Grad Colloquium Ms - Cv/EsDinesh KumarNessuna valutazione finora

- Dyno Nobel 2010Documento32 pagineDyno Nobel 2010Zaka EmadNessuna valutazione finora

- Brochure - Ground Freezing, MoretrenchDocumento8 pagineBrochure - Ground Freezing, Moretrenchedward the iiiNessuna valutazione finora

- 2013 Rock Excavatability in LimestoneDocumento13 pagine2013 Rock Excavatability in Limestoneofelix505Nessuna valutazione finora

- 3-Room and PillarDocumento67 pagine3-Room and Pillardenis mejiaNessuna valutazione finora

- Cardox CivilsDocumento9 pagineCardox CivilsaaspathisNessuna valutazione finora

- 01 - Anagnostou Torino 2008Documento50 pagine01 - Anagnostou Torino 2008JinChongNessuna valutazione finora

- Slug Bouwer-RiceDocumento67 pagineSlug Bouwer-RiceAnonymous PdzpkUNessuna valutazione finora

- Ground Freezing123Documento28 pagineGround Freezing123Dangol RupeshNessuna valutazione finora

- Soil MixingDocumento7 pagineSoil MixingLuchiian CezarNessuna valutazione finora

- Rock Excavation Tests For Drill-Blast & TBM Tunnels-Predicting Cutter WearDocumento41 pagineRock Excavation Tests For Drill-Blast & TBM Tunnels-Predicting Cutter WearLipsa MahapatraNessuna valutazione finora

- EZ Det Delay Patterns: Construction BlastingDocumento10 pagineEZ Det Delay Patterns: Construction BlastingDinoYancachajllaNessuna valutazione finora

- Watergel or EmulsionDocumento2 pagineWatergel or EmulsionPoorna KumarageNessuna valutazione finora

- Atomic St. Package PDFDocumento28 pagineAtomic St. Package PDFSatvik RaoNessuna valutazione finora

- Tips For A Healthy PregnancyDocumento2 pagineTips For A Healthy PregnancyLizaNessuna valutazione finora

- Automatic Train OperationDocumento6 pagineAutomatic Train OperationAnupam KhandelwalNessuna valutazione finora

- Precision CatalogDocumento256 paginePrecision CatalogImad AghilaNessuna valutazione finora

- BITS Pilani: Determination of Extreme Pressure, Wear Preventive Characteristics of Lubricants Using Four Ball TesterDocumento10 pagineBITS Pilani: Determination of Extreme Pressure, Wear Preventive Characteristics of Lubricants Using Four Ball Testerakash chNessuna valutazione finora

- SR No Service CodeDocumento30 pagineSR No Service CodeShiva KrishnaNessuna valutazione finora

- Liftchain (LC2A) Catalog AirHoistDocumento10 pagineLiftchain (LC2A) Catalog AirHoisteduardshark100% (1)

- Kimi No Na Wa LibropdfDocumento150 pagineKimi No Na Wa LibropdfSarangapani BorahNessuna valutazione finora

- Yoga SadhguruDocumento6 pagineYoga Sadhgurucosti.sorescuNessuna valutazione finora

- V. Jovicic and M. R. Coop1997 - Stiffness, Coarse Grained Soils, Small StrainsDocumento17 pagineV. Jovicic and M. R. Coop1997 - Stiffness, Coarse Grained Soils, Small StrainsxiangyugeotechNessuna valutazione finora

- Ecall Vs NG EcallDocumento6 pagineEcall Vs NG EcallTrần Văn DũngNessuna valutazione finora

- Model Detailed Project Report: Animal Feed Making UnitDocumento19 pagineModel Detailed Project Report: Animal Feed Making UnitShashi ShekharNessuna valutazione finora

- Prevailing Torque Locknut Technical SpecificationsDocumento3 paginePrevailing Torque Locknut Technical SpecificationsLiu YangtzeNessuna valutazione finora

- Chillers VoltasDocumento4 pagineChillers Voltasanil shuklaNessuna valutazione finora

- Frye LGD As A Function of The Default Rate 091013 PDFDocumento13 pagineFrye LGD As A Function of The Default Rate 091013 PDFSushant SinghNessuna valutazione finora

- ELS 06 Maret 223Documento16 pagineELS 06 Maret 223Tri WinarsoNessuna valutazione finora

- Kinder DLL Week 8Documento15 pagineKinder DLL Week 8Jainab Pula SaiyadiNessuna valutazione finora

- TM 10-3930-669-34 Forklift Truck 6K Drexel MDL R60SL-DC Part 1Documento294 pagineTM 10-3930-669-34 Forklift Truck 6K Drexel MDL R60SL-DC Part 1AdvocateNessuna valutazione finora

- Iso 8033 2016Documento9 pagineIso 8033 2016Eric ChuNessuna valutazione finora

- Compiled LecsDocumento24 pagineCompiled LecsNur SetsuNessuna valutazione finora

- Rectifier 5G High Density Embedded Power (3U Power Rack, Three Phase Four Wire) E...Documento4 pagineRectifier 5G High Density Embedded Power (3U Power Rack, Three Phase Four Wire) E...Lintas LtiNessuna valutazione finora

- Critical Analysis of W.H Auden Poems The PDFDocumento8 pagineCritical Analysis of W.H Auden Poems The PDFMöĤämmĔd äĹ-ŚäÁdï100% (1)

- 01-20 Optical Multiplexer and Demultiplexer BoardDocumento57 pagine01-20 Optical Multiplexer and Demultiplexer BoardDaler ShorahmonovNessuna valutazione finora

- Welcome To Our 2Nd Topic: History of VolleyballDocumento6 pagineWelcome To Our 2Nd Topic: History of VolleyballDharyn KhaiNessuna valutazione finora

- Data SiEMEx School SafetyPreparedness 25 26 NOVDocumento81 pagineData SiEMEx School SafetyPreparedness 25 26 NOVSuraj RajuNessuna valutazione finora

- Homeo Treatment of Eye Diseases and AllergiesDocumento17 pagineHomeo Treatment of Eye Diseases and AllergiesZia AbbasiNessuna valutazione finora

- Manual GA 55 VSD Atlas CompresorDocumento114 pagineManual GA 55 VSD Atlas Compresormondaxa_mme50% (4)

- Concrete Super Structure ReportDocumento43 pagineConcrete Super Structure ReportLivian TeddyNessuna valutazione finora

- ContempoDocumento4 pagineContempoPrincess Jonette YumulNessuna valutazione finora

- Veronte Autopilot Kit DatasheetDocumento2 pagineVeronte Autopilot Kit DatasheetEkmedzicNessuna valutazione finora

- Arizona, Utah & New Mexico: A Guide to the State & National ParksDa EverandArizona, Utah & New Mexico: A Guide to the State & National ParksValutazione: 4 su 5 stelle4/5 (1)

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptDa EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptValutazione: 5 su 5 stelle5/5 (1)

- The Bahamas a Taste of the Islands ExcerptDa EverandThe Bahamas a Taste of the Islands ExcerptValutazione: 4 su 5 stelle4/5 (1)

- New York & New Jersey: A Guide to the State & National ParksDa EverandNew York & New Jersey: A Guide to the State & National ParksNessuna valutazione finora

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensDa EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNessuna valutazione finora

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoDa EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoValutazione: 5 su 5 stelle5/5 (1)