Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

D I Il I: Ma4Hine D6Flfrn

Caricato da

MostafaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

D I Il I: Ma4Hine D6Flfrn

Caricato da

MostafaCopyright:

Formati disponibili

) \

?-

,\ t r

/-)

<.__

__)

l-

.

<-<'*2J

)

t:-

( . - . J

Third Year Mechaniaal Produclion $cclion MAr.tllNO D6$l&N

AIN SHAMS UNI\Tf,RSITY

F'ACULTY OF ENGINEERING

PNre f,

'':.i.ij

..r.2!lt!4'

-.Y/:l-iLlrl.ri.

-rtlt!/.i1,-ti41iy'i..

t_{-ii*i#i.4ii*j#1,

to f,uno 200J

DEiIGN A PYDDULTION 6NGIN66F{NG Dg?AFTMENT

Thi rd Year Mechani cal . Producti on Secti on

Semester,2006-2007 10 June 2OOT Ti me: 4.00 Hrs

MA4HINE D6flfrN

The Exam Consists of Three Questions in Three Pages.

Ll 3

il

t

t

I

I

H

I

d

I

il

I

il

t

t

I

I

E

T

3

ts

A*A n',"LssLwg data vuay be re,asowabLg assv+rn'ted

(1 MPa: 10 kg/sq cm

,

1 kg/sq.mm: 10 MPa)

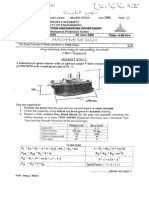

QJ^E.STION 1-

A company for designing safety slip clutches claims (.r.9 that it produces clutches under the

following conditions:

The clutch can safely transmit 898 If (670 KW) at 42 RPM under the uniform wear distribution

case at a

"pv"

value of 11.5

*

104 kg/ms (1 1.5

*

105 N/ms), where

"p" is the pressurd between the friction surfaces and

"v" is the

penpheral speed at the mean diameter of the friction surfaces.

Friction surf'ace oronerties

Outer diameter 1850 mm

Inner diameter 1500 mm

Coefilcient of friction o.32

You are requi red to

Spring properties

Coil diameter

T 34 mm

Spri ng i ndex

3

Number of springs t 2

Number of coils 9

The springs are located at a PCD of 1700 mm

Material: Cr Mo Ni steel 0.8%C t al l : 600I t { Pa

G: 0. 8

*

l os MPa

I Check whether the claim of the company is True or Fulse and find the deviation of

their claim in HP, if any.

2 Estimate the necessary spring deJlection required for transmitting the 898 HP (670

Kw).

J Calculate the actual tvorking torsional shear stress induced in the spring wire when

transmittins the 898 HP

4 Estimate the vorking bending stresses acting on the spur gear teeth when

transmitting the 898 IIP, if the PCD of the gear teeth

:1920

mm. Consider "b*m"

=

5000 mm2 and Kv

*

Kvl Ks

: 0. 16

I;or use.fitl data, please see end of exam.

?rof. iaml T. 6beid

third Ycar Mezhanical ?rodualion $culion MP4ilINO D6flAN

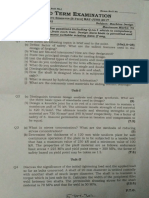

Q,IE.STION 2

A handling belt conveyor in a factory runs at a speed of

1.02 m/s (conveyor pulley speed

:

24 RPM and is located

on tlre right of the bevel gear in the given sketch). The

conveyor is operated through a system that consists of

four main elements:

1. Electric motor.

3. Coupl i ng.

to duoo?-001 ?MO 2-t7

2. Worm gear unit.

4. Open bevel drive.

:

I

F

F

l

E

II

i

F

I

:

r

I

t

I

I

I

I

I

I

I

I

Y i redto

OPEN PINION-GEAR BEVEL DRIVE

Speed ratro 3: 1

Number of pinion teeth l 8

Diameter of pinion 144 mm

Pinion material

St60 oall

:200

MPa

b*m 450 mm"

WORM GEAR UNIT

Number of starts 2

Number of eear teeth 40

Normal pressure angle 20"

Normal module of sear teeth 65 mm

Gear teeth width 50 mm

Worm helix ansle 17.50

Coeffrcient of friction between teeth

i

0.0s

Effi ci ency of dri ve 8/-20

Gear rim material

1 Phosphour bronze oall

:100

N{Pa

ou ar e u

1 Estimate

'the

maximum pmeer that can be transmitted by the system based upon the

power tlrat can be carried by the gear drives when the working stresses on the gear

teeth are the allowable bending stresses of their materials (consider Static Strength

condifions onlv).

2 Estimate the expecte d temperature rke of the wonn gear drive.

J Present a complete

free-hand

sketch

for

the worm gear unit and the bevel drive

only On your drawing show the details of the shafts, gears, rolling bearings and

casing. At least TWO views should be used.

Prof. taml J. 6beid

9kaut*et/ea.aa3. . ..-

-

il

I

r

r

I

il

I

fl

I

I

I

I

3

I

il

I

m

t

r

Third Year Mechanical Produclion Scclion

State whether the followi

MMHINE P65l&N to Tuns 2J0J

Useful Data

Bevel Gears

Worm-Gear Dri ve

Kv*Ky/ Ks

| 0. 3

Pt g* Ks= O* b* m* Kv* Ky

n: t any/ t an( y+p' )

p: pt

*

cos ct n

pt

:

tan po

632( l - n) * HP: 330* A* AT

Spri ng Equat i ons

d

: 8F, *6pt / do) "

[ N/ G) ,

r

=4. 03 *

Fs* ( D/ d3)

Q_r^ESt-toN 3

statements are True or False.

PPGc. VK

V-belts are

over flat ones for short centre-distance drives

9 The frictional

torque equation .rsed foi

lindrical clutches but for 0:90 d

lhe rnarn dttlerence between single and double thrust ball bearings lies in the direction of

rotation (T

or F).

Modified form factor 0.486

-

(3.852/z\

KuKt

0.9

Wear and Lubrication Factor 135

Pt

* Kr * Kl :

O* b* m[ 1

- b/ L] *

Kv* Ky

Por spur gecrs: K1

:

I and b/ L: 0

The equation T=rpFur* is the su-

distribution or uniform wear distribution (T or F).

The bending stresses rn flat belts are t

The force of attraction generated

bV un

trrcf,

$g"ld

"l*ayt

b" p..p".@lar

to the shaft axis (T or F)

The permissible

error in the design

(T

or F).

The "speed

na

unit (T or F).

In estimating ti@i,

helical

ear and not that of the pi ni on (T or F)

The creep factqr in belt dnves is usually

"ipr"ffi

?rof. $am.1 J. Ebeid

EA* ,*d fi r^t

""i^/r"b.

Potrebbero piacerti anche

- Machine Design Elements and AssembliesDa EverandMachine Design Elements and AssembliesValutazione: 3.5 su 5 stelle3.5/5 (2)

- 1472636232Documento48 pagine1472636232Mushini Nagabhushan33% (3)

- Thermodynamics - Fundamentals and Its Application in ScienceDocumento554 pagineThermodynamics - Fundamentals and Its Application in ScienceSchreiber_Dieses50% (2)

- F,') Er R: Maor+Lne DestqnDocumento3 pagineF,') Er R: Maor+Lne DestqnMostafaNessuna valutazione finora

- Wee1964 N001Documento9 pagineWee1964 N001Oliver RubioNessuna valutazione finora

- Question L: Machine DesigiDocumento3 pagineQuestion L: Machine DesigiMostafaNessuna valutazione finora

- Design of Machine Elements - IIDocumento8 pagineDesign of Machine Elements - IIprasaad26Nessuna valutazione finora

- Rotal No. of Questions-121 (Rotal No. of ' (?D J"JDocumento7 pagineRotal No. of Questions-121 (Rotal No. of ' (?D J"JAshenafi Gebremeskel MezgeboNessuna valutazione finora

- BARC Recruitment Exam: Previous Year PaperDocumento11 pagineBARC Recruitment Exam: Previous Year PaperRajat RajNessuna valutazione finora

- Is, S. Exam-Pa: HA", .201 FSI-P-MCHEDocumento9 pagineIs, S. Exam-Pa: HA", .201 FSI-P-MCHESachin KumarNessuna valutazione finora

- DMM Ii (2015)Documento35 pagineDMM Ii (2015)gorijalaNessuna valutazione finora

- Design of Machine Elements 2 Jan 2014Documento2 pagineDesign of Machine Elements 2 Jan 2014Prasad C M100% (1)

- ' "" 'I F 5:t"il) I:"h'xt'ilffi' : Pappr ID: (. (08191Documento2 pagine' "" 'I F 5:t"il) I:"h'xt'ilffi' : Pappr ID: (. (08191RaJan GargNessuna valutazione finora

- Torque Production in Permanent-MagnetDocumento6 pagineTorque Production in Permanent-MagnetTien Dung TranNessuna valutazione finora

- 4363 111 Machine Design IDocumento6 pagine4363 111 Machine Design Iyogesh_b_k100% (2)

- Is 4931 1995Documento17 pagineIs 4931 1995ak0% (1)

- Assignment 2Documento3 pagineAssignment 2sonawanepmsNessuna valutazione finora

- TE 2008 Mechanical Qp2013Documento56 pagineTE 2008 Mechanical Qp2013avinash119870% (1)

- T.E MechanicalDocumento62 pagineT.E MechanicalhaptooorNessuna valutazione finora

- 07a6ec05 Designofmachinemembers IIDocumento11 pagine07a6ec05 Designofmachinemembers IIzahid_polyNessuna valutazione finora

- Sem 6 Papers 1 PDFDocumento11 pagineSem 6 Papers 1 PDFBhupesh GuptaNessuna valutazione finora

- Machines-1 FinalDocumento8 pagineMachines-1 FinalAlwin lantinNessuna valutazione finora

- 8th Sem - Assignment - MD II (2962108)Documento5 pagine8th Sem - Assignment - MD II (2962108)rishabhk28995Nessuna valutazione finora

- BARC Exam: Mechanical Engineering Paper IDocumento10 pagineBARC Exam: Mechanical Engineering Paper IDurga PrasadNessuna valutazione finora

- 6ME04 (1) Machine DrwaingDocumento4 pagine6ME04 (1) Machine DrwaingPrashant OjhaNessuna valutazione finora

- Mechanics Ii Time Allowed: 2 HoursDocumento8 pagineMechanics Ii Time Allowed: 2 HourssubipuruNessuna valutazione finora

- Sathyabama University: Register NumberDocumento3 pagineSathyabama University: Register NumberSecret SecretNessuna valutazione finora

- Design of Multi-Axis Welding Positioner WithDocumento7 pagineDesign of Multi-Axis Welding Positioner Withsuraj dhulannavarNessuna valutazione finora

- Iso 6336 Hohn PDFDocumento6 pagineIso 6336 Hohn PDFmgualdiNessuna valutazione finora

- Questton T.: Pinion 32 30 83 80 Wear Stress Factor, Ko/So, MM 0 - 1 S 6 1.20 24 3 3 3 3 - 1 3 - 1Documento2 pagineQuestton T.: Pinion 32 30 83 80 Wear Stress Factor, Ko/So, MM 0 - 1 S 6 1.20 24 3 3 3 3 - 1 3 - 1MostafaNessuna valutazione finora

- Fif FFT - FT Fi) : Aott L Rotat Of: of HM LrithDocumento2 pagineFif FFT - FT Fi) : Aott L Rotat Of: of HM LrithmybestfriendgrewalNessuna valutazione finora

- Machine Design - LDocumento2 pagineMachine Design - LNilesh Mistry (Nilesh Sharma)Nessuna valutazione finora

- EMD June 2012Documento2 pagineEMD June 2012kmnath1965Nessuna valutazione finora

- Design For Static Load: Design of Machine Elements Module-IDocumento13 pagineDesign For Static Load: Design of Machine Elements Module-InikhilasoknNessuna valutazione finora

- Is, S. Exam-Pa H A", .201 Fsi-P-Mche: Question Paper Specific InstructionsDocumento8 pagineIs, S. Exam-Pa H A", .201 Fsi-P-Mche: Question Paper Specific Instructionsanon_375250591Nessuna valutazione finora

- Theory of Machines I 14 Dec. 2013Documento3 pagineTheory of Machines I 14 Dec. 2013Rohit GarateNessuna valutazione finora

- Kinematics of Machinery (MEE - 205) RCSDocumento2 pagineKinematics of Machinery (MEE - 205) RCSmanmonbhaNessuna valutazione finora

- Morphing BlDE FinalDocumento21 pagineMorphing BlDE FinalSoumian NarayananNessuna valutazione finora

- Determination of The Winding Inductances of A Two-Phase MachineDocumento7 pagineDetermination of The Winding Inductances of A Two-Phase MachineIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- B.Tech. (Sern. - 3'd) Theory of Machines - I Sub - Iect Code: Me-203 Paper ID: (AO8O2)Documento2 pagineB.Tech. (Sern. - 3'd) Theory of Machines - I Sub - Iect Code: Me-203 Paper ID: (AO8O2)draculagurdeepNessuna valutazione finora

- Technological Institute of The Philippines: Data and ResultsDocumento6 pagineTechnological Institute of The Philippines: Data and Resultsjec_tanez100% (3)

- Design of Machine Members II R5320305 Set 3Documento2 pagineDesign of Machine Members II R5320305 Set 3Ravi Kumar KamarthiNessuna valutazione finora

- SL 316 - Machine Design - I - Sem V - May 2017Documento7 pagineSL 316 - Machine Design - I - Sem V - May 2017Anantkumar GujarNessuna valutazione finora

- Dme - II Mid - I QP Set-1,2 (16bt50301)Documento2 pagineDme - II Mid - I QP Set-1,2 (16bt50301)Gangaraju MoopuriNessuna valutazione finora

- Me 331Documento5 pagineMe 331arumugam_rNessuna valutazione finora

- Rotating Electrical MachinesDocumento33 pagineRotating Electrical Machinesgurunathan14Nessuna valutazione finora

- Machine Design I 2014Documento8 pagineMachine Design I 201455511223344Nessuna valutazione finora

- Spe 950165 G PDocumento10 pagineSpe 950165 G Pmartin_montana55_479Nessuna valutazione finora

- DTS ND06-QPDocumento3 pagineDTS ND06-QPsrajapratyNessuna valutazione finora

- Mechanics Ii Time Allowed: 2 HoursDocumento6 pagineMechanics Ii Time Allowed: 2 HourssubipuruNessuna valutazione finora

- Conv Civil IDocumento12 pagineConv Civil Isonu_saurabhNessuna valutazione finora

- 07a60304 - Dynamics of MachineryDocumento8 pagine07a60304 - Dynamics of MachineryRajaganapathy GanaNessuna valutazione finora

- Iii Me Ii Sem Q.bank 2016-17Documento32 pagineIii Me Ii Sem Q.bank 2016-17Abhishek SakatNessuna valutazione finora

- Design of Electrical MachinesDocumento27 pagineDesign of Electrical MachinesAnaZanattaNessuna valutazione finora

- Pyrhonen Squirrel Cage Motor Calculation Mathcad13Documento35 paginePyrhonen Squirrel Cage Motor Calculation Mathcad13Mutee Ullah KhanNessuna valutazione finora

- Torsion Test1Documento6 pagineTorsion Test1musher95100% (1)

- ME2352 Design of Transmission Question BankDocumento4 pagineME2352 Design of Transmission Question BankKarthik SubramaniNessuna valutazione finora

- MD Handb2 Belt CalcDocumento5 pagineMD Handb2 Belt Calcoana2507Nessuna valutazione finora

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsDa EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNessuna valutazione finora

- Hosts 1Documento4 pagineHosts 1MostafaNessuna valutazione finora

- AkhdddhfDocumento6 pagineAkhdddhfMostafaNessuna valutazione finora

- AkhdddhfDocumento6 pagineAkhdddhfMostafaNessuna valutazione finora

- New Text DocumentDocumento2 pagineNew Text DocumentMostafaNessuna valutazione finora

- GasfasfDocumento2 pagineGasfasfMostafaNessuna valutazione finora

- AkhdddhfDocumento6 pagineAkhdddhfMostafaNessuna valutazione finora

- AkhdddhfDocumento6 pagineAkhdddhfMostafaNessuna valutazione finora

- AkdgjDocumento6 pagineAkdgjMostafaNessuna valutazione finora

- AkhdddhfDocumento6 pagineAkhdddhfMostafaNessuna valutazione finora

- AkhdddhfDocumento6 pagineAkhdddhfMostafaNessuna valutazione finora

- AkhdddhfDocumento6 pagineAkhdddhfMostafaNessuna valutazione finora

- AkdgjDocumento6 pagineAkdgjMostafaNessuna valutazione finora

- AkhdddhfDocumento6 pagineAkhdddhfMostafaNessuna valutazione finora

- AgkdgdDocumento5 pagineAgkdgdMostafaNessuna valutazione finora

- AgkdgdDocumento5 pagineAgkdgdMostafaNessuna valutazione finora

- AkhbidsDocumento5 pagineAkhbidsMostafaNessuna valutazione finora

- Akh BidsDocumento6 pagineAkh BidsMostafaNessuna valutazione finora

- AkhbidsDocumento6 pagineAkhbidsMostafaNessuna valutazione finora

- AkhdddhfDocumento6 pagineAkhdddhfMostafaNessuna valutazione finora

- AkhbidsDocumento6 pagineAkhbidsMostafaNessuna valutazione finora

- AkhbidsDocumento6 pagineAkhbidsMostafaNessuna valutazione finora

- AkhbidsDocumento5 pagineAkhbidsMostafaNessuna valutazione finora

- AkhbidsDocumento5 pagineAkhbidsMostafaNessuna valutazione finora

- AkhbidsDocumento5 pagineAkhbidsMostafaNessuna valutazione finora

- AkhbidsDocumento5 pagineAkhbidsMostafaNessuna valutazione finora

- AkhbidsDocumento5 pagineAkhbidsMostafaNessuna valutazione finora

- AkhbidsDocumento5 pagineAkhbidsMostafaNessuna valutazione finora

- AtffeaaasdaDocumento6 pagineAtffeaaasdaMostafaNessuna valutazione finora

- AtffeaaasdaDocumento6 pagineAtffeaaasdaMostafaNessuna valutazione finora

- AkhbidsDocumento6 pagineAkhbidsMostafaNessuna valutazione finora

- Spectrum Physics - May 2016Documento100 pagineSpectrum Physics - May 2016Popovici DraganNessuna valutazione finora

- MC-10 Propeller (Inc. M Nut, Cal. of Prop. Fit - Inpe. Record)Documento69 pagineMC-10 Propeller (Inc. M Nut, Cal. of Prop. Fit - Inpe. Record)Ruban FernandesNessuna valutazione finora

- (SOLUTION) PHY Race-#035Documento12 pagine(SOLUTION) PHY Race-#035Ashutosh paniNessuna valutazione finora

- Ques Ans After Lecture 15Documento10 pagineQues Ans After Lecture 15Farhan Hussain Ali RanaNessuna valutazione finora

- Thermal Physics (Concepts and Practice) Allen-L-Wasserman-CAMBRIDGE PDFDocumento320 pagineThermal Physics (Concepts and Practice) Allen-L-Wasserman-CAMBRIDGE PDFNeutron100% (1)

- Heat TransferDocumento382 pagineHeat TransferManish Chouhan100% (1)

- Material Properties and Impression MaterialsDocumento16 pagineMaterial Properties and Impression MaterialsAhmad Zezo FawziNessuna valutazione finora

- Introduction To SensorsDocumento17 pagineIntroduction To SensorsHossam AbdelmoneimNessuna valutazione finora

- Fib Bulletin 81 - ACI SP-315 - Punching Shear of Structural Concrete Slabs - Honoring Neil M. Hawkins PDFDocumento396 pagineFib Bulletin 81 - ACI SP-315 - Punching Shear of Structural Concrete Slabs - Honoring Neil M. Hawkins PDFPieter MeulendijksNessuna valutazione finora

- Chapter - 4Documento37 pagineChapter - 4Barnabas YohannesNessuna valutazione finora

- Course Outline For Reinforced Concrete IDocumento2 pagineCourse Outline For Reinforced Concrete ITefera TemesgenNessuna valutazione finora

- FLO-2D Limiting Froude Number GuidelinesDocumento2 pagineFLO-2D Limiting Froude Number GuidelinesYobani ChavezNessuna valutazione finora

- Impedance and Absorption of Acoustical Materials by Impedance Tube MethodDocumento9 pagineImpedance and Absorption of Acoustical Materials by Impedance Tube Methodjose miguelNessuna valutazione finora

- Using The Low Cycle Fatigue Approach When KT Nominal Stress Exceeds The Yield Strength: A Fundamental Mistake!Documento2 pagineUsing The Low Cycle Fatigue Approach When KT Nominal Stress Exceeds The Yield Strength: A Fundamental Mistake!VigneshwaraNessuna valutazione finora

- PHYSICS Syllabus UP NEP2020Documento48 paginePHYSICS Syllabus UP NEP2020I.T.S EnggNessuna valutazione finora

- Chapter 3. Failure of MaterialsDocumento20 pagineChapter 3. Failure of MaterialsVishal ShuklaNessuna valutazione finora

- Two-Dimensional Flow Modelling of A Thin Slice Kettle ReboilerDocumento17 pagineTwo-Dimensional Flow Modelling of A Thin Slice Kettle ReboilerGreat AmpongNessuna valutazione finora

- Question BankDocumento13 pagineQuestion Bankayat essaNessuna valutazione finora

- ANSYS Mechanical APDL Theory Reference PDFDocumento908 pagineANSYS Mechanical APDL Theory Reference PDFNam Vo100% (1)

- Lecture1-2 15852 SpringsDocumento160 pagineLecture1-2 15852 SpringsL.K. BhagiNessuna valutazione finora

- (B) Velocity and Acceleration in Polar CoordinateDocumento2 pagine(B) Velocity and Acceleration in Polar CoordinateAkshay SharmaNessuna valutazione finora

- Physicschapter 6Documento14 paginePhysicschapter 6Owais FarooqNessuna valutazione finora

- Class Ix Motion Cpp-1 (Uniform Motion)Documento3 pagineClass Ix Motion Cpp-1 (Uniform Motion)Vikram BatraNessuna valutazione finora

- ECS 2-1-2 - 1 - 800c21d4Documento10 pagineECS 2-1-2 - 1 - 800c21d4Florin Daniel AnghelNessuna valutazione finora

- Fundamentals of Metal FormingDocumento38 pagineFundamentals of Metal FormingAd Man GeTigNessuna valutazione finora

- Unit 1 MCQ Set 1Documento5 pagineUnit 1 MCQ Set 1Narendra ModiNessuna valutazione finora

- 2021 Nov Final Preboard HydgeoDocumento7 pagine2021 Nov Final Preboard HydgeoMacatangay Mhorien100% (1)

- Retaining Wall 03Documento13 pagineRetaining Wall 03HanafiahHamzahNessuna valutazione finora

- Project State of MatterDocumento6 pagineProject State of Matterpaloma silvaNessuna valutazione finora