Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

AS4041 ASME B31 - 3 Pipe Wall Thickness

Caricato da

cutefrenzyTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

AS4041 ASME B31 - 3 Pipe Wall Thickness

Caricato da

cutefrenzyCopyright:

Formati disponibili

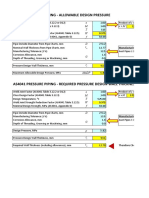

AS4041 PRESSURE PIPING - ALLOWABLE DESIGN PRESSURE

Weld Joint Factor (AS4041 Table 3.12.2 or D12) e 1.00 Product of e x M not less than 0.7

Class Design Factor (AS4041 Table 3.12.3) M 1.00 e x M

Design Temperature, C T 525

Weld Joint Strength Reduction Factor (AS4041 Table 3.12.5) W 0.975

Material Design Strength, MPa (AS4041, Appendix D) f 82.68

Pipe Outside Diameter from Pipe Charts, mm D 273.2

Nominal Wall Thickness from Pipe Charts, mm t

m

12.77 Manufacturing Tolerances

Manufacturing Tolerance ( %) 12.5 Aust Pipes 10%; American Pipes 12.5%

Corrosion Allowance, mm 1.6

Depth of Threading, Grooving or Machining, mm 0.0

Pressure Design Wall Thickness, mm t

f

9.57

Maximum Allowable Design Pressure, MPa MADP 5.86

AS4041 PRESSURE PIPING - REQUIRED PRESSURE DESIGN WALL THICKNESS

Weld Joint Factor (AS4041 Table 3.12.2 or D12) e 1.00 Product of e x M not less than 0.7

Class Design Factor (AS4041 Table 3.12.3) M 1.00 e x M

Design Temperature, C T 525.00

Weld Joint Strength Reduction Factor (AS4041 Table 3.12.5) W 0.975

Material Design Strength, MPa (AS4041, Appendix D) f 82.68

Pipe Outside Diameter from Pipe Charts, mm D 273.2

Manufacturing Tolerance ( %) 12.5 Manufacturing Tolerances

Corrosion Allowance, mm 1.6 Aust Pipes 10%; American Pipes 12.5%

Depth of Threading, Grooving or Machining, mm 0.0

Design Pressure, MPa p 5.82

Pressure Design Wall Thickness, mm t

f

9.51

Required Wall Thickness (including allowances), mm t

m

12.70 Therefore Choose DN250 S/S pipe will a nominal thickness > 12.7 mm

G

G

Product of e x M not less than 0.7

1

Manufacturing Tolerances

Aust Pipes 10%; American Pipes 12.5%

AS4041 PRESSURE PIPING - REQUIRED PRESSURE DESIGN WALL THICKNESS

Product of e x M not less than 0.7

1.0

Manufacturing Tolerances

Aust Pipes 10%; American Pipes 12.5%

Therefore Choose DN250 S/S pipe will a nominal thickness > 12.7 mm

ASME B31.3 PROCESS PIPING - ALLOWABLE DESIGN PRESSURE

Weld Joint Quality Factor (ASME B31.3 Table 302.3.4) E

j

1.00 Seamless ASTM A312 TP304

Coefficient Y (ASME B31.3 Table 304.1.1) Y 0.40

Design Temperature, C T 525 975F

Weld Joint Strength Reduction Factor (ASME B31.3 Cl. 302.3.5(e)) W 0.975

Material Allowable Stress, MPa (ASME B31.3 Table A-1M) S 82.68 12 ksi

Pipe Outside Diameter from Pipe Charts, mm D 273.2 10.75"

Nominal Wall Thickness from Pipe Charts, mm t

m

12.77

Manufacturing Tolerance ( %) 12.5

Corrosion Allowance, mm 1.6

Depth of Threading, Grooving or Machining, mm 0.0

Pressure Design Thickness, mm t 9.59

Maximum Allowable Internal Design Gauge Pressure, MPa MADP 5.82

ASME B31.3 PROCESS PIPING - REQUIRED PRESSURE DESIGN WALL THICKNESS

Weld Joint Quality Factor (ASME B31.3 Table 302.3.4) E

j

1.00 Seamless ASTM A312 TP304

Coefficient Y (ASME B31.3 Table 304.1.1) Y 0.40

Design Temperature, C T 525 975F

Weld Joint Strength Reduction Factor (ASME B31.3 Cl. 302.3.5(e)) W 0.975

Material Allowable Stress, MPa (ASME B31.3 Table A-1M) S 82.68 12 ksi

Pipe Outside Diameter from Pipe Charts, mm D 273.2 10.75"

Manufacturing Tolerance ( %) 12.5

Corrosion Allowance, mm 1.6

Depth of Threading, Grooving or Machining, mm 0.0

Design Pressure, MPa P 5.82 845 psi

Pressure Design Thickness, mm t 9.58 0.377

Minimum Required Thickness (including allowances), mm t

m

12.77

c

G

Seamless ASTM A312 TP304

Manufacturing Tolerances

Aust Pipes 10%; American Pipes 12.5%

ASME B31.3 PROCESS PIPING - REQUIRED PRESSURE DESIGN WALL THICKNESS

Seamless ASTM A312 TP304

Manufacturing Tolerances

Aust Pipes 10%; American Pipes 12.5%

inches

0.502 inches

Therefore Choose DN250 S/S pipe will a nominal thickness > 12.77 mm

AS4041 PRESSURE PIPING - REQUIRED PRESSURE DESIGN WALL THICKNESS FOR BENDS

Weld Joint Factor (AS4041 Table 3.12.2 or D12) e 1.00 Product of e x M not less than 0.7

Class Design Factor (AS4041 Table 3.12.3) M 1.00 e x M

Design Temperature, C T 525.00

Weld Joint Strength Reduction Factor (AS4041 Table 3.12.5) W 0.975

Bend Radius, measured to pipe centreline, mm R

1

1270

Material Design Strength, MPa (AS4041, Appendix D) f 82.68

Pipe Outside Diameter from Pipe Charts, mm D 273.2

Manufacturing Tolerance ( %) 12.5 Manufacturing Tolerances

Corrosion Allowance, mm 1.6 Aust Pipes 10%; American Pipes 12.5%

Depth of Threading, Grooving or Machining, mm 0.0

Design Pressure, MPa p 5.82

"I " at the Intrados I 1.060

"I " at the Extrados I 0.951

Pressure Design Wall Thickness @ Intrados, mm t

f

8.99 Problem with AS4041 formula compared to ASME B31.3 formula.

Pressure Design Wall Thickness @ Extrados, mm t

f

9.98 The intrados should get thicker and the extrados thinner.

Required Wall Thickness @ Intrados, mm t

m

12.10 As thickness is "lost"during the bending process, it would be normal

Required Wall Thickness @ Extrados, mm t

m

13.24 to multiply the required wall thickness at the extrados by a factor of

1.1 to 1.125 dependent upon how "tight"the bend radius is. The resulting

value will give the nominal thickness of pipe required for bending.

G

AS4041 PRESSURE PIPING - REQUIRED PRESSURE DESIGN WALL THICKNESS FOR BENDS

Product of e x M not less than 0.7

1.0

Manufacturing Tolerances

Aust Pipes 10%; American Pipes 12.5%

Problem with AS4041 formula compared to ASME B31.3 formula.

The intrados should get thicker and the extrados thinner.

As thickness is "lost"during the bending process, it would be normal

to multiply the required wall thickness at the extrados by a factor of

1.1 to 1.125 dependent upon how "tight"the bend radius is. The resulting

value will give the nominal thickness of pipe required for bending.

ASME B31.3 PROCESS PIPING - REQUIRED PRESSURE DESIGN WALL THICKNESS FOR BENDS

Weld Joint Quality Factor (ASME B31.3 Table 302.3.4) E

j

1.00

Coefficient Y (ASME B31.3 Table 304.1.1) Y 0.40

Design Temperature, C T 525.00

Weld Joint Strength Reduction Factor (ASME B31.3 Cl. 302.3.5(e)) W 0.975

Bend Radius, measured to pipe centreline, mm R

1

1270

Material Allowable Stress, MPa (ASME B31.3 Table A-1M) S 82.68

Pipe Outside Diameter from Pipe Charts, mm D 273.2

Manufacturing Tolerance ( %) 12.5

Corrosion Allowance, mm 1.6

Depth of Threading, Grooving or Machining, mm 0.0

Internal Gauge Pressure, MPa P 5.82

"I " at the Intrados I 1.060

"I " at the Extrados I 0.951

Pressure Design Thickness @ Intrados, mm t 10.14

Pressure Design Thickness @ Extrados, mm t 9.13

Required Wall Thickness @ Intrados, mm t

m

13.42

Required Wall Thickness @ Extrados, mm t

m

12.26

G

ASME B31.3 PROCESS PIPING - REQUIRED PRESSURE DESIGN WALL THICKNESS FOR BENDS

Manufacturing Tolerances

Aust Pipes 10%; American Pipes 12.5%

As thickness is "lost"during the bending process, it would be normal

to multiply the required wall thickness at the extrados by a factor of

1.1 to 1.125 dependent upon how "tight"the bend radius is. The resulting

value will give the nominal thickness of pipe required for bending.

Potrebbero piacerti anche

- The Smith Generator BlueprintsDocumento36 pagineThe Smith Generator BlueprintsZoran AleksicNessuna valutazione finora

- Get Rich and Financially Independent with The Wealthy BarberDocumento219 pagineGet Rich and Financially Independent with The Wealthy BarbercutefrenzyNessuna valutazione finora

- Pipe Thickness Calculation PDFDocumento1 paginaPipe Thickness Calculation PDFHeny Martha67% (3)

- Pipe Wall Thickness (ASME B31.3)Documento12 paginePipe Wall Thickness (ASME B31.3)Rachmad HidayatNessuna valutazione finora

- 577 ExerciseDocumento40 pagine577 Exerciseariyamanjula2914100% (1)

- PTC & Branch Calc_ASME B31.3_Upto NPS 24 for hot water washingDocumento4 paginePTC & Branch Calc_ASME B31.3_Upto NPS 24 for hot water washingalvinchuan100% (1)

- Pipe Thickness Calculation For Straight Pipe Under Internal PressureDocumento7 paginePipe Thickness Calculation For Straight Pipe Under Internal PressureMakhdoom Ibad HashmiNessuna valutazione finora

- CBT For BDDDocumento13 pagineCBT For BDDGregg Williams100% (5)

- Nozzle ProDocumento185 pagineNozzle Progoodspeed_ph83% (6)

- AS4041 ASME B31 - 3 Pipe Wall ThicknessDocumento11 pagineAS4041 ASME B31 - 3 Pipe Wall Thicknessamini_mohiNessuna valutazione finora

- Audio - Questions: Safety Equipment Reliability Handbook (SERH) 4th EditionDocumento29 pagineAudio - Questions: Safety Equipment Reliability Handbook (SERH) 4th EditionLuc SchramNessuna valutazione finora

- DS Barred Tee (Rev)Documento2 pagineDS Barred Tee (Rev)Advis100% (2)

- ASME B31.3 Process Piping Wall Thickness CalculationDocumento27 pagineASME B31.3 Process Piping Wall Thickness CalculationJesus Magallanes SNessuna valutazione finora

- ASME B31 3 Calculator V2Documento11 pagineASME B31 3 Calculator V2gerrydimayuga100% (3)

- Pipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressDocumento58 paginePipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressJOELNessuna valutazione finora

- Welding Defects GuideDocumento16 pagineWelding Defects Guidepozolab0% (1)

- Welding Defects GuideDocumento16 pagineWelding Defects Guidepozolab0% (1)

- Pipes. Wall Thickness Calculation According ASME B31.3Documento98 paginePipes. Wall Thickness Calculation According ASME B31.3Saravanan SilambanNessuna valutazione finora

- 8 AS4041 ASME B31 3 Pipe Wall ThicknessDocumento8 pagine8 AS4041 ASME B31 3 Pipe Wall ThicknessĐinh Thiện SỹNessuna valutazione finora

- Weld Faults QuestionsDocumento70 pagineWeld Faults QuestionscutefrenzyNessuna valutazione finora

- Pipes. Wall Thickness Calculation According ASME B31.3Documento125 paginePipes. Wall Thickness Calculation According ASME B31.3musaveerNessuna valutazione finora

- ASME/ASTM standards overview for mechanical engineersDocumento3 pagineASME/ASTM standards overview for mechanical engineersrajesh100% (2)

- ASME 31 - 8mDocumento1 paginaASME 31 - 8mMarcoAlbaNessuna valutazione finora

- A Comparitive Study To Find Bend Thickness Calculation Using PASS START ELEMENT TOOLDocumento14 pagineA Comparitive Study To Find Bend Thickness Calculation Using PASS START ELEMENT TOOLJafer SayedNessuna valutazione finora

- Wall Thickness Calculation - ASME B31.8 2007 (Template)Documento1 paginaWall Thickness Calculation - ASME B31.8 2007 (Template)Hendra Yudistira100% (1)

- Thickness Calculation ASME B31.3 (Revised) HP LOOP ELBOWDocumento117 pagineThickness Calculation ASME B31.3 (Revised) HP LOOP ELBOWGohar ZamanNessuna valutazione finora

- AS4041 PRESSURE PIPING - REQUIRED PRESSURE DESIGN WALL THICKNESSDocumento33 pagineAS4041 PRESSURE PIPING - REQUIRED PRESSURE DESIGN WALL THICKNESSaike_5Nessuna valutazione finora

- Pipe cap thickness and coupling rating calculationsDocumento2 paginePipe cap thickness and coupling rating calculationsmasaminathanNessuna valutazione finora

- Pipe Wall Thickness (Complete)Documento40 paginePipe Wall Thickness (Complete)Andri PutraNessuna valutazione finora

- Wall Thickness Pipeline (Gas) B31Documento25 pagineWall Thickness Pipeline (Gas) B31Rais Brian Abdurahman100% (6)

- API 510 Bolted Flat Head ThicknessDocumento11 pagineAPI 510 Bolted Flat Head ThicknessAleiser Quevedo Acuña100% (1)

- SU Blind Plate ThicknessDocumento2 pagineSU Blind Plate Thicknessmanoj19801226100% (1)

- Kathy Davis - Dancing Tango - Passionate Encounters in A Globalizing World-New York University Press (2015)Documento236 pagineKathy Davis - Dancing Tango - Passionate Encounters in A Globalizing World-New York University Press (2015)Csongor KicsiNessuna valutazione finora

- Ansys Multiphysics Systems CouplingDocumento33 pagineAnsys Multiphysics Systems CouplingmanjunathbagaliNessuna valutazione finora

- Pipe Reinforcement Calculation (ASME-B31.3)Documento3 paginePipe Reinforcement Calculation (ASME-B31.3)jenshid100% (2)

- ASME VIII Calc - Shell - HeadsDocumento4 pagineASME VIII Calc - Shell - HeadsMuh Safaat100% (1)

- Design Code: Asme B31.3 Process Piping - For Straight Pipe Under Internal PressureDocumento10 pagineDesign Code: Asme B31.3 Process Piping - For Straight Pipe Under Internal Pressurefaisman100% (1)

- Asme B31.8Documento14 pagineAsme B31.8omar equihua100% (1)

- Wall Thickness Calculation ASME B31!8!2007Documento1 paginaWall Thickness Calculation ASME B31!8!2007shafeeqm3086Nessuna valutazione finora

- Minimum Pipe Thickness - B31.1 - PG1Documento10 pagineMinimum Pipe Thickness - B31.1 - PG1ravivarmadatla2011Nessuna valutazione finora

- Uniform-Section Disk Spring AnalysisDocumento10 pagineUniform-Section Disk Spring Analysischristos032Nessuna valutazione finora

- Wall THK Calculation Asme b31.4Documento5 pagineWall THK Calculation Asme b31.4Dwi Hermawan100% (2)

- Above Ground Piping Wall Thickness CalculationsDocumento7 pagineAbove Ground Piping Wall Thickness Calculationslutfi awn100% (1)

- Pressure Form Test RecordDocumento1 paginaPressure Form Test Recordphyo7799Nessuna valutazione finora

- Pressure Piping Allowable Wall Thickness For Bends (ASME B31.3)Documento2 paginePressure Piping Allowable Wall Thickness For Bends (ASME B31.3)alvinchuanNessuna valutazione finora

- Branch Reinforcement Pad Requirement CalculationDocumento2 pagineBranch Reinforcement Pad Requirement CalculationAntoshal100% (4)

- Catalyst Chage OperationDocumento59 pagineCatalyst Chage OperationcutefrenzyNessuna valutazione finora

- As4041 Pressure Piping - Allowable Design PressureDocumento1 paginaAs4041 Pressure Piping - Allowable Design Pressurealvinchuan100% (1)

- Wall Thickness Calculation of 36in Gas PipelineDocumento1 paginaWall Thickness Calculation of 36in Gas PipelineLU1228100% (3)

- MD He Tema Asme v0.1Documento31 pagineMD He Tema Asme v0.1Sharon Lambert100% (1)

- Hydrostatic Test Pressure Calculation: Pipe DataDocumento2 pagineHydrostatic Test Pressure Calculation: Pipe DataAkram AlhaddadNessuna valutazione finora

- 8 AS4041 ASME B31 3 Pipe Wall ThicknessDocumento12 pagine8 AS4041 ASME B31 3 Pipe Wall Thicknesswhah11Nessuna valutazione finora

- Cakasa Cakasa: Sea Water Filter Inlet Ine Input Description Unit General DataDocumento6 pagineCakasa Cakasa: Sea Water Filter Inlet Ine Input Description Unit General DatasterlingNessuna valutazione finora

- ASME 31 - 4 CalcDocumento1 paginaASME 31 - 4 CalcMarcoAlbaNessuna valutazione finora

- ASME B31.3 Process PipingDocumento1 paginaASME B31.3 Process PipingalvinchuanNessuna valutazione finora

- Lewis Corporation Case 6-2 - Group 5Documento8 pagineLewis Corporation Case 6-2 - Group 5Om Prakash100% (1)

- Branch Reinforcement Calculation: Pipe Material Design Temperature Design Pressure Allowable StressDocumento32 pagineBranch Reinforcement Calculation: Pipe Material Design Temperature Design Pressure Allowable Stressnitin_bir100% (3)

- ASME B31.3.4.8 Wall Thickness CalculatorDocumento26 pagineASME B31.3.4.8 Wall Thickness Calculatoreko123Nessuna valutazione finora

- Cot 2Documento3 pagineCot 2Kathjoy ParochaNessuna valutazione finora

- Area replacement calculation for CC1 E-1A LNG Vaporizer branchDocumento2 pagineArea replacement calculation for CC1 E-1A LNG Vaporizer branchJahsbuck100% (1)

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Documento1 paginaPipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadNessuna valutazione finora

- Pipe Wall Thickness Calculation ASME B31.8Documento16 paginePipe Wall Thickness Calculation ASME B31.8DikaAnindyajati100% (2)

- Thickness Calculation For PipeDocumento7 pagineThickness Calculation For PipeNAYEEM100% (5)

- Asme Pipe Wall ThicknessDocumento3 pagineAsme Pipe Wall ThicknessYoke ShuNessuna valutazione finora

- Branch Reinforcement Per Asme B31.4 PipelineDocumento1 paginaBranch Reinforcement Per Asme B31.4 PipelinegateauxboyNessuna valutazione finora

- Piping Thickness by ScheduleDocumento4 paginePiping Thickness by SchedulekkabbaraNessuna valutazione finora

- Pipe Wall Thickness Calculation ASME B31.3 Straight PipeDocumento5 paginePipe Wall Thickness Calculation ASME B31.3 Straight Pipeaike_5Nessuna valutazione finora

- A11Documento1 paginaA11liviu_dovaNessuna valutazione finora

- Spiral Wound GasketsDocumento3 pagineSpiral Wound GasketsHarish GundaNessuna valutazione finora

- As4041 Pressure Piping - Allowable Design Pressure: E M T W F D ExmDocumento8 pagineAs4041 Pressure Piping - Allowable Design Pressure: E M T W F D ExmAkhil CNessuna valutazione finora

- 8 AS4041 ASME B31 3 Pipe Wall ThicknessDocumento12 pagine8 AS4041 ASME B31 3 Pipe Wall ThicknessAnggaNessuna valutazione finora

- As4041 Pressure Piping Allowable Wall Thickness For BendsDocumento1 paginaAs4041 Pressure Piping Allowable Wall Thickness For BendsalvinchuanNessuna valutazione finora

- Asme B31.3 Process Piping - Asme B31.3 Process Piping - Allowable Design Pressureallowable Design PressureDocumento1 paginaAsme B31.3 Process Piping - Asme B31.3 Process Piping - Allowable Design Pressureallowable Design PressureRicardo LanderNessuna valutazione finora

- AS4041 ASME B31 - 3 Pipe Wall ThicknessDocumento1 paginaAS4041 ASME B31 - 3 Pipe Wall ThicknesselleNessuna valutazione finora

- Case Study To Find Pipe Thickness Calculation Using PASS START ELEMENT TOOLDocumento13 pagineCase Study To Find Pipe Thickness Calculation Using PASS START ELEMENT TOOLJafer SayedNessuna valutazione finora

- RDC Product CatalogDocumento4 pagineRDC Product CatalogcutefrenzyNessuna valutazione finora

- Nickel Alloy Material SelectionDocumento39 pagineNickel Alloy Material SelectioncutefrenzyNessuna valutazione finora

- Effect of Welding On Microstructure and Mechanical Properties of An Industrial Low Carbon SteelDocumento5 pagineEffect of Welding On Microstructure and Mechanical Properties of An Industrial Low Carbon Steelmalika_00Nessuna valutazione finora

- Belzona 1391Documento2 pagineBelzona 1391cutefrenzyNessuna valutazione finora

- Genralized Corrosion Cost AnalysisDocumento34 pagineGenralized Corrosion Cost AnalysiscutefrenzyNessuna valutazione finora

- XRF and XRDDocumento2 pagineXRF and XRDcutefrenzyNessuna valutazione finora

- Tempil-Iron Carbon DiagramDocumento1 paginaTempil-Iron Carbon DiagramcutefrenzyNessuna valutazione finora

- Effect of Welding On Microstructure and Mechanical Properties of An Industrial Low Carbon SteelDocumento5 pagineEffect of Welding On Microstructure and Mechanical Properties of An Industrial Low Carbon Steelmalika_00Nessuna valutazione finora

- Keep Computer Awake - Alt + F8 To Break Into Loop and ExitDocumento3 pagineKeep Computer Awake - Alt + F8 To Break Into Loop and ExitcutefrenzyNessuna valutazione finora

- Peening and FatigueDocumento6 paginePeening and FatiguecutefrenzyNessuna valutazione finora

- Mek4450 Ife Day1 Lesson2Documento32 pagineMek4450 Ife Day1 Lesson2cutefrenzyNessuna valutazione finora

- Mine Development Surface Water Engineering PlanDocumento10 pagineMine Development Surface Water Engineering PlancutefrenzyNessuna valutazione finora

- Fundamentals of Multiphase FlowDocumento410 pagineFundamentals of Multiphase FlowF.L.YNessuna valutazione finora

- Oil & Gas Downstream - EN-weldingDocumento22 pagineOil & Gas Downstream - EN-weldingcutefrenzyNessuna valutazione finora

- Intro To Basic UTDocumento41 pagineIntro To Basic UTgirish310100% (1)

- Hfss 2way Thermal DimensionsDocumento34 pagineHfss 2way Thermal DimensionscutefrenzyNessuna valutazione finora

- Support Design PDFDocumento42 pagineSupport Design PDFbalramkinageNessuna valutazione finora

- Manual Recipientes Sometidos Presion PDFDocumento29 pagineManual Recipientes Sometidos Presion PDFckkashyap0007Nessuna valutazione finora

- Eddy Current Carburzation Measurements in TubesDocumento9 pagineEddy Current Carburzation Measurements in TubescutefrenzyNessuna valutazione finora

- IOS Interior Routing ProtocolsDocumento1 paginaIOS Interior Routing ProtocolsRhythum KumarNessuna valutazione finora

- Read Me InterimDocumento1 paginaRead Me InterimcutefrenzyNessuna valutazione finora

- ReadmeDocumento1 paginaReadmecutefrenzyNessuna valutazione finora

- Equilibruim of Forces and How Three Forces Meet at A PointDocumento32 pagineEquilibruim of Forces and How Three Forces Meet at A PointSherif Yehia Al MaraghyNessuna valutazione finora

- Peran Dan Tugas Receptionist Pada Pt. Serim Indonesia: Disadur Oleh: Dra. Nani Nuraini Sarah MsiDocumento19 paginePeran Dan Tugas Receptionist Pada Pt. Serim Indonesia: Disadur Oleh: Dra. Nani Nuraini Sarah MsiCynthia HtbNessuna valutazione finora

- Meet Your TeamDocumento2 pagineMeet Your TeamAyushman MathurNessuna valutazione finora

- Kate Elizabeth Bokan-Smith ThesisDocumento262 pagineKate Elizabeth Bokan-Smith ThesisOlyaGumenNessuna valutazione finora

- Problem Set SolutionsDocumento16 pagineProblem Set SolutionsKunal SharmaNessuna valutazione finora

- Letter From Attorneys General To 3MDocumento5 pagineLetter From Attorneys General To 3MHonolulu Star-AdvertiserNessuna valutazione finora

- Command List-6Documento3 pagineCommand List-6Carlos ArbelaezNessuna valutazione finora

- CDI-AOS-CX 10.4 Switching Portfolio Launch - Lab V4.01Documento152 pagineCDI-AOS-CX 10.4 Switching Portfolio Launch - Lab V4.01Gilles DellaccioNessuna valutazione finora

- France Winckler Final Rev 1Documento14 pagineFrance Winckler Final Rev 1Luciano Junior100% (1)

- Assembly ModelingDocumento222 pagineAssembly ModelingjdfdfererNessuna valutazione finora

- Iphoneos 31Documento159 pagineIphoneos 31Ivan VeBoNessuna valutazione finora

- Level 10 Halfling For DCCDocumento1 paginaLevel 10 Halfling For DCCQunariNessuna valutazione finora

- BIT 4107 Mobile Application DevelopmentDocumento136 pagineBIT 4107 Mobile Application DevelopmentVictor NyanumbaNessuna valutazione finora

- Simba s7d Long Hole Drill RigDocumento2 pagineSimba s7d Long Hole Drill RigJaime Asis LopezNessuna valutazione finora

- Rapport DharaviDocumento23 pagineRapport DharaviUrbanistes du MondeNessuna valutazione finora

- PNBONE_mPassbook_134611_6-4-2024_13-4-2024_0053XXXXXXXX00 (1) (1)Documento3 paginePNBONE_mPassbook_134611_6-4-2024_13-4-2024_0053XXXXXXXX00 (1) (1)imtiyaz726492Nessuna valutazione finora

- Chapter 19 - 20 Continuous Change - Transorganizational ChangeDocumento12 pagineChapter 19 - 20 Continuous Change - Transorganizational ChangeGreen AvatarNessuna valutazione finora

- Why Choose Medicine As A CareerDocumento25 pagineWhy Choose Medicine As A CareerVinod KumarNessuna valutazione finora

- EIRA v0.8.1 Beta OverviewDocumento33 pagineEIRA v0.8.1 Beta OverviewAlexQuiñonesNietoNessuna valutazione finora

- Hi-Line Sportsmen Banquet Is February 23rd: A Chip Off The Ol' Puck!Documento8 pagineHi-Line Sportsmen Banquet Is February 23rd: A Chip Off The Ol' Puck!BS Central, Inc. "The Buzz"Nessuna valutazione finora

- WWW - Commonsensemedia - OrgDocumento3 pagineWWW - Commonsensemedia - Orgkbeik001Nessuna valutazione finora

- MCQ Ch16solDocumento4 pagineMCQ Ch16solandiswahlongwa870Nessuna valutazione finora

- 1st SemDocumento3 pagine1st SemARUPARNA MAITYNessuna valutazione finora