Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Intallation Manual RAM 70 80QH4 (En)

Caricato da

Babis ArbiliosDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Intallation Manual RAM 70 80QH4 (En)

Caricato da

Babis ArbiliosCopyright:

Formati disponibili

< S552 : B >

Height difference

FOR SERVICE PERSONNEL ONLY

INVERTER SYSTEM MULTI TYPE

OUTDOOR UNIT INSTALLATION MANUAL

MODEL

RAM-70QH4

RAM-80QH4

Carefully read through the procedures of proper installation before starting installation work.

The sales agent should inform customers regarding the correct operation of installation.

Explanation for indoor unit is in the How To Use (Instruction Manual) that packed with indoor unit.

Tools Needed For Installation Work (Mark is exclusive use tool for R410A)

Screwdriver Measuring Tape Knife Saw 65mm Power Drill Hexagonal Wrench

Key ( 4mm) Wrench (14,17,22,26,27mm) Gas Leakage Detector Pipe Cutter Putty

Vinyl Tape Pliers Flare Tool Vacuum Pump Adapter Manifold Valve Charge Hose

Vacuum Pump

Read the safety precautions carefully before operating the unit.

The contents of this section are vital to ensure safety. Please pay special attention to the following

sign.

WARNING....... Incorrect methods of installation may cause death or serious injury.

CAUTION........ Improper installation may result in serious consequence.

Make sure to connect earth line.

This sign in the figures indicates prohibition.

Be sure that the unit operates in proper condition after installation. Explain to customer the proper

watt of operating the unit as described in the users guide.

SAFETY PRECAUTION

WARNING

Please request your sales agent or qualified technician to install your unit. Water leakage, short circuit or

fire may occur if you do the installation work yourself.

Please observe the instructions stated in the installation manual during the process of installation. Improper

installation may cause water leakage, electric shock and fire.

Make sure that the units are mounted at locations which are able to provide full support to the weight of

the units. If not, the units may collapse and impose danger.

Observe the rules and regulations of the electrical installation and the methods described in the installation

manual when dealing with the electrical work. Use wire which are approved official in your country. A

short circuit and fire may occur due to the use of low quality wire or improper work.

Be sure to use the specified wire for connecting the indoor and outdoor units. Please ensure that the

connections are tight after the conductors of the wire are inserted into the terminals. Improper insertion

and loose contact may cause over-heating and fire.

Please use the specified components for installation work. Otherwise, the unit may collapse or water

leakage, electric shock and fire may occur.

When installing or transferring an air conditioner to another location, make sure that air other than the

specified refrigerant (R410A) does not enter the refrigeration cycle. If other air should enter, the pressure

level of the refrigeration cycle may increase abnormally which could result in a rupture and injury.

Be sure to use the specified piping set for R410A. Otherwise, this may result in broken copper pipes or

faults.

When installing or removing an air conditioner, do not allow air or moisture to remain in the refrigeration

cycle. Otherwise, pressure in the refrigeration cycle may become abnormally high so that a rupture may

be caused.

Be sure to ventilate fully if a refrigerant gas leak while at work. If the refrigerant gas comes into contact

with fire, a poisonous gas may occur.

After completion of installation work, check to make sure that there is no refrigeration gas leakage. If the

refrigerant gas leaks into the room, coming into contact with fire in the fan-driven heater, space heater,

etc., a poisonous gas may occur.

Unauthorized modifications to the air conditioner may be dangerous. If a breakdown occurs please call

a qualified air conditioner technician or electrician. Improper repairs may result in water leakage, electric

shock and fire, etc.

Be sure to connect the earth line from the power supply wire to the outdoor unit and between

the outdoor and indoor unit. Improper earthing may cause electric shock.

CAUTION

A circuit breaker must be installed in the house distribution box for the direct connected power

supply wire to the outdoor unit. In case of other installations a main switch with a contact gap or

more than 3mm has to be installed. Without a circuit breaker, the danger of electric shock exists.

Do not install the unit near a location where there is flammable gas. The outdoor

unit may catch fire if flammable gas leaks around it. Piping shall be suitable

supported with a maximum spacing of 1m between the supports.

Please ensure smooth flow of water when installing the drain hose.

An IEC approved power cord should be used. Power cord type : NYM.

Accessories to Outdoor unit:

No. Item Quantity

a Drain pipe 1

b Bushing 1

THE CHOICE OF MOUNTING SITE

(Please note the following matters and obtain permission from customer before installation.)

WARNING

The outdoor unit must be mounted at a location which can support heavy weight. Otherwise, noise

and vibration will increase.

CAUTION

Do not expose the unit under direct sunshine or rain. Besides, ventilation must be good and clear of

obstruction.

The air blown out of the unit should not point directly to animals or plants.

The clearance of the unit from top, left, right and front are specified in figure below. At least two of

the above sides must be open air. If it is possible to open only two sides, make sure the discharging

side is one of them.

Be sure that the hot air blown out of the unit and noise do not disturb the neighbourhood.

Do not install at a location where there is flammable gas, steam, oil and smoke.

The location must be convenient for water drainage.

Place the outdoor unit and its connection wire at least 1m away from the antenna or signal line of

television, radio or telephone. This is to avoid noise interference.

RAM-70QH4

Piping length

(Within

10m)

(Within

10m)

Outdoor unit

Outdoor unit

RAM-80QH4

RAM-70QH4

RAM-80QH4

L1

L1 L2 L3 L4

L2 L3

Indoor unit 1 Indoor unit 2 Indoor unit 3

Outdoor unit

L1 + L2 + L3 = Maximum 60m

(However, L1 + L2 = Maximum 35m)

Maximum piping length for one indoor unit is 25m.

* Additional charge of refrigerant is not required.

(L1 + L2) = (L3 + L4) = Maximum 35m

Maximum piping length for one indoor unit is 25m.

* Additional charge of refrigerant is not required.

Indoor unit 1 Indoor unit 2

Outdoor unit

Indoor unit 3 Indoor unit 4

[Outdoor unit installation]

The pipe connection ports of the outdoor unit and connectable indoor units are shown below. (Connection

of the compressors is as shown below.)

RAM-70QH4

To the outdoor unit, up to three indoor units can be connected until the total value of each units

capacity from 5.0kW to 11.0kW.

One unit of 2.5kW or 3.5kW

One unit of 2.5kW, 3.5kW or

4.0kW

One unit of 2.5kW, 3.5kW, 4.0kW or 5.0kW

(5kW unit: Optional flare adaptor for piping is necessary.)

O

u

t

d

o

o

r

u

n

it

p

ip

e

c

o

n

n

e

c

t

io

n

p

o

r

t

C

o

m

p

r

e

s

s

o

r

B

C

o

m

p

r

e

s

s

o

r

A

In

d

o

o

r u

n

it 3

In

d

o

o

r u

n

it 2

In

d

o

o

r u

n

it 1

6.35 (1/4")

9.52 (3/8")

6.35 (1/4")

9.52 (3/8")

6.35 (1/4")

9.52 (3/8")

RAM-80QH4

To the outdoor unit, up to four indoor units can be connected until the total value of each units capacity

reaches 12.0kW. However, install indoor units so that total capacity of Indoor unit 1 and Indoor unit 2

and total capacity of Indoor unit 3 and Indoor unit 4 are approached. For example, when two 2.5kW

units and two 3.5kW units are to be connected, connect as shown below.

Connect 3 or more indoor units. If only two units are to be connected, connect them as Indoor unit 1

and Indoor unit 2 or Indoor unit 3 and Indoor unit 4. However, when two 3.5kW units are connected or

when one 2.5kW unit and one 4kW unit are connected, capacity may be less than indicated capacity.

One unit of 2.5kW or 3.5kW

One unit of 2.5kW, 3.5kW, 4.0kW or 5.0kW

(5kW unit: Optional flare adaptor for piping is necessary.)

One unit of 2.5kW or 3.5kW

One unit of 2.5kW, 3.5kW, 4.0kW or 5.0kW

(5kW unit: Optional flare adaptor for piping is necessary.)

O

u

t

d

o

o

r

u

n

it

p

ip

e

c

o

n

n

e

c

t

io

n

p

o

r

t

C

o

m

p

r

e

s

s

o

r

B

C

o

m

p

r

e

s

s

o

r

A

In

d

o

o

r u

n

it 3

In

d

o

o

r u

n

it 2

In

d

o

o

r u

n

it 1 6.35 (1/4")

9.52 (3/8")

6.35 (1/4")

9.52 (3/8")

6.35 (1/4")

9.52 (3/8")

6.35 (1/4")

9.52 (3/8")

Indoor unit 1

Indoor unit 2

Indoor unit 3

Indoor unit 4

2.5kW

3.5kW

2.5kW

3.5kW

Total 7.0kW

Install so that both total capacities are approached.

Total 7.0kW

Total capacity of 4 units:

12.0kW or less

Remove electric box cover and three cord bands. Then, remove side panel and front panel in sequence.

(If side panel cannot be removed at this time, remove top cover.)

* 100mm or more

200mm or more

100mm or more

* 500mm or more

200mm or more

* Keep as far away as possible.

Dimension of Mounting

Stand of the outdoor unit

(unit: mm)

150 500

12

3

7

0

2

0

Condensed Water Disposal of Unit

There is a hole on the base of outdoor unit for

condensed water to exhaust.

In order for condensed water to flow to the draining

part, install the unit on the level ground or block so

that the unit is 100mm above the ground same as

figure shown. Join the drain pipe to one hole and cover

the rest with bushing. If there are other holes or gaps,

cover them with putty to prevent water from leaking

out.

At first insert one portion of the hook to the base,

then pull the drain pipe in the direction shown by the

arrow while inserting the hook into the base. After

installation, check whether the drain pipe cling to the

base firmly.

If you wish to prepare the copper tubes and insulation material in the field, we recommend the following:

Deoxidized annealed copper pipe with 12.7mm O.D., 1.0mm wall thickness.

Deoxidized annealed copper pipe with 6.35mm O.D., 0.8mm wall thickness.

Deoxidized annealed copper pipe with 9.52mm O.D., 1.0mm wall thickness.

Flare nuts with 6.35mm O.D.. Small dia.

4.0kW

or less

2

Flare

nut

Large dia. Flare nuts with 9.52mm O.D..

Flare nuts with 6.35mm O.D.. Small dia.

5.0kW

Large dia. Flare nuts with 12.7mm O.D..

Foamed polyethylene insulation pipe which does not corrode the copper tube.

Large dia. pipe side: 15mm I.D., 8mm wall thickness.

Small dia. pipe side: 8mm I.D., 7mm wall thickness.

3 Insulation for refrigerating pipe

Deoxidized annealed copper pipe with 6.35mm O.D., 0.8mm wall thickness. Small dia.

No. Material Specification

4.0kW

or less

1

Copper

tube

Large dia.

Small dia.

5.0kW

Large dia.

Refer to item 2.1. 4 Copper wire

5 Vinyl tape

6 Sealer (Putty)

7 Refrigerator oil

8 Bushing for refrigerating pipes

1. Proper place for installation

1.1 Outdoor unit

(1) Keep the space around the unit for maintenance and avoiding the effects of hindrance for normal

ventilation of the unit.

(2) The northern or eastern side of the building is better to install. At the installation on the southern

or western side unavoidably, some blind should be set up for the unit. (In this case, the blind must

not obstruct the ventilation of the unit.)

(3) Youd better not put the unit at a place where is full of dirt and at a place where is wet in the rain.

(4) Place as near as possible to the indoor unit.

2. Checking of the power source and the voltage range

2.1 Before installation, the power source must be checked and necessary wiring work must be completed.

To make the wiring capacity proper, use the wire gauges list below for the lead-in from a pole transformer

and for the wiring from a switch board of fuse box to the outlet in consideration of the locked rotor

current.

IMPORTANT

Important:

The wires in this main lead are coloured in accordance with the following code:

CAUTION

Since power is supplied through outdoor unit, do not connect power source to indoor unit.

In

d

o

o

r u

n

it 4

Wire length Wire gauge

Up to 25m 4.0mm

2

THIS APPLIANCE MUST BE EARTHED.

WARNING

NAMES OF EACH PART AND DIMENSIONS

Air outlet

Air intake

(Back, Left side)

Connecting cord and

insulation pipe for piping

Exhaust port (under)

In relation to outdoor unit

Even if operation stops, fan is running for 10 to 60

seconds to reduce heat of electric components.

CAUTION

When heating operation, drain or defrosted water

flows out from outdoor unit. Dont stop up drain

outlet portion in chilly area so as not to freeze

these.

MODEL WIDTH HEIGHT DEPTH

RAM-70QH4

RAM-80QH4

850mm (32-1/2") 830mm (32-11/16") 340mm (13-3/8")

Above 100mm

bBushing

Outer diameter

above 16mm aDrain pipe

Drain hole

bBushing

Push Push

Drain hole

Fuse capacity

32A time delay fuse

USE A FUSE AS FOLLOWING IMPORTANT

2.2 Investigate the power supply capacity and other

electrical conditions at the installation location.

Depending on the model of room air conditioner to

be i nstal l ed, request the customer to make

arrangements for the necessary electrical work etc.

The electrical work includes the wiring work up the

outlet.

In localities where electrical conditions are poor, use of a voltage regulation is recommended.

2.3 In the electrical installation a separator with a contact gap of more than 3mm has to be installed.

During cleaning or service the set has to be switched off with this separator.

3. Installation procedure and notice

Especially, the selection of installation place need great care for the split type air conditioner, because

it is very difficult to move from place to place after the first installation.

3.1 Wiring

(1) Connect the electrical wiring between the Indoor and Outdoor unit, as shown in Fig. 3-1. Never

connect the wiring by mistake.

(2) The connecting cord must be fixed by the band which is located near the terminal board.

Please remove the side plate for wire connection.

Connecting cord

1.6 or 2.0

For Indoor unit No. 1

RAM-70QH4

Wiring Pattern

Indoor unit no.1 Indoor unit no.2 Indoor unit no.3

Screw for ground, earth screw Screw for ground, earth screw Screw for ground, earth screw

Terminal

board

Terminal

board

Terminal

board

Green-and-

Yellow

Green-and-

Yellow

Green-and-

Yellow

Connecting cord

1.6 or 2.0 Connecting cord 1.6 or 2.0

Terminal board Terminal board Terminal board

Screw for ground,

earth screw

Green-and-Yellow

Power cord

Screw for ground, earth screw Screw for ground, earth screw Screw for ground,

earth screw

For Indoor unit No. 2 For Indoor unit No. 3

Terminal board

Indoor Unit

Outdoor Unit

3.2 Connection of the connecting cords and power cord

(1) Cut off the connecting cord, the power cord and strip the insulation of the wire, as shown in

Fig. 3-2.

(2) Connect the connecting cord and power cord to the terminal board. (Fig. 3-3)

(3) Fix the connecting cords and power cord with steel band certainly. (Fig. 3-3)

Detail of cutting connecting cord

Fig. 3-2

Detail of cutting power cord

Green-and yellow

(ground)

Connecting cord

50mm

40mm

14mm

10mm

Green-and yellow

(ground)

Power cord

60mm

50mm

14mm

10mm

If you cannot attach the side plate due to the connecting cord, please press the

connecting cord in direction to the front panel to fix it.

Be sure that the hooks of the side plate is fixed in certainly. Otherwise water

leakage may occur and this causes short circuit or faults.

The connecting cord should not touch the service valve and pipes. (It becomes

high temperature in heating operation.)

WARNING

Connecting cord

1.6 or 2.0

RAM-80QH4

Indoor Unit

Fig. 3-1

Indoor unit no.1 Indoor unit no.2 Indoor unit no.3 Indoor unit no.4

Screw for ground, earth screw

Terminal

board

Screw for ground, earth screw

Terminal

board

Screw for ground,

earth screw

Terminal

board

Screw for ground, earth screw

Terminal

board

Green-and-

Yellow

Green-and-

Yellow

Green-and-

Yellow

Green-and-

Yellow

Connecting cord 1.6 or 2.0

Connecting cord

1.6 or 2.0

Power cord

Green-and-

Yellow

Screw for ground, earth screw

Connecting cord

1.6 or 2.0

For Indoor unit No. 1 For Indoor unit No. 2 For Indoor unit No. 3 For Indoor unit No. 4

Screw for ground,

earth screw

Screw for ground,

earth screw

Screw for ground,

earth screw

Screw for ground,

earth screw

Terminal board Terminal board Terminal board Terminal board

Terminal board

Outdoor Unit

Flare adaptor for piping

The flare adaptor for piping is

requi red dependi ng on

combination of indoor units.

9.52 (3/8") 12.7 (1/2")

parts number HFD43D-4 001

Indoor unit 1 Indoor unit 2 Indoor unit 3

Indoor unit 1 Indoor unit 2 Indoor unit 3 Indoor unit 4

Height difference between indoor units

should be not more than 5m.

Height difference between indoor units

should be not more than 5m.

Mounting

stand

Wind

< S552 : B >

Below figure shows a case of RAM-80QH4.

Connecting cord shall put away

in the inside of side plate after

fixation by cord band.

Terminal indications

Indoor unit Indoor unit Indoor unit Indoor unit Main

No. 1 No. 2 No. 3 No. 4 Switch

Brown Red Brown Red Brown Red Brown Red

Fig. 3-3

When putting 2 connecting cords through the band.

3.3 Preparation of pipe

Use a pipe cutter to cut the copper pipe.

Outer A (mm) Rigid Flaring tool

Diameter ()

For R410A tool For R22 tool

6.35 (1/4") 0 - 0.5 1.0

9.52 (3/8") 0 - 0.5 1.0

12.7 (1/2") 0 - 0.5 1.0

3.4 Pipe connection

Connecting the pipe to outdoor unit

(1) Remove the flare nut and seal cap from the service valve.

(2) Apply refrigerator oil to the service valve and the flared portion of the pipe.

(3) Using a wrench, securely tighten.

Fig. 3-4

In case of removing flare nut of an Indoor unit, first remove a nut of small diameter

side, or a seal cap of large diameter side will fly out. Free from water into the

piping when working. CAUTION

Please be careful when bending the copper pipe.

Screw in manually while adjusting the center. After that, use a torque wrench to tighten the connection.

Flare nut

Wrench

Torque

wrench

Outer diameter Torque Nm

of pipe () (kgfcm)

Small diameter side 6.35 (1/4") 13.7-18.6 (140-190)

Large diameter side

9.52 (3/8") 34.3-44.1 (350-450)

12.7 (1/2") 44.1-53.9 (450-550)

Valve head

Small diameter side 6.35 (1/4") 19.6-24.5 (200-250)

cap

Large diameter side

9.52 (3/8") 19.6-24.5 (200-250)

12.7 (1/2") 29.4-34.3 (300-350)

Valve core cap 12.3-15.7 (125-160)

Fig. 3-5

Hold the handle of the side cover, slide down and take off the corner hook, then pull. Reverse these

steps when installing.

Pipe connection port for Indoor unit 1

Pipe connection port for Indoor unit 2

Pipe connection port for Indoor unit 3

Indoor unit No. 1

Indoor unit No. 2

Indoor unit No. 3

Pipe connection port for Indoor unit 1

Pipe connection port for Indoor unit 2

Pipe connection port for Indoor unit 3

Pipe connection port for Indoor unit 4

Connecting cord should

have arranged with piping

using tape previously.

Indoor unit No. 1

Indoor unit No. 2

Indoor unit No. 3

Indoor unit No. 4

Before flaring, please put on the flare nut.

Copper pipe

Trimming tool

A

Die

Die

Copper pipe

Please use exclusive tool.

RAM-70QH4

RAM-80QH4

4. Air purging

After completing the piping, purge the air from the connected pipe and indoor unit. If this work is not

done, the discharge pressure will abnormally rise so that the refrigerating cycle unit will possible be

damaged or inoperable.

4.1 Air purging by using vacuum pump

Fig. 4-2

Service valve on wide pipe

Valve cap

Service valve on narrow pipe

Valve cap

Valve cap of valve core

When the meter reaches 101KPa

(76cmHg) during pumping, fully

tighten the shuttle.

Meter showing pressure

Closed

R410A

Manifold valve

Vacumn

pump

Vacumn

pump adapter

Valve

Charge hose

When pumping starts, slightly loosen the flare nut

to check of air sucked in. Then tighten the flare nut.

Valve

Fig. 4-1

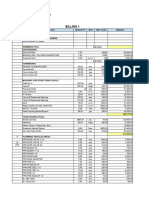

RAM-80QH4 (Reference value)

COOLING HEATING

CAPACITY RATING

(kW) (RANGE)

POSSIBLE

COMBINATIONS

TO OPERATE

OUTDOOR UNIT OUTDOOR UNIT

CAPACITY RATING

(kW) (RANGE)

POWER

CONSUMPTION

(W)

AMPERE

(A)

230V

POWER

CONSUMPTION

(W)

AMPERE

(A)

230V

Air purging by vacuum pump

Connecting cord should

have arranged with piping

using tape previously.

Screw

Insulating plate

Cord

band

Connecting cord

Tighten all the way by hand.

Do not tighten all at once, but tighten it while fitting the

flared surface to the pipe.

Vacuum for more than 10 min.

Remove the valve cap of valve core.

Connect the charge hoses to the vacuum

pump and the charge port of the valve core

l arge di a. pi pe si de servi ce val ve,

respectively.

Fully open the LO knob of the manifold valve.

Put the vacuum pump into run.

Close the LO knob of the manifold valve.

Stop the vacuum pump.

Remove the valve cap from the spindle of

the service valve.

Turn the spindles of each large and small dia.

pipe side service valves full counterclockwise

until they are securely tightened. Then

retighten them more than 10 degrees [using

a hexagon wrench key (4mm ) without

fail].

Valve cap

Valve core

Pipe

Valve cap of valve core Stopper

O-Ring

Pipe

Seal cap

Flare nut

Spindle

Fig. 4-3

The refrigerant channel is opened so that the

refrigerant will flow from the outdoor unit into

the indoor unit.

Gas Leakage Inspection

Please use gas leakage detector to check if leakage

occurs at connection of flare nut as shown on the right.

If gas leakage occurs, further tighten the connection to

stop leakage. (Use the detector provided for R410A.)

Tighten the valve cap of valve core.

[Torque 12.3-15.7 Nm (125-160 kgfcm)]

Attach the valve cap to the spindles of each

large and small dia. pipe side service valves.

Tighten the valve cap of the spindle.

[Torque 19.6-24.5 Nm (200-250 kgfcm)]

Disconnect the charge hose from the service

valve.

COOL/HEAT CAPACITY SPEC, FOR INDOOR UNITS COMBINATIONS

RAM-70QH4 (Reference value)

COOLING HEATING

CAPACITY RATING

(kW) (RANGE)

POSSIBLE

COMBINATIONS

TO OPERATE

OUTDOOR UNIT OUTDOOR UNIT

CAPACITY RATING

(kW) (RANGE)

POWER

CONSUMPTION

(W)

AMPERE

(A)

230V

POWER

CONSUMPTION

(W)

AMPERE

(A)

230V

O

N

E

U

N

IT

T

H

R

E

E

U

N

IT

S

Two units Each unit is connected to each compressor.

Two units Two units are connected to one compressor.

2.5

3.5

4.0

5.0

2.5+2.5

2.5+3.5

2.5+4.0

2.5+5.0

3.5+3.5

3.5+4.0

3.5+5.0

4.0+4.0

4.0+5.0

2.5+2.5

2.5+3.5

2.5+4.0

3.5+3.5

2.5+2.5+2.5

2.5+2.5+3.5

2.5+2.5+4.0

2.5+2.5+5.0

2.5+3.5+3.5

2.5+3.5+4.0

2.5+3.5+5.0

2.5+4.0+4.0

3.5+3.5+3.5

3.5+3.5+4.0

2.50

(1.00~2.80)

3.50

(1.00~3.90)

4.00

(1.00~4.50)

5.00

(1.00~5.60)

2.50+2.50

(1.50~5.60)

2.50+3.50

(1.50~6.60)

2.50+4.00

(1.50~7.00)

2.50+4.50

(1.50~7.60)

3.50+3.50

(1.50~7.60)

3.30+3.70

(1.50~7.60)

2.90+4.10

(1.50~7.60)

3.50+3.50

(1.50~7.60)

3.10+3.90

(1.50~7.60)

2.50+2.50

(1.50~5.50)

2.30+3.30

(1.50~6.20)

2.20+3.40

(1.50~6.20)

2.80+2.80

(1.50~6.20)

2.33+2.33+2.33

(3.00~7.90)

2.05+2.05+2.90

(3.00~7.90)

1.95+1.95+3.10

(3.00~7.90)

1.75+1.75+3.50

(3.00~7.90)

1.80+2.60+2.60

(3.00~7.90)

1.75+2.45+2.80

(3.00~7.90)

1.60+2.20+3.20

(3.00~7.90)

1.70+2.65+2.65

(3.00~7.90)

2.33+2.33+2.33

(3.00~7.90)

2.20+2.20+2.60

(3.00~7.90)

780

(360~980)

1160

(360~1280)

1340

(360~1480)

1910

(360~2100)

1560

(640~1720)

1990

(640~2190)

2220

(640~2440)

2580

(640~2840)

2580

(640~2840)

2580

(640~2840)

2580

(640~2840)

2580

(640~2840)

2580

(640~2840)

1660

(640~1830)

1860

(640~2050)

1860

(640~2050)

1860

(640~2050)

2180

(650~3180)

2180

(650~3180)

2180

(650~3180)

2180

(650~3180)

2180

(650~3180)

2180

(650~3180)

2180

(650~3180)

2180

(650~3180)

2180

(650~3180)

2180

(650~3180)

3.4

5.1

5.9

8.4

6.9

8.7

9.7

11.3

11.3

11.3

11.3

11.3

11.3

7.3

8.2

8.2

8.2

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

3.90

(1.10~4.70)

4.80

(1.10~5.80)

6.00

(1.10~6.80)

6.70

(1.10~7.60)

3.90+3.90

(1.50~8.60)

3.90+4.80

(1.50~9.60)

3.50+5.50

(1.50~9.90)

3.00+6.00

(1.50~9.90)

4.70+4.70

(1.50~10.30)

4.50+4.90

(1.50~10.30)

3.90+5.50

(1.50~10.30)

4.70+4.70

(1.50~10.30)

4.20+5.20

(1.50~10.30)

2.90+2.90

(1.50~6.40)

2.60+3.60

(1.50~6.80)

2.40+3.80

(1.50~6.80)

3.10+3.10

(1.50~6.80)

3.20+3.20+3.20

(3.00~10.60)

2.80+2.80+4.00

(3.00~10.60)

2.60+2.60+4.40

(3.00~10.60)

2.35+2.35+4.90

(3.00~10.60)

2.53+3.53+3.53

(3.00~10.60)

2.40+3.40+3.80

(3.00~10.60)

2.10+3.10+4.40

(3.00~10.60)

2.20+3.70+3.70

(3.00~10.60)

3.20+3.20+3.20

(3.00~10.60)

3.10+3.10+3.40

(3.00~10.60)

1100

(320~1280)

1380

(320~1750)

1770

(320~1920)

2070

(320~2170)

2290

(600~2520)

2690

(600~2960)

3200

(600~3520)

3200

(600~3520)

3200

(600~3520)

3200

(600~3520)

3200

(600~3520)

3200

(600~3520)

3200

(600~3520)

1580

(600~1740)

1930

(600~2120)

1930

(600~2120)

1930

(600~2120)

2480

(620~3520)

2480

(620~3520)

2480

(620~3520)

2480

(620~3520)

2480

(620~3520)

2480

(620~3520)

2480

(620~3520)

2480

(620~3520)

2480

(620~3520)

2480

(620~3520)

4.8

6.1

7.8

9.1

10.1

11.8

14.1

14.1

14.1

14.1

14.1

14.1

14.1

6.9

8.5

8.5

8.5

10.9

10.9

10.9

10.9

10.9

10.9

10.9

10.9

10.9

10.9

T

W

O

U

N

IT

S

T

W

O

U

N

IT

S

O

N

E

U

N

IT

T

H

R

E

E

U

N

IT

S

F

O

U

R

U

N

IT

S

2.5

3.5

4.0

5.0

2.5+2.5

2.5+3.5

2.5+4.0

2.5+5.0

3.5+3.5

3.5+4.0

3.5+5.0

4.0+4.0

4.0+5.0

5.0+5.0

2.5+2.5

2.5+3.5

2.5+4.0

3.5+3.5

2.5+2.5+2.5

2.5+2.5+3.5

2.5+2.5+4.0

2.5+2.5+5.0

2.5+3.5+3.5

2.5+3.5+4.0

2.5+3.5+5.0

2.5+4.0+4.0

2.5+4.0+5.0

3.5+3.5+3.5

3.5+3.5+4.0

3.5+3.5+5.0

3.5+4.0+4.0

2.5+2.5+2.5+2.5

2.5+2.5+2.5+3.5

2.5+2.5+2.5+4.0

2.5+2.5+3.5+3.5

2.50

(1.00~2.80)

3.50

(1.00~3.90)

4.00

(1.00~4.50)

5.00

(1.00~5.60)

2.50+2.50

(1.50~5.60)

2.50+3.50

(1.50~6.60)

2.50+4.00

(1.50~7.00)

2.50+4.50

(1.50~7.60)

3.50+3.50

(1.50~7.60)

3.50+4.00

(1.50~8.00)

3.10+4.40

(1.50~8.00)

4.00+4.00

(1.50~8.20)

3.60+4.40

(1.50~8.20)

4.00+4.00

(1.50~8.20)

2.50+2.50

(1.50~5.50)

2.30+3.30

(1.50~6.20)

2.20+3.40

(1.50~6.20)

2.80+2.80

(1.50~6.20)

2.50+2.50+2.50

(3.00~8.20)

2.30+2.30+3.40

(3.00~8.50)

2.20+2.20+3.60

(3.00~8.50)

2.00+2.00+4.00

(3.00~8.50)

2.00+3.00+3.00

(3.00~8.50)

2.00+2.90+3.10

(3.00~8.50)

1.80+2.60+3.60

(3.00~8.50)

2.00+3.00+3.00

(3.00~8.50)

1.70+2.80+3.50

(3.00~8.50)

2.66+2.66+2.66

(3.00~8.50)

2.60+2.60+2.80

(3.00~8.50)

2.40+2.40+3.20

(3.00~8.50)

2.40+2.80+2.80

(3.00~8.50)

2.00+2.00+2.00+2.00

(3.00~9.20)

1.85+1.85+1.85+2.45

(3.00~9.20)

1.80+1.80+1.80+2.60

(3.00~9.20)

1.70+1.70+2.30+2.30

(3.00~9.20)

780

(360~980)

1160

(360~1280)

1340

(360~1480)

1910

(360~2100)

1560

(640~1720)

1990

(640~2190)

2220

(640~2440)

2580

(640~2840)

2580

(640~2840)

2720

(640~2990)

2720

(640~2990)

2760

(640~3040)

2760

(640~3040)

2760

(640~3040)

1660

(640~1830)

1860

(640~2050)

1860

(640~2050)

1860

(640~2050)

2420

(650~3000)

2580

(650~3200)

2580

(650~3200)

2580

(650~3200)

2580

(650~3200)

2580

(650~3200)

2580

(650~3200)

2580

(650~3200)

2580

(650~3200)

2580

(650~3200)

2580

(650~3200)

2580

(650~3200)

2580

(650~3200)

2650

(650~3200)

2650

(650~3200)

2650

(650~3200)

2650

(650~3200)

3.4

5.1

5.9

8.4

6.9

8.7

9.7

11.3

11.3

11.9

11.9

12.1

12.1

12.1

7.3

8.2

8.2

8.2

10.6

11.3

11.3

11.3

11.3

11.3

11.3

11.3

11.3

11.3

11.3

11.3

11.3

11.6

11.6

11.6

11.6

3.90

(1.10~4.70)

4.80

(1.10~5.80)

6.00

(1.10~6.80)

6.70

(1.10~7.60)

3.90+3.90

(1.50~8.60)

3.90+4.80

(1.50~9.60)

3.50+5.50

(1.50~9.90)

3.00+6.00

(1.50~9.90)

4.70+4.70

(1.50~10.30)

4.50+4.90

(1.50~10.30)

4.00+5.60

(1.50~10.60)

4.80+4.80

(1.50~10.60)

4.30+5.30

(1.50~10.60)

4.80+4.80

(1.50~10.60)

2.90+2.90

(1.50~6.40)

2.60+3.60

(1.50~6.80)

2.40+3.80

(1.50~6.80)

3.10+3.10

(1.50~6.80)

3.40+3.40+3.40

(3.00~11.20)

3.00+3.00+4.20

(3.00~11.20)

2.80+2.80+4.60

(3.00~11.20)

2.60+2.60+5.00

(3.00~11.20)

2.60+3.80+3.80

(3.00~11.20)

2.60+3.60+4.00

(3.00~11.20)

2.30+3.30+4.60

(3.00~11.20)

2.40+3.90+3.90

(3.00~11.20)

2.30+3.50+4.40

(3.00~11.20)

3.40+3.40+3.40

(3.00~11.20)

3.20+3.20+3.80

(3.00~11.20)

3.00+3.00+4.20

(3.00~11.20)

3.20+3.50+3.50

(3.00~11.20)

2.75+2.75+2.75+2.75

(3.00~12.40)

2.50+2.50+2.50+3.50

(3.00~12.40)

2.40+2.40+2.40+3.80

(3.00~12.40)

2.30+2.30+3.20+3.20

(3.00~12.40)

1100

(320~1280)

1380

(320~1750)

1770

(320~1920)

2070

(320~2170)

2290

(600~2520)

2690

(600~2960)

3200

(600~3520)

3200

(600~3520)

3200

(600~3520)

3200

(600~3520)

3300

(600~3630)

3300

(600~3630)

3300

(600~3630)

3300

(600~3630)

1580

(600~1740)

1930

(600~2120)

1930

(600~2120)

1930

(600~2120)

2530

(620~3630)

2530

(620~3630)

2530

(620~3630)

2530

(620~3630)

2530

(620~3630)

2530

(620~3630)

2530

(620~3630)

2530

(620~3630)

2530

(620~3630)

2530

(620~3630)

2530

(620~3630)

2530

(620~3630)

2530

(620~3630)

2630

(620~3630)

2630

(620~3630)

2630

(620~3630)

2630

(620~3630)

4.8

6.1

7.8

9.1

10.1

11.8

14.1

14.1

14.1

14.1

14.5

14.5

14.5

14.5

6.9

8.5

8.5

8.5

11.1

11.1

11.1

11.1

11.1

11.1

11.1

11.1

11.1

11.1

11.1

11.1

11.1

11.6

11.6

11.6

11.6

T

W

O

U

N

IT

S

T

W

O

U

N

IT

S

WARNING

The naked part of the wire core should be 10mm and fix it to the terminal tightly. Then try to pull the

individual wire to check if the contact is tight. Improper insertion may burn the terminal.

Be sure to use only wire specified for the use of air conditioner.

Please refer to the installation manual for wire connection and the wiring technique should meet the

standards of electrical installation.

There is an AC voltage drop between the LN terminals if the power is on. Therefore, be sure to

switch off the power supply.

WARNING

Connecting cord should be connected according to Fig. 3-1, that the Indoor unit No.

agree with terminal board No. of Outdoor unit.

Be sure to fix the connecting cord with the band as shown below. Otherwise water

leakage causes short circuit or faults.

CAUTION

Jagged edge will cause leakage.

Point the side to be trimmed downwards

during trimming to prevent copper chips

from entering the pipe.

WARNING

Leave some space in the connecting cord

for maintenance purpose and be sure to

secure it with the cord band.

Secure the connecting cord along the

coated part of the wire using the cord band.

Do not exert pressure on the wire as this

may cause overheating or fire.

Two units Each unit is connected to each compressor.

Two units Two units are connected to one compressor.

Install the unit in a stable place to minimize vibration or noise.

After arranging the cords and pipes, secure them in place.

Potrebbero piacerti anche

- Nissan Automatic Transmission RE4R01A Service Manual PDFDocumento350 pagineNissan Automatic Transmission RE4R01A Service Manual PDFFrank Ch Ccaico88% (8)

- Ultimate Guide: Wiring, 8th Updated EditionDa EverandUltimate Guide: Wiring, 8th Updated EditionValutazione: 3.5 su 5 stelle3.5/5 (4)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDa Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsValutazione: 4 su 5 stelle4/5 (1)

- SRP170Documento23 pagineSRP170waleedyehia100% (1)

- Installation Manual: Air Conditioner (Multi Type)Documento32 pagineInstallation Manual: Air Conditioner (Multi Type)tonylyfNessuna valutazione finora

- Ras-E10h2 E14h2Documento102 pagineRas-E10h2 E14h2Ama DeeaNessuna valutazione finora

- Ultimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsDa EverandUltimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsValutazione: 3 su 5 stelle3/5 (8)

- 4804 4Documento11 pagine4804 4abhaybhosaleNessuna valutazione finora

- Manual Oficina PDFDocumento20 pagineManual Oficina PDFFelipe Douglas da Silva100% (1)

- Installation Instruction Sheet: Split Type Air ConditionerDocumento8 pagineInstallation Instruction Sheet: Split Type Air ConditionerSyed Noman AhmedNessuna valutazione finora

- RXN RKN 15-18-24KEVJU Installation ManualDocumento14 pagineRXN RKN 15-18-24KEVJU Installation ManualdimchienNessuna valutazione finora

- Tasaki Instalation ManualDocumento10 pagineTasaki Instalation ManualChalitha Nayana Hewawasam100% (1)

- Manual For HRVDocumento22 pagineManual For HRVmilanorubNessuna valutazione finora

- 3MXS24JVJU Installation ManualDocumento16 pagine3MXS24JVJU Installation Manualsrt1024@engineer.comNessuna valutazione finora

- Installation Instructions: - Split System Air ConditionerDocumento45 pagineInstallation Instructions: - Split System Air ConditionerpejdewitNessuna valutazione finora

- Air-Conditioners: SEZ-A12, A18, A24ARDocumento16 pagineAir-Conditioners: SEZ-A12, A18, A24ARCalmus CristinelNessuna valutazione finora

- 2MXSGVJU Installation ManualDocumento15 pagine2MXSGVJU Installation Manualsrt1024@engineer.comNessuna valutazione finora

- RXS09 - 12DAVJU Installation ManualDocumento8 pagineRXS09 - 12DAVJU Installation ManualhyreepktNessuna valutazione finora

- IOM-Indoor Inverter TraneDocumento32 pagineIOM-Indoor Inverter TraneLeo FrontelliNessuna valutazione finora

- Hitachi - AirExchange Instruction ManualDocumento36 pagineHitachi - AirExchange Instruction ManualtheophiloNessuna valutazione finora

- Installation Manual Air Conditioner: LSN-LSU-90-120HYVDocumento2 pagineInstallation Manual Air Conditioner: LSN-LSU-90-120HYVzzlesleyzzNessuna valutazione finora

- Fujitsu Klima Uredjaj Zidni Inverter Asyg12llcc Aoyg12llcc Installation ManualDocumento2 pagineFujitsu Klima Uredjaj Zidni Inverter Asyg12llcc Aoyg12llcc Installation ManualMirko MirkovicNessuna valutazione finora

- Ductless Install ManualDocumento8 pagineDuctless Install Manualguitarman337@hotmail.comNessuna valutazione finora

- AC Carrier PDFDocumento114 pagineAC Carrier PDFcristiangodeanuNessuna valutazione finora

- AM5O 120HPDC1 Installation Operation Manual EngDocumento28 pagineAM5O 120HPDC1 Installation Operation Manual EngRahul DubeyNessuna valutazione finora

- Aircond Split UnitDocumento20 pagineAircond Split UnitLyk LooNessuna valutazione finora

- Mitsubishi Plaa36ba4 Puzha36nha2 Installation ManualDocumento56 pagineMitsubishi Plaa36ba4 Puzha36nha2 Installation ManualTawanda Elton Makwasha MadzureNessuna valutazione finora

- Installation Manual VRV III BSVQ - PVJU - DaikinDocumento17 pagineInstallation Manual VRV III BSVQ - PVJU - Daikinvineeth8624Nessuna valutazione finora

- FDXS - DVJU Concealed Installation ManualDocumento0 pagineFDXS - DVJU Concealed Installation ManualJesus RoldanNessuna valutazione finora

- FXMQ72 96M Install ManualDocumento12 pagineFXMQ72 96M Install ManualSaran RockerNessuna valutazione finora

- Split Unit Air Conditioner Installation Manual: For Service Personnel OnlyDocumento2 pagineSplit Unit Air Conditioner Installation Manual: For Service Personnel OnlyJoyee BasuNessuna valutazione finora

- Split Air Conditioner: Installation Manual Residential Air ConditionersDocumento15 pagineSplit Air Conditioner: Installation Manual Residential Air ConditionersLionelkeneth120% (1)

- Pellet Stove ManualDocumento17 paginePellet Stove ManualDan DareNessuna valutazione finora

- Installation Manual: Daikin Room Air ConditionerDocumento56 pagineInstallation Manual: Daikin Room Air ConditionerKevin AryaNessuna valutazione finora

- Manual Air Condition Daewoo DSB-070L DSB-091LDocumento32 pagineManual Air Condition Daewoo DSB-070L DSB-091LzefraNessuna valutazione finora

- Samsung Air Conditionner Installation ManuelDocumento28 pagineSamsung Air Conditionner Installation Manueljeromef3Nessuna valutazione finora

- Split Air Conditioner Wall Mounted Type Service Manual: AUS-07C (H) 53R010Lx AUS-07C (H) 53R150Lx AUS-09C (H) 53R150LxDocumento42 pagineSplit Air Conditioner Wall Mounted Type Service Manual: AUS-07C (H) 53R010Lx AUS-07C (H) 53R150Lx AUS-09C (H) 53R150Lxanon_226950787Nessuna valutazione finora

- Auya30lblu - Aoya30lbtl - InstallDocumento2 pagineAuya30lblu - Aoya30lbtl - InstallpepondeAvilesNessuna valutazione finora

- Op Ras-25 35WX8 Rac-25 35WX8Documento26 pagineOp Ras-25 35WX8 Rac-25 35WX8Cristian TopalaNessuna valutazione finora

- Service Manual Avant 167SKV-E5Documento98 pagineService Manual Avant 167SKV-E5Daniel PelteaNessuna valutazione finora

- Safety Precautions: CautionDocumento2 pagineSafety Precautions: Cautionavinash rathodNessuna valutazione finora

- Installation Instruction Sheet: Cassette TypeDocumento2 pagineInstallation Instruction Sheet: Cassette TypepepondeAvilesNessuna valutazione finora

- 2 Standard Operating Procedures For HospitalsDocumento19 pagine2 Standard Operating Procedures For HospitalsFaquruddin AliNessuna valutazione finora

- Pa Amplifier A-1706 A-1712 A-1724: Operating InstructionsDocumento12 paginePa Amplifier A-1706 A-1712 A-1724: Operating InstructionsCristi BudNessuna valutazione finora

- Vertu Installation ManualDocumento16 pagineVertu Installation Manualcmorley5057Nessuna valutazione finora

- Luna Installation ManualDocumento16 pagineLuna Installation Manualcmorley5057Nessuna valutazione finora

- Outline and DimentionsDocumento23 pagineOutline and DimentionsAngel Joy TiabaNessuna valutazione finora

- Cl20702 705 Manual Mup HiDocumento33 pagineCl20702 705 Manual Mup HiRamadan RashadNessuna valutazione finora

- Service Manual: Split TypeDocumento112 pagineService Manual: Split TypeVăn NamNessuna valutazione finora

- Air Conditioner Climatiseur: Model - Modèle - ModeloDocumento23 pagineAir Conditioner Climatiseur: Model - Modèle - Modelobigbigbig90003270Nessuna valutazione finora

- 2008-11-14 Installation Manual - Multi V Plus II Outdoor Unit - mfl46912303Documento247 pagine2008-11-14 Installation Manual - Multi V Plus II Outdoor Unit - mfl46912303experthvachomeNessuna valutazione finora

- XPower Platinum&Gold PDFDocumento115 pagineXPower Platinum&Gold PDFMalay K GhoshNessuna valutazione finora

- PXV4 ManualDocumento25 paginePXV4 ManualduyphuocNessuna valutazione finora

- Installation Manual: Electric RangeDocumento10 pagineInstallation Manual: Electric RangeAndrewWerdnaNessuna valutazione finora

- Maxon Service Manual09 12Documento42 pagineMaxon Service Manual09 12Manuel Azabache GrandezNessuna valutazione finora

- LV Series 30 36 ODU Installation ManualDocumento14 pagineLV Series 30 36 ODU Installation ManualdanidansoanimNessuna valutazione finora

- Toshiba SKV SKVR Service ManualDocumento121 pagineToshiba SKV SKVR Service ManualyankurokuNessuna valutazione finora

- Toshiba Ducted Airconditioning Operating InstructionsDocumento22 pagineToshiba Ducted Airconditioning Operating InstructionshellodesNessuna valutazione finora

- Panasonic S-Mu1 My2 Mf2 Mt2 Mk2 Mk1 E5a Technical Data (Sbpac1403010ce)Documento360 paginePanasonic S-Mu1 My2 Mf2 Mt2 Mk2 Mk1 E5a Technical Data (Sbpac1403010ce)kukurikuyu100% (1)

- Installation Instructions For Model DBF4XL Dryer Exhaust BoosterDocumento4 pagineInstallation Instructions For Model DBF4XL Dryer Exhaust Boosterplumwood1Nessuna valutazione finora

- 2011-05-05 Installation Manual - Multi V II Water-Source Heat-Pump Unit - mfl63748901Documento229 pagine2011-05-05 Installation Manual - Multi V II Water-Source Heat-Pump Unit - mfl63748901Alejandro Felipe ReyesNessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Handbook - TGO Data BookDocumento44 pagineHandbook - TGO Data Bookmnt6176Nessuna valutazione finora

- Dynaco Hydraulic PDFDocumento36 pagineDynaco Hydraulic PDFnbgearsNessuna valutazione finora

- Auxiliary Machine Systems 5000Documento41 pagineAuxiliary Machine Systems 5000ndlongndNessuna valutazione finora

- Pem PDFDocumento4 paginePem PDFkishanNessuna valutazione finora

- KGF and KGF-HP: Clarkson Slurry Knife Gate ValvesDocumento12 pagineKGF and KGF-HP: Clarkson Slurry Knife Gate Valveswilfredo3014Nessuna valutazione finora

- CVS Controls Series 470 Piston Actuators: Instruction ManualDocumento12 pagineCVS Controls Series 470 Piston Actuators: Instruction ManualisctomaslopezNessuna valutazione finora

- Modelling of A Pressure RegulatorDocumento11 pagineModelling of A Pressure RegulatorErick Renzo Hidalgo OrtegaNessuna valutazione finora

- User'S Manual: Zj40Dbst Drilling RigDocumento48 pagineUser'S Manual: Zj40Dbst Drilling RigJohn Simanca100% (1)

- 7-88 Flammable Liquid Storage TanksDocumento44 pagine7-88 Flammable Liquid Storage TanksAchraf BoudayaNessuna valutazione finora

- SAV Sizing Manual - ImpulseDocumento4 pagineSAV Sizing Manual - ImpulseDar Fall0% (1)

- VW MKIV Golf-Jetta 1.8T EVAP System ServicingDocumento88 pagineVW MKIV Golf-Jetta 1.8T EVAP System Servicingfmjmx100% (1)

- Reparacion Motor Giro PC220 Een00022-00 - 14104Documento22 pagineReparacion Motor Giro PC220 Een00022-00 - 14104ALEJANDRO SANCHEZNessuna valutazione finora

- Constant Pressure Module PVBDocumento2 pagineConstant Pressure Module PVBFelipe Doria RibeiroNessuna valutazione finora

- DFFFFDocumento29 pagineDFFFFAman RatheeNessuna valutazione finora

- Dinesh Qa-Qc EngineerDocumento6 pagineDinesh Qa-Qc EngineerDinesh SomwanshiNessuna valutazione finora

- L8-Water Supply Pipe AppurtenancesDocumento10 pagineL8-Water Supply Pipe AppurtenancesMidhun Chowdary100% (1)

- 1.T3 SUREFIRE Double Interlock - Self ContainedDocumento18 pagine1.T3 SUREFIRE Double Interlock - Self ContainedKnightspageNessuna valutazione finora

- Chapter 5 - Hydraulic ValvesDocumento85 pagineChapter 5 - Hydraulic ValvesMuhammad AbdullahNessuna valutazione finora

- Core BarrelsDocumento20 pagineCore BarrelsEmerson PasquarelliNessuna valutazione finora

- Two-Post Lift Model:210C 210CXDocumento36 pagineTwo-Post Lift Model:210C 210CXventitapostNessuna valutazione finora

- Swimming Pool and Commercial BuildingDocumento44 pagineSwimming Pool and Commercial BuildingDrexler FelicianoNessuna valutazione finora

- ACI 304.2R - 96 Placing Concrete by Pumping MethodsDocumento28 pagineACI 304.2R - 96 Placing Concrete by Pumping MethodsvasanthNessuna valutazione finora

- Valves HandbookDocumento51 pagineValves Handbookedhy_0367% (3)

- OM011 D TI Manual Power Unit Diesel Hydraulic OptimizedDocumento147 pagineOM011 D TI Manual Power Unit Diesel Hydraulic OptimizedDiana RosadoNessuna valutazione finora

- 4 Sewage Pumping StationsDocumento14 pagine4 Sewage Pumping StationsMassi MateenNessuna valutazione finora

- 785C Off-Highway Truck APX00001-UP (MACHINE) POWERED BY 3512B Engine (SEBP3021 - 219) - Sistemas y ComponentesDocumento7 pagine785C Off-Highway Truck APX00001-UP (MACHINE) POWERED BY 3512B Engine (SEBP3021 - 219) - Sistemas y ComponentesCarlos Andres Campos TorresNessuna valutazione finora