Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

IGt To IGf Circuit

Caricato da

damm35100%(1)Il 100% ha trovato utile questo documento (1 voto)

11K visualizzazioni5 pagineThis document describes a solution to allow greater ignition timing adjustment beyond +/- 6 degrees when using an e-manage ignition controller with Toyota 4AGZE and 7MGTE engines. The solution involves creating an external IGf signal generation circuit using an NPN transistor and resistor on a veroboard. This circuit generates an IGf signal from the ECU's IGt signal to fool the ECU into thinking the ignition timing has not changed, even when it has using the e-manage controller. Instructions are provided on how to build, install, and use the external IGf generation circuit.

Descrizione originale:

Toyota IGf ti IGt Circuit

Titolo originale

IGt to IGf Circuit

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document describes a solution to allow greater ignition timing adjustment beyond +/- 6 degrees when using an e-manage ignition controller with Toyota 4AGZE and 7MGTE engines. The solution involves creating an external IGf signal generation circuit using an NPN transistor and resistor on a veroboard. This circuit generates an IGf signal from the ECU's IGt signal to fool the ECU into thinking the ignition timing has not changed, even when it has using the e-manage controller. Instructions are provided on how to build, install, and use the external IGf generation circuit.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

11K visualizzazioni5 pagineIGt To IGf Circuit

Caricato da

damm35This document describes a solution to allow greater ignition timing adjustment beyond +/- 6 degrees when using an e-manage ignition controller with Toyota 4AGZE and 7MGTE engines. The solution involves creating an external IGf signal generation circuit using an NPN transistor and resistor on a veroboard. This circuit generates an IGf signal from the ECU's IGt signal to fool the ECU into thinking the ignition timing has not changed, even when it has using the e-manage controller. Instructions are provided on how to build, install, and use the external IGf generation circuit.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 5

Page 1 of 5

E-manage ignition timing with DLI 4AGZE and 7MGTE engines

Background

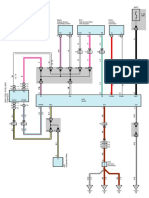

Some Toyota ECUs (such as the 4AGZE and 7MGTE) expect a return signal from the Ignitor for

each ignition signal sent. The expected IGf signal is a ground signal (from the igniters) in response

to a charge signal (from the IGt ECU point to the igniter).

Problem

When using the e-manages ignition harness with these ECUs the maximum advance/retard that can

be set is around +/- 6 degrees. Any more than this will result in an error being detected as there will

be a time difference between the IGt signal being sent and the IGf signal being received by the

ECU. This will result in the Check Engine light coming on, base ignition timing being set and in

some cases the injectors may be shut-off. This restricts usage of the e-manages ignition timing

function to only +/- 6 degrees.

Solution

There is an IGf Signal Generation Circuit within the Igniter which creates the IGf signal using a

switching transistor from the same signal that is sent out of the igniter to the ignition coil. This

circuit can be created external to the igniter and can be used to generate an IGf signal directly from

the ECUs IGt signal before the e-manage intercepts (and alters) the IGt signal. Using this external

circuit, the ECU is provided with a consistent IGf signal even if the actual ignition event is earlier

or later than the IGt signal is triggering.

ECU

Ground

CH1

out

CH1

in

E-manage Ignition Harness

External IGf

generation

circuit

Page 2 of 5

Making the circuit

You will need the following tools:

Soldering iron (and solder)

Wire stripper

2cm Heat-shrink tubing (and lighter).

You will need the following parts:

NPN 2N3904 switching transistor

1watt 1K (1000) ohm resister

Veroboard (at least 3x9 holes)

3 x 10cm lengths of different coloured wires.

1. Cutdown the veroboard using a hacksaw or sharp knife to the correct size.

Note: I found some veroboard that had 2 complete tracks and then 2 broken tracks and cut it

so there was a complete track along each long edge and 2 incomplete tracks in the middle.

2. Bend the pins of the transistor so it can be inserted in the veroboard.

3. Bend the ends of the resistor so it can be inserted veroboard.

Your parts should look something like this:

4. Solder the transistor into one end of the veroboard so that pin 1 and pin 3 are using the

complete tracks. Note: refer to picture below for pin locations on the transistor.

5. Solder the resistor in-line with pin 2 and bridge the points between pin 2 and the resistor.

6. If you have used veroboard without complete tracks, solder links between pin 1 and the end

of that track and pin 3 and the end of that track.

7. Solder the 3 different colour wires onto each of the 3 track ends and note which colours you

used for each of the pins.

8. Clip off the excess pins and wires from the back of the veroboard, check over all of your

connections and either heat-shrink the circuit or install it in a small box for protection.

Page 3 of 5

This is the circuit using a veroboard with tracks:

This is the circuit using a veroboard without tracks (and therefore with links):

Installing the circuit (permanently)

1. Cut the IGt wire farther away from the ECU than where the RPM signal has been spliced

into it.

2. Solder the CH1 in wire (from the ignition harness) and the pin 2 wire (from the external IGf

generation circuit) to the IGt wire coming from the ECU and heat-shrink the joint to

protect it.

3. Solder the CH1 out wire to the IGt wire going to the igniter and heat-shrink the joint to

protect it.

4. Splice the pin 1 wire (from the external IGf generation circuit) to the ECU ground wire

(which you used for the E-manage ground: E) and heat-shrink the joint to protect it.

5. Cut the IGf wire at a similar length from the ECU as the IGt was cut.

6. Solder the pin 3 wire (from the external IGf generation circuit) to the IGf wire going to the

ECU and heat-shrink the joint to protect it.

7. Heat-shrink the IGf wire coming from the igniter to protect it from shorting out.

Installing the circuit (non-permanently)

As the IGf signal is a fail-safe feature, bypassing the true IGf signal (from the igniter) will remove

the fault checking capability of the igniter/ECU. Therefore, you may want to consider installing the

circuit using bullet connectors on the IGf wire so that you can swap the external IGf generated

signal with the true IGf signal easily. To install the circuit in this manner, perform steps 1-5 and:

6. Install a male bullet connector on the IGf wire going to the ECU

7. Install a female bullet connector on the pin 3 wire (from the external IGf generation circuit)

8. Install a female bullet connector on the IGf wire coming from the igniter and heat-shrink

the connector to protect it from shorting out.

9. Connect the male bullet (on the IGf wire going to the ECU) to the female bullet going to

the IGf generation circuit.

Page 4 of 5

I went one step further and used bullet connectors for all of the connections (so I can remove the

whole circuit if I need to).

The top wire in the above picture is the ground signal (which has a male bullet coming off for the e-

manage ground wire). I tapped a small wire with a male bullet off a ground point on the ECU. The

middle wire (which has an adapted splitter that comes with the e-manage) is the IGt feed. The male

bullet goes into a female bullet attached to the IGt point on the ECU (see below picture) and the two

female points are used for the e-manage CH1 in signal and the e-mange RPM signal. Finally the

bottom wire is the IGf generator wire which is connected as described in steps 6 to 9 above.

Note: you can easily remove the pins from an ECU plug (see above) by inserting a small

screwdriver into the plug from the ECU side and levering the small tab that holds the point in. You

can then pull on the wire and the point will slide out of the plug (dont forget which point it came

out from!).

If you ever need to check to see if your igniter is faulty, you can:

1. Change to an ignition map that has less than +/- 6 degrees of advance/retard

(it is probably best to switch to a standard map with all zeros)

2. Swap the pin 3 wire (coming from the external IGf generation circuit) with the IGf wire

coming from the igniter by disconnecting the joint and connecting the other female bullet.

Page 5 of 5

How does it work?

An NPN transistor is a small and fast switch that allows a signal to flow from the collector to the

emitter when a signal is received from the base.

In the IGf generation circuit, when there is an IGt signal (connected to the base) the transistor

permits a signal to flow from the ECU Ground (connected to the collector) to the IGf input on the

ECU (connected to the emitter) which grounds the IGf point each time an IGt signal is received.

Other thoughts/information

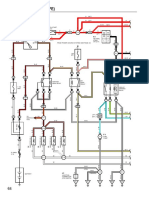

Although the DLI setup also uses another ECU signal to the igniter (IGd on 4AGZE and

IGdA/IGdB on 7MGTE) to trigger which coil to fire, intercepting the IGt signal and selecting a

distributor configuration works fine. This is initially a little confusing, but looking at the following

picture shows that the IGt signal is constantly oscillating regardless of which coil is being fired.

References and thanks

Thanks to Rollamods from www.twincam.org for informing me of the Greddy e-manage and also

the existence of this circuit (and for the second photo of the circuit).

Thanks to tsupra33 from the E-manage Yahoo Group for the diagram of the 7MGTE circuit in the

files section of the E-manage Yahoo Group.

Major thanks to J ohn Simmerman from the Supra Owners Group International (SOGI) for

originally designing the circuit.

Diagrams of Toyota ignition setup came from www.autoshop101.com.

Definition of transistors operation is loosely based on an explanation given in the Beginners Guide

to Electronics by Martin T. Pickering available free from The Cool Bookshop.

Cheers,

J amitGZE.

Potrebbero piacerti anche

- Nissan Patrol Y61 2.8 TD Ecu Pinout DescriptionDocumento10 pagineNissan Patrol Y61 2.8 TD Ecu Pinout Descriptionvali_nedelea67% (6)

- Ga16de Ecu PinoutDocumento4 pagineGa16de Ecu PinoutAlejandro García73% (11)

- Ecm Tacoma 2005-2008Documento4 pagineEcm Tacoma 2005-2008Patricio Valencia100% (1)

- 1G ECU PinoutsDocumento4 pagine1G ECU PinoutsRodrigo Henrique73% (11)

- 4g63 Ecu PinoutDocumento1 pagina4g63 Ecu PinoutEthan Eliezer Lim Pabalan80% (10)

- Subaru 2004 Forester XT Transmission TCM IO PinoutDocumento3 pagineSubaru 2004 Forester XT Transmission TCM IO PinoutMarco Cisternas100% (3)

- M Overall Electrical Wiring Diagram: 2005 HIGHLANDER (EWD592U)Documento67 pagineM Overall Electrical Wiring Diagram: 2005 HIGHLANDER (EWD592U)Meng Hort100% (1)

- Pin Out Ecu 4E-FEDocumento2 paginePin Out Ecu 4E-FEMaster Coy67% (3)

- Acronyms TOYOTA PDFDocumento5 pagineAcronyms TOYOTA PDFAlex Molina100% (3)

- Raising The Rev Limiter On Your 4EFE, ECU ModDocumento4 pagineRaising The Rev Limiter On Your 4EFE, ECU Modjavier.abraham100% (1)

- 2005 Nissan X Trail 52391Documento80 pagine2005 Nissan X Trail 52391Adam Olow100% (4)

- EC Qg18deDocumento1.956 pagineEC Qg18deGabriel Balcazar100% (8)

- C - ECU Pinout - Toyota - Land Crusier 5vz-Fe (6 Cylinder - 1 Coil Control 2 Ignition Point) - 5vz-3rz-Right Manual For Lahore Landcruiser 5vz-1998Documento4 pagineC - ECU Pinout - Toyota - Land Crusier 5vz-Fe (6 Cylinder - 1 Coil Control 2 Ignition Point) - 5vz-3rz-Right Manual For Lahore Landcruiser 5vz-1998Boomer Boomer100% (1)

- A B C D: Toyota Hiace ECU Terminal List, With 2.7L 2TR-FE EngineDocumento3 pagineA B C D: Toyota Hiace ECU Terminal List, With 2.7L 2TR-FE EngineG. F.100% (4)

- Engine Control System AcronymsDocumento4 pagineEngine Control System Acronymsmeorom22450% (2)

- Toyota Obd1Documento2 pagineToyota Obd1Ly Fotoestudio Digitalca100% (1)

- Technical Information ECU HondaDocumento3 pagineTechnical Information ECU HondaWhiro Opo AriefNessuna valutazione finora

- 1kd 2kd Ect PDFDocumento4 pagine1kd 2kd Ect PDFKyawzin Min100% (5)

- 7 Yaris (TMC Made) (Cont. Next Page) : Engine Control (1NR-FE)Documento7 pagine7 Yaris (TMC Made) (Cont. Next Page) : Engine Control (1NR-FE)MaiChiVu100% (2)

- Engine Control (5S-Fe)Documento8 pagineEngine Control (5S-Fe)Toysport Automotive100% (1)

- 96 Altima ECU PinoutDocumento8 pagine96 Altima ECU PinoutErickStaMaria100% (1)

- Nissan Primera Engine Control SystemDocumento1.794 pagineNissan Primera Engine Control SystemMarek100% (2)

- zd30 PinoutDocumento1 paginazd30 PinoutJoel R. ChanNessuna valutazione finora

- 4AFE Wiring DiagramDocumento35 pagine4AFE Wiring DiagramFarabi Ardhianto100% (3)

- Installation Information Emg Model: DG-20 (Pro-Series Assembly)Documento2 pagineInstallation Information Emg Model: DG-20 (Pro-Series Assembly)Pablo Vázquez CarrilloNessuna valutazione finora

- Distribuidor Nissan B14Documento4 pagineDistribuidor Nissan B14Jose Luis Velasquez RomeroNessuna valutazione finora

- Wiring Diag 2nzDocumento5 pagineWiring Diag 2nzEric Tsayim100% (1)

- 1g Circuit Diagram PDFDocumento96 pagine1g Circuit Diagram PDFDaniel CampbellNessuna valutazione finora

- Toyota Ecu Pinout AbbreviationsDocumento4 pagineToyota Ecu Pinout AbbreviationsSergio Mauricio Arce MarínNessuna valutazione finora

- 2004 Corolla Electrical Diagram - Door Lock ControlDocumento8 pagine2004 Corolla Electrical Diagram - Door Lock ControlNick Baptiste100% (1)

- Grandis Engine ElectricalDocumento29 pagineGrandis Engine Electricalmillanz100% (3)

- d2fee44ce3373b7c092a008235dbd2f5Documento153 pagined2fee44ce3373b7c092a008235dbd2f5Ovvc100% (2)

- Pin Out ToyotaDocumento60 paginePin Out Toyotaariboro100% (9)

- DTC P0340/12 Engine Speed Sensor Circuit 1 (TDC or G1 Circuit)Documento2 pagineDTC P0340/12 Engine Speed Sensor Circuit 1 (TDC or G1 Circuit)Andi KaNessuna valutazione finora

- Body Electrical Echo/yaris 2002Documento117 pagineBody Electrical Echo/yaris 2002Tomas Dominguez100% (1)

- Ec sr20 PDFDocumento332 pagineEc sr20 PDFIshmael Wooloo100% (1)

- Terminals of Ecm: E17 E16 E15 E14Documento5 pagineTerminals of Ecm: E17 E16 E15 E14Martin ChilbetNessuna valutazione finora

- Toyota Sensors Basic WaveformsDocumento6 pagineToyota Sensors Basic Waveformscartronix2010100% (5)

- 4afe Wiring DiagramDocumento2 pagine4afe Wiring Diagrampranda dika0% (1)

- Starting (2rz-Fe and 3rz-Fe)Documento4 pagineStarting (2rz-Fe and 3rz-Fe)ezu11100% (2)

- Toyota 1nz Trasnsmision AutomaticaDocumento3 pagineToyota 1nz Trasnsmision AutomaticaCristhian Cazas100% (2)

- 031 - Engine - Igniter Circuit Malfunction (No. 1)Documento6 pagine031 - Engine - Igniter Circuit Malfunction (No. 1)Ayun AhmNessuna valutazione finora

- Honda Stream 18 i-VTEC PDFDocumento5 pagineHonda Stream 18 i-VTEC PDFFabian Carrasco Naula100% (1)

- 4afe WiringDocumento243 pagine4afe WiringnishiNessuna valutazione finora

- DLC3 01 01Documento1 paginaDLC3 01 01kaka100% (1)

- S14 Zenki SR20 PinoutDocumento1 paginaS14 Zenki SR20 Pinoutkeidesh868Nessuna valutazione finora

- DTC P2138 App Sensor DTC P2138 App Sensor Component DescriptionDocumento9 pagineDTC P2138 App Sensor DTC P2138 App Sensor Component DescriptionAndres AriasNessuna valutazione finora

- Power Source Air Conditioner Air ConditionerDocumento1 paginaPower Source Air Conditioner Air Conditionerสนั่น วิริยะเจริญกุล100% (3)

- 2tz Fze 2Documento22 pagine2tz Fze 2che-ahmad-majdi-7191Nessuna valutazione finora

- Serena 2003 Automatic Continuously Variable Transmission CVT Wiring Diagram & VoltagesDocumento4 pagineSerena 2003 Automatic Continuously Variable Transmission CVT Wiring Diagram & VoltagesrayNessuna valutazione finora

- Toyota OBD CodesDocumento2 pagineToyota OBD Codesnanorutamilan100% (1)

- 4EFTE 4EFE Engine Diagnotsic CodeDocumento6 pagine4EFTE 4EFE Engine Diagnotsic Codedimitris honiasNessuna valutazione finora

- K179. Unipolar Steppermotor Driver: Five, Six or Eight Wires. Five-Wire Motors Have The TwoDocumento2 pagineK179. Unipolar Steppermotor Driver: Five, Six or Eight Wires. Five-Wire Motors Have The TwoducchungNessuna valutazione finora

- Design and Develop An IGBT Inverter For AC Motor Drive ApplicationsDocumento40 pagineDesign and Develop An IGBT Inverter For AC Motor Drive Applicationselectron1999100% (1)

- 555 TimerDocumento26 pagine555 TimerEngr Wahab MarwatNessuna valutazione finora

- Remote Controlled FanDocumento4 pagineRemote Controlled FanJostin PunnasseryNessuna valutazione finora

- ULN2004APG Datasheet en 20101203Documento13 pagineULN2004APG Datasheet en 20101203Kirk Freire LópezNessuna valutazione finora

- 338 Tachometer InstructionsDocumento3 pagine338 Tachometer InstructionsjuanNessuna valutazione finora

- Physics Investigatory ProjectDocumento20 paginePhysics Investigatory ProjectarunatchalamNessuna valutazione finora

- Ignition System: 1988 Toyota CelicaDocumento7 pagineIgnition System: 1988 Toyota CelicaToua Yaj100% (1)

- Maths Formula's Pocket BookDocumento113 pagineMaths Formula's Pocket BookPOLUNATI SAHITHI POLUNATI SAHITHI100% (1)

- A Mathematical Model For The Spatiotemporal Epidemic Spreading of COVID19Documento13 pagineA Mathematical Model For The Spatiotemporal Epidemic Spreading of COVID19Barbara BusanelloNessuna valutazione finora

- Inorganic Qualitative AnalysisDocumento9 pagineInorganic Qualitative AnalysisShireen SuhailNessuna valutazione finora

- Laser Jet AlignmentDocumento190 pagineLaser Jet AlignmentsatfasNessuna valutazione finora

- Machine Vision Technology: Past, Present, and FutureDocumento12 pagineMachine Vision Technology: Past, Present, and FutureMekaTronNessuna valutazione finora

- Sardar Raja College of Engineering Department of Electrical and Electronics Engineering Micro Lesson PlanDocumento4 pagineSardar Raja College of Engineering Department of Electrical and Electronics Engineering Micro Lesson PlanKarthi SathyaNessuna valutazione finora

- Datasheet PDFDocumento15 pagineDatasheet PDFperro sNessuna valutazione finora

- The Death of Science.Documento1 paginaThe Death of Science.sam iam / Salvatore Gerard MichealNessuna valutazione finora

- T5L DGUSII Application Development Guide V2.5Documento219 pagineT5L DGUSII Application Development Guide V2.5ZillaIllozNessuna valutazione finora

- Unit I. Bascis of Manufacturing ProcessesDocumento30 pagineUnit I. Bascis of Manufacturing Processes070 ARITRITA BRAHMA ECENessuna valutazione finora

- The Periodic TableDocumento16 pagineThe Periodic TableKayla HerdsmanNessuna valutazione finora

- Valvoline HTO 32Documento1 paginaValvoline HTO 32octo widodoNessuna valutazione finora

- Toshiba VFS15 User ManualDocumento361 pagineToshiba VFS15 User ManualdanyNessuna valutazione finora

- Nizami Akturk 1993 PHD ThesisDocumento299 pagineNizami Akturk 1993 PHD ThesisGerman ToledoNessuna valutazione finora

- LinuxDocumento16 pagineLinuxJon ExcaliburNessuna valutazione finora

- FenestrationDocumento14 pagineFenestrationKing AravindNessuna valutazione finora

- Service Bulletin RT-18.4: Technical Information To All Owners / Operators of Wärtsilä RTA and RT-flex EnginesDocumento14 pagineService Bulletin RT-18.4: Technical Information To All Owners / Operators of Wärtsilä RTA and RT-flex Engineszbkt07Nessuna valutazione finora

- Pradhan Mantri Awas Yojana Housing For All (Urban) in AP StateDocumento120 paginePradhan Mantri Awas Yojana Housing For All (Urban) in AP StateKishore Nayak kNessuna valutazione finora

- ACPI Embedded SATAIII mSATA SSD MSS4Q-L 3K PE Datasheet 20190611Documento16 pagineACPI Embedded SATAIII mSATA SSD MSS4Q-L 3K PE Datasheet 20190611Daniel CrespoNessuna valutazione finora

- MTH101 TutorialDocumento2 pagineMTH101 TutorialOnochie EnunwaonyeNessuna valutazione finora

- Torque - Slip Characteristic of A Three - Phase Induction MachineDocumento28 pagineTorque - Slip Characteristic of A Three - Phase Induction MachineAli AltahirNessuna valutazione finora

- Analog - RF VLSI Design (ECE 503) (Makeup) PDFDocumento2 pagineAnalog - RF VLSI Design (ECE 503) (Makeup) PDFRahul PinnamaneniNessuna valutazione finora

- Biology Final Exam - Print - QuizizzDocumento5 pagineBiology Final Exam - Print - QuizizzrubelliteNessuna valutazione finora

- Yuva Nikhil Reddy LonkaDocumento9 pagineYuva Nikhil Reddy LonkaankulNessuna valutazione finora

- Ih 03Documento141 pagineIh 03Abhinav GargNessuna valutazione finora

- Fulton Steam: FB-S SeriesDocumento76 pagineFulton Steam: FB-S Seriesbth8320Nessuna valutazione finora

- Example 1 Hec RasDocumento16 pagineExample 1 Hec Rasasep sulaemanNessuna valutazione finora

- Theory of ProductionDocumento24 pagineTheory of ProductionKanika BakshiNessuna valutazione finora

- As 4678 2002 Earth Retaining Structures CorrectionDocumento6 pagineAs 4678 2002 Earth Retaining Structures CorrectionMacNessuna valutazione finora

- Operators in CDocumento22 pagineOperators in CUjjWal MahAjan100% (1)