Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Further Excellence Campaign ISO9001

Caricato da

musaismail88630 valutazioniIl 0% ha trovato utile questo documento (0 voti)

29 visualizzazioni2 pagineuytujt

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentouytujt

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

29 visualizzazioni2 pagineFurther Excellence Campaign ISO9001

Caricato da

musaismail8863uytujt

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

FURTHER EXCELLENCE

COMPETITIVE ADVANTAGE CONTINUAL IMPROVEMENT

CUSTOMER FOCUS CUSTOMER SATISFACTION

WHAT HELPS YOU CONTINUOUSLY EXCEED

CUSTOMER EXPECTATIONS?

ISO 9001 QUALITY MANAGEMENT SYSTEMS AUDIT, CERTIFICATION

& TRAINING SERVICES

ISO 9001:2008 Quality

Management System certification

enables you to stand out from

the competition. It demonstrates

your commitment to meeting the

highest standards of quality and

customer satisfaction and supports

you in continuously improving your

quality management systems.

It is based on the principles of:

Customer focus

Leadership

Involvement of people

Process approach

System approach

Continual improvement

Fact-based decision making

Mutually beneficial

supplier relationships

THE BENEFITS

ISO 9001:2008 enhances the reliability

of your operations, increases your

performance and potentially has a

positive impact on your bottom line.

Demonstrating a commitment to quality

drives constant improvement and

transforms your corporate culture. Your

certificate from SGS enables you to

show you have the high levels of service

quality needed for international contracts

and local new business. SGS is the most

widely accredited certification body with

over 40 ISO 9001 accreditations held in

more than 40 countries.

To date, over 1.1 million ISO 9001

certificates have been issued globally.*

A valid ISO 9001 certificate shows

your organisation follows the most

internationally recognised quality

management principles.

* Source: ISO Survey 2010.

HOW THE CERTIFICATION

PROCESS WORKS

Step A - Tailored proposal from SGS.

Step B Optional pre-audit of

readiness and weaknesses.

Step C Formal audit Stage 1

Readiness Review. Documents and

other key system elements are evaluated

and non-compliances reported.

Step D Stage 2: interviews,

examination of records and

observation of working practices.

Non-conformances are addressed.

Step E Surveillance visits to

check the system and action

plan implementation.

Step F Re-certification audit

after three years.

RELATED SERVICES

ISO 9001 training (all levels of ability

and awareness). Please view the

worldwide course schedule at

www.sgs.com/training

ISO 9001 Gap Assessment: Assesses

readiness for certification

Integrated Management Systems

Certification: Audit solutions against

bespoke quality performance criteria

Process Improvement solutions

WHY SGS?

SGS is the worlds leading inspection,

verification, testing and certification

company. SGS is recognised as the

global benchmark for quality and integrity.

With more than 75 000 employees, SGS

operates a network of over 1 500 offices

and laboratories around the world.

Enhancing processes, systems and skills

is fundamental to your ongoing success

and sustained growth. We enable you to

continuously improve, transforming your

services and value chain by increasing

performance, managing risks, better

meeting stakeholder requirements and

managing sustainability.

With a global presence, we have a

history of successfully executing

large-scale, complex international

projects. Our people speak the

language, understand the culture of the

local market and operate globally in a

consistent, reliable and effective manner.

TO LEARN HOW SGS CAN HELP YOU

EXCEED CUSTOMER EXPECTATIONS,

VISIT WWW.SGS.COM/ISO9001 OR

CONTACT CERTIFICATION@SGS.COM

FOR MORE INFORMATION.

ISO 9001:2008 CERTIFICATION PROCESS

STEP A

Agree

Contract

STEP B

Optional

Pre-Audit

SURVEILLANCE VISITS TYPICALLY

AT 6 TO 12 MONTH INTERVALS

STEP C

Stage 1

Audit

STEP D

Stage 2

Audit

Certificate

Issue on

Completion

of Successful

Audit

STEP E

Surveillance

Visits

STEP F

Recertification

Audit

Action and Closure of

Identified Non-Conformities

Action and

Closure of

Identified

Non-Conformities

Certification Cycle Typically 3 years

ASSESSMENT AND CERTIFICATION

S

G

S

G

r

o

u

p

M

a

n

a

g

e

m

e

n

t

S

A

2

0

1

3

A

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

-

S

G

S

i

s

a

r

e

g

i

s

t

e

r

e

d

t

r

a

d

e

m

a

r

k

o

f

S

G

S

G

r

o

u

p

M

a

n

a

g

e

m

e

n

t

S

A

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- 02 MechanicalDocumento44 pagine02 Mechanicalmusaismail8863Nessuna valutazione finora

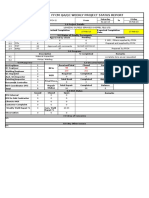

- FFCM-MSI QAQC Weekly Project Status Report (07.02. 15-13 02 15)Documento1 paginaFFCM-MSI QAQC Weekly Project Status Report (07.02. 15-13 02 15)musaismail8863100% (1)

- Material Specification Sheet Saarstahl - C40E (Ck40)Documento2 pagineMaterial Specification Sheet Saarstahl - C40E (Ck40)musaismail8863Nessuna valutazione finora

- Abs Guide Rules For Fpso ConversionDocumento1 paginaAbs Guide Rules For Fpso Conversionmusaismail8863Nessuna valutazione finora

- AS 1100 Part 301 Architectural DrawingDocumento24 pagineAS 1100 Part 301 Architectural DrawingHao Much100% (2)

- MDR NDT Drawing Tembikai As of 08.11.2014Documento1 paginaMDR NDT Drawing Tembikai As of 08.11.2014musaismail8863100% (1)

- Risks in Facility Build Quality and Project Handover: What Happened?Documento3 pagineRisks in Facility Build Quality and Project Handover: What Happened?musaismail8863Nessuna valutazione finora

- Instruction Manual - Dial Thickness Gauge Kit How Replica Tape WorksDocumento6 pagineInstruction Manual - Dial Thickness Gauge Kit How Replica Tape Worksmusaismail8863Nessuna valutazione finora

- 232 50Documento2 pagine232 50musaismail8863Nessuna valutazione finora

- Apartment Harga SederhanaDocumento3 pagineApartment Harga Sederhanamusaismail8863Nessuna valutazione finora

- 16 - Metal and SpecialtyDocumento12 pagine16 - Metal and Specialtymusaismail8863Nessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Know Your TcsDocumento8 pagineKnow Your TcsRocky SinghNessuna valutazione finora

- Fco - 63 - 61 - Alim-AiiDocumento2 pagineFco - 63 - 61 - Alim-AiiAmiNessuna valutazione finora

- DO-178B Compliance: Turn An Overhead Expense Into A Competitive AdvantageDocumento12 pagineDO-178B Compliance: Turn An Overhead Expense Into A Competitive Advantagedamianpri84Nessuna valutazione finora

- Managing The Operation FunctionsDocumento13 pagineManaging The Operation FunctionsJoseph ObraNessuna valutazione finora

- Opportunities in The Global Halal MarketDocumento31 pagineOpportunities in The Global Halal MarketMubashir KhawajaNessuna valutazione finora

- Tara Machines BrochureDocumento8 pagineTara Machines BrochureBaba Jee Shiva ShankarNessuna valutazione finora

- Legal Notice in The Matter of The International Cotton Association LimitedDocumento3 pagineLegal Notice in The Matter of The International Cotton Association LimitedMahfuz Law RuNessuna valutazione finora

- Canto Cumulus: What's New?: Product InformationDocumento12 pagineCanto Cumulus: What's New?: Product InformationTeppo TestaajaNessuna valutazione finora

- Organizational Culture and ChangesDocumento3 pagineOrganizational Culture and ChangesCherry MoldeNessuna valutazione finora

- 42 Master IndexDocumento734 pagine42 Master Indexapi-3702030Nessuna valutazione finora

- Intellectual Capital Is The Collective Brainpower or Shared Knowledge of A WorkforceDocumento3 pagineIntellectual Capital Is The Collective Brainpower or Shared Knowledge of A WorkforceKatherine Rosette ChanNessuna valutazione finora

- Types of SamplingDocumento16 pagineTypes of SamplingNidhin NalinamNessuna valutazione finora

- Payment Advice TUCKSHOP IBM-20230717-20230719Documento3 paginePayment Advice TUCKSHOP IBM-20230717-20230719spraju1947Nessuna valutazione finora

- The Merchant of Venice CrosswordDocumento2 pagineThe Merchant of Venice CrosswordAnonymous lTXTx1fNessuna valutazione finora

- Lesson 1 Part 1 Introduction To ICTDocumento25 pagineLesson 1 Part 1 Introduction To ICTChou PapiNessuna valutazione finora

- Law of Contract: Prepared ByDocumento50 pagineLaw of Contract: Prepared Bymusbri mohamed98% (44)

- MATH Practice With Answer (Besavilla)Documento121 pagineMATH Practice With Answer (Besavilla)aj100% (1)

- Which Public Goods Should Be Public/privateDocumento12 pagineWhich Public Goods Should Be Public/privateRozyNessuna valutazione finora

- 810 Pi SpeedxDocumento1 pagina810 Pi SpeedxtaniyaNessuna valutazione finora

- Sip Zudus PerformanceDocumento104 pagineSip Zudus PerformanceAkshay Jiremali100% (1)

- VAT Transfer PostingDocumento1 paginaVAT Transfer PostingabbasxNessuna valutazione finora

- Special Consideration For The Sole Practitioner Operating As A Management ConsultantDocumento3 pagineSpecial Consideration For The Sole Practitioner Operating As A Management ConsultantJessyNessuna valutazione finora

- Tugas Review Jurnal PDFDocumento71 pagineTugas Review Jurnal PDFMelpa GuspariniNessuna valutazione finora

- Bank of Rajasthan LTDDocumento2 pagineBank of Rajasthan LTDProfessor Sameer Kulkarni100% (1)

- Case Study PahiiiiiiiiiiDocumento4 pagineCase Study Pahiiiiiiiiiirohitbhargo0% (1)

- Investment BankingDocumento62 pagineInvestment Bankingकपिल देव यादवNessuna valutazione finora

- Chapter5 Project PlanningDocumento38 pagineChapter5 Project PlanningSanchit BatraNessuna valutazione finora

- Revaluation ModelDocumento7 pagineRevaluation ModelkyramaeNessuna valutazione finora

- Listing Reg. EX-50% NED - 1/3 Ned But Related - 50%Documento3 pagineListing Reg. EX-50% NED - 1/3 Ned But Related - 50%Avinash BahadurNessuna valutazione finora

- Bmsa Book With CoverDocumento251 pagineBmsa Book With CoverHurol Samuel100% (7)