Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Instruction Manual SIMEAS P

Caricato da

iwan.satyaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Instruction Manual SIMEAS P

Caricato da

iwan.satyaCopyright:

Formati disponibili

Siemens AG 2000; All Rights Reserved

SIMEAS P

Power Meter

Instruction manual

Foreword

Commissioning 1

Operation 2

Measured variables 3

Device parameterization 4

Profibus DP 5

Edition: 01.05.01

Commissioning Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 2 out of 60-

Information for

Your Own Safety

This manual does not contain a full list of the safety measures for operation of the equipment (module,

device) because special operating conditions may necessitate further measures. However, it does

contain information which must be adhered to in the interests of your own personal safety and to avoid

material damages. This information is highlighted by a warning triangle and are represented as follows,

depending on the degree of potential danger:

_____________________________________________________________________________________________

Warning

means that failure to take the necessary safety precautions can result in death, serious injury or

considerable material damage

Caution

means that failure to take the necessary safety precautions will result in death, serious injury or

considerable material damage

_____________________________________________________________________________________________

Qualified personnel

Commissioning and operation of the equipment (module, device) described in this manual may only be

performed by qualified personnel. Qualified personnel in the sense of the safety information contained in

this manual are persons who are authorized to commission, start up, ground and label devices, systems

and circuits according to safety standards.

Use for the intended purpose

The equipment (device, module) may only be used for the application cases specified in the catalog and

the technical manual and only in connection with OEM devices and components recommended and

approved by Siemens.

The prerequisites for perfect, reliable operation of the product are proper transport, proper storage,

installation and assembly, as well as proper operation and maintenance.

When operating electrical equipment, certain parts of this equipment automatically carry dangerous

voltages. Improper handling can therefore result in serious injury or material damage:

The equipment must be grounded at the PE terminal before making any connections whatsoever.

Dangerous voltages may occur in all circuit components connected to the power supply.

Dangerous voltages may still exist in the equipment even after it has been disconnected from the

power supply (capacitor memory)

Equipment with current transformer circuits may not be operated in an open state.

The limit values specified in the manual and in the operating instructions must not be exceeded; this

must also be taken into account during inspection and commissioning

_____________________________________________________________________________________________

Exclusion of liability

We have checked the contents of this publication and every

effort has been made to ensure that the descriptions of both

hardware and software are as accurate as possible. However,

deviations from the description cannot be completely ruled out,

so that no liability can be accepted for any errors or omissions

contained in the information given.

The data in this manual are checked regularly and the

necessary corrections are included in subsequent editions. We

are grateful for any improvements that you care to suggest.

Subject to technical modifications without notice.

Copyright

Copyright Siemens AG April d, yyyy 2:10 a10/p10 All Rights

Reserved

It is prohibited to pass on or copy this document or to use or

disclose its contents without our express permission. Any

duplication is a violation of the law and subject to criminal and

civil penalties. All rights reserved, particularly in the event of a

patent award or utility model registration.

Registered trademarks

SIMATIC

, SIMATIC NET

, SINAUT

and SICAM

are

registered trademarks of the SIEMENS AG. The other names

appearing in this manual may be trade names the use of which

by third parties for their own purposes may infringe the rights

of the owners.

_____________________________________________________________________________________________

Commissioning Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 3 out of 60-

Foreword

Purpose of this manual

This manual describes the functions of the Power Meter SIMEAS P

Target group

This manual addresses the users of SIMEAS P.

Standards

SIMEAS P was developed according to the principles of ISO 9000.

Additional support

If you have questions concerning SIMEAS P please contact:

Your local Siemens distributor

The Siemens hotline (workdays from 7.30 to 17.00 h):

+0049(0)180- 5247000

Fax: 0180-5242471

or

Email: EVS-Serviceline@nbg6.siemens.de

More information under:

www.powerquality.de

Commissioning Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 4 out of 60-

Commissioning

1.1 Scope of delivery..................................................................................................5

Dimensions and weight .................................................................................................5

1.3 Block diagram......................................................................................................5

1.4 Interface and terminals.......................................................................................6

1.4.1 Terminal assignment of SIMEAS P ....................................................................... 6

1.4.2 Pin assignment of the interface............................................................................... 6

1.4.3 Connection examples ............................................................................................... 7

1.4.3.1 General.................................................................................................................. 7

1.4.3.2 Single-phase AC current ....................................................................................... 7

1.4.3.3 Three-wire three-phase-balanced.......................................................................... 8

1.4.3.4 Three-wire three-phase unbalanced ( 2 I ) ............................................................ 8

1.4.3.5 Three-wire three-phase unbalanced ( 3 I ) ............................................................ 8

1.4.3.6 Three-phase four-wire balanced ........................................................................... 8

1.4.3.7 Three-phase four-wire, unbalanced (low-voltage system).................................... 9

1.4.3.8 Three-phase four-wire, unbalanced (high-voltage system)................................... 9

1.4.4 Commissioning......................................................................................................... 9

1

Commissioning Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 5 out of 60-

Inputs / Outputs

Binary output 1

Binary output 2

Communication

interface

9-pin D/SUB

Auxiliary energy

Universal power

supply

24 to 250V DC

100 to 230V AC

U L1

U L2

U L3

U N

I L1

I L2

I L3

AC/

DC

1.1 Scope of delivery

Delivery note

Original cardboard box with the SIMEAS P logo.

Contents:

1 device SIMEAS P

2 fixings for panel mounting.

1 instruction manual

1 return note

1 test report of the device

1.2 Dimensions and weight

Technical data of housing

Housing type:

Switchboard cabinet according to DIN

43700

Degree of protection:

Front IP 41

Terminals IP 20

Dimensions of cabinet:

144 x 144 x 86 ( W x H x D )

Weight:

approx. 0.9 kg

Connection elements

Auxiliary energy:

Terminals for cable diameter 2.5 mm

2

Voltage inputs:

Terminals for cable diameter 2.5 mm

2

Current inputs:

Terminals for cable diameter 4.0 mm

2

Binary outputs:

Terminals for cable diameter 2.5 mm

2

RS485 bus interface:

9-pin D-Sub-connector

1.3 Block diagram

Commissioning Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 6 out of 60-

1.4 Interface and terminals

1.4.1 Terminal assignment of SIMEAS P

1.4.2 Pin assignment of the interface

Pin-N. RS485 interface Profibus interface

1 Protective earth Protective earth

2

3 A B (RxD/TxD-P)

4 RTS CTRL-A

5 GNDEXT GNDEXT

6 +5 VEXT +5 VEXT

7

8 B A (RxD/TxD-N)

9

The housing of the RS 485 interface is connected to the protective earth (PE).

The bus termination is accomplished in the connecting cable.

The isolated supply voltage of the interface is available at the D-SUB female

connector to enable the terminating resistors for the data signals to be connected

in the connecting cable.

Commissioning Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 7 out of 60-

1.4.3 Connection examples

1.4.3.1 General

The following examples of input wirings are examples (according to DIN 43807).

Up to the rated maximum current and voltage values, the device can also be

connected without an interposed current or voltage transducers.

Voltage transducers can be applied in star connection or in V-connection.

All input or output terminals not required for the measurement remain unoccupied.

Designation of the terminals of AC current and three-phase current

measuring devices according to DIN 43807 / Oct. 1983:

DIN 43807 1 3 4 6 7 9 11 2 5 8

Terminal

IL1

IL1

IL2

IL2

IL3

IL3

N UL1 UL2 UL3

SIMEAS P E1 E2 E3 E4 E5 E6 F4 F1 F2 F3

Caution:

The earth continuity of the transducers is represented in this way only for the sake

of simplicity.

The grounding must be performed directly at the transducer and for each

transducer separately.

1.4.3.2 Single-phase AC current

Commissioning Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 8 out of 60-

1.4.3.3 Three-wire three-phase-balanced

1.4.3.4 Three-wire three-phase unbalanced ( 2 I )

1.4.3.5 Three-wire three-phase unbalanced ( 3 I )

Ohne Bild

1.4.3.6 Three-phase four-wire balanced

Commissioning Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 9 out of 60-

1.4.3.7 Three-phase four-wire, unbalanced (low-voltage system)

1.4.3.8 Three-phase four-wire, unbalanced (high-voltage system)

1.4.4 Commissioning

Before switching on the auxiliary voltage, it must be verified that the operational

characteristics correspond to those indicated on the rating plate. This applies in

particular to the auxiliary voltage and the rated current and voltage values of the

station. After a 15-minute warm-up phase, the device observes the error limits.

Operation Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 10 out of 60-

Operation

2.1 Display of the screens........................................................................................11

2.2 Contents of the screens......................................................................................11

2.2.1 Screen types............................................................................................................ 11

2.2.2 2 Measured values digital...................................................................................... 12

2.2.3 2 Measured values digital / analog ....................................................................... 12

2.2.4 4 Measured values digital...................................................................................... 12

2.2.5 4 Measured values digital / analog ....................................................................... 12

2.2.6 Arrow diagram..................................................... Fehler! Textmarke nicht definiert.

2.2.7 Harmonics screens ................................................................................................. 13

2.2.8 Min Max values................................................................................................... 13

2.2.9 Oscilloscope ............................................................................................................ 14

2.2.9.1 General............................................................................................................... 14

2.2.9.2 Menu.................................................................................................................. 14

2.2.9.3 Characteristics of "Instantaneous value" recording........................................... 15

2.2.9.4 Characteristics of "Rms value" recording.......................................................... 16

2.2.10 Status line ............................................................................................................... 17

2

Operation Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 11 out of 60-

2.1 Display of the screens

When SIMEAS P has been adapted to its measuring task (chapter 4) and

connected (chapter 2), the measured variables determined by the user are

displayed on screens.

The screens can be selected via

the two front buttons.

Press a button once to display the

next or the previous screen.

Hold the button to scroll through

the screens automatically.

Equally, a fixed automatic scrolling

through the screens can be

parameterized.

You scroll through screens in a loop,

i.e after the last screen the first is

displayed and vice versa.

2.2 Contents of the screens

The user must be able to read all information relevant for the measurement task at

a glance.

For this purpose, the screens feature a simple and individual design. The number

of screens (max. 20), the screen types and their contents can be individually

parameterized by the user

The following screen types are available:

2.2.1 Screen types

2 MVS digital

2 MSV digital / analog

4 MSV digital

4 MSV digital / analog

Arrow diagram

Harmonic U / I

Min Max values

Oscilloscope Sinus / rms values

Operation Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 12 out of 60-

2.2.2 2 Measured values digital

Status line for SIMEAS P

Display of any 2 measured

variables from the measured

variable table.

2.2.3 2 Measured values digital / analog

Display of any 2 measured variables

from the measured variable table.

Parameterizable start and final value

of each analog bar.

2.2.4 4 Measured values digital

Display of any 4 measured variables

from the measured variable table.

2.2.5 4 Measured values digital / analog

Display of any 4 measured variables

from the measured variable table.

Parameterizable start and final value

of each analog bar.

2.2.6 Vector Diagram

Here the status of the system can be

read a glance.

Digital and graphic display of all

connected conductors

measured variables: U / I / cos phi

Operation Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 13 out of 60-

2.2.7 Harmonics screens

Graphic display of screens with

harmonics of current or voltage.

Display of all odd numbers in all

conductors up to 21 harmonics.

When "ENTER" is pressed,

a window appears on the right upper

screen indicating the digital values

of one harmonic for all three conductors.

Via the buttons all odd harmonics up to 21 can be selected in the

displayed window.

Hold the "ENTER" button to enter the main menu of level 2.

Graphic display in % of the measured value. 100% represents the maximum

value of the first harmonic of one of the three conductors. Digital values:

voltages in %, current in A.

The harmonics (5th,7th,11th,13th,17th,19th) considered important in the

standard can also be displayed individually as measured variables on the

measured values screens.

2.2.8 Min Max values

Up to 8 measured variables from

measured variable tables (except

energy and metered values) can be

monitored here.

Display of the minimum value, the

average value, and the maximum value

of a variable measured since the start

of the recording.

The recording starts with the "Reset" of the Min Max values on the

parameterization level or when the device is switched on.

If no time is set, the duration of the recording is indicated in hours and minutes.

If the time is set, the date and the time of the recording start are indicated.

Any number of listing screens can be parameterized.

Using space lines instead of measured variables provides a clearer overview of

the representation.

Operation Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 14 out of 60-

2.2.9 Oscilloscope

2.2.9.1 General

The oscilloscope represents a special case among the screens. Only one screen

oscilloscope can be selected. The settings are made directly on the screen

oscilloscope via the button Enter = Menu.

Always 3 measured variables are recorded.

The level height of each measured variable is accomplished automatically.

Display of the measured value of each measured variable via cursor position.

Generally, 10 % of the history of each recording is displayed.

Only one recording is possible. When initiating a new recording, the previous

one is deleted.

When triggering the oscilloscope via limit violation, the recording can also be

executed in the background.

Only the first of several limit violations which triggers a recording is recorded.

Further violations are ignored. A new recording must be activated in the menu

via "OK + enable".

The total duration of a recording including the pre-fault history and the post-

fault history is limited to 7040 measuring points for sinus values and 14000

measuring points for rms values per measured value.

2.2.9.2 Menu

Record type

Instantaneous value

Rms value

Measured values 1 to 3

From measured variable table

(depending on record type)

Trigger

Manual (after start-up via the front button "ENTER")

Limit value 1 to 6 (Upon selection and confirmation an input window for

modifying or confirming the limit value parameters appears. As described in the

chapter "Device parameterization, "Input window for limit values", hysteresis,

filter time, and the connection of several measured variables can be

determined.)

Recording time

The recording time depends on the record type.

For instantaneous values the setting of the recording time is fixed to 2 second.

For rms values it can be adjusted < 4.0 h.

* Record type : Instantaneous value

* Measured value 1 : U L1

* Measured value 2 : L2

* Measured value 3 : U E-N

* Trigger : Manual

* Length : 0 : 0 : 2

< Zoom off

< Cursor off

< Abortion

< OK + enable

< Main menu

Operation Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 15 out of 60-

Zoom

If the zoom function is activated via "on" and confirmed, the time axis can be

changed up to the minimum or maximum variable via the buttons

Cursor

If the cursor is activated via "on" and confirmed, the cursor can be moved on

the time axis by using the buttons . If the button is pressed once, the

cursor moves by one position. If the button is held, the cursor moves

automatically with increasing speed.

The values of the measured variables are automatically displayed on the Y

axis for the corresponding cursor position.

Abortion

Modified settings in the menu are not accepted. Back to the oscilloscope

screen.

OK + enable

Modified settings in the menu are accepted and trigger the recording. Back to

the oscilloscope screen.

Main menu

Here the user can access the main menu of level 2 from the oscilloscope

screen.

2.2.9.3 Characteristics of "Instantaneous value" recording

Recording time cannot be changed and is fixed to approx. 2s ( 200 ms of pre-

fault history and approx. 1800ms of post-fault history). (7040 measuring points

per measured variable).

The time axis in the screen can be changed via zoom from 60 ms to 2000 ms

Sampling points

The measuring interrupt is thus adapted to the frequency that each period is

sampled with 64 measuring points.

Therefore, the sampling rate is:

At 50 Hz = 3.20 kHz

At 60 Hz = 3.84 kHz

Trigger via limit violation:

The rms value of each half wave is calculated and tested for Max/Min violations. A

violation immediately triggers the recording.

Operation Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 16 out of 60-

Only the measured variables current

or voltage are available for input.

The parameters hysteresis and filter

time are meaningless.

2.2.9.4 Characteristics of "Rms value" recording

3 measured variables can be selected from the measured variable table except

energy and metered values.

Recording time can be modified up to a maximum of 3h 59min. (approx.

14000 measuring points per measured variable)

Each second one measuring point of a measured variable is saved.

Pre-fault history is always 10% of the selected recording time.

Time axis on the screen can be changed via the zoom function:

Note

As 10% of the recording time are always written as pre-fault history, the time for

writing the pre-fault history must expire before a new recording can be triggered.

The minimum time resolution on the display is limited for the recording time by the

number of the approx. 200 pixels. That is 1 pixel = 1s per measured value. The

shortest time period which can be displayed on the time axis is thus approx. 3 min.

For recording times < 3min, only a part of the display width is used for recording.

Operation Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 17 out of 60-

2.2.10 Status line

The screens ( except harmonics and oscilloscope ) feature a status line which

displays the status of SIMEAS P.

1.) Diagnostic messages

"><" Serial telegram was received.

"Bd" Searching for the Profibus baudrate

"Cfg" Waiting for the correct configuration of Profibus

"Prm" Waiting for the correct parameters of Profibus

q Direction of rotation from UL1 to UL2

Export or import

Limit violation of the relay ( the limit violation is displayed and not the

status of the relay)

,PSRUW RU H[SRUW

3KDVH URWDWLRQ

LQGLFDWRU

6FUHHQ QXPEHU DQG

WRWDO QXPEHU RI VFUHHQV

'LDJQRVLV RI EXV

DQG GHYLFH

6WDWXV RI ELQDU\ RXWSXWV 6WDWXV RI GHYLFH FRGH

SURWHFWLRQ

Measured variables Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 18 out of 60-

Measured variables

Measured variables depending on the connection type

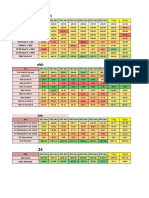

Table 1 Measured variables depending on the connection type

N Measured variable

1

-

p

h

a

s

e

A

C

c

u

r

r

e

n

t

T

h

r

e

e

-

w

i

r

e

t

h

r

e

e

-

p

h

a

s

e

-

b

a

l

a

n

c

e

d

T

h

r

e

e

-

w

i

r

e

t

h

r

e

e

-

p

h

a

s

e

u

n

b

a

l

a

n

c

e

d

3

I

T

h

r

e

e

-

w

i

r

e

t

h

r

e

e

-

p

h

a

s

e

u

n

b

a

l

a

n

c

e

d

2

I

T

h

r

e

e

-

p

h

a

s

e

f

o

u

r

-

w

i

r

e

b

a

l

a

n

c

e

d

T

h

r

e

e

-

p

h

a

s

e

f

o

u

r

-

w

i

r

e

u

n

b

a

l

a

n

c

e

d

Comments

1 (space line)* X X X X X X

2 Voltage L1-N X X X UL1

3 Voltage L2-N X UL2

4 Voltage L3-N X UL3

5 Voltage E-N X X X X X X UE-N

6 Voltage L1-L2 X X X X UL12

7 Voltage L2-L3 X X X X UL23

8 Voltage L3-L1 X X X X UL31

9 Voltage averag value L-N* L-N/3 L-N/3 L-N/3 L1-N L-N/3 U

10 Current L1 X X X X X X IL1

11 Current L2 X X X IL2

12 Current L3 X X X IL3

13 Current average value* X X I / 3 I

14 Current N X X I0

15 Active power L1 X X PL1

16 Active power L2 X PL2

17 Active power L3 X PL3

18 Active power X X X X X P

19 Reactive power L1 X X QL1

20 Reactive power L2 X QL2

21 Reactive power L3 X QL3

22 Reactive power X X X X X Q

23 Apparent power L1 X X SL1

24 Apparent power L2 X SL2

25 Apparent power L3 X SL3

26 Apparent power X X X X X S

27 Active factor cos L1 X X CosL1

28 Active factor cos L2 X CosL2

29 Active factor cos L3 X CosL3

30 Active factor cos X X X X X Cos

31 Power factor L1 X X LFL1

32 Power factor L2 X LFL2

33 Power factor L3 X LFL3

34 Power factor X X X X X LF

3

Measured variables Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 19 out of 60-

N Measured variable

1

-

p

h

a

s

e

A

C

c

u

r

r

e

n

t

T

h

r

e

e

-

w

i

r

e

t

h

r

e

e

-

p

h

a

s

e

-

b

a

l

a

n

c

e

d

T

h

r

e

e

-

w

i

r

e

t

h

r

e

e

-

p

h

a

s

e

u

n

b

a

l

a

n

c

e

d

3

I

T

h

r

e

e

-

w

i

r

e

t

h

r

e

e

-

p

h

a

s

e

u

n

b

a

l

a

n

c

e

d

2

I

T

h

r

e

e

-

p

h

a

s

e

f

o

u

r

-

w

i

r

e

b

a

l

a

n

c

e

d

T

h

r

e

e

-

p

h

a

s

e

f

o

u

r

-

w

i

r

e

u

n

b

a

l

a

n

c

e

d

Comments

35 Phase angle L1 X X PhiL1

36 Phase angle L2 X PhiL2

37 Phase angle L3 X PhiL3

38 Phase angle X X X X X Phi

39 Mains frequency X X X X X X Frq

40 Asymmetric voltage X USymU

41 Asymmetric voltage X USymI

42 THD voltage L1 X X THD UL1

43 THD voltage L2 X THD UL2

44 THD voltage L3 X THD UL3

45 THD current L1 X X THD IL1

46 THD current L2 X THD IL2

47 THD current L3 X THD IL3

48 Harmonic voltage L1* X X X X X X HUL1 5,7,11,13,17,19

49 Harmonic voltage L2* X X X HUL2 5,7,11,13,17,19

50 Harmonic voltage L3* X X X HUL3 5,7,11,13,17,19

51 Harmonic current L1* X X X X X X HIL1 5,7,11,13,17,19

52 Harmonic current L2* X X X HIL2 5,7,11,13,17,19

53 Harmonic current L3* X X X HIL3 5,7,11,13,17,19

54 Active power E import L1* X X PL1 imp. /h

55 Active power E import L2* X PL2 imp. /h

56 Active power E import L3* X PL3 imp. /h

57 Active power E import * X X X X X P imp. /h

58 Active power E export L1 X X PL1 exp. /h

59 Active power E export L2 X PL2 exp. /h

60 Active power E export L3 X PL3 exp. /h

61 Active power E export X X X X X P exp. /h

62 Active power absolute L1* PL1 sum /h

63 Active power absolute L2* PL2 sum /h

64 Active power absolute L3* PL3 sum /h

65 Active power absolute * P sum /h

66 P balance* X X X X X P balance /h

67 Reactive power ind. L1 X X QL1 ind. /h

68 Reactive power ind. L2 X QL2 ind. /h

69 Reactive power ind. L3 X QL3 ind. /h

70 Reactive power ind. X X X X X Q ind. /h

71 Reactive power cap. L1 X X QL1 cap. /h

72 Reactive power cap. L2 X QL2 cap. /h

73 Reactive power cap. L3 X QL3 cap. /h

74 Reactive power cap. X X X X X Q cap. /h

75 Reactive power absolute L1* X X QL1 sum /h

76 Reactive power absolute L2* X QL2 sum /h

77 Reactive power absolute L3* X QL3 sum /h

78 Reactive power absolute * X X X X X Q sum /h

79 Apparent power ES L1 X X SL1 /h

80 Apparent power ES L2 X SL2 /h

81 Apparent power ES L3 X SL3 /h

82 Apparent power ES X X X X X S /h

83 Counter 1 / 2 / 3 / 4* X X X X X X Cntr.1,2,3,4

Measured variables Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 20 out of 60-

* Explanation

Nr. Name Description

1 (space line) If a space line is selected, the field of this measured variable remains empty on

the display screens.

9 Votage average value L-N The average value of the applied phase voltages U-N is displayed here. For the

connection type 3-conductor.... this value is calculated

13 Current average value The average value of the 3 currents is displayed here.

48

to

53

Harmonics

U/I

The standard IEC 1000-2-2 and also EN 50160 specify compatibility levels from

the range up to 21 only for harmonics of orders 5, 7, 11, 13, 17, 19. Those of

even order and those divisible by 3 are considered irrelevant.

The selection in the "Harmonics" screen is therefore limited to all uneven orders

up to 21. The selection of single harmonics in the measured values screens is

limited to 5th, 7th, 11th, 13th, 17th and 19th.

For voltage the percentage value of the harmonics refers to the measured value.

For current the values are displayed directly in A.

54

to

57

Active power E import Import is given if a standards-conforming connection produces a positive

measured.

62

to

65

Active power absolute The sum of the absolute values (without sign) of import and export of the active

power.

66 P balance The balance of the active power of export and import is indicated. The import is

positive. (import minus export). As the variable can have different polarity, the

output as pulse via relay is not possible.

75

to

78

Reactive power absolute The sum of the absolute values (without sign) of cap. and ind. of the reactive

power.

83 Counters 1 / 2 / 3 / 4 Limit violations can be added and displayed digitally here.

Device parameterization Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 21 out of 60-

Device parameterization

4.1 Operating notes..................................................................................................22

4.1.1 Button functions..................................................................................................... 22

4.1.2 Window structure .................................................................................................. 22

4.1.3 Notes........................................................................................................................ 23

4.2 Overview of the levels........................................................................................23

4.3 Main menu .........................................................................................................24

4.3.1 Basic parameters.................................................................................................... 24

4.3.1.1 Overview of the parameters............................................................................... 24

4.3.1.2 Connection / transducer ..................................................................................... 25

4.3.1.3 Outputs............................................................................................................... 27

4.3.1.4 Interface............................................................................................................. 28

4.3.1.5 Changing the code ............................................................................................. 29

4.3.1.6 Calibration ......................................................................................................... 29

4.3.1.7 Additional settings............................................................................................. 30

4.3.2 Language / designation.......................................................................................... 30

4.3.3 Information on SIMEAS....................................................................................... 31

4.3.4 Date / time............................................................................................................... 31

4.3.5 Reset ........................................................................................................................ 31

4.3.6 Screens parameterization...................................................................................... 32

4.3.6.1 Screen structure ................................................................................................. 33

4

Device parameterization Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 22 out of 60-

4.1 Operating notes

This chapter describes all setting options of SIMEAS P adjustable via its front

buttons.

The main menu of the parameterization level can be accessed from the measured

values screen, the Min/Max screen and the arrow diagram screen via the "ENTER

button.

From the harmonics screen it can be accessed by holding the "ENTER" button

pressed.

From the oscilloscope screen via "ENTER" "MENU"

4.1.1 Button functions

The following functions can be executed via the buttons:

Moving the cursor to the entry line.

Scrolling through selection lists when entering parameters.

Selecting figures and characters when entering numerical values.

If the buttons are held pressed, the scrolling continues automatically.

The cursor, parameters or numbers in general are scrolled through via the buttons.

The selected line, parameter, or number are confirmed by applying the "ENTER"

button.

4.1.2 Window structure

Select * and "Enter" and the

cursor jumps directly to the enter

position in the same window.

Select > and "Enter" and

a new window opens for further

entries.

Apply < "OK" to confirm the setting

and to return to the previous level.

If you apply < "abortion", the modified settings are not saved and you return to the

screens of level 1.

ENTER

* Number of screens : 14

* Screen interval : 0 Sec.

* Illumination : 99 Min.

* Contrast : 5

> Screen construction

< OK

< Abortion

Device parameterization Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 23 out of 60-

4.1.3 Notes

The selection of the measured variables depends on the selected connection

type.

The input of numbers is plausibilized and displayed with the note: "Overflow".

The input value is then set to the maximum value.

If the auxiliary energy is switched off during parameterization, a log text for the

selection appears when the device is restarted. Therefore, the auxiliary energy

should only be switched off on level 1 (measuring screens).

Log text

Select "No" via the buttons to

retain the default settings prior to the

failure of the auxiliary energy.

Choose"Yes" by applying the "ENTER"

button to restore the default values.

4.2 Overview of the levels

Level 1 is the level with the measurement screens

The levels 2 to 4 are parameterization levels as will be described in the

following.

Basic

parameters

Parameterization

screens

Information on

SIMEAS P

Overview of

parameters

Connection

transducer

Outputs Inter-

faces

Change

code

Cali-

bration

Screen

structure

Language /

designation

Date / time Reset

Additional

settings

Main menu

Power Meter

Caution faulty parameters!

Reset ?

No Yes

( Arrow ) ( Enter )

Device parameterization Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 24 out of 60-

4.3 Main menu

Via the main menu the other

submenus can be accessed.

4.3.1 Basic parameters

Via the menu basic parameters the input

screens for the parameterization of the

device can be selected.

4.3.1.1 Overview of the parameters

Here, the most important settings of the

device are displayed on one screen.

> Basic parameters

> Language / designation

> Information on SIMEAS

> Date / Time

> Reset

> Parameterization screens

< Exit

> Overview of the parameters

> Output / transducer

> Outputs

> Interface

> Change code

> Calibration

> Additional settings

> OK

< Exit

Calculation mode: standard

4-conductor any load

Current: 1.2 A

Voltage: 480V

Rel 1: Limit value 1

Rel 1: Limit value 2

Bus Adr.: 01

< Abortion

Device parameterization Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 25 out of 60-

4.3.1.2 Connection / transducer

Connection:

As described in chapter 1:

"connection examples", the type of

power supply can be selected here.

1-phase AC current

Three-phase four-wire balanced

Three-phase four-wire unbalanced

Three-phase three-wire balanced

Three-phase three-wire unbalanced ( 2 x I )

Three-phase three-wire unbalanced ( 3 x I )

" Three-phase three-wire unbalanced " can be selected either with the connection

of 2 current transducers ( standard / Aron measuring circuit ) or with 3 current

transducers.

Current transducers:

Yes ( Transducer input can be selected/ max. prim: 999 999 A; sec: 6 A)

No ( Transducer input cannot be selected)

Measuring range:

1.2 A ( rated range 1 A )

6 A ( rated range 5 A )

Here, the user himself can select the internal current measuring range of SIMEAS

P.

Caution:

The measuring range must be determined for the setting with and without

transducer.

The selected measuring range must be greater than the secondary value of the

transducer!

The accuracy of SIMEAS P refers to this measuring range.

The determination of this range indicates the maximum current measuring

range which can be displayed on the device.

Example:

Transducer: 500 / 1 A

Measuring range 1.2 A: Max. display range : 0 to 600A

Measuring range 6 A: Max. display range: 0 to 3000A

Recommendation: Generally 6 A

Connection

* Three-phase four-wire unbalanced

* Current transducer: Yes

* 100 A / 1 A

* Measuring range: 1.2 A

* Voltage transducer: No

* kV / V

* Measuring range L N : 480 V

< OK

< Abortion

Device parameterization Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 26 out of 60-

Current transducer

Yes ( Transducer input can be selected / max. prim: 1000.00 kV; sec.: 420 V)

No ( Transducer input cannot be selected)

Measuring range L-L:

132 V ( rated range 100/110 V )

228 V ( rated range 190 V )

480 V ( rated range 400 V )

828 V ( rated range 690 V )

Conversion table for line voltage L-L into phase voltage L-N

Selectable measuring

range L - L

Equivalent to

measuring range L - N

0 to 132 V 0 to 76.2 V

0 to 228 V 0 to 132 V

0 to 480 V 0 to 276 V

0 to 828 V 0 to 480 V

Here, the user himself can select the internal measuring range of SIMEAS P. Up to

Y 400 / 690V can be connected directly without a transducer.

Caution:

The range must be determined for the setting with and without transducer.

The selected measuring range must be greater than the secondary value of the

transducer!

The accuracy of SIMEAS P refers to this measuring range.

The determination of this range indicates the maximum range which can be

displayed on the device.

The frequency measurement of SIMEAS P is initiated only when the

determined voltage is >20%.

Also for "Connection: single-phase AC current" the measuring range must be

indicated as line to line voltage L-L. The L-N measuring range must be

determined according to the conversion table.

Example:

Transducer: 10 kV / 100 V

Measuring range 132 V: Max display range: 0 to 13.2 kV

Measuring range 228 V: Max display range: 0 to 22.8 kV

Recommendation:

If the connection is made to transducers featuring secondary voltages of 100, 115

or 120V, the measuring range "132 V" should be selected.

If the connection is performed directly to Y 230 / 400V, the measuring range

"480 V" should be chosen.

If the connection is made directly to Y 400 / 690V, the measuring range of

"828 V" should be selected.

If "Connection: Single-phase AC current is made to 230V, the measuring range

"480 V" (=256V L-N) should be chosen.

Device parameterization Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 27 out of 60-

4.3.1.3 Outputs

Here, the user can determine the

function of the binary outputs.

(Electronic relay potential-free)

The various options for setting a relay

will be presented in the following.

Selection:

Off Relay has no function

Device in operation Relay connected if auxiliary energy is applied.

Energy pulses If selected, a new window "Energy pulses" appears.

Limit values 1 If selected, a new window "Limit value 1" appears.

Limit values 2 If selected, a new window "Limit value 2" appears.

Limit values 3 If selected, a new window "Limit value 3" appears.

Limit values 4 If selected, a new window "Limit value 4" appears.

Limit values 5 If selected, a new window "Limit value 5" appears.

Limit values 6 If selected, a new window "Limit value 6" appears.

Input window for energy pulses

Energy

Selection of all energy variables

from measured variable tables

depending on the type of the

connection

Value

Input of the energy value per pulse

Pulse duration

Can be selected from 50, 100, 150, 200......to 500 ms.

* Relay 1: Limit values 5

* Relay 2: Energy pulses

< OK

< Abortion

Energy pulses

* Energy: P L1 import. / h

* Value: 1.0000 kWh / imp

* Pulse interval: 200 ms

< OK

< Abortion

Device parameterization Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 28 out of 60-

Input window for limit value

The values entered for hysteresis,

pulse duration and filter time are valid

for all logically connected measured

variables.

Hysteresis

Input of 0,1 to 10 % max.

Value refers to the rated values.

Pulse duration

0,5s; 1s; 5s; 10s; 30s; 60s; 300s;

(triggering for as long as a limit

violation applies)

Filter time

Input of 0.0 to 9.9s max.

(Minimum time during which a limit

violation must occur to

launch a triggering)

Limit values

Selection of any measured variable from the measured variable table ( no

energy variable or metered variable)

It must be determined whether the triggering is launched if the measured

variable is undershot or overshot( < > ).

Indicating the measured value which initiates the triggering.

Further measured variables can be connected logically via "and" or "or". A

maximum of up to any 6 measured variables is possible.

4.3.1.4 Interface

Bus address

Input of address 1 to 255

Baudrate

Selection only for connection to

a PC.The baudrate of the Profibus

is supported automatically up to

12 MBd with the selection being

performed via the master station.

Protocol

PC-RS485 ( For connection to a PC via parameterization software )

Profibus

Limit value 5

* Hysteresis: 1.0 %

* Pulse duration: 30 s

* Filter time: 1.0 s

* U L1 < 9,8 kV or

* U L1 > 10,2 kV

< OK

< Abortion

* Bus address: 3

* Baudrate: 9600 Bd

* Protocol: PC RS 485

< OK

< Abortion

Device parameterization Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 29 out of 60-

4.3.1.5 Changing the code

Code 1:

Off: No function

On: ( only active in connection

with code 2).

Secured functions:

Parameterization of the screens

Reset

Language / designation

Code 2:

Off: No function (code 1 also deactivated )

On: Code activated.

Secured functions:

Basic parameters

Notes:

A password always consists of a 6-digit number.

If you have forgotten the password, the device can also be activated by using

the master password.

Code 1 is only active if code 2 is also activated.

If both code 1 and code 2 are activated, the password of code 2 can be used to

access all protected functions of code 1.

If an identical password is chosen for code 1 and code 2, all functions of code

1 and code 2 can be activated by means of one single password.

In level 1 a lock displayed on the status line indicates whether the status of the

device is protected (closed) or unprotected (open).

After a codeword has been parameterized, a time of 1 minute expires before it

is activated in level 1 (the activation can be recognized by the closing of the

lock on the status line).

If the protected functions are called in the menu, a window for entering the

password appears.

If a protected parameter is activated by means of a password, all other

parameters of this code, too, are activated. A re-activation is performed only

after a time of 1 minute has expired in level 1.

4.3.1.6 Calibration

See chapter "Calibration.

* Code 1 : 000000

* off

* Code 2 : 000000

* off

< OK

< Abortion

Device parameterization Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 30 out of 60-

4.3.1.7 Additional settings

Counters 1 to 4

On the screens the counters

1 to 4 can be displayed digitally.

Limit values can be assigned to these

counters. When a counter is selected,

a second window opens for the input

of the corresponding values

(see binary outputs).

Calculation mode

Standard

DIN

Fourier

The calculation mode for some measured variables can be changed here. For

further information see chapter "Measured variables.

Current direction

+ (Standard if connection was performed correctly pursuant to the standard)

- (Current direction is negated)

The current direction can be changed here, so that connections do not have to be

exchanged.

4.3.2 Language / designation

Sprache / Language

The language of SIMEAS P

can be selected here.

D = German

GB = English

Designation

Changing the conductor names on the screens

L1, L2, L3

a, b, c

> Counter 1 - Limit value 1

> Counter 2 - Limit value 2

> Counter 3 - Limit value 3

> Counter 4 - Limit value 4

* Calculation mode: Standard

* Current direction: +

< OK

< Abortion

* Sprache / Language : D

* Designation L1, L2, L3

< OK

< Abortion

Device parameterization Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 31 out of 60-

4.3.3 Information on SIMEAS

All device characteristics are

displayed on one window.

4.3.4 Date / time

Only few functions of the SIMEAS P

basic version require time information

and even there it is not forcibly

necessary.

Oscilloscope

Date of calibration

Since the basic version does not

dispose of a battery buffering, time

information is reset if the auxiliary energy fails.

4.3.5 Reset

Reset

Total reset of SIMEAS P

All energy values

Min Aver Max values

Counter limit violations

Order number: 7KG7000-8AA

Serial number: BF0101047653

Version number: 01.00.12

Bus address: 1

Date of calibration: 18.01.2000

< OK

* Date : 01. 02. 2001

* Time : 10 : 17 : 57 am

* 12 / 24h : 12

< OK

< Abortion

* Total reset of SIMEAS P: No

* Reset energy values : No

* Reset MinAver-Max : No

* Reset alarm counter : No

< OK

< Abortion

Device parameterization Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 32 out of 60-

4.3.6 Screens parameterization

The contents and display mode of

the screens can be determined in this

window.

Number of screens

Between 1 and 20

Number of screens which can be

selected on level 1 via the front buttons.

Screen interval

Between 0 and 60 seconds

0 sec. = fixed screens ( selection only via the front buttons )

Illumination:

Between 0 and 99 minutes

0 Min. = Illumination off

99 Min. = Illumination on permanently

Contrast:

Between 0 and 9

* Number of screens : 14

* Screen interval : 0 Sec.

* Illumination : 99 Min.

* Contrast : 5

> Screen structure

< OK

< Abortion

Device parameterization Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 33 out of 60-

4.3.6.1 Screen structure

The contents of the screens can be

determined in the window "Screen

structure.

Screen:

Selection of a screen among the

number previously determined.

The contents of the screens are

automatically displayed when switching from one screen to the next.

Contents:

The contents of the selected screens can be modified here.

2 MSV digital

2 MSV digital / analog

4 MSV digital

4 MSV digital / analog

Harmonics U / I

Min Max values

Arrow diagram

Oscilloscope sinus / rms values

If a content is selected, the input of the other characteristics is automatically

displayed below this value. E.g. for 4 MSV digital the selection of the 4 measured

variables with conductor.

* Screen : 14

* Contents : 4 MSV digital

* 1 : I L1

* 2 : I L2

* 3 : I L3

* 4 : freq

< OK

< Abortion

Profibus DP Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 34 out of 60-

Profibus DP

5.1 Introduction.......................................................................................................35

5.2 General introduction.........................................................................................35

5.3 SIMEAS P integration into an automation system........................................37

5.3.1 Basic setting of SIMEAS P.................................................................................... 37

5.3.2 Integration via the file ........................................................................................... 38

5.4 Cyclic data exchange.........................................................................................39

5.4.1 Basic types for the cyclic data exchange .............................................................. 40

5.4.2 Overview of the basic types................................................................................... 41

5.5 Data exchange via PROFIBUS DPV1 .............................................................44

5.6 Diagnostics .........................................................................................................44

5.7 Detailed protocol description ...........................................................................45

5.7.1 Introduction............................................................................................................ 45

5.7.2 Standard services ................................................................................................... 46

5.7.2.1 File transfer: From master to slave .................................................................... 46

5.7.2.2 File transfer: From slave to master .................................................................... 47

5.7.2.3 Mapping to Profibus-DP.................................................................................... 48

5.7.3 Device protocol SIMEAS P (layer +).................................................................... 49

5.7.3.1 Continuous transmission of measured data ....................................................... 49

5.7.3.2 Basic type 1 ....................................................................................................... 50

5.7.3.3 Basic type 2 ....................................................................................................... 50

5.7.3.4 Basic type 3 ....................................................................................................... 50

5.7.4 Transmission of measured data upon request..................................................... 50

5.7.5 Parameterization.................................................................................................... 52

5.7.5.1 Device information............................................................................................ 53

5.7.5.2 Measurement information (status) (comfort)..................................................... 53

5.7.5.3 Send/receive measurement settings ................................................................... 54

5.7.5.4 Connection setting ............................................................................................. 59

5.7.5.5 Measured values ................................................................................................ 59

Profibus DP Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 35 out of 60-

5.1 Introduction

The following chapter contains a description of how the communication

facilites of the SIMEAS P Power Meter ( 7KG7000-8AA ) are connected.

The brief, general introduction on the topics communication and

PROFIBUS is followed by chapters providing all relevant information

concerning the PROFIBUS connection of SIMEAS P. In the annex you will find the

PROFIBUS data records in detail.

5.2 General introduction

PROFIBUS- DP is an open, standardized and manufacturer-independ field bus

system. PROFIBUS DP is standardized according to DIN (E) 19424 Part 3 / EN

50170 and thus provides the ideal basis required for the high demands posed to

data exchange in the domain of distributed peripherals and field devices. More

than 1000 manufactures to date (date: Sept. 2000) offer more than 1500 products

and user organisations in 23 countries provide technical support for the users of

the approx. 3 million PROFIBUS nodes installed worldwide.

Further integration and connection to common automation concepts is equally

unproblematic since all major manufacturers of programmable logic controllers

(PLC) offer PROFIBUS DP master modules and the systems operate nearly in

realtime due to the high transmission rates of up to 12 Mbaud.

The protocol used for the communication of the PROFIBUS nodes provides for the

communication between the complex, democratic automation devices (masters)

thus enabling each node to accomplish its communication tasks within specified

time intervals.

Furthermore a cylic data exchange is implemented via the Profibus for the

communication of a master with the associated simple peripherals (slaves) with

small effort.

For this purpose, PROFIBUS relies on a hybrid control system for bus access

consisting of a central token-passing procedure between the active bus nodes

(masters) and one central master-slave procedure for data exchange between

active and passive bus nodes.

This control system for bus access enables the following system configurations to

be implemented:

- Pure master-slave system

- Pure master-master system with token passing

- A system consisting of a combination of both procedures

5

Profibus DP Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 36 out of 60-

Sensor Drive Actuator

Trans -

ducer Sensor Sensor

M

Drive

M

V

PROFIBUS

Passive Stations, Slave Devices

Active Stations, Master Devices

Locigal Token Ring between the Master Devices

The figure depicts an example with 3 master modules and 7 slaves. The 3 master

devices constitute a logic circle. Control of the token is accomplished by the MAC

(bus access control). In the start-up phase it generates the token and controls that

only one token is passed within the logic circle.

Each slave communicating cyclically via the PROFIBUS is assigned one class-1

master. The cyclic data exchange is accomplished according to the DP standard

profile (DPV0). A class-1 master primarily fulfils automation tasks. In addition to the

cyclic data exchange a class-1 master can also establish an acyclic communication

connection to its slaves and thus utilize the expanded functions of a slave.

A class-2 master is especially appropriate to accomplish commissioning tasks,

diagnostics and visualization tasks. It is connected to the PROFIBUS in addition to

a class-1 master and can address slaves and exchange data via acyclic services,

provided this is permitted by the slaves.

The acyclic data transmission is accomplished via DPV1. DPV 1 supplements the

existing PROFIBUS standard by several functions. Among others this enables the

slave configuration to be modified during running operation and to establish an

acyclic data exchange. DPV1 also enables data to be read directly from the slave

by a class-2 master although the slave still entertains a connection to a class-1

master.

A suitable example is represented by the cyclic data exchange between a power

meter and the PLC as class-1 master and the simultaneous acyclic visualization

e.g. by means of the WinCC monitoring system installed on a PC with a

PROFIBUS interface (class-2 master).

Profibus DP Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 37 out of 60-

5.3 SIMEAS P integration into an automation system

5.3.1 Basic setting of SIMEAS P

Call the input window "interface in the parameterization menu of SIMEAS P.

Settings:

Bus address: 3 to 125

Protocol: Profibus

Specifying the baudrate has no

function for the protocol Profibus DP.

Baudrate is selected via the master

station. (max. 12Mbit/s)

* Bus address: 3

* Baudrate: 9600 Bd

* Protocol: PC RS 485

< OK

< Abortion

Profibus DP

communication

of SIMEAS P

Communication

(class-1 master)

Communication

with the

(class-2 master)

Integration as

DP standard slave

Configuration with

GSD file and

master-specific tool

Operating and

monitoring via

DPV1 with HMI system

(e.g. WinCC)

Operating and

monitoring and

diagnostics via DPV1

with one additional

PLC

PC/PLC

Profibus DP Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 38 out of 60-

5.3.2 Integration via the GSD file

The configuration of the device parameters is accomplished via a configuration tool

which each DP standard master contains. If a SIMATC S7 is applied as master,

this is the HW Config of the SIMATIC STEP7 package. If it is not a SIMATIC S7,

the configuration can be performed in dependence of the master e.g. via COM

PROFIBUS.

If the GSD file containing the device master data of the power meter has not yet

been installed, this file must previously be integrated into the configuration tool. For

this purpose, you can, e.g., copy the GSD file to the subdirectory in which all GSD

files of the configuration tool are stored and update the device library via the

corresponding menu item. All parameters are stored in the GSD file which must be

sent by the master during start-up of the slave.

Subsequently, select the SIMEAS P Power Meter from the device catalog, the

desired basic type and all other parameters, measured variables and addresses of

the data transmission.

Via the GSD file the SIMEAS P Power Meter is always integrated as DP standard

slave. Optionally, additional data can easily be transmitted also via DPV1 and e.g.

parameters can be modified.

HW Config of STEP7 featuring the integration of a DP slave via GSD file

Profibus DP Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 39 out of 60-

Measured variables in HW Config of STEP7

5.4 Cyclic data exchange

During cyclic data transfer each telegram transfers a specified number of user

data. For this purpose, it must be determined during the configuration of the slave

(here SIMEAS P) how many and what data are exchanged cyclically between the

power meter and the PLC. Cyclic data exchange therefore represents the best

option for transferring information which are required continuously and rapidly. The

time interval between two values depends on the number of nodes, the data

volume and the baudrate.

Subsequent modifications of the data volume during operation are not possible.

Therefore, the exclusively cyclic data exchange is very well suited for a

communication that operates with a small volume of user data.

Profibus DP Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 40 out of 60-

5.4.1 Basic types for the cyclic data exchange

Due to the large data volume provided by the SIMEAS P Power Meters, a

compromise between the data volume and the performance on the bus had to be

found. If the information volume transmitted during data exchange is too large and

only a small amount of the data can be used, the performance of the PROFIBUS is

impaired.

Therefore, three basic types are available for efficient and flexible transmission.

During configuration this enables the best-suited basic type and the corresponding

bus configuration to be selected for the specific application case. Configuration is

accomplished by means of a PROFIBUS configuration tool such as e.g. COM

PROFIBUS or HW Config of Simatic S7. The basic types are already pre-assigned

and enable a fast commissioning without additional configuration /

parameterization.

Selection of the basic types

Of course, configuration within one basic type can also be defined by the user.

Note: Data that is not required permanently can additionally be transmitted via

DPV1.

Profibus DP Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 41 out of 60-

5.4.2 Overview of the basic types

The following table provides an overview of the basic types including the size and

the division of the information which can be called cyclically by SIMEAS P.

Byte Basic type1 Basic type 2 Basic type 3

0-3

Status

SIMEAS P

Status

SIMEAS P

Status

SIMEAS P

4-7

Data block 1 Data block 1 Data block 1

8-11

Data block 2 Data block 2 Data block 2

12-15

Data block 3 Data block 3 Data block 3

16-19

Data block 4 Data block 4

20-23

Data block 5 Data block 5

24-27

Data block 6 Data block 6

28-31

Data block 7

32-35

Data block 8

36-39

Data block 9

40-43

Data block 10

44-47

Data block 11

48-51

Data block 12

Overview of the Input Packet Layouts of the different basic types

If the configuration is modified, the desired data block numbers can be determined

to transmit any information within one basic type.

Profibus DP Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 42 out of 60-

Explanation of the status bytes for SIMEAS P

Bit number SIMEAS P

0 Binary output 1

1 Binary output 2

2 Binary output 3

3 Binary output 4

4-7 not used

8-31 not used

Status bytes SIMEAS P

Overview of the input data for SIMEAS P

Byte Basic type 1, 2 and 3

0-7 Control bits

Explanation of the control bits

Byte number SIMEAS P

0 Command ID

1-7 Parameters

Overview of the commands

Command ID Parameter Typ

Zero command 0x00 --- ---

Reset 0x10 Min-Aver-Max = 0x01

Energy values = 0x02

Alarm counter = 0x04

Bit array 8bit

Set clock 0x20 Date + time in seconds from 1.1.1980 long

Profibus DP Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 43 out of 60-

<Data Block>

A measured value is transmitted as floating-point value in a data block.

Floating Point

Floating Point Number

Notation: Floating-Point (4 octets)

Range of Values: see IEEE Std 754 Short Real Number (32 bits)

Coding: see IEEE Std 754 Short Real Number (32 bits)

Coding of Data of Data Type Floating Point

Profibus DP Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 44 out of 60-

5.5 Data exchange via PROFIBUS DPV1

PROFIBUS DPV1 is an expansion of the PROFIBUS DP protocol. Devices for

PROFIBUS DP and also for PROFIBUS DPV1 can be connected to one line. It is

downward compatible; therefore the PROFIBUS DP protocol and the PROFIBUS

DPV1 protocol can run over the same line. Additional data blocks can thus be

transmitted acyclically with up to 240 bytes of user data by means of application

programs such as STEP7 or WinCC.

The PROFIBUS DPV1 protocol thus constitutes the basis for a comfortable data

exchange of e.g. parameter data, diagnostic data, control data, and test data.

The prerequisite is a DPV1-compatible class-1 master or class-2 master. They

enable the above mentioned data to be transmitted via an additional established

channel.

The class-2 master can even establish communication to slaves that are not

configured and parameterized by this master and which still entertain a connection

to a class-1 master. A class-2 master is especially suitable for commissioning,

diagnostics, and visualization tasks e.g. by using the program WinCC.

5.6 Diagnostics

If the SIMEAS P Power Meter has problems during data transmission or if an

important status occurs in the power meter, it generates a high-priority diagnostic

telegram. The master collects this high-priority diagnostic telegram as soon as

possible, thus enabling the user to react fast if critical states occur.

For a Simatic S7 this diagnostic telegram initiates a diagnosis alarm and the object

block (OB82) responsible for the processing of diagnosis alarms is invoked. If the

object block is not programmed, the alarm indication is not processed and the PLC

enters the Stop mode. If the object block is programmed, the alarm indication can

be evaluated and subsequent actions and indications for the user can be initiated.

Profibus DP Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 45 out of 60-

5.7 Detailed protocol description

5.7.1 Introduction

A protocol for SIMEAS P (power meter) via Profibus DP V1 will be defined in the

following. This protocol is used for different purposes. Among others, the protocol

supports the parameterization as required by the end user, the calibration, the

collection of measured values and the final testing of the device.

The individual layers required for providing the communication services according

to the ISO-OSI reference model will be explained.

Layer 1: according to Profibus

Layer 2: according to Profibus

Layer 3-7: not relevant

Layer +: DP profile: device functionality of SIMEAS P

7

6

5

4

3

2 (data link layer)

1 (physical layer)

+ SIMEAS P

DP Functionality

Layerwise subdivison of the communication services

Physical layer

The physical layer is designed according to Profibus DP (RS485).

Data link layer

The link layer is designed according to Profibus DP.

Profibus DP Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 46 out of 60-

5.7.2 Standard services

Standardized services for the application layer are described which are currently

limited to the file transfer as the sole service. The file transfer is defined in the two

directions of data transfer. From the master (controlling station) to the slave

(controlled station) and vice versa. The definition is in accordance with the

IEC 870-5-5 file transfer.

5.7.2.1 File transfer: From master to slave

Application function of

master

Application function of

slave

Communication

services

A_FILE_READY.Send

A_SECTION1_Segment1.Send

A_FILE_READY.Ind

Confirm (ACK/NACK)

A_SECTION1_Segment1.Ind

A_SECTION1_Segment1.Conf

Confirm (ACK/NACK)

A_SECTION1_Segment2.Send

A_SECTION1_Segment2.Ind

A_SECTIONn_Segment1.Send

A_SECTIONn_Segment1.Ind

A_SECTIONn_Segmentm.Send

A_SECTIONn_Segmentm.Ind

Confirm (ACK/NACK)

A_SECTIONn_Segmentm.Conf

A_EOF.Send

A_EOF.ind

Confirm (ACK/NACK)

A_EOF.Conf(ACK/NACK)

A_FILE_READY.Conf(ACK/ NACK)

Profibus DP Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 47 out of 60-

Description:

File transfer is used here to transmit data from the master to the slave. The master

subdivides the file into sections. Each section can be further divided into segments.

If no data is available for sending, the master does not send a

SectionN_SegmentM telegram and the A_EOF telegram follows directly after the

confirmation A_File_Ready.

Corrupted data:

If the master detects an error in the data received it responds by sending NACK.

The slave then repeats the telegram. If the slave does not send a response, the

master repeats the sending of the telegram after a certain period of time (timeout).

5.7.2.2 File transfer: From slave to master

Application function of

slave

Application function of

master

Communication

services

A_SELECT_FILE.Conf (ACK/

NACK)

A_File_READY.respond

Confirm (ACK/NACK)

A_Data.ind

A_Data.request (0)

A_File_READY.ind

A_Data.request (1)

A_Data.ind

A_SECTION1_SEGMENT1.resp

A_SECTION1_SEGMENT1.ind

A_SECTIONM_SEGMENTn.resp

A_SECTIONM_SEGMENTn.ind

A_Data.ind

A_DATA.request (n)

A_EOF.respond

A_EOF.ind

A_SELECT_FILE.ind

A_SELECT_FILE.Send

Profibus DP Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 48 out of 60-

Description:

This file transfer is used to receive data from the slave. The master subdivides the

file into sections. Each section can be further divided into segments. If the slave

has no data to send, no SectionN_SegmentM telegram is sent and the A_EOF

telegram follows immediately after the confirmation A_File_Ready. The data

request contains a counter number which is incremented by 1 for each

transmission step. The counting starts at 0. When the maximum value has been

achieved, the counter number is reset to 0.

Corrupted data:

If the slave detects an error in the telegrams received, it responds by sending

NACK. The master then repeats the telegram. If the slave does not send a

response, the master repeats the request after a certain period of time (timeout).

Timeouts are defined independently of each other for each telegram.

5.7.2.3 Mapping to Profibus-DP

The standard for Profibus DP does not provide a service that is directly comparable

to file transfer. The nature of file transfer is the bitwise transmission of larger data

volumes upon request. This contradicts the operating principle of Profibus to a

great deal. Originally, Profibus DP performed only cyclic data transmission of a

specified length; the expansions (DPV1), however, at least enable acyclic data

transmission upon request. These are, however, restricted to a permanently

assigned address space of 64kB. For this reason a file transfer is established by

means of the available services. However, it cannot be assumed that this file

transfer is supported by standards-compatible application software on the master

as a standard feature. File transfer under Profibus is thus only suitable for

application services with an optional structure (they can also be renounced) or

redundant (standards-compatible support is also available).

The file transfer on Profibus DP relies on acyclic data transmission (MSAC1 or

MSAC2 , API=0). Competence for this service is assumed by slot 0, index 240

whose assignment corresponds to the telegram structure in "Maintenance protocol

ASCII" (see Fehler! Verweisquelle konnte nicht gefunden werden.).

The communication procedures SEND/CONFIRM or REQUEST/RESPOND of the

ASCII protocol are mapped to the services DDLM_Rd_Outp/ DDLM_Rd_Inp of the

Profibus protocol. All requests to a slave are thus mapped by writing a data block

(0.240) and the responses from the device by reading a data record (0.240).

Profibus DP Manual for SIMEAS P Power Meter

Siemens AG 2000; All Rights Reserved Page 49 out of 60-

5.7.3 Device protocol SIMEAS P (layer +)

5.7.3.1 Continuous transmission of measured data

The cyclic transmission of measured data to the master is accomplished via the