Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CIP 16 - Measuring Concrete Flexural Strength

Caricato da

Mrcoke Seie0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

240 visualizzazioni2 pagineFlexural strength measures a concrete beam's ability to resist failure in bending. It is determined by loading concrete beams and measuring the modulus of rupture. Flexural strength testing is sensitive to specimen preparation and handling. While useful for design and research, flexural strength testing is not recommended for field acceptance due to variability. Compressive strength testing of cylinders is preferred for quality control and acceptance due to being more reliable and familiar to inspectors. When correlations are established, compressive strengths of cores can be used to estimate flexural strength for investigation of low strengths.

Descrizione originale:

Flexural Strength of concrete

Titolo originale

Flexural Strength

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoFlexural strength measures a concrete beam's ability to resist failure in bending. It is determined by loading concrete beams and measuring the modulus of rupture. Flexural strength testing is sensitive to specimen preparation and handling. While useful for design and research, flexural strength testing is not recommended for field acceptance due to variability. Compressive strength testing of cylinders is preferred for quality control and acceptance due to being more reliable and familiar to inspectors. When correlations are established, compressive strengths of cores can be used to estimate flexural strength for investigation of low strengths.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

240 visualizzazioni2 pagineCIP 16 - Measuring Concrete Flexural Strength

Caricato da

Mrcoke SeieFlexural strength measures a concrete beam's ability to resist failure in bending. It is determined by loading concrete beams and measuring the modulus of rupture. Flexural strength testing is sensitive to specimen preparation and handling. While useful for design and research, flexural strength testing is not recommended for field acceptance due to variability. Compressive strength testing of cylinders is preferred for quality control and acceptance due to being more reliable and familiar to inspectors. When correlations are established, compressive strengths of cores can be used to estimate flexural strength for investigation of low strengths.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

CIP 16 - Flexural Strength Concrete

WHAT is Flexural Strength?

Flexural strength is one measure of the tensile strength

of concrete. It is a measure of an unreinforced con-

crete beam or slab to resist failure in bending. It is

measured by loading 6 x 6-inch (150 x 150-mm) con-

crete beams with a span length at least three times the

depth. The flexural strength is expressed as Modulus

of Rupture (MR) in psi (MPa) and is determined by

standard test methods ASTM C 78 (third-point load-

ing) or ASTM C 293 (center-point loading).

Flexural MR is about 10 to 20 percent of compressive

strength depending on the type, size and volume of

coarse aggregate used. However, the best correlation

for specific materials is obtained by laboratory tests

for given materials and mix design. The MR deter-

mined by third-point loading is lower than the MR de-

termined by center-point loading, sometimes by as much

as 15%.

Designers of pavements use a theory based on flex-

ural strength. Therefore, laboratory mix design based

on flexural strength tests may be required, or a

cementitious material content may be selected from

past experience to obtain the needed design MR. Some

also use MR for field control and acceptance of pave-

ments. Very few use flexural testing for structural con-

crete. Agencies not using flexural strength for field con-

trol generally find the use of compressive strength con-

venient and reliable to judge the quality of the concrete

as delivered.

Beam specimens must be properly made in the field.

Pavement concrete mixtures are stiff (1/2 to 2

1

/2-inch

slump). Consolidate by vibration in accordance with

ASTM C 31 and tap sides to release air pockets. For

higher slump, after rodding, tap the molds to release

air pockets and spade along the sides to consolidate.

Never allow the beam surfaces to dry at any time.

Immerse in saturated limewater for at least 20 hours

before testing.

Specifications and investigation of apparent low

strengths should take into account the higher variabil-

ity of flexural strength results. Standard deviation for

concrete flexural strengths up to 800 psi (5.5 MPa) for

projects with good control range from about 40 to 80

psi (0.3 to 0.6 MPa). Standard deviation values over

100 psi (0.7 MPa) may indicate testing problems. There

is a high likelihood that testing problems, or moisture

differences within a beam caused from premature dry-

ing, will cause low strength.

Where a correlation between flexural and compres-

sive strength has been established in the laboratory,

core strengths by ASTM C 42 can be used for com-

pressive strength to check against the desired value

using the ACI 318 criteria of 85 percent of specified

strength for the average of three cores. It is impracti-

cal to saw beams from a slab for flexural testing. Saw-

ing beams will greatly reduce measured flexural

WHY Test Flexural Strength?

How to Use Flexural Strength?

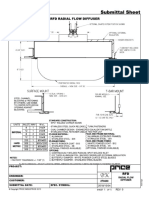

ASTM C 78 - Third-Point Loading - half the load is applied at each third

of the span length. MR is lower than center-point loading. Maximum

stress is present over the center 1/3 portion of the beam

ASTM C 293 - Center-Point Loading - the entire load is applied at the

center span. The MR will be greater than third-point loading. The maxi-

mum stress is present only at the center of the beam

1/2 Load 1/2 Load

Load

1988, 1989, 1991 AND 2000

strength and should not be done. In some instances,

splitting tensile strength of cores by ASTM C 496 is

used, but experience is limited on how to apply the data.

Another procedure for in-place strength investigation

uses compressive strength of cores calibrated by com-

parison with acceptable placements in proximity to the

concrete in question:

WHAT are the Problems with Flexure?

Flexural tests are extremely sensitive to specimen prepa-

ration, handling, and curing procedure. Beams are very

heavy and can be damaged when handled and trans-

ported from the jobsite to the lab. Allowing a beam to

dry will yield lower strengths. Beams must be cured in

a standard manner, and tested while wet. Meeting all

these requirements on a jobsite is extremely difficult

often resulting in unreliable and generally low MR val-

ues. A short period of drying can produce a sharp

drop in flexural strength.

Many state highway agencies have used flexural

strength but are now changing to compressive strength

or maturity concepts for job control and quality assur-

ance of concrete paving. Cylinder compressive

strengths are also used for concrete structures.

The data point to a need for a review of current test-

ing procedures. They suggest also that, while the flex-

ural strength test is a useful tool in research and in

laboratory evaluation of concrete ingredients and

proportions, it is too sensitive to testing variations

to be usable as a basis for the acceptance or rejec-

tion of concrete in the field. (Reference 3)

NRMCA and the American Concrete Pavement As-

sociation (ACPA) have a policy that compressive

strength testing is the preferred method of concrete

acceptance and that certified technicians should con-

duct the testing. ACI Committees 325 and 330 on con-

crete pavement construction and design and the Port-

land Cement Association (PCA) point to the use of

compressive strength tests as more convenient and

reliable.

The concrete industry and inspection and testing agen-

cies are much more familiar with traditional cylinder

compression tests for control and acceptance of con-

crete. Flexure can be used for design purposes, but the

corresponding compressive strength should be used to

order and accept the concrete. Any time trial batches

are made; both flexural and compressive tests should

be made so that a correlation can be developed for

field control.

References:

1. How Should Strength be Measured for Concrete Paving? Ri-

chard C. Meininger, NRMCA TIL 420, and Data Summary,

NRMCA TIL 451, NRMCA, Silver Spring, MD.

2. Concrete Strength Testing, Peggy Carrasquillo, Chapter 14,

ASTM STP 169C, Significance of Tests and Properties of

Concrete and Concrete-Making Materials, American Society

for Testing and Mater-ials, West Conshohocken, PA.

3. Studies of Flexural Strength of Concrete, Part 3, Effects of

Variations in Testing Procedures, Stanton Walker and D. L.

Bloem, NRMCA Publication No. 75, NRMCA, Silver Spring,

MD.

4. Variation of Laboratory Concrete Flexural Strength Tests, W.

Charles Greer, Jr., ASTM Cement, Concrete and Aggregates,

Winter, 1983, American Society for Testing and Materials,

West Conshohocken, PA.

5. Concrete Mixture Evaluation and Acceptance for Air Field

Pavements Richard C. Meininger and Norm Nelson, NRMCA

Publication 178, September 1991, NRMCA, Silver Spring,

MD.

6. Compression vs. Flexural Strength for Quality Control of Pave-

ments, Steve Kosmatka, CTT PL 854, 1985, Portland Cement

Association, Skokie, IL.

7. Time to Rein in the Flexure Test, Orrin Riley, ACI Concrete

International, August, 1994, American Concrete Institute,

Farmington Hills, MI.

Method to Troubleshoot Flexural Strength Using

Compressive Strength of Cores

Lot 1 Lot 2 Lot 3

MR, psi 730 (OK) 688 (?) 731 (OK)

Core, psi 4492 4681 4370

Estimate Flexural Strength of Lot 2 =

4681 x (

730 + 731

) = 771 psi (OK)

4492 + 4370

Potrebbero piacerti anche

- A Guide To Flame Photometer AnalysisDocumento17 pagineA Guide To Flame Photometer Analysisarun231187100% (1)

- RefractoriesDocumento11 pagineRefractoriesANSH JAINNessuna valutazione finora

- Rotary Kiln Alignment & InspectionDocumento5 pagineRotary Kiln Alignment & InspectionAhmad Husni RizalNessuna valutazione finora

- Classification & Properties of Refractories-1Documento4 pagineClassification & Properties of Refractories-1pothan33% (3)

- Ceramic Phase Equilibrium Diagrams PDFDocumento42 pagineCeramic Phase Equilibrium Diagrams PDFPelita Mu'minatus SholihahNessuna valutazione finora

- Flame Photometer TDF-TMFDocumento2 pagineFlame Photometer TDF-TMFvtl_murthal6240Nessuna valutazione finora

- Curricullum VitaeDocumento2 pagineCurricullum Vitaeujang.pantri2001100% (1)

- Cement Industry To Select Energy Efficiency MeasuresDocumento14 pagineCement Industry To Select Energy Efficiency MeasureszeeNessuna valutazione finora

- White CementDocumento11 pagineWhite CementLdiabiNessuna valutazione finora

- ch01 Mekanik BahanDocumento78 paginech01 Mekanik BahanAzman SamerNessuna valutazione finora

- DATE:-2020.01.07 Experiment No: - 09 Experiment Name: - Determination of Ash Content Natural RubberDocumento6 pagineDATE:-2020.01.07 Experiment No: - 09 Experiment Name: - Determination of Ash Content Natural RubberChalani KuruneruNessuna valutazione finora

- Cement Eng 1 PDFDocumento48 pagineCement Eng 1 PDFBülent BulutNessuna valutazione finora

- Refractorymaterials 150313053315 Conversion Gate01Documento19 pagineRefractorymaterials 150313053315 Conversion Gate01tesfayregs gebretsadikNessuna valutazione finora

- CementDocumento54 pagineCementGSN World100% (1)

- Collective SecurityDocumento10 pagineCollective Securitybakex645Nessuna valutazione finora

- Engineering Materials: For Further VolumesDocumento168 pagineEngineering Materials: For Further VolumesKhalid AbdohNessuna valutazione finora

- Coal Miners SuitDocumento4 pagineCoal Miners SuitSudipta BainNessuna valutazione finora

- Fluid Mechanics Textbook on ScribdDocumento2 pagineFluid Mechanics Textbook on ScribdJebDes0% (2)

- Fluidised Bed SeederDocumento11 pagineFluidised Bed SeederAmritanshu ManuNessuna valutazione finora

- Process Technology For Efficient and Sustainable Cement ProductionDocumento10 pagineProcess Technology For Efficient and Sustainable Cement ProductionAnonymous NxpnI6jCNessuna valutazione finora

- Bending Test Determines Ductility of Steel Reinforcing BarsDocumento6 pagineBending Test Determines Ductility of Steel Reinforcing BarsWes FerrerNessuna valutazione finora

- Costs of Individual Equipment ExplainedPacked towers:C, = 1.7C, + Nf&fC, + CDocumento7 pagineCosts of Individual Equipment ExplainedPacked towers:C, = 1.7C, + Nf&fC, + CNishithNessuna valutazione finora

- What Is Green Concrete PDFDocumento3 pagineWhat Is Green Concrete PDFVelchuri SairamNessuna valutazione finora

- Sleeve or Plain Bearing LubricationDocumento3 pagineSleeve or Plain Bearing LubricationVolety_Sarma_1703100% (1)

- Adaptive Software Development (ASD)Documento4 pagineAdaptive Software Development (ASD)Lord KoyoNessuna valutazione finora

- Fineness and StrengthDocumento19 pagineFineness and StrengthserkalemtNessuna valutazione finora

- Research Report On Library Facilities of Comilla UniversityDocumento12 pagineResearch Report On Library Facilities of Comilla Universityparvez khanNessuna valutazione finora

- Report in Technical Analysis CEMENTDocumento26 pagineReport in Technical Analysis CEMENTNatrium KirchhoffNessuna valutazione finora

- SN3148 - Use of Limestone in Cements PDFDocumento78 pagineSN3148 - Use of Limestone in Cements PDFKalindaMadusankaDasanayakaNessuna valutazione finora

- Smoke Tunnel ReportDocumento11 pagineSmoke Tunnel ReportRana HanzlaNessuna valutazione finora

- Lucky Cement - KPIDocumento1 paginaLucky Cement - KPITanha Larka KarachiNessuna valutazione finora

- Fluid Mechanics Lectures (1) (University of Baghdad) - Omar F. HasanDocumento14 pagineFluid Mechanics Lectures (1) (University of Baghdad) - Omar F. HasanOmar F. HasanNessuna valutazione finora

- Creep and Visco Lasticity: Empirical Creep Strain: GeneralDocumento10 pagineCreep and Visco Lasticity: Empirical Creep Strain: Generalksangeeth2000Nessuna valutazione finora

- Unit-3: Heat Balance Calculation: 9/8/2008 Section: Calculations By: PROCESS DEPTDocumento2 pagineUnit-3: Heat Balance Calculation: 9/8/2008 Section: Calculations By: PROCESS DEPTPradeepNessuna valutazione finora

- Industrial Waste As Alternative Fuel in Cement Industry: Its Impact On EnvironmentDocumento7 pagineIndustrial Waste As Alternative Fuel in Cement Industry: Its Impact On EnvironmentBilal El YoussoufiNessuna valutazione finora

- The Influence of Air-Fuel Ratio On Engine Performance and Pollutant Emission of An SI Engine Using Ethanol-Gasoline-Blended FuelsDocumento8 pagineThe Influence of Air-Fuel Ratio On Engine Performance and Pollutant Emission of An SI Engine Using Ethanol-Gasoline-Blended FuelsISLAM I. Fekry100% (1)

- Group - 5-Cement ProductionDocumento147 pagineGroup - 5-Cement ProductionAli Aliyev100% (1)

- Assessment of Laboratory Leaching Test For Predicting The Impact of Fill Material On Ground Water and Surface Water QualityDocumento173 pagineAssessment of Laboratory Leaching Test For Predicting The Impact of Fill Material On Ground Water and Surface Water QualityApriladi Putra PegaganNessuna valutazione finora

- TN680 MHTC 96 Drop CalorimetryDocumento9 pagineTN680 MHTC 96 Drop CalorimetryMiruna PetriaNessuna valutazione finora

- Composites TestingDocumento29 pagineComposites TestingThiru MoorthyNessuna valutazione finora

- RBC FGDocumento18 pagineRBC FGdragon_ecuNessuna valutazione finora

- Operations: The PlantDocumento4 pagineOperations: The Plantemad sabriNessuna valutazione finora

- The Cement Grinding Office: Blaine Specific Surface Area (Cement Density)Documento5 pagineThe Cement Grinding Office: Blaine Specific Surface Area (Cement Density)Anonymous XX9Om322lNessuna valutazione finora

- ENERGY STAR Guide For The Cement Industry 28-08-2013 FinalDocumento141 pagineENERGY STAR Guide For The Cement Industry 28-08-2013 Finalnsprasad88Nessuna valutazione finora

- 2010 Abstract Booklet Complete.9!28!10Documento67 pagine2010 Abstract Booklet Complete.9!28!10Manfred GithinjiNessuna valutazione finora

- MILL INTERNALS GENERAL INFORMATIONDocumento2 pagineMILL INTERNALS GENERAL INFORMATIONbrpnaidu2157Nessuna valutazione finora

- Ora 11 JonDocumento4 pagineOra 11 JonS.M. YAMINUR RAHMAN100% (1)

- 03 SOLVED Gravity Settling Chamber Problem 2016-17 PDFDocumento6 pagine03 SOLVED Gravity Settling Chamber Problem 2016-17 PDFmanelNessuna valutazione finora

- Duo FlexDocumento8 pagineDuo Flexdwindra ramadhan100% (1)

- Power Sector - 72 - UltraTech - Sewagram - 0Documento70 paginePower Sector - 72 - UltraTech - Sewagram - 0BHUVANESH MNessuna valutazione finora

- Energy Audit Helps Cement Plant Improve EfficiencyDocumento14 pagineEnergy Audit Helps Cement Plant Improve Efficiencytsrinivasan5083Nessuna valutazione finora

- The Importance of Proper Bearing LubricationDocumento7 pagineThe Importance of Proper Bearing LubricationSRINIVASA RAO DUVVADANessuna valutazione finora

- Modeling The Prediction of Compressive Strength For Cement andDocumento12 pagineModeling The Prediction of Compressive Strength For Cement andAnil Kumar Sharma100% (1)

- 6177-4 Press and Shrink FitsDocumento11 pagine6177-4 Press and Shrink FitsRajesh RajwadeNessuna valutazione finora

- Incomplete CombustionDocumento5 pagineIncomplete CombustionDineshkumarNessuna valutazione finora

- Machine Vibration Standards - Part 3 - Absolute-Machine SpecificDocumento12 pagineMachine Vibration Standards - Part 3 - Absolute-Machine SpecificRicardo Zevallos CruzNessuna valutazione finora

- CIP16-Flexural Strenght of ConcreteDocumento2 pagineCIP16-Flexural Strenght of Concrete7774R105Nessuna valutazione finora

- CIP16 - Flexural Strength of ConcreteDocumento2 pagineCIP16 - Flexural Strength of ConcretePECMURUGANNessuna valutazione finora

- CIP 16 - Flexural Strength of ConcreteDocumento2 pagineCIP 16 - Flexural Strength of ConcreteEkinawa AwanikeNessuna valutazione finora

- Flexural Strength of ConcreteDocumento3 pagineFlexural Strength of ConcretevikasNessuna valutazione finora

- Bagasse Ash as Effective Fly Ash Replacement in BricksDocumento6 pagineBagasse Ash as Effective Fly Ash Replacement in BricksMrcoke SeieNessuna valutazione finora

- Reinforced Concrete Beam DesignDocumento8 pagineReinforced Concrete Beam DesignLindy Kho100% (1)

- Waste Sector ProjectsDocumento5 pagineWaste Sector ProjectsMrcoke SeieNessuna valutazione finora

- Bagasse Ash as Effective Fly Ash Replacement in BricksDocumento6 pagineBagasse Ash as Effective Fly Ash Replacement in BricksMrcoke SeieNessuna valutazione finora

- BS 1014-1975 Specification For Pigments For Portland Cement and Portland Cement ProductsDocumento15 pagineBS 1014-1975 Specification For Pigments For Portland Cement and Portland Cement ProductsMrcoke SeieNessuna valutazione finora

- Road Sub BaseDocumento2 pagineRoad Sub BaseMrcoke SeieNessuna valutazione finora

- A Brief History of Pullout TestingDocumento10 pagineA Brief History of Pullout TestingMrcoke SeieNessuna valutazione finora

- Elcometer Adhesion Tester Brochure PDFDocumento11 pagineElcometer Adhesion Tester Brochure PDFPardhu YellaNessuna valutazione finora

- Road Sub BaseDocumento2 pagineRoad Sub BaseMrcoke SeieNessuna valutazione finora

- Testing and LabDocumento6 pagineTesting and LabMrcoke SeieNessuna valutazione finora

- Sand EquivalentDocumento11 pagineSand EquivalentMrcoke SeieNessuna valutazione finora

- MsDocumento1 paginaMsMrcoke SeieNessuna valutazione finora

- PumpsDocumento10 paginePumpsMrcoke SeieNessuna valutazione finora

- Damp Proof Membrane To PIFA Standard Datasheet 12-08-2011Documento3 pagineDamp Proof Membrane To PIFA Standard Datasheet 12-08-2011Mrcoke SeieNessuna valutazione finora

- Guidance Note 4-31-02 of The UK Water Research Centre.Documento6 pagineGuidance Note 4-31-02 of The UK Water Research Centre.Mrcoke SeieNessuna valutazione finora

- FiltrationDocumento15 pagineFiltrationMrcoke SeieNessuna valutazione finora

- MsDocumento1 paginaMsMrcoke SeieNessuna valutazione finora

- MsDocumento1 paginaMsMrcoke SeieNessuna valutazione finora

- Mechanical Completion ProcedureDocumento38 pagineMechanical Completion ProcedureNaPo Service100% (8)

- TDS Renderoc RGM IndiaDocumento4 pagineTDS Renderoc RGM IndiaKishore Nayak kNessuna valutazione finora

- TWJO-ITP-RDW-0013-CHK-003 Revb Pre-Cast RC-Pipe ChecklistDocumento2 pagineTWJO-ITP-RDW-0013-CHK-003 Revb Pre-Cast RC-Pipe ChecklistBangkit SamosirNessuna valutazione finora

- An Experimental Study On Strength of Concrete Using Tyre Rubber & Replacing Aggregates of Different Percentage With Tyre RubberDocumento3 pagineAn Experimental Study On Strength of Concrete Using Tyre Rubber & Replacing Aggregates of Different Percentage With Tyre RubberIJRT OnlineNessuna valutazione finora

- RFD Radial Flow Diffuser SubmittalDocumento2 pagineRFD Radial Flow Diffuser SubmittalJ.P. PazaNessuna valutazione finora

- Overview of History Ofconstruction Technology and EquipmentDocumento18 pagineOverview of History Ofconstruction Technology and EquipmentDipesh ChaudharyNessuna valutazione finora

- Engineering Specification for Ceramic Fiber Blanket InsulationDocumento5 pagineEngineering Specification for Ceramic Fiber Blanket InsulationlightsonsNessuna valutazione finora

- Project Quality Plan for Alumina and Coke SilosDocumento32 pagineProject Quality Plan for Alumina and Coke SilosSagar AliasjackeyNessuna valutazione finora

- HSC Members Behavior and Design under Axial and Flexural LoadsDocumento28 pagineHSC Members Behavior and Design under Axial and Flexural LoadsngodangquangNessuna valutazione finora

- LHS-DI-MAR-MEP-042 - Duct and Pipe Support - Diamond - R0 PDFDocumento2 pagineLHS-DI-MAR-MEP-042 - Duct and Pipe Support - Diamond - R0 PDFMelvin Angelo LopenarioNessuna valutazione finora

- Com-, Meaning "Together," and Struere Meaning "To Pile Up." in Addition To The Building of General Types of Construction (Physical Orientation)Documento7 pagineCom-, Meaning "Together," and Struere Meaning "To Pile Up." in Addition To The Building of General Types of Construction (Physical Orientation)Bienvenida Ycoy MontenegroNessuna valutazione finora

- Building or Construction ContractDocumento2 pagineBuilding or Construction ContractBest Bar EverNessuna valutazione finora

- Manish Shamrao Bhandarkawathekar.: - : Curriculam VitaeDocumento11 pagineManish Shamrao Bhandarkawathekar.: - : Curriculam VitaeSACHINNessuna valutazione finora

- TG4 - 17 Anchorage Systems For ScaffoldingDocumento24 pagineTG4 - 17 Anchorage Systems For ScaffoldingDerek ReddinNessuna valutazione finora

- Temporary Structures GuideDocumento27 pagineTemporary Structures GuideKaushikJainNessuna valutazione finora

- Methodology For Installation of Fire Pro PDFDocumento4 pagineMethodology For Installation of Fire Pro PDFswamyNessuna valutazione finora

- Tata Steel - MRVCDocumento16 pagineTata Steel - MRVCRahul NirbaanNessuna valutazione finora

- The Extec C-12: Features and Benefits BookDocumento21 pagineThe Extec C-12: Features and Benefits BookReyna CoaquiraNessuna valutazione finora

- ClarkDietrich - 20200622 - MasterStructuralDocumento102 pagineClarkDietrich - 20200622 - MasterStructuralJENPARK0Nessuna valutazione finora

- Sika Rapid Technology BrochureDocumento2 pagineSika Rapid Technology BrochuredipinnediyaparambathNessuna valutazione finora

- G+24 Project Structural Design Basis ReportDocumento28 pagineG+24 Project Structural Design Basis ReportShobhit Mohta100% (1)

- Thermal InsulationDocumento60 pagineThermal InsulationSpyros IliakisNessuna valutazione finora

- An Investigation Into The Behaviour of Scale Model Brick Walls PDFDocumento8 pagineAn Investigation Into The Behaviour of Scale Model Brick Walls PDFVíctor MolinaNessuna valutazione finora

- AWWCE Unit Rates For Pipe Work - LegaDocumento24 pagineAWWCE Unit Rates For Pipe Work - LegaMiko Abi0% (1)

- Single Station Manufacturing CellDocumento21 pagineSingle Station Manufacturing CellRafaelVegaCanNessuna valutazione finora

- Steel Design Problems With Solution (Using NSCP 2001, 2010 and 2015) - UPDATED-1 PDFDocumento76 pagineSteel Design Problems With Solution (Using NSCP 2001, 2010 and 2015) - UPDATED-1 PDFLC Lee60% (5)

- 2.4 Road Note 29 (RN-29)Documento33 pagine2.4 Road Note 29 (RN-29)Rajesh Khadka85% (13)

- TEC-131100 - MET-DoR-001 (Method Statement For Swimming Pool & Jacuzzi) (K)Documento16 pagineTEC-131100 - MET-DoR-001 (Method Statement For Swimming Pool & Jacuzzi) (K)Hoằng Phạm ĐứcNessuna valutazione finora

- Guidelines For Tank Foundation Designs (Process Industry Practices Pip)Documento83 pagineGuidelines For Tank Foundation Designs (Process Industry Practices Pip)Suresh Rao100% (2)

- CHAPTER-2 Selection OffoundationDocumento7 pagineCHAPTER-2 Selection Offoundationmalik macNessuna valutazione finora

- To Engineer Is Human: The Role of Failure in Successful DesignDa EverandTo Engineer Is Human: The Role of Failure in Successful DesignValutazione: 4 su 5 stelle4/5 (137)

- Chemical Process Safety: Learning from Case HistoriesDa EverandChemical Process Safety: Learning from Case HistoriesValutazione: 4 su 5 stelle4/5 (14)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDa EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNessuna valutazione finora

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksDa EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksValutazione: 5 su 5 stelle5/5 (1)

- Summary of Neil Postman's Amusing Ourselves to DeathDa EverandSummary of Neil Postman's Amusing Ourselves to DeathValutazione: 4 su 5 stelle4/5 (2)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDa EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNessuna valutazione finora

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationDa EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationValutazione: 4 su 5 stelle4/5 (18)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDa EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansValutazione: 4.5 su 5 stelle4.5/5 (21)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetDa EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetValutazione: 4.5 su 5 stelle4.5/5 (10)

- Cable Supported Bridges: Concept and DesignDa EverandCable Supported Bridges: Concept and DesignValutazione: 5 su 5 stelle5/5 (1)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeDa EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeValutazione: 4.5 su 5 stelle4.5/5 (59)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationDa EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNessuna valutazione finora

- Advanced Process Control: Beyond Single Loop ControlDa EverandAdvanced Process Control: Beyond Single Loop ControlNessuna valutazione finora

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentDa EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNessuna valutazione finora

- Methodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaDa EverandMethodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaNessuna valutazione finora

- Nuclear Energy in the 21st Century: World Nuclear University PressDa EverandNuclear Energy in the 21st Century: World Nuclear University PressValutazione: 4.5 su 5 stelle4.5/5 (3)

- Guidelines for Siting and Layout of FacilitiesDa EverandGuidelines for Siting and Layout of FacilitiesNessuna valutazione finora

- Guidelines for the Management of Change for Process SafetyDa EverandGuidelines for the Management of Change for Process SafetyNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Shallow Foundations: Discussions and Problem SolvingDa EverandShallow Foundations: Discussions and Problem SolvingValutazione: 5 su 5 stelle5/5 (1)