Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Quality Assurance Plan (Template)

Caricato da

Sajeel Zaman0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

325 visualizzazioni16 paginefull template for quality assurance plan

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentofull template for quality assurance plan

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

325 visualizzazioni16 pagineQuality Assurance Plan (Template)

Caricato da

Sajeel Zamanfull template for quality assurance plan

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 16

Page 1 of 16

Home Delivery of Fresh Fruits

and Vegetables Baskets

Quality Assurance Plan

Document Status

Version Number: 1.0

Date: 11-May-2014

Status: Draft

Page 2 of 16

Preface

For more information on this document, contact:

Haris Zaman

Manager Quality Assurance (MQA)

Home delivery of Fresh Fruits and Vegetables Baskets

051-5584784

Document Location

MQAs Office at Head Office in F/8 Islambad.

Document Revision History

Date Version Author Comments

11-May-14 1.0 Haris Zaman Initially drafted

Page 3 of 16

Document Approval

Yasir Zaman General manager

Signature

Date 11-MAY-2014

Sajeel Zaman Manager Operations

Signature Date 10-MAY-2014

Haris Zaman Manager QA

Signature

Date 10-MAY-2014

Document Review

The following people have been consulted in the compilation of this document:

Business Area Name Role

Management Yasir Zaman General Manager (GM)

Departments Usman Paracha Manager Marketing

Hasnain Khan Manager Finance

Sajeel Zaman Manager Operations

Faizan Shah Manager HR

Page 4 of 16

Contents

1 INTRODUCTION ................................................................................................... 5

1.1 Purpose of this document ................................................................................................................. 5

1.2 Intended Audience ............................................................................................................................ 5

1.3 Approach ........................................................................................................................................... 5

1.4 Document Scope .............................................................................................................................. 5

1.5 Definitions ......................................................................................................................................... 6

2 QUALITY ASSURANCE MANAGEMENT ............................................................ 7

2.1 Quality Assurance Organisation Structure ........................................................................................ 7

2.2 Project Organisation Structure .......................................................................................................... 8

2.3 Roles & Responsibilities ................................................................................................................... 8

3 METHODOLOGY & STANDARDS ....................................................................... 9

3.1 Methodology...................................................................................................................................... 9

3.2 Standards ........................................................................................................................................ 10

4 COACHING & MENTORING .............................................................................. 11

5 DELIVERABLES REVIEWS & AUDITS ............................................................. 12

5.1 Deliverable Reviews ....................................................................................................................... 12

5.2 Process Reviews ............................................................................................................................ 12

5.3 Quality Assurance Progress Reviews ............................................................................................. 12

5.4 Quality Assurance Lessons Learned Review ................................................................................. 12

5.5 Independent Review of Quality Assurance ..................................................................................... 13

5.6 Schedule of Quality Assurance Activities ....................................................................................... 13

6 FEEDBACK & REPORTS .................................................................................. 14

7 PROBLEM REPORTING & CORRECTIVE ACTION ......................................... 15

Page 5 of 16

1 Introduction

1.1 Purpose of this document

The purpose of Quality Assurance Plan is to provide internal Quality Assurance (QA)

guidance to all the operating and management functions. This guidance allows all the

functions to operate under standardized, Quality Assurance Plan (QAP) and ensures that

our clients are consistently provided with data that are of known and documented quality.

QAP also fulfils the requirement of our clients and of government programs to document

this.

1.2 Intended Audience

This document is prepared and provided to all the partners, top management, the HODs

of all departments and the staff. It can also b provided to the suppliers and the customers

on demand. It will help in quality operations to ensure customer satisfaction.

1.3 Approach

This document is prepared with great experience and keeping in view all the aspects of

the project. The industry standards, competitors approach and other different international

standards of quality were studied and investigated. The experts of this specific field were

also consulted for expert opinions, suggestions and expertise. Also other departmental

heads were also consulted while preparing this document.

1.4 Document Scope

The management and all the staff of Fresh Fruits and Vegetables Baskets.

Page 6 of 16

1.5 Definitions

Term / Acronym Definition

AM Assistant manager

AMQA Assistant manager Quality Assurance

CAR Corrective Action Request

GM General Manager

HOD Head of Department

HR Human Resource

JD Job Description

MQA Manager Quality Assurance

PAR Preventive Action Request

QA Quality Assurance

QAO Quality Assurance Observer

QAP Quality Assurance Plan

QMS Quality Management System

SOP Standard Operating Procedure

Page 7 of 16

2 Quality Assurance Management

The management is committed to providing quality services that meet the requirements of

our clients and satisfy applicable regulatory requirements. Management is dedicated to

providing an environment that encourages the achievement of excellence, demands

integrity in all aspects of its operations, and requires active participation of all associates

and vendors in meeting its quality goals.

Implementation of the QAP is the responsibility of all quality assurance associates.

Management at every level has the responsibility and authority to lead the development

and implementation of a structured management system that supports the quality

programs. Management must ensure that the principles and practices of the quality

program are followed and implemented at all levels.

Each company outlet has day-to-day independent operational authority that is overseen

by the various corporate functions (Senior Management, Operations, Quality Assurance,

Finance and Human Resources). The outlet has, therefore, the operational staff

supported by local management, namely, a manager QA, assistant manager QA safety

coordinator, QA observers and administrative support. This team is directed by the

franchise manager to meet daily workload commitments with a degree of autonomy.

These support functions have a level of responsibility to the corporate level staff and

management. Quality Assurance is an example of a function which is independent from

the outlets day-to-day operations. Even though a key member on the outlet team, the

Quality Assurance Observer (QAO) has direct access to the Manager Quality Assurance

(MQA) on all quality issues and their proper reporting. All QA candidate selection, hiring

and disciplinary actions are approved by the MQA. This approach ensures independence

of judgment and integrity without the influence of financial and scheduling pressures.

2.1 Quality Assurance Organisation Structure

General

Manager

MQA

Safety

Coordinator

AMQA

QA Observer QA Observer

Page 8 of 16

2.2 Project Organisation Structure

2.3 Roles & Responsibilities

Name Role Responsibilities

MQA Overall monitoring & reporting to

top management

To ensure monitoring at all levels and

reporting to top management.

AMQA Timely conducting internal &

external audits, effective

utilization of QA observers

Responsible to MQA for all the duties

assigned. Scheduling of internal &

external audits.

Safety Coordinator Monitoring overall safety Ensure safe handling & deliveries of

products and ensure health &

environmental safety.

QA Observers Spot/snap checks at all stages of

operations

Keep a watch on each stage in all

departments for implementations of

policies and reporting shortcomings to

AMQA.

GM

Manager

Finance

AM

Finance

AM

Accounts

Manager

Marketing

AM

Marketing

Manager

QA

Safety

Coordinator

AMQA

QA

Observer

QA

Observor

Manager

Operations

AM

Operations

Manager

HR

Page 9 of 16

3 Methodology & Standards

3.1 Methodology

Quality Assurance ensures to establish and implement required procedures within the

organization as per the standard of the organization. The required documents may

include Organization Chart, Corporate Policy, System Procedures, Standard Operating

Procedures (SOPs), Process Flow Charts, Departmental Objectives, Job Descriptions

(JD) and the Quality Plans as per the Quality Management System (QMS). The QA

Department will also ensure to maintain records of all activities being carried out within

the organization.

The QA Department will ensure that all documents and records are controlled. For this

purpose the QA Department will establish a unique identification number for each

document and record.

The QA Department will ensure that each department of the organization should establish

SOPs for relevant activities of the department and also prepare job description for each

designation. The QA staff will monitor that all activities are carried out as per the

established SOPs. They will also ensure that every individual is aware of his job

description. This department will also keep a check on maintaining proper record of each

activity being carried out by the departments.

The QA Department will prepare different plans of monitoring the activities of all

departments. These plans may include Spot/Snap checks by the QA Observers on daily

basis, weekly/monthly supervisory checks by the QA department, monthly operations

meeting, Management review meetings on specified frequency and Internal/External

Audits as per annual plans.

Any violation of written procedures/instructions will be termed as CAR whereas the

potential hazards (not violation of written procedures) will be termed as PAR. The

CARs/PARs will be initiated whenever violation or potential hazard is observed by the QA

staff/supervisors. Corrective actions on these CARs/PARs will be taken by the respective

department and the action will be confirmed by the QA staff through follow up visits.

Similarly the audit reports will be compiled after each internal/external audit and will be

followed by raising of CARs/PARs.

The QA Department may establish a procedure to ask customer feedback with specified

intervals from all customers. Observation/complaint (if any) will be actioned through

raising of CARs/PARs. Corrective actions on these CARs/PARs will be ensured by the

QA staff through follow up visits.

Page 10 of 16

3.2 Standards

Standard Reference Monitoring and Assurance

Documentation QMS Ensure the documents and records are

controlled through internal & external audits,

spot/snap checks with regular intervals

Evaluation Auditing Implementation of the documented

standards

Record Keeping Auditing Evidences of all activities

Page 11 of 16

4 Coaching & Mentoring

The QA Department will arrange awareness classes on all safety related activities for all

personnel of the organization at specified frequency or whenever required. QA

department will maintain a record of the participation of such classes.

Page 12 of 16

5 Deliverables Reviews & Audits

5.1 Deliverable Reviews

Deliverable to Review When Reviewed by Quality

Assurance (Status or Criteria)

How Reviewed by Quality Assurance

All fruits and vegetables On receipt from suppliers Randomly on a specified percentage

All fruits and vegetables At segregation point Randomly on a specified percentage

All fruits and vegetables During Packing Randomly on a specified percentage

All fruits and vegetables At outlets Randomly on a specified percentage

5.2 Process Reviews

Process to Review When Reviewed by Quality

Assurance (Status or Criteria)

How Reviewed by Quality Assurance

All processes (purchasing,

segregation, packing, delivering)

Any complaint from the customer At different points with increase

frequency of inspection

All processes (purchasing,

segregation, packing, delivering)

Drastic change in climate At different points with increase

frequency of inspection

All processes (purchasing,

segregation, packing, delivering)

Change in market demand At different points with increase

frequency of inspection

All processes (purchasing,

segregation, packing, delivering)

QA observers report At different points with increase

frequency of inspection

5.3 Quality Assurance Progress Reviews

Spot/Snap checks by the QA Observers on daily basis.

Spot/Snap checks by AMQA on weekly basis.

Spot/Snap check by MQA on monthly basis.

Coordination Council Meeting on monthly basis.

Customer feedback by QA Department on quarterly basis.

Internal Audits conducted by QA Department on six monthly basis.

Management Review Meeting on six monthly basis.

External Audit by representative of Accreditation body once in a year.

5.4 Quality Assurance Lessons Learned Review

Major/combined points collected in all departments during spot/snap checks and internal

audits.

Page 13 of 16

5.5 Independent Review of Quality Assurance

Coordination Council Meeting on monthly basis.

Internal Audits conducted by QA Department on six monthly basis.

Customer feedback by QA Department on quarterly basis.

Management Review Meeting on six monthly basis.

External Audit by representative of Accreditation body once in a year.

5.6 Schedule of Quality Assurance Activities

Stage quality by the QA Observers at every stage on daily basis.

Random check by AMQA on weekly basis.

Random check of all products by MQA on monthly basis.

Annual meeting plan.

Six monthly reviews.

Annual Audit Plan.

Page 14 of 16

6 Feedback & Reports

Reports and Quality Records Provided to Whom Provided When Provided How

Feedbacks of customers Top Management Quarterly basis On specified form

Spot/Snap check record Top Management Whenever observed On specified form

Reports of Audits Top Management After every Audit On specified form

Corrective Action Request (CAR) &

Preventive Action Request (PAR)

Top Management Whenever initiated On specified form

Customer Complaints Top Management Whenever received On specified form

Page 15 of 16

7 Problem Reporting & Corrective Action

When a violation of written procedure is observed by QA Observer, AMQA, MQA or

internal/external auditor, a corrective action request (CAR) will be initiated on a specified

form. Similarly when a potential hazard (Not a violation of written procedure) is observed,

the preventive action request (PAR) is initiated. The corrective action on these

CARs/PARs will be completed by the concerned HODs and action taken will be intimated

to MQA. The MQA will ensure the action taken during his follow up visit and the CAR will

be closed accordingly. The HODs will also find out the root cause of the CARs and will

take preventive actions to avoid reoccurring of similar CARs. The unresolved issues will

be brought in the notice of top management on monthly basis by MQA.

Page 16 of 16

Potrebbero piacerti anche

- Quality Assurance Plan A Complete Guide - 2020 EditionDa EverandQuality Assurance Plan A Complete Guide - 2020 EditionNessuna valutazione finora

- QA Plan Template BlankDocumento31 pagineQA Plan Template Blankorawan_j100% (4)

- Quality assurance QA The Ultimate Step-By-Step GuideDa EverandQuality assurance QA The Ultimate Step-By-Step GuideNessuna valutazione finora

- Quality Assurance PlanDocumento12 pagineQuality Assurance Plannyquisttt100% (1)

- Quality Assurance Plan TemplateDocumento7 pagineQuality Assurance Plan Templateapi-369888877% (13)

- Supplier Quality Management System A Complete Guide - 2020 EditionDa EverandSupplier Quality Management System A Complete Guide - 2020 EditionNessuna valutazione finora

- The Steps of Quality Assurance ProcessDocumento4 pagineThe Steps of Quality Assurance ProcessAnjum BalochNessuna valutazione finora

- Quality Assurance ManualDocumento29 pagineQuality Assurance ManualpoojanewNessuna valutazione finora

- Online Library Management System: Software Quality Assurance Plan For TheDocumento8 pagineOnline Library Management System: Software Quality Assurance Plan For Theroja50% (2)

- Appendix 1 Quality Assurance PlanDocumento6 pagineAppendix 1 Quality Assurance PlanRio Marthin Tambunan100% (1)

- Example Quality PlanDocumento11 pagineExample Quality PlanSeida Glez Zuazua100% (1)

- Quality Control and Quality Assurance ManualDocumento41 pagineQuality Control and Quality Assurance ManualMamadou Thioye100% (1)

- Quality Assurance Strategic PlanDocumento16 pagineQuality Assurance Strategic PlanSyed Moinullah HussainiNessuna valutazione finora

- QA Process and ProceduresDocumento4 pagineQA Process and ProceduresLucy SuriNessuna valutazione finora

- Software Quality Assurance Plan PDFDocumento35 pagineSoftware Quality Assurance Plan PDFanjas_tsNessuna valutazione finora

- Quality Assurance ProcessDocumento130 pagineQuality Assurance Processbrijeshcoco100% (1)

- Quality Assurance ManualDocumento113 pagineQuality Assurance ManualSehrish Mohsin100% (1)

- Software Quality Assurance PlanDocumento8 pagineSoftware Quality Assurance PlanAhmad Shahid100% (2)

- Quality Assurance PlanDocumento2 pagineQuality Assurance PlanKarmyog Hi-Tech Machineries InfoNessuna valutazione finora

- QualityDocumento42 pagineQualityStone100% (1)

- Example Quality PlanDocumento11 pagineExample Quality PlanzafeerNessuna valutazione finora

- Quality System Manual (ISO 9001: 2000) : Hi-Tech Engineering Corporation India Pvt. LTDDocumento30 pagineQuality System Manual (ISO 9001: 2000) : Hi-Tech Engineering Corporation India Pvt. LTDAdminGauriRenakeNessuna valutazione finora

- QA QC ManualDocumento25 pagineQA QC ManualWaldo At100% (1)

- QA-2 - Quality Assurance - Simple Quality Management - CompletedDocumento15 pagineQA-2 - Quality Assurance - Simple Quality Management - CompletedSoe LwinNessuna valutazione finora

- Quality Assurance and Quality ControlDocumento17 pagineQuality Assurance and Quality Controltraslie0% (1)

- QA Processes - FoundationDocumento8 pagineQA Processes - FoundationCristina Silvia Maria BaciuNessuna valutazione finora

- PMI 05 100 Quality Management PlanDocumento37 paginePMI 05 100 Quality Management PlanJohn Truzcak100% (1)

- Asq What Is A Quality PlanDocumento3 pagineAsq What Is A Quality PlanCloud RedfieldNessuna valutazione finora

- Quality Assurance Plan DocumentDocumento6 pagineQuality Assurance Plan Documentachari_swapnil100% (1)

- 003 Qualification and Validation An Overview1Documento45 pagine003 Qualification and Validation An Overview1Dr.Adel Salem Sultan100% (4)

- CalibrationDocumento6 pagineCalibrationMadhavan RamNessuna valutazione finora

- Audit Question SampleDocumento27 pagineAudit Question SampleimamudeenNessuna valutazione finora

- Project-Specific Quality PlanDocumento9 pagineProject-Specific Quality PlanAlmario Sagun100% (2)

- Quality Manual TemplateDocumento40 pagineQuality Manual TemplateDarthVader975Nessuna valutazione finora

- Quality Assurance For Service IndustriesDocumento16 pagineQuality Assurance For Service IndustriesDr Srinivasan Nenmeli -K100% (11)

- QA QC ManualDocumento58 pagineQA QC Manualoregomez432963Nessuna valutazione finora

- Quality AssuranceDocumento47 pagineQuality AssuranceSheila Mae MalesidoNessuna valutazione finora

- Quality Assurance Plan ChecklistDocumento8 pagineQuality Assurance Plan ChecklistJanell Parkhurst, PMP100% (8)

- Quality Control and Quality AssuranceDocumento16 pagineQuality Control and Quality AssurancemuhibNessuna valutazione finora

- Design and Development ISODocumento7 pagineDesign and Development ISObrenda smith100% (1)

- Test Strategy Document: Version #: Date of IssueDocumento6 pagineTest Strategy Document: Version #: Date of IssuevenukomanapalliNessuna valutazione finora

- Validation ReportDocumento73 pagineValidation ReportWahida Febriana100% (1)

- Quality AssuranceDocumento50 pagineQuality Assurancedirregular92% (13)

- Quality Assurance and Quality ControlDocumento23 pagineQuality Assurance and Quality Controlamitywave1Nessuna valutazione finora

- Validation Part1Documento39 pagineValidation Part1Andy Rojas100% (2)

- Quality Objectives Cy 2015: Bicol UniversityDocumento3 pagineQuality Objectives Cy 2015: Bicol UniversityChristian MedelNessuna valutazione finora

- Quality Control PlanDocumento53 pagineQuality Control PlanMuhammad Irfan76% (17)

- QC, QA and GMPDocumento45 pagineQC, QA and GMPsiddhuNessuna valutazione finora

- Identification and TraceabilityDocumento3 pagineIdentification and TraceabilityRainer-Slawetzki100% (1)

- 702 AssignmentDocumento29 pagine702 AssignmentAsim AkbarNessuna valutazione finora

- Total Quality Management (Volkswagen) : ERP AssignmentDocumento11 pagineTotal Quality Management (Volkswagen) : ERP AssignmentSrihari UttanurNessuna valutazione finora

- QMS Manual Update TarasimaDocumento25 pagineQMS Manual Update TarasimasahadatNessuna valutazione finora

- Process Approach-Tqm StudyDocumento9 pagineProcess Approach-Tqm StudyShekinah Faith RequintelNessuna valutazione finora

- Health, Safety and EnvironmentDocumento8 pagineHealth, Safety and Environmentfdfddf dfsdfNessuna valutazione finora

- QADocumento117 pagineQANikhil ArtNessuna valutazione finora

- Quality Management in Aviation IndustryDocumento52 pagineQuality Management in Aviation IndustryMichelle Peterson92% (12)

- Isrs7 PSM Brochure Rev 7 - tcm155-273420Documento12 pagineIsrs7 PSM Brochure Rev 7 - tcm155-273420Fani Purnama HasanNessuna valutazione finora

- Total Quality Management: January 2017Documento11 pagineTotal Quality Management: January 2017shubham moonNessuna valutazione finora

- PharmaceuticalQualityAssurance CleanedDocumento5 paginePharmaceuticalQualityAssurance CleanedTomás Zamorano FernándezNessuna valutazione finora

- Swabi IntroductionDocumento12 pagineSwabi IntroductionSajeel ZamanNessuna valutazione finora

- Sample Paper ABLDocumento8 pagineSample Paper ABLsuhailhansNessuna valutazione finora

- Cpec (China-Pakistan Ecenomic Corridor)Documento3 pagineCpec (China-Pakistan Ecenomic Corridor)Sajeel ZamanNessuna valutazione finora

- Globalization of KFC (Kentucky Fried Chicken) : Presented By: Hina AfridiDocumento12 pagineGlobalization of KFC (Kentucky Fried Chicken) : Presented By: Hina AfridiSajeel ZamanNessuna valutazione finora

- Recruitment and SelectionDocumento16 pagineRecruitment and SelectionSajeel ZamanNessuna valutazione finora

- Aldi Edition 18 Full PDFDocumento4 pagineAldi Edition 18 Full PDFTalha KhubaibNessuna valutazione finora

- AssignmentDocumento2 pagineAssignmentSajeel ZamanNessuna valutazione finora

- Roles and Duties of Operation ManagerDocumento10 pagineRoles and Duties of Operation ManagerSajeel ZamanNessuna valutazione finora

- Questionnaire On Job Satisfaction Level of The EmployeesDocumento4 pagineQuestionnaire On Job Satisfaction Level of The EmployeesSajeel ZamanNessuna valutazione finora

- Consumer BehaviorDocumento4 pagineConsumer BehaviorSajeel ZamanNessuna valutazione finora

- Consumer's Preferences and PerceptionsDocumento19 pagineConsumer's Preferences and PerceptionsSajeel ZamanNessuna valutazione finora

- GlobalizationDocumento23 pagineGlobalizationSajeel ZamanNessuna valutazione finora

- Marketing Mix and The Brand Reputation of NokiaDocumento15 pagineMarketing Mix and The Brand Reputation of NokiaImran KhanNessuna valutazione finora

- Deviance and Its TypesDocumento27 pagineDeviance and Its TypesSajeel Zaman100% (1)

- Invitation Letter ExampleDocumento1 paginaInvitation Letter ExampleSajeel Zaman100% (1)

- Kinds of Sentence According To UseDocumento3 pagineKinds of Sentence According To UseSajeel Zaman0% (1)

- Intro To BusinessDocumento24 pagineIntro To BusinessSajeel ZamanNessuna valutazione finora

- Template For Gap AnalysisDocumento14 pagineTemplate For Gap AnalysisSajeel ZamanNessuna valutazione finora

- 177015Documento11 pagine177015ttttaaaayyyyuuuuNessuna valutazione finora

- Higher Education 2010Documento2 pagineHigher Education 2010Sajeel ZamanNessuna valutazione finora

- Keyboard ShortcutsDocumento2 pagineKeyboard ShortcutsSajeel ZamanNessuna valutazione finora

- Template For Gap AnalysisDocumento14 pagineTemplate For Gap AnalysisSajeel ZamanNessuna valutazione finora

- Drug AbuseDocumento5 pagineDrug AbuseSajeel ZamanNessuna valutazione finora

- TCS Express and LogisticsDocumento12 pagineTCS Express and LogisticsSajeel ZamanNessuna valutazione finora

- KFC ReportDocumento14 pagineKFC ReportSajeel ZamanNessuna valutazione finora

- Telecommunication Switching Systems and Networks by Thiagarajan Viswanathan Manav Bhatnagar B00tqoystkDocumento5 pagineTelecommunication Switching Systems and Networks by Thiagarajan Viswanathan Manav Bhatnagar B00tqoystkKittu KumarNessuna valutazione finora

- Blender 04Documento38 pagineBlender 04Ana Maria100% (1)

- A Transactive Energy Future PDFDocumento6 pagineA Transactive Energy Future PDFGilberto CastrejeNessuna valutazione finora

- Demographic Questions: Imagineh2O'S Water Energy Nexus Prize Competition Younoodle Registration QuestionsDocumento3 pagineDemographic Questions: Imagineh2O'S Water Energy Nexus Prize Competition Younoodle Registration QuestionstmangatNessuna valutazione finora

- HILTI Typical Plumbing ApplicationsDocumento140 pagineHILTI Typical Plumbing ApplicationskuraimundNessuna valutazione finora

- Pioneer pdp-424mv Pdp-42mve1 (ET)Documento122 paginePioneer pdp-424mv Pdp-42mve1 (ET)Manuel PeraltaNessuna valutazione finora

- P287 SCIL Programming BasicsDocumento78 pagineP287 SCIL Programming BasicsOscar GarciaNessuna valutazione finora

- Manual New AswanDocumento18 pagineManual New AswanmohamedmosallamNessuna valutazione finora

- Appendix 1: Lesson Plan (Template)Documento4 pagineAppendix 1: Lesson Plan (Template)Anonymous X7u8sMNessuna valutazione finora

- Blue Brain-The Future TechnologyDocumento27 pagineBlue Brain-The Future TechnologyZuber MdNessuna valutazione finora

- BTW-ST300MW Pure Sine Wave Inverter ManualDocumento15 pagineBTW-ST300MW Pure Sine Wave Inverter ManualCarlos ZubietaNessuna valutazione finora

- 90 61 085 Transportation ValvesDocumento18 pagine90 61 085 Transportation ValvesarrikanNessuna valutazione finora

- Drainage CapacityDocumento33 pagineDrainage Capacityfan_luc89Nessuna valutazione finora

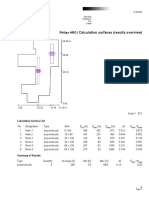

- Calculation Surfaces (Results Overview) : Philips HRODocumento4 pagineCalculation Surfaces (Results Overview) : Philips HROsanaNessuna valutazione finora

- Types of CCTVDocumento12 pagineTypes of CCTVpradeeplava950Nessuna valutazione finora

- Astm D979 12 PDFDocumento7 pagineAstm D979 12 PDFJohnCarlosGilNessuna valutazione finora

- SAP ABAP ResumeDocumento3 pagineSAP ABAP Resumeshakti1392821Nessuna valutazione finora

- Chapter 6 PDFDocumento26 pagineChapter 6 PDFDayang Azraa AfeefaaNessuna valutazione finora

- Acetic 2520acid 2520 Energy 2520balanceDocumento6 pagineAcetic 2520acid 2520 Energy 2520balancembeni0751Nessuna valutazione finora

- C ElanchezhianDocumento8 pagineC ElanchezhiankeshavuvceNessuna valutazione finora

- PanavisionSVI ELIS 1024A Datasheet PDS0004RevJDocumento13 paginePanavisionSVI ELIS 1024A Datasheet PDS0004RevJAmarnath M DamodaranNessuna valutazione finora

- IOT SyllabusDocumento3 pagineIOT Syllabuspoojan thakkarNessuna valutazione finora

- CASE STUDY - Collapsed Wind Tower - A Root Cause Investigation (Element Materials Technology)Documento3 pagineCASE STUDY - Collapsed Wind Tower - A Root Cause Investigation (Element Materials Technology)engrrahman3135Nessuna valutazione finora

- Serie: Guía RápidaDocumento12 pagineSerie: Guía RápidalumapueNessuna valutazione finora

- Manual de Partes LDW1003 (6B01E0)Documento54 pagineManual de Partes LDW1003 (6B01E0)Enrique AssmannNessuna valutazione finora

- Artificial LightingDocumento7 pagineArtificial Lightingkookie maeNessuna valutazione finora

- 2020.04.24 BC thamtratonghop TKCS Trường Fulbright Lần 1Documento32 pagine2020.04.24 BC thamtratonghop TKCS Trường Fulbright Lần 1Khac Hoang PhamNessuna valutazione finora

- OpenCV 3.0 Computer Vision With Java - Sample ChapterDocumento27 pagineOpenCV 3.0 Computer Vision With Java - Sample ChapterPackt PublishingNessuna valutazione finora

- Task 3.a-WordDocumento22 pagineTask 3.a-WordVenkata jahnavi PunatiNessuna valutazione finora

- CE5604 Term PaperDocumento6 pagineCE5604 Term PaperCemre CaglarNessuna valutazione finora

- Sully: The Untold Story Behind the Miracle on the HudsonDa EverandSully: The Untold Story Behind the Miracle on the HudsonValutazione: 4 su 5 stelle4/5 (103)

- The Fabric of Civilization: How Textiles Made the WorldDa EverandThe Fabric of Civilization: How Textiles Made the WorldValutazione: 4.5 su 5 stelle4.5/5 (58)

- Hero Found: The Greatest POW Escape of the Vietnam WarDa EverandHero Found: The Greatest POW Escape of the Vietnam WarValutazione: 4 su 5 stelle4/5 (19)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaDa EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNessuna valutazione finora

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDa EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNessuna valutazione finora

- A Place of My Own: The Architecture of DaydreamsDa EverandA Place of My Own: The Architecture of DaydreamsValutazione: 4 su 5 stelle4/5 (242)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestDa EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestValutazione: 4 su 5 stelle4/5 (28)

- Highest Duty: My Search for What Really MattersDa EverandHighest Duty: My Search for What Really MattersNessuna valutazione finora

- Reality+: Virtual Worlds and the Problems of PhilosophyDa EverandReality+: Virtual Worlds and the Problems of PhilosophyValutazione: 4 su 5 stelle4/5 (24)

- 35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Da Everand35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Valutazione: 4 su 5 stelle4/5 (21)

- Pale Blue Dot: A Vision of the Human Future in SpaceDa EverandPale Blue Dot: A Vision of the Human Future in SpaceValutazione: 4.5 su 5 stelle4.5/5 (588)

- The End of Craving: Recovering the Lost Wisdom of Eating WellDa EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellValutazione: 4.5 su 5 stelle4.5/5 (81)

- Packing for Mars: The Curious Science of Life in the VoidDa EverandPacking for Mars: The Curious Science of Life in the VoidValutazione: 4 su 5 stelle4/5 (1395)

- System Error: Where Big Tech Went Wrong and How We Can RebootDa EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootNessuna valutazione finora

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationDa EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationValutazione: 4.5 su 5 stelle4.5/5 (46)

- Transformed: Moving to the Product Operating ModelDa EverandTransformed: Moving to the Product Operating ModelValutazione: 4 su 5 stelle4/5 (1)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerDa EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerValutazione: 4.5 su 5 stelle4.5/5 (122)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureDa EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureValutazione: 5 su 5 stelle5/5 (125)

- Mini Farming: Self-Sufficiency on 1/4 AcreDa EverandMini Farming: Self-Sufficiency on 1/4 AcreValutazione: 4 su 5 stelle4/5 (76)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyDa EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNessuna valutazione finora

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDa EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterNessuna valutazione finora

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDa EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNessuna valutazione finora

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerDa EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerValutazione: 4.5 su 5 stelle4.5/5 (54)

- The Weather Machine: A Journey Inside the ForecastDa EverandThe Weather Machine: A Journey Inside the ForecastValutazione: 3.5 su 5 stelle3.5/5 (31)