Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Introducing The GEK Gasifier Systems - Rev5

Caricato da

Dimuthu Prasad WijethungeTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Introducing The GEK Gasifier Systems - Rev5

Caricato da

Dimuthu Prasad WijethungeCopyright:

Formati disponibili

770-00034

Introducing

the Power Pallet

770-00034

I . Overview and Specifications

ALL Power Labs offers downdraft gasifier systems in various sizes: 10kW, 20kW, and 100kW.

These kWe ratings reference the potential of electrical power capable in a gasifier/ICE/generator

system at the gasifier's maximum gas flow capacity. The GEK Power Pallet integrates an internal

combustion engine and a generator with automated controls with the ability to utilize the gas for other

purposes, while the GEK Gasifier comes as an assemble-yourself kit that provides stand-alone wood

gas for a variety of end uses. Below are the specifications of the systems provided by ALL Power Labs.

GEK Gasifier System Sizes provided by ALL Power Labs

10kW GEK 20kW GEK 100kW GEK

electrical capacity range (kW) 2 - 10 4 - 20 20 - 100

gas flow range (m^2/hr) 5 -27 11 - 53 53 - 267

gas heat flow at max (BTU/hr) 168,993 331,727 8,355,765

biomass consumption rate (kg/day) 160 - 320 320 - 640 640 - 3200

gasifier system footprint (excluding hopper) (ft) 2 x 4 2 x 4 4 x 7

The GEK Systems are offered at various integration stages as well as at different kit levels to

make the equipment accessible at various price points. The kit 'Levels' refer to the completeness of the

offered product. The levels are as follows:

Level I: free CAD files available online

Level III: Weld-It-Yourself kit (mild steel only)

Level IV: Assemble-It-Yourself kit (stainless steel only)

Level V: Completely Assembled and Integrated

GEK Gasifier Models, Levels and Features Offered

Model Sizes

(kW)

Levels

Available

Included Features

Basic GEK 10, 20 I, III, IV Reactor, gas filter only. Gas drive system: ejector

GEK TOTTI 10, 20,

100

III, IV Basic GEK with Pyrocoil and Drying Bucket. Gas drive system:

ejector

GEK Power

Pallet

10, 20 V GEK TOTTI, PCU, logic and components for automation, engine

and generator. Gas drive system: blowers. Integrated on a 4x4

pallet. Available in 120V/208/240V AC, 60/50Hz, and in single,

split, or three phase configurations.

Biomass Requirements of the GEK Gasifier Systems

Most downdraft gasifier systems require specified feedstock characteristics and can be sensitive

770-00034

to feed stocks that lie outside of the required specifications for the given equipment. Across all of the

GEK Models above, ALL Power Labs has implemented designs in both the reactor and the bulk

handling systems that broaden the allowed feedstock characteristic requirements of typical systems of

its size. Below are the suggested ranges for given feedstock characteristics to be used in the GEK

systems.

Biomass Requirements

particle size (in) .5 - 1.5

moisture content (% by dry weight) <25

fixed to volatile ratio >0.25

ash content (%) >5

Please refer to the Feedstock Requirements and Preparation Guide for more information.

The GEK Systems are designed for raw biomass and organic-based feed stocks. Experimental

feed stocks lying outside of the suggested ranges may require modification of the equipment and

testing of the gas quality produced. For experimental and research, ALL Power Labs offers a Research

Experimenters Kit with test and control equipment valuable for gas testing or further development off

of the base systems. Contact sales@allpowerlabs.org for more information.

770-00034

I I . I dentifying the GEK System Components

770-00034

GEK System Components con't

1. Feedstock Hopper

2. Drying Bucket

3. Fuel Level Switch

4. Pyrocoil Exhaust Port

5. Reactor

6. Auxiliary Port

7. Gas Cowling

8. Manual Grate Shaker

9. Ash Port

10. Dual Channel Manometer and Thermocouple

Port

11. Cyclone Condensate Jar

12. Air Inlet Check Valve

13. Lighting Port

14. Cyclone

15. Gas Service Connection Port

16. Biomass Feed Auger

17. Ejector Compressed Air Connection

18. Ejector Gas Drive

19. Swirl Burner

20. Manual Air-Premix Valve

21. Gas Shut-off Valve

22. Packed Bed Gas Filter

23. Hopper Barrel Puff Bung

24. Flare Stack

25. Air Blower

26. Engine Radiator Coolant Port

27. Engine Alternator

28. 12V DC Car Battery (not included)

29. Fuel Level Switch

30. Pyrocoil and Exhaust Insulation Jacket

31. Engine Exhaust

32. Engine Gas Valve

33. Packed Bed Gas Filter Lid Access

34. Filter Condensate Drain Port

35. Automatic Flare Igniter

36. Air Blower

37. Air Filter

38. System Safety Relief Valve

39. Generator and Electrical Connection Box

40. Engine Starter Motor

41. Engine Condensate Trap

42. Engine Oil Filter

43. Governor and Engine Throttle

45. Oxygen Sensor

46. Automated Grate Shaker

47. Feedstock Hopper View Port

48. Dual Gas Blower

49. Pyrocoil Heat Exchanger

50. Gas Line Access Port

51. Process Control Unit (PCU) and Control Logic

52. Main Operation Panel

770-00034

I I I . I dentifying the Power Pallet Control Panel and PCU Components

53. Hour Meter

54. Oxygen Sensor Air/Fuel

Ratio Dial

55. LCD Display

56. 4 Input Buttons

57. System Main Power

58. Engine Key Switch

59. Dual Gas Blower

Adjustment Knob

60. Air Blower Adjustment

Knob

61. PCU USB Connection Port

62. Warning Alarm

a. Power Input

b. FETs

c. RS232 Communication Port

d. ATX Power Supply

e. Input Buttons and Keypad Off-board

Connection

f. Relay Board I/O Connectors

g. Thermocouple Screw Terminal

Connectors

h. Thermocouple Standard Connectors

i. LCD Display and Contrast Knob

j. Micro SD card

k. Low Range Pressure

Sensors

l. High Range Pressure

Sensors

m. Analog Inputs

n. ATmel MicroProcessor

o. CAN Bus

Communication Port

p. Reset Button

q. Status LEDs

r. USB Communication Port

s. Servo Control Ports

t. Timer

770-00034

I V. Description of the GEK Gasifier Process Flows

The GEK Process starts with the introduction of feedstock into the hopper. After the hopper, the

feedstock passes through an auger and enters the gasifier. The auger is controlled by a level switch

incorporated into the reactor lid. The feedstock fills the GEK reactor and stages needed for passes

through the stages of gasification: drying, pyrolysis, combustion, and reduction. The hot gas exits the

reactor and passes through a cyclone to separate char particulates. The GEK Gasifier systems are

designed to utilize the heat from the gas produced to dry the incoming feedstock through the Drying

Bucket. After the Drying Bucket, the gas passes through the gas filter and gas drive system. The GEK

Gasifier systems have two main valves to switch between one of two operational modes: Flare or

Engine Mode (or other gas utilization mode). For Engine Mode, the Pyrocoil heat exchanger, included

in the TOTTI design, increases the efficiency of the reaction by supporting the heat needed for the

pyrolysis zone by utilizing the waste heat from the exhaust of an engine or other process.

The GEK Gasifier Kits and the Power Pallet have different gas drive systems as shown in the

GEK Process Flow diagram above. For the GEK Kits, the gas enters the gas filter, and passes through

the ejector gas drive system. Here the air is then mixed for the flare.

For the Power Pallet, the gas by-passes the filter on start-up and the blower system provides gas and air

for the flare. After start-up, the flare is then shut off and the engine pulls gas through the gas filter.

The Basic GEK Kit does not include the Drying Bucket, Pyrocoil, or Auger shown in the diagram

above. The Basic GEK Kit has a simple lid on top of the reactor and is to be filled manually. The Basic

GEK Kits are offered as the most simple experimental development platform.

Potrebbero piacerti anche

- IELTS Writing Band 9 Essays PDFDocumento187 pagineIELTS Writing Band 9 Essays PDFEranda90% (31)

- Construct Updraft GasifierDocumento8 pagineConstruct Updraft GasifierHariharan SivaramagopalakrishnanNessuna valutazione finora

- Hydroformed Metal Bellows - Design HandbookDocumento128 pagineHydroformed Metal Bellows - Design Handbookchipulino100% (1)

- Introducing The GEK Gasifier Systems - Rev3 PDFDocumento18 pagineIntroducing The GEK Gasifier Systems - Rev3 PDFpicotto100% (1)

- 12 Cooling Load CalculationsDocumento61 pagine12 Cooling Load Calculationssp suNessuna valutazione finora

- Uol Thesis TemptDocumento17 pagineUol Thesis TemptShahzad Chaudhry100% (1)

- Masonry Heaters: Planning Guide For Architects, Home Designers and BuildersDocumento13 pagineMasonry Heaters: Planning Guide For Architects, Home Designers and Buildersginghinac100% (1)

- Solar Permitting Guidebook - 2017Documento130 pagineSolar Permitting Guidebook - 2017Alo100% (1)

- 2the Complete Biogas HandbookDocumento7 pagine2the Complete Biogas HandbookJhe Inibam100% (1)

- Installation Guide for Cylinder Head ReplacementDocumento5 pagineInstallation Guide for Cylinder Head ReplacementJuan Francisco Canto Diez100% (1)

- MI 3317-2eDocumento52 pagineMI 3317-2ejalilemadi100% (2)

- FT 8 PDFDocumento33 pagineFT 8 PDFvcharles100% (1)

- Power SupplyDocumento9 paginePower SupplyMuhammed HuzaifaNessuna valutazione finora

- Cryogenic Insulation TechnologyDocumento61 pagineCryogenic Insulation TechnologyNurcahyo Djati WNessuna valutazione finora

- Syngas Production Using Natural Gas From The EnvirDocumento19 pagineSyngas Production Using Natural Gas From The EnvirAdi Gunawan PrasetiaNessuna valutazione finora

- Paxman SpecsDocumento9 paginePaxman Specsbastech100% (2)

- Wood Gas As Engine FuelDocumento86 pagineWood Gas As Engine FuelSv Tinh NguyệnNessuna valutazione finora

- Gasifier Engine SystemDocumento7 pagineGasifier Engine SystemRajkumar MeenaNessuna valutazione finora

- Standard Technical Features of BTG System for Supercritical Thermal UnitsDocumento222 pagineStandard Technical Features of BTG System for Supercritical Thermal Unitsshanmars007100% (2)

- Handbook of Biomass Downdraft Gasifier Engine SystemsDocumento149 pagineHandbook of Biomass Downdraft Gasifier Engine SystemsRodolfo90% (10)

- Dasifier The Up-Downdraft Gasifier For Metal Melting 2001 PDFDocumento3 pagineDasifier The Up-Downdraft Gasifier For Metal Melting 2001 PDFguytr2Nessuna valutazione finora

- Design Princples For Wood Burning Cook StovesDocumento20 pagineDesign Princples For Wood Burning Cook Stoveshana temesegenNessuna valutazione finora

- Plasma Assisted CombustionDocumento8 paginePlasma Assisted CombustionEddie WinklerNessuna valutazione finora

- Sustainable building foundations guideDocumento4 pagineSustainable building foundations guidek1l2d3Nessuna valutazione finora

- Microwave TubesDocumento58 pagineMicrowave TubesDhyey DesaiNessuna valutazione finora

- Biodiesel From Micro AlgaeDocumento3 pagineBiodiesel From Micro Algaeraanja2Nessuna valutazione finora

- Gasification of Municipal Solid WastesDocumento8 pagineGasification of Municipal Solid WastesSalman Zafar100% (2)

- Building, Installing and Maintaining The HELPS International Nixtamal CookerDocumento6 pagineBuilding, Installing and Maintaining The HELPS International Nixtamal CookerTefera AdugnaNessuna valutazione finora

- Biomass Gasification: A Thermochemical Conversion ProcessDocumento27 pagineBiomass Gasification: A Thermochemical Conversion ProcessMalli ReddyNessuna valutazione finora

- Charcoal by Gary GilmoreDocumento10 pagineCharcoal by Gary GilmoreMarky MaypoNessuna valutazione finora

- BiogasDocumento11 pagineBiogasAnand RathiNessuna valutazione finora

- Biogas Technology: Construction, Utilization and Operation ManualDocumento52 pagineBiogas Technology: Construction, Utilization and Operation ManualDwi Cahyo NugrohoNessuna valutazione finora

- Design, Process Simulation and Construction of An Atmospheric Dual Fluidized Bed CombustionDocumento9 pagineDesign, Process Simulation and Construction of An Atmospheric Dual Fluidized Bed Combustionapi-3799861Nessuna valutazione finora

- Press MUd To Bio GasDocumento5 paginePress MUd To Bio GasAyush AgrawalNessuna valutazione finora

- MS5002E NewDocumento8 pagineMS5002E Newecs71100% (2)

- Free gas movement systemDocumento9 pagineFree gas movement systemClinica de TermopaneNessuna valutazione finora

- No Smoke Stove Using BiomassDocumento55 pagineNo Smoke Stove Using BiomassShashank100% (1)

- Small Scale Gas Producer Engine SystemsDocumento284 pagineSmall Scale Gas Producer Engine Systemsbogz12100% (1)

- GE 10-1 Gas TurbineDocumento29 pagineGE 10-1 Gas TurbineAtanda Babatunde Mutiu33% (3)

- Biomass Pellet MillsDocumento4 pagineBiomass Pellet MillsRadmila BlagojevicNessuna valutazione finora

- Basic Design of a Fluidized Bed Gasifier for Rice HuskDocumento8 pagineBasic Design of a Fluidized Bed Gasifier for Rice HuskAnna Yunita SitompulNessuna valutazione finora

- Fluidized Bed GasifiersDocumento9 pagineFluidized Bed GasifiersNikhilesh BhargavaNessuna valutazione finora

- Biomass Downdraft Gasifier Engine SystemsDocumento148 pagineBiomass Downdraft Gasifier Engine Systemssounds4uniqueNessuna valutazione finora

- CEP SamalkotDocumento96 pagineCEP SamalkotkukugargNessuna valutazione finora

- StovesDocumento5 pagineStovesElsa LaminNessuna valutazione finora

- Gassification For Practical ApplicationsDocumento350 pagineGassification For Practical ApplicationshugogalindoNessuna valutazione finora

- DCM FieldsupplyunitDocumento18 pagineDCM FieldsupplyunitStancu BranNessuna valutazione finora

- Offshore Wind Farms Selected Project References 2019Documento7 pagineOffshore Wind Farms Selected Project References 2019Iqbal MeskinzadaNessuna valutazione finora

- Naphtha Steam Reforming For Hydrogen ProductionDocumento9 pagineNaphtha Steam Reforming For Hydrogen ProductionsatishchemengNessuna valutazione finora

- GKMOSS Wood Boiler System BrochureDocumento8 pagineGKMOSS Wood Boiler System BrochureJose Lorenzo Toral100% (1)

- Rhgs4biomass StovesA TWO-BURNER CONTINUOUS-TYPE RICE HUSK GAS STOVE DEVELOPED FOR HOUSEHOLD/SMALL COTTAGE INDUSTRYDocumento3 pagineRhgs4biomass StovesA TWO-BURNER CONTINUOUS-TYPE RICE HUSK GAS STOVE DEVELOPED FOR HOUSEHOLD/SMALL COTTAGE INDUSTRYplcuserNessuna valutazione finora

- Energy Production From Steam Gasification Processes and Parameters That Contemplate in Biomass Gasifier - A ReviewDocumento11 pagineEnergy Production From Steam Gasification Processes and Parameters That Contemplate in Biomass Gasifier - A ReviewAyush dave100% (1)

- Rice Husker Construction Manual - Appropedia - The Sustainability Wiki PDFDocumento17 pagineRice Husker Construction Manual - Appropedia - The Sustainability Wiki PDFMarcos MorschNessuna valutazione finora

- Biomass Gasification PDFDocumento29 pagineBiomass Gasification PDFHotib PerwiraNessuna valutazione finora

- Development of An Enhanced Biomass Gasifier Charcoal StoveDocumento9 pagineDevelopment of An Enhanced Biomass Gasifier Charcoal StoveInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Rice Husk Stove UpdateDocumento3 pagineRice Husk Stove UpdateTefera AdugnaNessuna valutazione finora

- Handbook of Biomass Downdraft Gasifier Engine Systems by Thomas B. Reed - Agua DasDocumento31 pagineHandbook of Biomass Downdraft Gasifier Engine Systems by Thomas B. Reed - Agua DasEmanuel GustavoNessuna valutazione finora

- Methane Production GuideDocumento9 pagineMethane Production GuideElmer CeledonioNessuna valutazione finora

- A-318 Apcseet 2011 Josh WilkeyDocumento24 pagineA-318 Apcseet 2011 Josh WilkeyJosh ApfelstrudelNessuna valutazione finora

- Design and Development of Updraft Gasifier Using Solid Biomass (ACUAN)Documento8 pagineDesign and Development of Updraft Gasifier Using Solid Biomass (ACUAN)Joe MambayaNessuna valutazione finora

- For Biomass 2 LRDocumento20 pagineFor Biomass 2 LRJuan Domingo OrlandiniNessuna valutazione finora

- Experiment of Briquetting MachineDocumento4 pagineExperiment of Briquetting MachineRaihan KabirNessuna valutazione finora

- GasifiersDocumento53 pagineGasifiersRaphael Lomonaco100% (1)

- Biogas Mass Balance PDFDocumento9 pagineBiogas Mass Balance PDFHafizhun SoekiswoNessuna valutazione finora

- Incineration of Municipal Waste: Specialized Seminars on Incinerator Emissions of Heavy Metals and Particulates, Copenhagen, 18–19 September 1985 and Emission of Trace Organics from Municipal Solid Waste Incinerators, Copenhagen, 20–22 January 1987Da EverandIncineration of Municipal Waste: Specialized Seminars on Incinerator Emissions of Heavy Metals and Particulates, Copenhagen, 18–19 September 1985 and Emission of Trace Organics from Municipal Solid Waste Incinerators, Copenhagen, 20–22 January 1987Robert B. DeanNessuna valutazione finora

- 1 - Introducing The GEK Gasifier Systems - Rev5 PDFDocumento7 pagine1 - Introducing The GEK Gasifier Systems - Rev5 PDFwawanUAINessuna valutazione finora

- 60 MW GE Frame 7B+ Gas Turbine Generator Package PG 7801BDocumento5 pagine60 MW GE Frame 7B+ Gas Turbine Generator Package PG 7801BvcharlesNessuna valutazione finora

- g3520c Natural Gas For 1950Documento6 pagineg3520c Natural Gas For 1950Shahzad AliNessuna valutazione finora

- PB-TM2500-SSDocumento9 paginePB-TM2500-SShpfmachineryNessuna valutazione finora

- 9077-tm2500 Mix 1Documento7 pagine9077-tm2500 Mix 1Serg MarushkoNessuna valutazione finora

- Zarya TurbineDocumento66 pagineZarya TurbineEbrahim ZolfagharyNessuna valutazione finora

- Energy Technology Criteria List 2013Documento177 pagineEnergy Technology Criteria List 2013dekraguljNessuna valutazione finora

- IGCC Preliminary DesignDocumento34 pagineIGCC Preliminary DesignOnnuri WonNessuna valutazione finora

- Epfl TH7598 PDFDocumento147 pagineEpfl TH7598 PDFDimuthu Prasad WijethungeNessuna valutazione finora

- Xuan - Convective Heat TransferDocumento5 pagineXuan - Convective Heat TransferDimuthu Prasad WijethungeNessuna valutazione finora

- Http://Chem Ps Uci Edu/ kieron/Dft/BookDocumento104 pagineHttp://Chem Ps Uci Edu/ kieron/Dft/BookjmartiarNessuna valutazione finora

- Reactor Scale Simulation of Atomic Layer DepositionDocumento92 pagineReactor Scale Simulation of Atomic Layer DepositionDimuthu Prasad WijethungeNessuna valutazione finora

- CFD Analysis of Solar Flat Plate CollectorDocumento6 pagineCFD Analysis of Solar Flat Plate CollectorDimuthu Prasad WijethungeNessuna valutazione finora

- A Human Thermal Model For Improved Thermal ComfortDocumento150 pagineA Human Thermal Model For Improved Thermal ComfortJoel Flores MoraNessuna valutazione finora

- Equação Biotermica de Pennes OriginalDocumento30 pagineEquação Biotermica de Pennes OriginalFabricio BuenoNessuna valutazione finora

- CHP Thesis KTHDocumento98 pagineCHP Thesis KTHDimuthu Prasad WijethungeNessuna valutazione finora

- Modelling Phase Change in A 3D Thermal Transient AnalysisDocumento22 pagineModelling Phase Change in A 3D Thermal Transient AnalysisDimuthu Prasad WijethungeNessuna valutazione finora

- Multi-Objective Optimization of HVAC System With An Evolutionary Computation AlgorithmDocumento10 pagineMulti-Objective Optimization of HVAC System With An Evolutionary Computation AlgorithmDimuthu Prasad WijethungeNessuna valutazione finora

- Optimum Duct Design For Variable Air Volume SystemsDocumento172 pagineOptimum Duct Design For Variable Air Volume SystemsDimuthu Prasad WijethungeNessuna valutazione finora

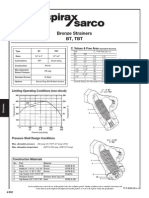

- Bronze Strainers BT, TBT: C Values & Free AreaDocumento2 pagineBronze Strainers BT, TBT: C Values & Free AreabuddhansamratNessuna valutazione finora

- SC4850E-ZYT User Mannual (V100R001 - 01) PDFDocumento38 pagineSC4850E-ZYT User Mannual (V100R001 - 01) PDFEnderson Peralta100% (1)

- Basis For Computing The Estimated Electricity Consumption of Home Appliances For The Meralco Appliance CalculatorDocumento3 pagineBasis For Computing The Estimated Electricity Consumption of Home Appliances For The Meralco Appliance CalculatorUlysses Monsale33% (3)

- Nuetech Solar Systems Private LimitedDocumento71 pagineNuetech Solar Systems Private LimitedPrashanth PB100% (1)

- Datasheet Panel SolarDocumento2 pagineDatasheet Panel SolarCandy Fabiola Salinas ChavezNessuna valutazione finora

- ENERGY USE AND CONSERVATION TIPSDocumento28 pagineENERGY USE AND CONSERVATION TIPSMarcus Abracosa CaraigNessuna valutazione finora

- Animal Food Processing PlantDocumento30 pagineAnimal Food Processing PlantDaniel OkereNessuna valutazione finora

- Earth Won T Wait. Neither Will We.: That S PowerfulDocumento1 paginaEarth Won T Wait. Neither Will We.: That S Powerfulafnan a.muhammadNessuna valutazione finora

- Assignment by Electrical Mentor: Author: BNSS Shankar, M.Tech (IITK)Documento11 pagineAssignment by Electrical Mentor: Author: BNSS Shankar, M.Tech (IITK)anjaneyuluNessuna valutazione finora

- CEO Talk OGIP 2020 - Gunawan MuktiwibowoDocumento11 pagineCEO Talk OGIP 2020 - Gunawan Muktiwibowodion gunawanNessuna valutazione finora

- Optimal Design of Low-Cost and Reliable Hybrid Renewable Energy System Considering Grid BlackoutsDocumento7 pagineOptimal Design of Low-Cost and Reliable Hybrid Renewable Energy System Considering Grid BlackoutsNelson Andres Entralgo MaldonadoNessuna valutazione finora

- Stratified 24kwe ManualDocumento20 pagineStratified 24kwe Manualshivanandr2481Nessuna valutazione finora

- Powerpoint Carburettor SystemsDocumento10 paginePowerpoint Carburettor SystemsVahid KhanNessuna valutazione finora

- 18me751 Module 1Documento43 pagine18me751 Module 1tejus8104Nessuna valutazione finora

- Transparent Concrete As An Eco-Friendly Material For BuildingDocumento8 pagineTransparent Concrete As An Eco-Friendly Material For BuildinginventionjournalsNessuna valutazione finora

- ELC or IGCDocumento3 pagineELC or IGCbkvuvce8170Nessuna valutazione finora

- 125 KWp SOLAR POWER PLANT OVERVIEW DRAWINGDocumento1 pagina125 KWp SOLAR POWER PLANT OVERVIEW DRAWINGHarish ArnepalliNessuna valutazione finora

- MPV 125.2/2C-SA311A-11002: Technical DataDocumento3 pagineMPV 125.2/2C-SA311A-11002: Technical DataDerkung BenowatNessuna valutazione finora

- Procedure For Burner Handover and TakeoverDocumento7 pagineProcedure For Burner Handover and TakeoverArjun Shantaram ZopeNessuna valutazione finora