Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Introduction To EasyRail Wheel Flange Lubrication Systems

Caricato da

Sahil KumarTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Introduction To EasyRail Wheel Flange Lubrication Systems

Caricato da

Sahil KumarCopyright:

Formati disponibili

Slide 2

SKF Platforms

Slide 3

Railway Applications

2014-05-02 SKF Slide3

WillyVogel AG, a brandof the SKF Group

Wheel Flange Lubrication SKF EasyRail

Slide 4

Introduction

Wheel & Rail Lubrication Systems

Slide 4

Slide 5

Why Wheel Flange Lubrication?

Flan ge We ar

R ed u ced R isk of

D erailm e n t :

R ail wea r

Area of Wear

re d u ced friction coefficien t

in flan ge a rea re q uire s

in cre a sed sh ear forces to

allow wh e el clim b in g.

Slide 6

How does Wheel Flange Lubrication work?

lu b ricatin g film

on wh e el flan ge

lu b ricatin g film

on rail flan ge

Slide 7

On-Board-Systems for Wheel Flange Lubrication

Fu n ction of O B S

Lu b rication m od u le and lu b rican t b ased on th e train

Transfer & app lication of lu b rican t by com p ressed air

P recise m eterin g of lu b rican t by p um p or sp ray n ozzles

H igh er reliab ility th an waysid e lu b ricators

Slide 8

What can WFL achieve for our customers?

L ess track an d wh eel wear

Track resistan ce d rops by u p to 3 5 %, with ou t effect on b rakin g

Lon ger in tervals b etween wh eel resh apin g or replacem en t

M ain ten an ce-op tim ized system con figu ration

In creased availability/m ileage of rollin g stock +b etter LC C

P reven t d erailm en ts by cu rb in g ten d en cy of wh eel clim b in g

B etter and safer rid e qu ality

C om p lian ce with environ m en tal regu lation s

Fu el/en ergy savin gs +u se of b iodegrad ab le lu b rican ts +less n oise

Slide 9

SKF EasyRail Lubrication one Family, two Systems

S in gle -lin e

S ystem s

D u al-lin e

S ystem s

Slide 10

How does it work

EasyRail High Pressure

Dual Line Systems

Slide 10

Slide 11

SKF EasyRail High PressureWheel Flange Lubrication

Application

R ail veh icles with a m a x o f 2 0 m

d istan ce b etween wh eel sets to b e

sp rayed

M ax lin e len gth b etween

p um p an d sp ray n ozzle 1 0 m

L ub rican t system p ressu re u p

to 1 0 0 b a r

Benefits

op era tion al u n d er low

am b ien t tem p era tu re

con d itio ns

selectab le b i-d irection al

op era tion

sep ara b le n ozzle feed in g

(rig h t/left)

exa ct sp ray-n ozzle m eterin g

N ew S pray n ozzle design

SP8-5

P u m p u n it

with reservoir

Slide 12

SKF EasyRail High PressureWheel Flange Lubrication

easy access to

reservoir with pu m p

u n it via ou tside flap

Slide 13

SKF EasyRail High PressureWheel Flange Lubrication

Standard layout of SKF EasyRail High Pressure system

P iston p um p

R eservoir

F ilter

S p ray n ozzles

C on trol U nit

Slide 14

SKF EasyRail High PressureWheel Flange Lubrication

Slide 15

SKF EasyRail High PressureWheel Flange Lubrication

Function of the Piston Pump for EasyRail High Pressure

Air com m an d

L ub rican t su ction

L ub rican t relief

valve

P n eu m a tic relie f

L ub rican t ou tlet

Slide 16

SKF EasyRail High PressureWheel Flange Lubrication

How the SP8 nozzle works: Part I

T h e m e te red q u a n tity of lu b rica n t is p osition ed b en eath

th e m e terin g p iston .

T h e lu b rica n t d elivered by th e p u m p p u sh es th e con trol p iston u p to its stop .

C on trol d u ct 1 le a d in g to th e m e te rin g p iston is op e n ed . T h e lu b rica n t d elivered

p u sh es th e m e terin g p iston d own . T h e m e te red q u a n tity of lu b rica n t b en eath

th e m e tered p iston is p u sh ed in to th e m ixin g ch a m b er. T h e e jected lu b rica n t

com e s tog e th er with th e com p re ssed a ir in th e m ixin g ch a m b er a n d is sp ra yed

ou t th rou gh th e op e n in g of th e n ozzle .

C ontrol piston

C ontrol du ct 1

C ontrol du ct 2

M eterin g piston

M ixin g ch am ber

L u brican t port

Air port

Slide 17

How the SP8 nozzle works:

Part II

T h e p re ssu re in th e lu b rica n t lin e is re lieved a fte r th e p u m p stop s. T h e con trol p iston is m o ved in to its in itia l

p osition by sp rin g force . C on trol d u ct 2 from th e b ottom to top o f th e m e te rin g p iston is e n a b led . T h e m e te rin g

p iston re tu rn s to its in itia l p osition , a n d th e m e te red q u a n tity of lu b rica n t flows in to th e sp ace b en eath th e

m e te rin g p iston .

SKF EasyRail High PressureWheel Flange Lubrication

Slide 18

SKF EasyRail High PressureWheel Flange Lubrication

New SP8-5 nozzle design:

Slide 19

Highspeed equipped with SKFEasyRail High Pressure

2014-05-02 SKF Slide19

WillyVogel AG, a brandof the SKF Group

Alstom Pendolino - ETR 610

Alstom Cisalpino ETR 470 Alstom EMU CRH5

Alstom Pendolino Finland

Slide 20

How does it work

EasyRail Low Pressure

1 November, 2006 SKF Group Slide 20

Slide 21

SKF EasyRail Low PressureWheel Flange Lubrication

P ressu rized reservoir without separate grease pu m p

C om p act d esign and very low m ain ten an ce

S eparate nozzle feed in g right/left

E xact sp ray-n ozzle m eterin g

Very h igh cycle frequ en cy

Slide 22

Inside view of

pressurized reservoir BF

4.5

O p tica l grease level

Air con n ectio n

Air reservoir

G rea se reservoir

L ub rican t ou tlet

SKF EasyRail Low PressureWheel Flange Lubrication

Slide 23

How the SP9 nozzle works

T h e p re ssu rized lu b rica n t is p u sh ed in to th e p iston s

m e te rin g slot.

T h e con trolle d com p re ssed a ir slid es th e p iston u p to its stop . As a re su lt, th e

m e te rin g groo ve is n o w in fron t of th e n o zzle e xit, a n d th e a ir du ct le a d in g to

th e m e terin g groo ve is op e n ed . T h e com p re ssed a ir b lows th e lu b rica n t ou t of

th e m e terin g groo ve, a n d th e lu b rica n t/a ir m ixtu re is sp ra yed ou t th rou gh th e

n o zzle e xit.

Air duct

P iston

M eterin g

groove

L u brican t port

Air port

SKF EasyRail Low PressureWheel Flange Lubrication

Slide 24

How the SP9 nozzle works

T h e com p re ssed a ir ap p lied to th e n o zzle is sh u t off. T h e p iston a ssu m es its in itia l p osition , a n d th e m e te rin g

groo ve is filled with lu b rica n t aga in .

SKF EasyRail Low PressureWheel Flange Lubrication

Slide 25

Intercity equipped with SKFEasyRail Low Pressure

2014-05-02 SKF Slide25

WillyVogel AG, a brandof the SKF Group

DB AG Tilting ICE Fleet

DSB Contessa resund-Express

Slide 26

How does it work

SKF EasyRail Compact

Single Line Systems

Slide 26

Slide 27

SKF EasyRail Compact Wheel Flange Lubrication

Application

S u ita b le for oil an d flu id g rease

con tain in g h ig h p ercen tag e of

solid a d d itives (2 5 %)

Ap p lica b le on a ll veh icle typ es

a lso su itab le for retrofittin g p rojects

Benefits

C om p act system

E asy in stallation an d

m a in ten an ce

L ow L ife Cycle C ost

F low divider

S pray n ozzles

M P 5 0 piston

pu m p

Slide 28

SKF EasyRail Compact Wheel Flange Lubrication

Snapshot of WFL pump-reservoir module & positioning in bogie structure

Slide 29

SKF EasyRail Compact Wheel Flange Lubrication

Standard layout of SKF EasyRail Compact system

Slide 30

SKF EasyRail Compact Wheel Flange Lubrication

Revised unit design with 11 l reservoir & quick

connector for easy lubricant refilling

Slide 31

SKF EasyRail Compact Wheel Flange Lubrication

Slide 32

SKF EasyRail Compact Wheel Flange Lubrication

N ozzle

position in g

K orail M etro Train

S eou l, S ou th K orea

Lu brication M odu le,

in stalled in bogie section

C on trol U n it

1 1 0 V D C

Slide 33

P u m p with

1 1 liter

reservoir

SKF EasyRail Compact Wheel Flange Lubrication

D iesel S h u n ter

C lass T -2 3 9

S pray N ozzle

1 6 9 -0 0 0 -4 0 0

C S 2 0 0

C on trol U n it

1 6 9 -0 0 0 -4 1 0

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Railway Wheel DrawingDocumento1 paginaRailway Wheel DrawingSahil KumarNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- TDS 11S TrainingDocumento221 pagineTDS 11S TrainingMohammed TidjaniNessuna valutazione finora

- Numericals AptitudeDocumento4 pagineNumericals AptitudeNarendra PalandeNessuna valutazione finora

- 480V 3-Line Electrical Schematics PDFDocumento38 pagine480V 3-Line Electrical Schematics PDFfabyanoNessuna valutazione finora

- 7FGCU3 6500SpecSheetDocumento6 pagine7FGCU3 6500SpecSheetEdwin NgNessuna valutazione finora

- Ortilinghaus Pneumatic Clutch LayoutDocumento1 paginaOrtilinghaus Pneumatic Clutch LayoutSahil KumarNessuna valutazione finora

- Electric Discharge Machining PDFDocumento16 pagineElectric Discharge Machining PDFSahil KumarNessuna valutazione finora

- The True History and The Religion of IndiaDocumento821 pagineThe True History and The Religion of IndiaSahil KumarNessuna valutazione finora

- Material EquivalentsDocumento2 pagineMaterial EquivalentsSahil KumarNessuna valutazione finora

- Bearing Installation FittingDocumento4 pagineBearing Installation FittingNishant GuptaNessuna valutazione finora

- Ansys User Guide PDFDocumento33 pagineAnsys User Guide PDFSahil KumarNessuna valutazione finora

- Design of Involute Gear ToothDocumento11 pagineDesign of Involute Gear ToothSahil KumarNessuna valutazione finora

- Corporate Strategy NotesDocumento3 pagineCorporate Strategy NotesSahil KumarNessuna valutazione finora

- MWM India Construction Machinery 2016Documento174 pagineMWM India Construction Machinery 2016Sahil Kumar100% (2)

- Missile IndiaDocumento10 pagineMissile IndiaSahil KumarNessuna valutazione finora

- Imtma Annual Report16 17Documento50 pagineImtma Annual Report16 17Sahil KumarNessuna valutazione finora

- MWM India Material Handling Equipment 2016Documento161 pagineMWM India Material Handling Equipment 2016Sahil Kumar50% (2)

- Timken Tapered Roller Bearing CatalogDocumento760 pagineTimken Tapered Roller Bearing CatalogJesus Almanzar SantosNessuna valutazione finora

- IMx-W WIndcon BoxDocumento2 pagineIMx-W WIndcon BoxSahil KumarNessuna valutazione finora

- Cage MaterialDocumento2 pagineCage MaterialSahil KumarNessuna valutazione finora

- SKF Supergrip BoltDocumento29 pagineSKF Supergrip BoltSahil KumarNessuna valutazione finora

- CompaniesAct2013 PDFDocumento288 pagineCompaniesAct2013 PDFSahil KumarNessuna valutazione finora

- IELTS Words ListDocumento6 pagineIELTS Words ListSahil KumarNessuna valutazione finora

- Factors Influencing TBU PerformanceDocumento27 pagineFactors Influencing TBU PerformanceSahil Kumar0% (1)

- Missile IndiaDocumento10 pagineMissile IndiaSahil KumarNessuna valutazione finora

- Shaft Tolerances For BearingsDocumento1 paginaShaft Tolerances For BearingsSahil KumarNessuna valutazione finora

- RDSO Vendor Directory July 2017 - ElectricalDocumento132 pagineRDSO Vendor Directory July 2017 - ElectricalSahil KumarNessuna valutazione finora

- Fiat Bogies For Indian RailwaysDocumento14 pagineFiat Bogies For Indian RailwaysSahil KumarNessuna valutazione finora

- Load Calculation - LHB Axle BoxDocumento3 pagineLoad Calculation - LHB Axle BoxSahil KumarNessuna valutazione finora

- Traction Motor ShaftDocumento1 paginaTraction Motor ShaftSahil KumarNessuna valutazione finora

- Static Loads - LHB Axle BoxDocumento5 pagineStatic Loads - LHB Axle BoxSahil KumarNessuna valutazione finora

- Alstom Manual Volume 1 PDFDocumento24 pagineAlstom Manual Volume 1 PDFSahil Kumar100% (1)

- Hitachi Traction MotorDocumento174 pagineHitachi Traction MotorSahil Kumar100% (1)

- Solutions For TMsDocumento20 pagineSolutions For TMsSahil KumarNessuna valutazione finora

- M313, M315, M316, M318 Và M322 CAT HyraulicsDocumento9 pagineM313, M315, M316, M318 Và M322 CAT Hyraulicsgiapy0000Nessuna valutazione finora

- Lada Niva Dakar Preparation Part2 PDFDocumento16 pagineLada Niva Dakar Preparation Part2 PDFhamoNessuna valutazione finora

- Oil and Fat Assignment PDFDocumento21 pagineOil and Fat Assignment PDFM Asrar SidonNessuna valutazione finora

- Construction Fire SafetyDocumento10 pagineConstruction Fire SafetyAshish MauryaNessuna valutazione finora

- (Naphtha) Waste Plastic Conversion Into Chemical Product Like Naphtha PDFDocumento6 pagine(Naphtha) Waste Plastic Conversion Into Chemical Product Like Naphtha PDFsodgoweisjdNessuna valutazione finora

- Albania - Regional Gasification StudyDocumento21 pagineAlbania - Regional Gasification StudyMikeJbNessuna valutazione finora

- Challenges Crude ProcessingDocumento17 pagineChallenges Crude ProcessingAnonymous msVFzaNessuna valutazione finora

- Rashid KhanDocumento2 pagineRashid KhanEngr Saeed AnwarNessuna valutazione finora

- CAT 320D ManualDocumento284 pagineCAT 320D ManualMuhammad rizki100% (4)

- Fyp TurbochargerDocumento5 pagineFyp TurbochargerEngr Jahanzaib KhanNessuna valutazione finora

- dr9 Track PDFDocumento20 paginedr9 Track PDFAlejandro DiazNessuna valutazione finora

- Comparision of Piping CodeDocumento14 pagineComparision of Piping CodeAnonymous J1vjrU2Nessuna valutazione finora

- Curriculum Vitae: Mohamed Saber Mohamed Gad Nemat AllaDocumento5 pagineCurriculum Vitae: Mohamed Saber Mohamed Gad Nemat Allamohamed aliNessuna valutazione finora

- Injection Pump Test SpecificationsDocumento2 pagineInjection Pump Test SpecificationsEdinson Ariel Chavarro QuinteroNessuna valutazione finora

- Annexure 11 - Safety HandbookDocumento50 pagineAnnexure 11 - Safety Handbookmanu2020Nessuna valutazione finora

- Classification of FireDocumento10 pagineClassification of FireAhasa FarooqNessuna valutazione finora

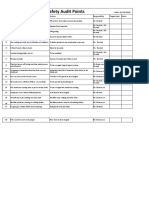

- Tata Safety Audit Points: SR - No. Observation Points Actions Responsibility Targate Date StatusDocumento2 pagineTata Safety Audit Points: SR - No. Observation Points Actions Responsibility Targate Date StatusNeeraj SinghNessuna valutazione finora

- 3welding AllDocumento82 pagine3welding AlljyothilalNessuna valutazione finora

- Consider New Technology To Produce Clean DieselDocumento9 pagineConsider New Technology To Produce Clean DieselCarlos ReNessuna valutazione finora

- VELVEX - Automotive LubesDocumento4 pagineVELVEX - Automotive LubesVaradrajan jothiNessuna valutazione finora

- Final Project Report: Uop, LLCDocumento165 pagineFinal Project Report: Uop, LLCSiddharth KishanNessuna valutazione finora

- 2010 Kawasaki kx450f ManualDocumento170 pagine2010 Kawasaki kx450f ManualDalllin HolltNessuna valutazione finora

- Product Description: 1 Wastewater PumpDocumento8 pagineProduct Description: 1 Wastewater PumpTahirJabbarNessuna valutazione finora

- Lubrication Specs - Cone CrusherDocumento1 paginaLubrication Specs - Cone CrusherAnonymous OfU0JSNessuna valutazione finora

- DR005 Piping Slope BDocumento4 pagineDR005 Piping Slope BMadhan RajNessuna valutazione finora

- Doosan Db58s Engine Service ManualDocumento152 pagineDoosan Db58s Engine Service ManualRas-Sherwin A. Jalani100% (6)