Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ofite Manual

Caricato da

Puspendra Singh YadavCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ofite Manual

Caricato da

Puspendra Singh YadavCopyright:

Formati disponibili

Model MB HTHP Filter Press

171-50 (115V)

171-51 (230V)

For temperatures up to 350F (177C)

Instruction Manual

Updated 5/6/2011

Ver. 2.1

OFI Testing Equipment, Inc.

11302 Steeplecrest Dr. Houston, Texas 77065 U.S.A.

Tele: 832.320.7300 Fax: 713.880.9886 www.ofite.com

Copyright OFITE 2011

Table of

Contents

Intro.......................................................................................................2

Specifications ......................................................................................2

Components.........................................................................................3

Safety....................................................................................................6

Procedure.............................................................................................7

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ofite.com

1

The OFITE Model MB HTHP Filter Press is designed to test drilling fluids

and cement under elevated temperatures and pressures. This simulates

various downhole conditions and provides a reliable method for determin-

ing the effectiveness of the material being tested. The complete assembly

consists of a controlled pressure source, regulators, a high pressure cell, a

system for heating the cell, a pressurized collection cell able to maintain

proper back pressure in order to prevent flashing or evaporation of the fil-

trate, and a suitable stand.

Size: 19" x 21" x 28" (49 x 54 x 72 cm)

Weight: 40 lbs. (18.2 kg)

Shipping Size: 23" x 13" x 13" (59 x 33 x 33 cm)

Shipping Weight: 50 lbs. (22.8 kg)

Maximum Temperature: 350F (176C)

Maximum Pressure: 1,500 PSI (10,342.5 kPa)

Pressure Source: 2 CO

2

Cartridges

Test Cell Capacity: 250 mL

Voltage: #171-50: 115V; #171-51-C: 230V

Heater: 200 Watt

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ofite.com

2

Specifications

Intro

Components

#153-16 Glass Graduated Cylinder; 25 mL x 2/10 mL

#153-55 Silicone Stopcock Grease; 150 g Tube

#154-10 Dual-Scale Thermometer with Metal Dial; 5" Stem; 50 - 500F; 0

- 250C

#170-19 2" (6.35 cm) Filter Paper; Specially Hardened for Filter

Presses

#171-56 Complete HTHP Cell

#170-34 " x " NPT Male Needle Valve; Qty: 2

#171-72 T-handle for Needle Valve; Qty: 2

#171-64 Male Coupling; Qty: 2

#171-60 HTHP Cell

#171-78 Locking Screw; Qty: 3

#171-52 O-ring; 2 5/16" x 2" x 3/32"

#171-62 Cell Lid

#171-57 HTHP Regulator Assembly

#142-58 O-ring for HTHP Coupling

#143-02-10 CO

2

Puncture Head Assembly

#143-03 Barrel for CO

2

Cartridge

#144-15 Plated Brass Bushing; " NPT Male to 1/8" NPT Female;

Qty: 2

#170-34 " x " NPT Male Needle Valve

#171-53 High-Pressure Regulator

#171-73-1 1000-PSI Gauge; 1/8" Bottom; 1" Face

#171-74-1 2000-PSI Gauge; 1/8" Bottom; 1" Face

#171-76 Female Coupling for Top Valve

#171-77 Coupling Ring for Top Valve

#171-58 HTHP Complete Back Pressure Receiver

#142-37 Victor Regulator

#142-58 O-Ring for HTHP Coupling

#142-61 200-PSI Gauge; 2"; " Bottom Connection

#143-02-10 CO

2

Puncture Head Assembly

#143-03 Barrel for CO

2

Cartridge

#143-06 Safety Bleeder Valve

#143-09 200-PSI Relief Valve

#170-07 O-ring; Qty: 2

#170-32 1/8" x 1/8" NPT Male Needle Valve

#171-66 Stainless Steel Receiver Tube

#171-75 Receiver Body

#171-79 " Hex Wrench

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ofite.com

3

#171-50 HTHP Filter Press Without Case (115V):

#171-55 HTHP Heating Jacket and Stand; 115V

#142-58 O-ring for HTHP Coupling

#170-07 O-Ring

#170-11 Heating Element; 115V; 200W; Qty: 4

#171-54 Fuse

#171-59 Stand; Base and Leg

#171-59-1 Micarta Insulator Strip

#171-61 Heating Block Jacket

#171-63 Dial Plate for Thermostat

#171-65 Fuse Block

#171-67 Thermostat Knob

#171-68 Red Pilot Light

#171-69 White Pilot Light

#171-70-1 Waterproof Thermostat Cover

#171-71 Thermostat

#171-71-1 Thermostat Space Plate

#171-71-2 Sleeve and Nut for Thermostat

#171-82 Power Cord with Male Plug Only; 8'; 16/3 SJ; Round

#171-51 HTHP Filter Press Without Case (230V):

#171-55-1 HTHP Heating Jacket and Stand; 230V

#142-58 O-ring for HTHP Coupling

#164-32 Male Connector for Power Cable; 230V

#165-40-2 18 Gauge Cable; 3-Conductor; SJ00W; Qty: 8

#170-07 O-Ring

#170-11 Heating Element; 115V; 200W; Qty: 4

#171-54 Fuse

#171-59 Stand; Base and Leg

#171-59-1 Micarta Insulator Strip

#171-61 Heating Block Jacket

#171-63 Dial Plate for Thermostat

#171-65 Fuse Block

#171-67 Thermostat Knob

#171-68 Red Pilot Light

#171-69 White Pilot Light

#171-70-1 Waterproof Thermostat Cover

#171-71 Thermostat

#171-71-1 Thermostat Space Plate

#171-71-2 Sleeve and Nut for Thermostat

Optional:

#143-05 EZ Puncture CO

2

Bulbs; 8-Gram; UN #1013; Package of 10

#143-20 Repair Kit for High-Pressure Victor Regulator (#171-53)

#171-81 Stainless Steel Carrying Case

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ofite.com

4

#171-50-SP Spare Parts for #171-50 and #171-51:

#140-60-01 Bleeder Valve O-ring; Qty: 4

#142-42 Diaphragm; Qty: 2

#142-58 HTHP Coupling O-ring; Qty: 36

#142-61 200-PSI Gauge; 2"; " Bottom Connection

#143-02-13 Puncture Pin Holder Assembly O-ring; CO

2

Cartridge; Qty: 2

#143-02-14 Puncture Pin Holder Assembly O-ring; Qty: 2

#143-05 EZ Puncture CO

2

Bulbs; (8-GRAM); (UN #1013); Box of

10; Qty: 60

#143-19 Repair Kit for Victor Regulator; Qty: 2

#143-20 Repair Kit for High-Pressure Victor Regulator; Qty: 2

#153-16 Glass Graduated Cylinder; 25 mL x 2/10 mL; Qty: 2

#153-55 Silicone Stopcock Grease; 150 g Tube; Qty: 2

#154-10 Dual-Scale Thermometer with Metal Dial; 5" Stem; 50 -

500F; 0 - 250C

#170-07 O-ring; Qty: 2

#170-11 200-Watt Heating Element; 115V; Qty: 4

#170-19 2" (6.35 cm) Filter Paper; Specially Hardened for Filter

Presses; Qty: 10

#171-52 O-ring; 2 5/16" x 2" x 3/32"; Qty: 12

#171-54 Fuse

#171-67 Thermostat Knob

#171-68 Red Pilot Light

#171-69 White Pilot Light

#171-71 Thermostat

#171-73-1 1000-PSI Gauge; 1/8" Bottom; 1" Face

#171-78 Cell Screw; Qty: 4

#171-79 " Hex Wrench

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ofite.com

5

Safety

Carbon Dioxide gas is normally supplied in small bulbs or cartridges, which

contain approximately 900 PSI (6,206 kPa) pressure when new. Because

they are highly portable, they are usually used in field operations. These

bulbs should not be exposed to high heat (50C/120F) as they can

explode if over heated.

Carbon Dioxide cartridges are pressurized to approximately 900 PSI at 1

atmosphere (sea level). Therefore, they should never be transported by

airplane without proper packing because cabin de-pressurization may

cause an explosion.

Do not use nitrous oxide cartridges as pressure sources for high-tem-

perature, high-pressure (HTHP) filtration. Under high temperature

and pressure, nitrous oxide can detonate in the presence of grease,

oil, or carbonaceous materials. Nitrous oxide cartridges are to be

used only for Garrett Gas Train Carbonate Analysis.

Due to the high temperatures and pressures involved in this test, extreme

care must be exercised at all times. All safety precautions must be met,

especially in the cell breakdown procedure after the filtration procedure has

been completed.

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ofite.com

6

Important

!

Procedure

1. Connect the heating well power cord to the appropriate power source.

Place a dial-type metal thermometer in the well in the heating jacket

and preheat to 10F (6C) above the desired test temperature. A pilot

light will come on when the heating jacket is at the desired temperature

as selected by the thermostat control knob.

2. Stir the sample for 10 minutes with a high speed mixer. Close both

needle valves on the test cell by turning them counter-clockwise. Invert

the cell and carefully pour the test fluid into the cell body. Leave at

least 0.5" (13 mm) of empty space below the o-ring groove to allow for

heat expansion of the fluid. Do not spill fluid on the o-ring inside the

cell.

3. Place a circle of filter paper in the groove and place an o-ring on top of

the paper. Place the cell cap into the cell, and twist it into position so

the cap locking screws will fasten to the wings of the cell cap. Evenly

tighten the set screws with the allen wrench.

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ofite.com

7

Needle Valve (Inlet)

(#170-34)

Test Cell

(#171-56)

Needle Valve (Outlet)

(#170-34)

O-ring Groove Cell Cap (#171-62) Locking Screws (#171-78)

4. Place the cell in the heating jacket with the outlet or filter side of the cell

cap properly oriented down. Make sure both valves on the cell are

closed. Transfer the thermometer into the thermometer well within the

cell.

5. Check the o-ring on the inside of the female coupling on the top pres-

sure assembly for nicks and cuts. Apply a thin coat of silicone grease

to the o-ring but do not seal up the hole with grease. Connect the pres-

suring assembly to the top male slip coupling by lifting the lock ring and

sliding the pressure assembly onto the male coupling. Release the lock

ring and the top pressure assembly has been installed.

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ofite.com

8

Locking Ring

Male Coupling

(#171-64)

Back Pressure Receiver

Needle Valve

(#170-32)

Needle Valve

(#170-34)

Pressuring Assembly (#171-57) Back Pressure Receiver (#171-58)

Cartridge Holder

(#143-03)

T-screw

T-screw

O-ring

(#142-58)

6. If you will be operating above 200F (93.3C), place the back pressure

receiver on the bottom valve assembly in the same manner.

7. Remove the CO

2

cartridge holder from both the top pressuring assem-

bly and the back pressure receiver. Make sure both regulator T-screws

are unscrewed completely and the needle valves are completely

closed. Place a CO

2

cartridge in each holder and screw the holder onto

the pressuring assemblies until the cartridges puncture. If the red relief

valve on the backpressure receiver is not already pulled out, pull it out

now.

8. Keeping the test cell valves closed, adjust the top and bottom regula-

tors to the recommended back pressure for your test. Open the top

valve one full turn to pressurize the sample. This pressure will mini-

mize boiling while the sample is heating. Maintain this pressure on the

fluid until the desired temperature is stabilized, as indicated by the ther-

mometer. The heating time of the sample should never exceed one

hour.

The upper and lower limits of the test pressure differential are deter-

mined by the test temperature. As this temperature exceeds 212F

(100C), the back pressure must be increased in order to prevent

vaporization of the filtrate. The 500 PSI differential pressure must be

maintained, so the top pressure will have to be increased accordingly.

The table below shows the pressures recommended for various test

temperatures.

9. When the fluid sample reaches the desired test temperature, increase

the pressure on the top pressure unit to 500 PSI (3,447.5 kPa) above

the back pressure. Open the bottom valve to initiate filtration and begin

timing.

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ofite.com

9

Note

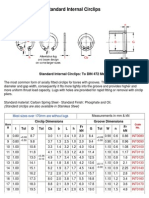

Recommended Minimum Back Pressure

Test Temperature Vapor Pressure Minimum Back Pressure

F C PSI kPa PSI kPa

212 100 14.7 101 100 690

250 121 30 207 100 690

300 149 67 462 100 690

350 177 135 932 160 1,104

400* 204 247 1,704 275 1,898

450* 232 422 2,912 450 3,105

500* 260 680 4,692 700 4,830

*For tests above 400F, use Teflon o-rings.

10. Collect the filtrate for 30 minutes maintaining the selected test tempera-

ture within 5F ( 3C). If the back pressure rises above recommend-

ed setting during the test, reduce the pressure by carefully opening the

valve on the receiver and drawing off some of the filtrate into the gradu-

ated cylinder. When the pressure is back down to the recommended

setting, close the valve.

11. At the end of the test, close the top and bottom valves on the cell.

Unscrew the regulator T-screws and open the needle valves on the

pressuring assembly and the back pressure receiver to release all of

the pressure.

12. Remove the back pressure receiver and drain any remaining filtrate into

the graduated cylinder. Correct the total filtrate volume collected to a

standard filtration test area of 7.1 in

2

(45.8 cm

2

) by doubling the filtrate

volume collected in 30 minutes. Record this total filtrate volume (dou-

bled), and the temperature, pressure, and time.

13. Disconnect the primary pressure assembly by lifting the lock ring and

slipping the pressure assembly off the cell coupling. Remove the cell

from the heating jacket and allow it to cool to room temperature or

quick cool the cell by immersing it in cool water. Keep the cell in an

upright position during this procedure. When the cell has cooled, slowly

open the two needle valves to bleed off the cell pressure.

Pressure inside the sample cell will still be approximately 500 PSI

(3,450 kPa). Keep the cell upright and cool it to room temperature

before disassembling. The cell must be cool for at least one hour

at room temperature or at least 10 minutes in cool water before

loosening the cap locking screws and removing the cell cap.

14. Invert the cell and loosen the cell cap screws with the Allen wrench.

Use extreme care to save the filter paper and deposited filter cake.

Discard the fluid inside the cell, and retrieve the filter cake.

15. Wash the filter cake on the paper with a gentle stream of water.

Measure and report the thickness of the filter cake to the nearest 1/32"

(0.8 mm).

16. Clean and dry the apparatus thoroughly after each use. Inspect all o-

rings and replace if necessary.

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ofite.com

10

Important

!

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ofite.com

11

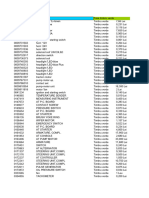

Stopcock Grease (#153-55)

Filter Paper (#170-19)

Male Needle Valve (#170-32)

CO

2

Cartridge Barrel (#143-03)

Female Coupling (#171-76)

Coupling Ring (#171-77)

Male Needle Valve (#171-80)

Thermostat Knob (#171-67)

White Pilot Light (#171-69)

Thermostat Cover (#171-70-1)

Male Needle Valve (#171-80)

Male Coupling (#171-64)

Back Pressure Receiver

(#171-75)

Thermostat Dial Plate (#171-63)

2000-PSI Gauge (#171-74-1)

Graduated Cylinder (#153-16)

Stand and Base (#171-59)

Victor Regulator (#142-37)

Safety Bleeder Valve (#143-06)

CO

2

Cartridge Barrel (#143-03)

200-PSI Gauge (#142-61)

1000-PSI Gauge (#171-73-1)

Bushing (#144-15)

Victor Regulator (#171-53)

Male Needle Valve (170-34)

Male Coupling (#171-64)

Heating Jacket

(#171-55/171-55-1)

Thermometer (#154-10)

Red Pilot Light (#171-68)

Potrebbero piacerti anche

- Dynamic Filter Press ManualDocumento23 pagineDynamic Filter Press ManualMobeen MurtazaNessuna valutazione finora

- Instruction Manual: Permeability Plugging TesterDocumento27 pagineInstruction Manual: Permeability Plugging TesterDukilson PersyNessuna valutazione finora

- 171-193 - Permeability Plugging Tester, 5000 PSIDocumento27 pagine171-193 - Permeability Plugging Tester, 5000 PSIJessica Matos TacuriNessuna valutazione finora

- 140-60 - Instructions Filtrado APIDocumento8 pagine140-60 - Instructions Filtrado APIMyrnaNessuna valutazione finora

- Roller Oven With Programmable TimerDocumento12 pagineRoller Oven With Programmable TimerSilvia DuranNessuna valutazione finora

- 130 38 20 Instructions TERMOCOPADocumento2 pagine130 38 20 Instructions TERMOCOPAGarcia ManuelNessuna valutazione finora

- Manual de OperacionDocumento12 pagineManual de OperacionGarcia ManuelNessuna valutazione finora

- Garrett Gas Train OfiteDocumento22 pagineGarrett Gas Train Ofitegplese0Nessuna valutazione finora

- Reg RedQ Specialy Regulators PDFDocumento20 pagineReg RedQ Specialy Regulators PDFDavid SaldarriagaNessuna valutazione finora

- VALVULA DE SOLENOIDE HS7 BulletinDocumento4 pagineVALVULA DE SOLENOIDE HS7 BulletinJoséMarcanoNessuna valutazione finora

- Fusible Dev 15RS128 Rev 0110Documento2 pagineFusible Dev 15RS128 Rev 0110Ali YusufNessuna valutazione finora

- 160.75-RP1 (210) - Yk (G)Documento92 pagine160.75-RP1 (210) - Yk (G)JayashtonNessuna valutazione finora

- Manual HORNO DE ROLADODocumento13 pagineManual HORNO DE ROLADOMarcialgonzalezpNessuna valutazione finora

- 165-14 - Instructions Retorta para CutingDocumento17 pagine165-14 - Instructions Retorta para CutingJuan SersopulosNessuna valutazione finora

- Diaphragm Valve, Metal: ConstructionDocumento4 pagineDiaphragm Valve, Metal: ConstructionDenial BasanovicNessuna valutazione finora

- Datasheet 4075 4475 High Temp Valve 0111 Rev1Documento6 pagineDatasheet 4075 4475 High Temp Valve 0111 Rev1nricquartNessuna valutazione finora

- Tapon Fusible RUELCODocumento2 pagineTapon Fusible RUELCOtremendousNessuna valutazione finora

- OFITE Filter Press With Nitrogen Cylinder 140-35Documento9 pagineOFITE Filter Press With Nitrogen Cylinder 140-35HenryNessuna valutazione finora

- Type A Pressure Relief Valve: Standard Features Parts List (Sizes 1/2" - 2")Documento2 pagineType A Pressure Relief Valve: Standard Features Parts List (Sizes 1/2" - 2")thomasoburNessuna valutazione finora

- Documents - MX API RP 42 EspanolDocumento17 pagineDocuments - MX API RP 42 EspanolHenryNessuna valutazione finora

- Automatic Valve Gemue DB - 512 - GBDocumento6 pagineAutomatic Valve Gemue DB - 512 - GBTaher Yusuf100% (1)

- API Filter Press - Test ProcedureDocumento8 pagineAPI Filter Press - Test ProcedureLONG LASTNessuna valutazione finora

- GSL 1100X6Documento19 pagineGSL 1100X6Adolfo LopezNessuna valutazione finora

- Maquina Iqf 500 KG X HoraDocumento4 pagineMaquina Iqf 500 KG X Horamanuelgonzalez1984100% (1)

- Stoerk 2004 enDocumento199 pagineStoerk 2004 enSousaFVNessuna valutazione finora

- Revc FinalDocumento12 pagineRevc FinalHasan KamalNessuna valutazione finora

- Climate Control Pro 3 PDFDocumento4 pagineClimate Control Pro 3 PDFhonghai_dlNessuna valutazione finora

- ST-100 (325K) ManualDocumento16 pagineST-100 (325K) Manualmpj2104100% (1)

- Dwyer - Valvula de Bola Inox Serie BV2M, IOMDocumento1 paginaDwyer - Valvula de Bola Inox Serie BV2M, IOMGabriel Ortiz MontesNessuna valutazione finora

- ASCO Info Filter Canada PDFDocumento8 pagineASCO Info Filter Canada PDFdicicaNessuna valutazione finora

- Excess Flow Valves Bleed Valves and Purge ValvesDocumento6 pagineExcess Flow Valves Bleed Valves and Purge ValvesNilesh MistryNessuna valutazione finora

- STI 7510A-HTR Instruction ManualDocumento2 pagineSTI 7510A-HTR Instruction ManualJMAC SupplyNessuna valutazione finora

- Machine Bolt Shut-Off Nozzle Type BHP: ApplicationsDocumento5 pagineMachine Bolt Shut-Off Nozzle Type BHP: ApplicationsRoni AdiNessuna valutazione finora

- 132-00 - Hank Crank InstructionsDocumento15 pagine132-00 - Hank Crank InstructionsNolanJohnsonNessuna valutazione finora

- Carrier38CKC 50HzDocumento20 pagineCarrier38CKC 50HzAaron LeveyNessuna valutazione finora

- Staitech Catalog - Web Rev1Documento44 pagineStaitech Catalog - Web Rev1vanbogaertetienneNessuna valutazione finora

- Dissolved Air Flotation Test ApparatusDocumento19 pagineDissolved Air Flotation Test ApparatusSY LeeNessuna valutazione finora

- Needle ValvesDocumento38 pagineNeedle ValvesRavichandran MohanNessuna valutazione finora

- Electric Mini Tank Water Heaters GL 2.5 - GL 4 - GL 6+: Mts Makes Use of Recycled PaperDocumento13 pagineElectric Mini Tank Water Heaters GL 2.5 - GL 4 - GL 6+: Mts Makes Use of Recycled PaperService Pemanas AirNessuna valutazione finora

- Pressurized Fluid Density Scale Instruction Manual: Part #: 100-70Documento10 paginePressurized Fluid Density Scale Instruction Manual: Part #: 100-70Prejit RadhakrishnaNessuna valutazione finora

- MP 5297Documento138 pagineMP 5297Marjorie RSNessuna valutazione finora

- Trend Thermistor DataDocumento4 pagineTrend Thermistor DataMike KeilyNessuna valutazione finora

- Manual For Filastruder ENGLISH PDFDocumento10 pagineManual For Filastruder ENGLISH PDFstavroula zarkadoulaNessuna valutazione finora

- Manifold PDFDocumento32 pagineManifold PDFvivek_enggNessuna valutazione finora

- Hoke Needle ValvesDocumento38 pagineHoke Needle ValvesmartinvandoornNessuna valutazione finora

- k10 Pts Manual OriginalDocumento35 paginek10 Pts Manual OriginalJosé López100% (1)

- Alfa Laval Koltek MH Valve enDocumento8 pagineAlfa Laval Koltek MH Valve enjpsingh75Nessuna valutazione finora

- Pilot CylindersDocumento7 paginePilot CylindersMohsin RazaNessuna valutazione finora

- IO Data Cable Data SheetDocumento194 pagineIO Data Cable Data SheetadiamiruNessuna valutazione finora

- Danfoss Expansion ValveDocumento42 pagineDanfoss Expansion ValveLokesh GandhiNessuna valutazione finora

- 015 Pipe Flanges Schedule 40Documento4 pagine015 Pipe Flanges Schedule 40MOHAMMAD ASIFNessuna valutazione finora

- Hot-Tap Saddle: Installation InstructionsDocumento2 pagineHot-Tap Saddle: Installation InstructionsSusan Sue Berrospi MerinoNessuna valutazione finora

- Autoclave AccessoriesDocumento20 pagineAutoclave Accessoriescmct0819Nessuna valutazione finora

- Viscosimetro OfiteDocumento20 pagineViscosimetro OfitejomarlucaNessuna valutazione finora

- Gate Valve: Standard Features Type P Parts (Sizes 1-1/2" - 6")Documento3 pagineGate Valve: Standard Features Type P Parts (Sizes 1-1/2" - 6")MOHAMMAD ASIFNessuna valutazione finora

- Style 808 Duo-Lock High Pressure Coupling: Product DescriptionDocumento2 pagineStyle 808 Duo-Lock High Pressure Coupling: Product Descriptionnrd9771Nessuna valutazione finora

- Temperature SensorsDocumento14 pagineTemperature SensorsViktor -stNessuna valutazione finora

- Advanced Temperature Measurement and Control, Second EditionDa EverandAdvanced Temperature Measurement and Control, Second EditionNessuna valutazione finora

- Pradeep Kumar Singh: Mob - No.+91-9350532171Documento2 paginePradeep Kumar Singh: Mob - No.+91-9350532171Puspendra Singh YadavNessuna valutazione finora

- Sr. Mud Engineer - MBPSDocumento1 paginaSr. Mud Engineer - MBPSPuspendra Singh YadavNessuna valutazione finora

- Project Manual: Sofcon India Pvt. Ltd. (Confidential-For Internal Use Only)Documento7 pagineProject Manual: Sofcon India Pvt. Ltd. (Confidential-For Internal Use Only)Puspendra Singh YadavNessuna valutazione finora

- TOC of InTouch Lab Manual V1.0 18.06.2013Documento2 pagineTOC of InTouch Lab Manual V1.0 18.06.2013Puspendra Singh YadavNessuna valutazione finora

- M07194 TXgard Plus User Manual Iss 4 Sep 11 GBDocumento2 pagineM07194 TXgard Plus User Manual Iss 4 Sep 11 GBPuspendra Singh YadavNessuna valutazione finora

- Well Control BPDocumento498 pagineWell Control BPcristianoclem100% (1)

- Differential Pressure of Mud MotorDocumento3 pagineDifferential Pressure of Mud MotorPuspendra Singh YadavNessuna valutazione finora

- Din 472Documento5 pagineDin 472Puspendra Singh Yadav0% (2)

- Stuck Pipe PreventionDocumento64 pagineStuck Pipe PreventionmmbatainehNessuna valutazione finora

- My Interview Questions and Answers (Electronics, Electrical and Instrumentation)Documento5 pagineMy Interview Questions and Answers (Electronics, Electrical and Instrumentation)Puspendra Singh YadavNessuna valutazione finora

- Manual de Servicio de Split Marca Fujitsu Modelo Arg25alcDocumento63 pagineManual de Servicio de Split Marca Fujitsu Modelo Arg25alcdaniel perezNessuna valutazione finora

- Operation Manual of The Intelligent Controller SR258: For Split Pressurized Solar Hot Water SystemDocumento49 pagineOperation Manual of The Intelligent Controller SR258: For Split Pressurized Solar Hot Water SystemMarlene AnghelNessuna valutazione finora

- DUK TSC 618 - PM PDFDocumento20 pagineDUK TSC 618 - PM PDFIgnacio SanchezNessuna valutazione finora

- Atwood Water Heater Service ManualDocumento40 pagineAtwood Water Heater Service ManualJohn LarsonNessuna valutazione finora

- Marvair Compact1 CompletoDocumento38 pagineMarvair Compact1 CompletoCarlosNessuna valutazione finora

- 630 Eurosit +INSTRUCTIONS1Documento11 pagine630 Eurosit +INSTRUCTIONS1Noureddine AbdellahNessuna valutazione finora

- Free Energy CatalogDocumento18 pagineFree Energy CatalogCaleb06866Nessuna valutazione finora

- G60UHV SeriesDocumento70 pagineG60UHV SeriesfogdartNessuna valutazione finora

- hp26 Eng HandbookDocumento58 paginehp26 Eng HandbookxbinfluxNessuna valutazione finora

- Honeywell Thermostat T87FDocumento8 pagineHoneywell Thermostat T87FKalyana AyyaswamyNessuna valutazione finora

- Sime Format 24 System Boiler InstDocumento36 pagineSime Format 24 System Boiler InstJer CotterNessuna valutazione finora

- Nirvana Cycling Refrigerated Dryer 75 Through 150 SCFM: Operators Manual D127NC D170NC D212NC D255NCDocumento18 pagineNirvana Cycling Refrigerated Dryer 75 Through 150 SCFM: Operators Manual D127NC D170NC D212NC D255NCoscar samo100% (1)

- EEE Taxa Timbru VerdeDocumento47 pagineEEE Taxa Timbru VerdeAdam SchwemleinNessuna valutazione finora

- 2-Engine Mechanical SystemDocumento256 pagine2-Engine Mechanical SystemFrankCubidesNessuna valutazione finora

- How To Build A Kerosene Fired Egg IncubatorDocumento12 pagineHow To Build A Kerosene Fired Egg IncubatorSchool Vegetable GardeningNessuna valutazione finora

- WSHP Svx01q enDocumento128 pagineWSHP Svx01q enMoriyasu NguyenNessuna valutazione finora

- User Manual: Plug-In, Electronic Digital Thermostat With Defrost ControlDocumento56 pagineUser Manual: Plug-In, Electronic Digital Thermostat With Defrost ControlRodrigo GouveiaNessuna valutazione finora

- CatalogDocumento66 pagineCatalogKishore KumarNessuna valutazione finora

- MST-M-0070 Hot Water CalorifiersDocumento10 pagineMST-M-0070 Hot Water CalorifiersJERINNessuna valutazione finora

- Catalog Axol UteDocumento247 pagineCatalog Axol Uteradu dermideNessuna valutazione finora

- Wgo Boiler ManualDocumento44 pagineWgo Boiler ManualJorge Felipe Sepúlveda HaugenNessuna valutazione finora

- Viessmann Airflow Hydronic Air HandlerDocumento4 pagineViessmann Airflow Hydronic Air HandlerCTHNessuna valutazione finora

- STS-JZ IQ: Installation / Owner'S ManualDocumento59 pagineSTS-JZ IQ: Installation / Owner'S ManualjollyNessuna valutazione finora

- BG 2000 SFDocumento43 pagineBG 2000 SFdbricchiNessuna valutazione finora

- Cempra3 Process Control 2022Documento30 pagineCempra3 Process Control 2022AndrewNessuna valutazione finora

- UVG X160 & X245 Installation and Operation ManualDocumento15 pagineUVG X160 & X245 Installation and Operation ManualAnonymous U18LFvdfDNessuna valutazione finora

- Hfcats14 011306Documento8 pagineHfcats14 011306Enrique Romero SanchezNessuna valutazione finora

- FILE - 20200925 - 101243 - C-PAC - W - 2018Documento30 pagineFILE - 20200925 - 101243 - C-PAC - W - 2018Qúy Trương ThiênNessuna valutazione finora

- Grundfos Catalogue Industry and Water UtilityDocumento542 pagineGrundfos Catalogue Industry and Water UtilityAdina Mariana Costache100% (7)

- Eelectron Tech Products Catalogue 2020Documento82 pagineEelectron Tech Products Catalogue 2020MustafaNessuna valutazione finora