Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Enterprise Model Driven Infrastructure

Caricato da

sistemcba0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

53 visualizzazioni13 pagineEnterprise-Model-Driven-Infrastructure

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoEnterprise-Model-Driven-Infrastructure

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

53 visualizzazioni13 pagineEnterprise Model Driven Infrastructure

Caricato da

sistemcbaEnterprise-Model-Driven-Infrastructure

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 13

Copyright 2009 Systems Integration Specialists Company, Inc.

All rights reserved

Creating an Enterprise Class Scalable Model Driven

Infrastructure

The use case for using IBM, OSIsoft, and SISCO

technologies

Version: 1.1 Date: May 28, 2009

Systems Integration Specialist Company, Inc.

6605 19 Mile Road

Sterling Heights, Michigan 48314

Creating an Enterprise Class Scalable Model Driven Infrastructure Page 2

Copyright 2009 Systems Integration Specialists Company, Inc. All rights reserved

Introduction

In order to understand Enterprise Model Driven Integration, it is important to first understand the

business use case for the integration. In order to discuss integration from a general perspective, this paper

will utilize the ISA 95 standard. This paper leaves it to the reader to correlate the ISA 95

information/business drivers for their purposes.

Figure 1: ISA 95 Functional Levels of Integration

1

Figure 1 depicts the four levels of integration/information exchange as defined by ISA 95. The figure

shows distinct integration/information exchange boundaries (e.g. between levels 3-4 and levels 2-3),

reality has shown that the boundaries are not as well defined and that functions are not necessarily as well

segmented as are shown.

An implementation view could show something similar to Figure 2.

ERP

MES

Process Coordination

B

u

s

i

n

e

s

s

P

r

o

c

e

s

s

C

h

o

r

e

o

g

r

a

p

h

y

Process

Information

Exchange

User Interaction

1

Courtesy of Keith Unger, Stone Technologies.

Creating an Enterprise Class Scalable Model Driven Infrastructure Page 3

Copyright 2009 Systems Integration Specialists Company, Inc. All rights reserved

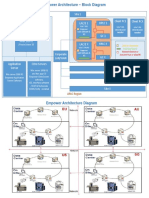

Figure 2: Possible Implementation Architecture

Each implementation layer, shown in Figure 2, could have its own set of tooling and user interfaces.

Additionally, a single layer might make use of different equipment from one or more vendors. The

choice for particular equipment is driven by business requirements. The selected vendors would typically

provide tooling and user interfaces for their equipment to maximize the user experience with the

equipment. In so doing, expertise and advocacy for particular tooling is developed within the business

organization which has the end effect of creating silos of expertise.

Consider the programming of two (2) different PLCs. Both PLCs monitor the production level of

particular business work centers. One PLC has been programmed to provide the information in register

4001. The other exposes production level in register I:177/17. The users that programs each PLC has the

documentation that details which register represents the production level of the cell. However, it would

be difficult for a non-PLC expert to know which register, or the different notations/tooling, to acquire the

production levels of each cell. Similar examples of data naming issues can typically be found between

different product offerings, even potentially from the same vendor.

Low Level Automation

Controllers and I/O

Distributed

Control Systems

Register

Address

Space

Historians

Tag Name

Address

Space

Figure 3: Normal Implementation Architecture to create contextual Tags

Use of Tags

In order to provide some context for the automation information, this information is typically placed/used

by higher level systems that provide the capability to alias automation information into human

recognizable names (e.g. Tags). Figure 3 depicts typical integration/process integration where the low

level automation information is exposed through either Distributed Control Systems (DCSs) or through

historians. There are multiple DCS and historian vendors that could be utilized within each integration

level in a corporate enterprise environment. Each vendor, as with the automation integration level, has

special constraints on Tag naming. Therefore, the general user/application is still required to understand

the special constraints of the system that needs to be accessed for a particular application/display.

Creating an Enterprise Class Scalable Model Driven Infrastructure Page 4

Copyright 2009 Systems Integration Specialists Company, Inc. All rights reserved

However, the single vendor selection strategy is not sufficient. Additionally, a corporate policy for Tag

naming needs to be developed and enforced. However, history has shown that even where there are

strong corporate policies, Tag name consistency does not occur in an enterprise due to several different

reasons:

Configuration errors: In order to comply with corporate naming policies, people must configure the

Tag names that correlate to particular automation information. This is typically a manual process and

is prone to errors (e.g. ProductionLevel and ProductionLvel).

Detection of such errors requires a large amount of naming/data validation.

Constraints on the Tag namespace: Most Tag namespaces do not allow for duplication of Tag names.

Therefore, if the higher level integration levels need to expose more than one ProductionLevel Tag,

the names are inherently forced to be unique.

This issue can be solved by adding an extension to the Tag name in order to provide uniqueness.

Most typical corporate policies dictate that the name of the system, work center, etc. be pre-pended to

the tag name.

As an example, the ProductionLevel for SeparatorTrain1 and SeparatorTrain2 needs to be provided.

The corporate mandated naming convention might specify the Tag names to be

SeparatorTrain1_ProductionLevel and SeparatorTrain2_ProductionLevel.

Most corporate naming conventions must take into account the business hierarchy. This policy could

extend the length of the Tag name to include:

<oil field name>_<platform name>_<production unit name>_<measurement name>

Names of entities change: One thing that has been proven is that over time names of

platforms/production units may be changed. The end effect, of such changes, is that as

platforms/production units names are changed, maintenance of the Tag names, and the applications

that utilize them, may become an issue.

Hierarchical Tag naming creates issues for other business views: The process business view is the

typical standard used to name Tags. However, there are other business related views (e.g.

AssetUtilization, Condition Based Maintenance, others) that would be better facilitated by the use

of another naming hierarchy/view of the information. In general, this is an issue with technologies

that only support hierarchical data organization.

Mergers and acquisitions: Experience has shown that most corporate Tag naming policies do not

provide naming conventions that include naming associated with the corporation or underlying

business units. The lack of this information in the name can create integration issues when

corporations merge.

Use of Models

In 1999, the Electric Power Research institute had an initiative to develop a standardized model and a set

of model access services. The intent of the initiative was to address the previously mentioned issues in

Creating an Enterprise Class Scalable Model Driven Infrastructure Page 5

Copyright 2009 Systems Integration Specialists Company, Inc. All rights reserved

addition to many others. SISCO has been involved in developing integration products and solutions

utilizing semantic models and Model Driven strategies.

Semantic Models

A semantic model is typically considered as:

a basic set of ontology elements classes, relations, functions, instances, intended to serve as

the conceptual defining vocabulary that will permit specification of the meanings of any

domain term or concept. It serves a function analogous to the controlled defining vocabularies

used in some traditional dictionaries to define words.

2

As an example, ISA 95 and ISA 88, define a semantic model that can be utilized in discrete and batch

oriented process

3

that go well beyond defining a hierarchy of measurement/process data access.

Identified by

ISA-88

Must Contain 1 or More

May Contain 1 or more

Area

Site

Enterprise

May Contain 1 or more

Must Contain

1 or More

May Contain

May Contain

Batch

Operations

Process

Cell

Unit

May

Contain

May

Contain

Equipment

Module

Control

Module

Specified by

ISA-88

Must Contain

1 or More

Must Contain

1 or More

Discrete

Operations

Inventory

Operations

Continuous

Operations

Work Cell

Production

Unit

Storage

Zone

Unit

Must Contain

1 or More

Storage

Unit

Area

Site

Enterprise

Specified by

ISA-95

Manufacturing

Line

Figure 4: Simplified representation of ISA 95 and ISA 88 Physical Model

4

Each block, shown is Figure 4, represents object definitions (e.g. expressible as UML classes) that

contain specific attribute definitions and types for the specified attribute. Although, Figure 4 appears to

be able to be expressed as a hierarchy, the diagram represents only one potential view of the process

oriented business functions.

A more accurate representation of the interactions/views required is shown in Figure 5.

2

Mitre Corporation

3

There are other well recognized semantic models such as MIMOSA, CIM, ISO 15926, IEC 61850, etc..

4

Courtesy of Keith Unger, Stone Technologies.

Creating an Enterprise Class Scalable Model Driven Infrastructure Page 6

Copyright 2009 Systems Integration Specialists Company, Inc. All rights reserved

Receiving Batch / Continuous and Discrete Work Centers Shipping

J. Keith Unger

Equipment Specific

Definitions Commands Responses

Equipment

Specific Data

Definition

Management

P

r

o

d

u

c

t

i

o

n

M

a

i

n

t

e

n

a

n

c

e

Q

u

a

l

i

t

y

I

n

v

e

n

t

o

r

y

Execution

Management

P

r

o

d

u

c

t

i

o

n

M

a

i

n

t

e

n

a

n

c

e

Q

u

a

l

i

t

y

I

n

v

e

n

t

o

r

y

Data

Collection

P

r

o

d

u

c

t

i

o

n

M

a

i

n

t

e

n

a

n

c

e

Q

u

a

l

i

t

y

I

n

v

e

n

t

o

r

y

Dispatching

P

r

o

d

u

c

t

i

o

n

M

a

i

n

t

e

n

a

n

c

e

Q

u

a

l

i

t

y

I

n

v

e

n

t

o

r

y

Resource

Management

P

r

o

d

u

c

t

i

o

n

M

a

i

n

t

e

n

a

n

c

e

Q

u

a

l

i

t

y

I

n

v

e

n

t

o

r

y

Detailed

Scheduling

P

r

o

d

u

c

t

i

o

n

M

a

i

n

t

e

n

a

n

c

e

Q

u

a

l

i

t

y

I

n

v

e

n

t

o

r

y

Analysis

P

r

o

d

u

c

t

i

o

n

M

a

i

n

t

e

n

a

n

c

e

Q

u

a

l

i

t

y

I

n

v

e

n

t

o

r

y

Tracking

P

r

o

d

u

c

t

i

o

n

M

a

i

n

t

e

n

a

n

c

e

Q

u

a

l

i

t

y

I

n

v

e

n

t

o

r

y

Operations

Capability

ISA

95

Operations

Definitions

Operations

Request

Operations

Response

ISA

95

ISA

95

ISA

95

How

Product Lifecycle Resource Planning

What

Schedule / Plan

When Delivery

Fulfillment

Enterprise Planning and Logistics Information

Figure 5: ISA 95 Manufacturing Activities

5

The figure 5 shows not only the manufacturing interactions, but the views of information/context that

need to be supported. In order to create the multiple views (e.g. Quality, Inventory, Production, and

Maintenance), mesh oriented model repositories/namespaces need to be utilized instead of hierarchical

namespaces.

In order to address the Tag oriented integration issues, enforcement of the class/attribute definitions is

required. Additionally, the possible relationships between instances needs to be appropriately specified

(e.g. UML associations). It is through the specification of the relationships that multiple business views

of the information can be created.

Implementations of Data Warehouses/Model Repositories that expose such instance relationships would

be considered Model Aware.

Model Driven

Although there are several technologies that can be utilized to create Model Aware repositories, there is a

difference between repositories that are Model Aware and enterprise integration strategies that are Model

Driven. Model Driven integration strategies need to encompass the functionality of being Model Aware

and the additional functionality of:

Support for a work flow that allows for the maintenance of the model within the model repository(s).

The work flow should be able to be integrated into choreographed business processes.

This is required so that model updates can be validated and model changes do not occur at an in-

opportune time. Although, this workflow can be achieved manually, it is recognized that electronic

5

Courtesy of Keith Unger, Stone Technologies.

Creating an Enterprise Class Scalable Model Driven Infrastructure Page 7

Copyright 2009 Systems Integration Specialists Company, Inc. All rights reserved

coordination, which integrates with other business process, offers higher business value.

This includes the dynamic modification of the model due to process changes and business

transactions (e.g. new Work Orders, Batch commands, etc..).

Since 1999, SISCO has developed products that implement those strategies. Over time, SISCO has

evolved its integration strategy to be applicable to other industries besides the electrical utility industry.

The resulting product family name is the SISCO Utility Integration Bus (UIB).

The initial UIB product provided a Model Driven integration infrastructure that utilized a model

repository to create Model Aware/Driven adapters that exchanged information over middleware. SISCO

offers a select set of adapters for the infrastructure:

OPC Client Adapters: Allows applications, which are OPC clients, to access information, in the

context of the model, without requiring the creation of a Data Warehouse or knowledge of the

authoritative source of the information.

OPC Server Adapters: Allows applications, which are OPC Servers, to have their information mapped

into the model and be exposed to the infrastructure as an authoritative source.

Adapter for OSIsoft PI: Allows the enterprise model to be imported/maintained within the PI Module

DataBase or PI AF

6

. This adapter allows for PI client applications (e.g. ProcessBook, RtWebParts,

and DataLink) to be used in a Model Driven fashion.

One of the desires, for the infrastructure, was to have the capability of electronic business choreography.

This ability is now provided within the IBM Integration and Information Framework (IIF) solution.

Additionally, IIF natively allows for electronic business transactions (e.g. EDI, S95, etc...) to be translated

and responded to in terms of the model.

Through the appropriate selection of the appropriate products, and architecture, users can create flexible

integration deployments.

Architecture

Due to the flexibility of the various product offerings, users will need to select the appropriate set of

products based upon corporate commitments to specific technologies, client application environment, and

desired business functions.

From a functional perspective, the suite of available products needs to be functionally classified. For this

purpose, it is desirable to use the following diagram:

6

OSIsoft has a stated strategy of transitioning away from the MDB to AF. SISCO is following that

strategy and is not currently updating the capabilities of the MDB version of the PI Adapter.

Creating an Enterprise Class Scalable Model Driven Infrastructure Page 8

Copyright 2009 Systems Integration Specialists Company, Inc. All rights reserved

Figure 6: Simplified Enterprise Integration Functions

Creating an Enterprise Class Scalable Model Driven Infrastructure Page 9

Copyright 2009 Systems Integration Specialists Company, Inc. All rights reserved

There are several different functional layers depicted in Figure 6:

Data Layer: Actually obtains information from the real-time process automation equipment/sensors.

Information Layer: Applies the semantics of the model to change data into contextual information.

One of this layers capabilities is to access automation/process information via SOA.

Business Process Layer: Allows configuration and implementation of workflow coordination on an

Enterprise level. It also provides a transactional capability (e.g. create a new purchase order, execute

a general batch, etc) from other SOA system.

It is typical for each layer to have one or more visualization components that are used to expose the

information from the layer. Therefore, the strategy does not mandate a single visualization components

use and must be flexible to accommodate multiple tools. However, it is desirable to be able to combine a

subset of the visualization tools, at least one from the Information and Business layer, into a single

method of access to the tools. This would typically be accomplished through exposing the visual

information through a single web portal technology (e.g. Websphere, SAP, or Microsoft) at the

discretion/selection of the customer.

Figure 7: Components of the combined SISCO, IBM, and OSIsoft infrastructure

Figure 7 shows the components/products that are used to create a model-driven infrastructure through

combining the IBMs Information Integration Framework (IIF) solution with SISCO and OSIsoft

products.

Creating an Enterprise Class Scalable Model Driven Infrastructure Page 10

Copyright 2009 Systems Integration Specialists Company, Inc. All rights reserved

Model

Driven

Infrastructure

Figure 8: Functional use of infrastructure components

IIF is an IBM software solution that is being leveraged for solutions in the domains of: Chemical and

Petroleum; Energy and Utilities; and other business application domains. The solution is based upon

IBM products which, in the past, have provided:

Complex Business Process Orchestration and Mediation: This functionality is provided by the IBMs

Webshpere Business Process Server. This product allows the definition of complex business process

interactions and workflow through the use of graphical configuration and Business Process Execution

Language (BPEL) technology.

Mediation and transformation of SOA messages: This functionality is provided within the Websphere

Application Server (WAS) product.

Middleware message transport and security: Provided through the Websphere Enterprise Service

Bus.

IIF adds model awareness to the components through a set of standards based Model related services.

These services allow:

Real-time information to be consumed by the applications so that the business workflow can adapt

based upon the current state of the actual processes within the enterprise.

As an example, consider the reception of an SOA transaction that is used to dispatch a production

batch to a specific production unit. However, that production unit is offline or has not completed its

current batch. The real-time information of the status of the production unit (e.g. that it is not

available) allows, through BPEL, to re-dispatch the batch to an alternate production unit(s) that are

available and are capable of producing the batch.

Creating an Enterprise Class Scalable Model Driven Infrastructure Page 11

Copyright 2009 Systems Integration Specialists Company, Inc. All rights reserved

The applications to query the virtualized model so that relationships/capabilities of equipment,

production units, measurements, etc. can be determined.

The previous batch example implies that the re-dispatching is based upon the knowledge of which

other production units are capable of producing a specific type of batch. The ability to query the

model for this information allows BPEL to dynamically determine which units meet the criteria as

opposed to being programmed (e.g. a priori) with the information.

This allows the designers of the production cells/units to change the model, and thereby allow

adaption in the workflow coordination, without requiring changes to the BPEL. It is the ability to

change the model and impact the coordination that is at the root of enabling the entire orchestration to

be Model Driven.

Historical information to be consumed by the applications in order to determine/adapt business

processes based upon past performance.

Applications to be coordinated and production and business process related metrics/events to be

produced or consumed as part of the overall coordination process.

As part of facilitating the application functionality, IIF also includes SISCO Utility Integration Bus (UIB)

components.

The SISCO UIB PI Adapter is used to populate and manage (e.g. update) OSIsofts AF repository with a

subset of the overall virtual enterprise model. The PI Adapter also allows the historical and real-time

information within the OSIsoft Server(s) to be exposed in the context of the enterprise model to the ESB.

The product also allows the IIF business oriented applications to store the business process generated

metrics/events to be stored within the OSIsoft environment.

Figure 7 shows the most typical OSIsoft products that would be utilized in the architecture. These

products provide the capability of:

Generation of process/production related Key Performance Indicators as well as a mechanism to

generate events that can be consumed as part of the business choreography within the IIF solution and

other components in the architecture.

Publication of process information to the infrastructure (e.g. through the SISCO PI Adapter) in real-

time.

Provides a repository for historical production process and business process information.

Provides a repository for a subset of the enterprise model so that OSIsoft tooling can be used to

visualize/report the information within the context of the enterprise model.

Creating an Enterprise Class Scalable Model Driven Infrastructure Page 12

Copyright 2009 Systems Integration Specialists Company, Inc. All rights reserved

Summary

Through the deployment of world-class products from IBM, OSIsoft, and SISCO; a robust Model Driven

infrastructure can be created that addresses the functional requirements of Enterprise integration.

Figure 9: Infrastructure components vs. enterprise integration layers

The solution also allows business process, production and Manufacturing Execution System (MES), and

process level coordination to occur.

Figure 10: Infrastructure components vs. scope of applicability and ISA levels

Creating an Enterprise Class Scalable Model Driven Infrastructure Page 13

Copyright 2009 Systems Integration Specialists Company, Inc. All rights reserved

For more details, please contact Systems Integration Specialists Company.

Acknowledgements

SISCO gratefully acknowledges the contributions of Troy Carbaugh, Lorenzo Childress, Herbert Falk,

and Ron Montgomery for their input and assistance in the creation of this paper.

Potrebbero piacerti anche

- Manufacturing Execution System A Complete Guide - 2020 EditionDa EverandManufacturing Execution System A Complete Guide - 2020 EditionNessuna valutazione finora

- B2MML V0401 EquipmentDocumento12 pagineB2MML V0401 EquipmentEsther Claravalls LópezNessuna valutazione finora

- LIMS For Lasers 2015 User ManualDocumento188 pagineLIMS For Lasers 2015 User Manualcharles_0814Nessuna valutazione finora

- ISPE Paper On Glass - Robert HarrisonDocumento5 pagineISPE Paper On Glass - Robert HarrisonrobertharrisonNessuna valutazione finora

- Blue M Manuel Operacion DC Ovens 146 Series 6-08-07Documento48 pagineBlue M Manuel Operacion DC Ovens 146 Series 6-08-07Ozzwald Estrada0% (1)

- B2 MMLDocumento10 pagineB2 MMLvpascarielloNessuna valutazione finora

- Applying GAMP 5 To Validate An ERP System: by Stephen R. FerrellDocumento7 pagineApplying GAMP 5 To Validate An ERP System: by Stephen R. FerrellRahmat DennyNessuna valutazione finora

- Manufacturing Execution System (MES) : ServiceDocumento48 pagineManufacturing Execution System (MES) : ServiceNhat Tan MaiNessuna valutazione finora

- Proces wp001 - en P PDFDocumento16 pagineProces wp001 - en P PDFReinaldo GomezNessuna valutazione finora

- Lecture 11 - QAQCDocumento36 pagineLecture 11 - QAQCTMTNessuna valutazione finora

- Guide Mqa 005 008Documento7 pagineGuide Mqa 005 008B112m4Nessuna valutazione finora

- Guidelines For Defining User Requirement SpecificaDocumento15 pagineGuidelines For Defining User Requirement SpecificaNguyễn Đình Phú100% (1)

- Eli Lilly Biotech Pilot Plant, Indianapolis, United States of AmericaDocumento5 pagineEli Lilly Biotech Pilot Plant, Indianapolis, United States of AmericaShyam Sunder BudhwarNessuna valutazione finora

- ISA-106: Using Procedural Automation To Improve Operational EfficiencyDocumento35 pagineISA-106: Using Procedural Automation To Improve Operational EfficiencyGlauco SantiagoNessuna valutazione finora

- Rockwell Software Product CatalogDocumento36 pagineRockwell Software Product CatalogAdhemar RodoNessuna valutazione finora

- WBF Implementing B2MMLDocumento9 pagineWBF Implementing B2MMLvpascarielloNessuna valutazione finora

- B2MML V0401 MaintenanceDocumento11 pagineB2MML V0401 MaintenanceEsther Claravalls LópezNessuna valutazione finora

- T061 Isa95-04Documento32 pagineT061 Isa95-04Haogoaro ZrNessuna valutazione finora

- Ignition GatewayDocumento101 pagineIgnition Gatewayvijikesh ArunagiriNessuna valutazione finora

- Empower ArchitectureDocumento2 pagineEmpower ArchitecturePinaki ChakrabortyNessuna valutazione finora

- LABWORKS 6.9 Admin GuideDocumento534 pagineLABWORKS 6.9 Admin GuideBilla SathishNessuna valutazione finora

- Oracle ShopFloor Operator FunctionsDocumento21 pagineOracle ShopFloor Operator Functionssuraj lNessuna valutazione finora

- Automated Packaging Systems Autolabel Pi-4000 In-Line, Programmable, Thermal Transfer PrinterDocumento2 pagineAutomated Packaging Systems Autolabel Pi-4000 In-Line, Programmable, Thermal Transfer PrinterEdgar HoowerNessuna valutazione finora

- B2MML V0401 ConfirmBODDocumento6 pagineB2MML V0401 ConfirmBODramani.rajesh9737Nessuna valutazione finora

- Programmable Controllers: Sheet 1 of 14 AREA: Grundartangi Reduction Plant SPEC No: 00/07/TS009 REV:C3Documento13 pagineProgrammable Controllers: Sheet 1 of 14 AREA: Grundartangi Reduction Plant SPEC No: 00/07/TS009 REV:C3Eyu Allaga Abanto-Busayong VegafriaNessuna valutazione finora

- Paperless Manufacturing Solutions With Mes Pas-X and Osisoft'S Pi System For Bio ManufacturingDocumento18 paginePaperless Manufacturing Solutions With Mes Pas-X and Osisoft'S Pi System For Bio ManufacturingSimrat DosanjhNessuna valutazione finora

- Ref Batch ManagementDocumento280 pagineRef Batch Managementjustine_fabian2Nessuna valutazione finora

- Module 1 Lesson 2 and 3 Systems Development Methods Tools and TechniquesDocumento15 pagineModule 1 Lesson 2 and 3 Systems Development Methods Tools and Techniquesjunex tanNessuna valutazione finora

- Isa S95-222Documento32 pagineIsa S95-222optisearchNessuna valutazione finora

- Concept Note - PMISDocumento7 pagineConcept Note - PMISAjitabh SinghNessuna valutazione finora

- MES For OPMDocumento148 pagineMES For OPMtenalisNessuna valutazione finora

- PLC Controlled Motion For Siemens - Position AMCDocumento182 paginePLC Controlled Motion For Siemens - Position AMCKASSIMNessuna valutazione finora

- Ignition Community Live MQTT Workshop: Cirrus LinkDocumento10 pagineIgnition Community Live MQTT Workshop: Cirrus LinkDaniel FernandezNessuna valutazione finora

- Starlims EvalDocumento1 paginaStarlims Evaljamvad13413Nessuna valutazione finora

- Automation Solution BookDocumento296 pagineAutomation Solution Bookpetrenee100% (1)

- Batch Failure InvestigationsDocumento31 pagineBatch Failure Investigationsnsk79in@gmail.comNessuna valutazione finora

- Apriso WhitePaper How Next Gen MOM Can DriveDocumento10 pagineApriso WhitePaper How Next Gen MOM Can DriveHarish AdityaNessuna valutazione finora

- Implementing ISA S88 For A Discrete Process With The Bottom-Up ApproachDocumento10 pagineImplementing ISA S88 For A Discrete Process With The Bottom-Up ApproachPaulo Ricardo Siqueira SoaresNessuna valutazione finora

- Pr06 - Factorytalk Innovationsuite For Process Control in Plantpax 5.0Documento26 paginePr06 - Factorytalk Innovationsuite For Process Control in Plantpax 5.0mika cabello100% (1)

- OPC UA Security Advise EN PDFDocumento24 pagineOPC UA Security Advise EN PDFDaniel Sánchez De MarcosNessuna valutazione finora

- ART - 0608 - Improving Ops With EBRDocumento4 pagineART - 0608 - Improving Ops With EBRkumar_chemicalNessuna valutazione finora

- U R T For A Supervisory Control and Data Acquisition (SCADA) Process Control SystemDocumento66 pagineU R T For A Supervisory Control and Data Acquisition (SCADA) Process Control SystemSurangaGNessuna valutazione finora

- Manufacturing Execution Systems (MES) : Overview and Case StudyDocumento21 pagineManufacturing Execution Systems (MES) : Overview and Case Studydamodara9bille100% (2)

- Plant Engineering - Magazine - Jan 2018, Feb 2018 PDFDocumento69 paginePlant Engineering - Magazine - Jan 2018, Feb 2018 PDFVarun KumarNessuna valutazione finora

- FDA Part11 Regulated Industries BR enDocumento40 pagineFDA Part11 Regulated Industries BR enRuchirNessuna valutazione finora

- Petronas OSI Soft PI A Case StudyDocumento2 paginePetronas OSI Soft PI A Case StudyAnas Abd Rahman100% (2)

- Lab Notebook Presentation - 8-12-2016Documento44 pagineLab Notebook Presentation - 8-12-2016Muhammad ALi SoomroNessuna valutazione finora

- 02 - Slide 3. Overview of RAMI 4.0 - r7Documento20 pagine02 - Slide 3. Overview of RAMI 4.0 - r7JoaquinNessuna valutazione finora

- Practical Enterprise Modelling: ISA 88 and ISA 95 StandardsDocumento59 paginePractical Enterprise Modelling: ISA 88 and ISA 95 StandardsAngie GordiansNessuna valutazione finora

- Knowledge Management in Manufacturing SectorDocumento22 pagineKnowledge Management in Manufacturing SectorVaishnavi PreranaNessuna valutazione finora

- 19 - User Roles and Privileges in LC-MS (Labsolutions)Documento11 pagine19 - User Roles and Privileges in LC-MS (Labsolutions)Dayanidhi dayaNessuna valutazione finora

- Towards An Integration of The Lean Enterprise System To, Total Quality Management, Six Sigma and Related Enterprise Process Improvement MethodsDocumento25 pagineTowards An Integration of The Lean Enterprise System To, Total Quality Management, Six Sigma and Related Enterprise Process Improvement MethodscybermagikNessuna valutazione finora

- Wayahead System ValidationDocumento41 pagineWayahead System Validationpate malabananNessuna valutazione finora

- B2MML BatchML V0401 Release NotesDocumento4 pagineB2MML BatchML V0401 Release Notesclpatricia1Nessuna valutazione finora

- Key Performan Indicators SoftwareIndustry1.2Documento8 pagineKey Performan Indicators SoftwareIndustry1.2Aaron_GeaNessuna valutazione finora

- MRP ErpDocumento32 pagineMRP ErpburhanNessuna valutazione finora

- Historian ConceptsDocumento29 pagineHistorian ConceptsDuqueCKNessuna valutazione finora

- Process Control and Industrial Automation Complete Self-Assessment GuideDa EverandProcess Control and Industrial Automation Complete Self-Assessment GuideNessuna valutazione finora

- 998 Psguard828 DatasheetDocumento2 pagine998 Psguard828 DatasheetsistemcbaNessuna valutazione finora

- Austin Energy - ADMS ImplementationDocumento21 pagineAustin Energy - ADMS Implementationsistemcba100% (1)

- AMRA Automation 05 Neumann Integration of Metering SystemsDocumento15 pagineAMRA Automation 05 Neumann Integration of Metering SystemssistemcbaNessuna valutazione finora

- Rome Architecture Best PracticesDocumento44 pagineRome Architecture Best PracticessistemcbaNessuna valutazione finora

- Model Driven IntegrationDocumento38 pagineModel Driven IntegrationsistemcbaNessuna valutazione finora

- Model-Driven Asset Management For Condition-Based MaintenanceDocumento3 pagineModel-Driven Asset Management For Condition-Based MaintenancegillermanNessuna valutazione finora

- 00scheduler PDFDocumento32 pagine00scheduler PDFsistemcbaNessuna valutazione finora

- Openesb XSLTDocumento12 pagineOpenesb XSLTsistemcbaNessuna valutazione finora

- SISCO Vision Interfaces Models ProtocolsDocumento48 pagineSISCO Vision Interfaces Models ProtocolssistemcbaNessuna valutazione finora

- Ips-Systems Overview Flyer 2010 EngDocumento2 pagineIps-Systems Overview Flyer 2010 EngsistemcbaNessuna valutazione finora

- 5 - IPS-ENERGY™ Enterprise - With and Without Foreign ERPDocumento10 pagine5 - IPS-ENERGY™ Enterprise - With and Without Foreign ERPsistemcbaNessuna valutazione finora

- Asset CategorizationDocumento292 pagineAsset CategorizationsistemcbaNessuna valutazione finora

- OpenESBv2 Project FujiDocumento31 pagineOpenESBv2 Project FujisistemcbaNessuna valutazione finora

- Model-Driven Asset Management For Condition-Based MaintenanceDocumento3 pagineModel-Driven Asset Management For Condition-Based MaintenancegillermanNessuna valutazione finora

- EPQU'07 - Paper 61000-4-30Documento4 pagineEPQU'07 - Paper 61000-4-30fsn88Nessuna valutazione finora

- 01File2File PDFDocumento31 pagine01File2File PDFsistemcbaNessuna valutazione finora

- 01 FacilityService GFESBv21 PDFDocumento57 pagine01 FacilityService GFESBv21 PDFsistemcbaNessuna valutazione finora

- My InventionsDocumento34 pagineMy InventionsJohn BatesNessuna valutazione finora

- Digital Substation AlstomDocumento36 pagineDigital Substation Alstomdipteshypatel100% (1)

- Iccp GuideDocumento57 pagineIccp GuidesistemcbaNessuna valutazione finora

- IEC 61850 Testing Tools ENUDocumento4 pagineIEC 61850 Testing Tools ENUconst_nos100% (1)

- Asset ManagementDocumento13 pagineAsset ManagementsistemcbaNessuna valutazione finora

- Soabpmvirtualboxreadme 1612068Documento50 pagineSoabpmvirtualboxreadme 1612068Sat AppsNessuna valutazione finora

- ICCP802Documento74 pagineICCP802sistemcbaNessuna valutazione finora

- AnunciatorDocumento60 pagineAnunciatorsistemcbaNessuna valutazione finora

- CIM For GenerationDocumento20 pagineCIM For GenerationsistemcbaNessuna valutazione finora

- SCADADocumento21 pagineSCADAsistemcbaNessuna valutazione finora

- WP Emeter SGR FrameworkDocumento12 pagineWP Emeter SGR FrameworksistemcbaNessuna valutazione finora

- SCADADocumento8 pagineSCADAsistemcbaNessuna valutazione finora

- DSP CepDocumento12 pagineDSP CepSameer KhanNessuna valutazione finora

- Method 2022Documento17 pagineMethod 2022we need youNessuna valutazione finora

- Grading Matrix - Tech-Development DeptDocumento1 paginaGrading Matrix - Tech-Development DeptJosep Lluís Marrugat ViñaNessuna valutazione finora

- Artificial Intelligence in Day To Day LifeDocumento11 pagineArtificial Intelligence in Day To Day LifeSagar chaudhariNessuna valutazione finora

- Abreu Et Al (2018) - An Empirical Workflow To Integrate Uncertainty and Sensitivity Analysis To Evaluate Agent-Based Simulation OutputsDocumento51 pagineAbreu Et Al (2018) - An Empirical Workflow To Integrate Uncertainty and Sensitivity Analysis To Evaluate Agent-Based Simulation OutputsSuryoKusumoNessuna valutazione finora

- Hands-On Scenario: Installation StepsDocumento2 pagineHands-On Scenario: Installation StepsAathithya Mahendranath33% (6)

- Networking Integration ChallengeDocumento3 pagineNetworking Integration ChallengeRica Pulongbarit0% (1)

- FEM-9 221 EnglischDocumento9 pagineFEM-9 221 EnglischxgclNessuna valutazione finora

- Road RunnerDocumento1 paginaRoad RunnercampbelljohntaylorNessuna valutazione finora

- Logic Inside AION 500 MK2 Proposal - 2023Documento19 pagineLogic Inside AION 500 MK2 Proposal - 2023logicinsideNessuna valutazione finora

- Rohrverguetung EN 1Documento20 pagineRohrverguetung EN 1Mohamad ZandiNessuna valutazione finora

- Propiñan de Melyor: Javier Martos CarreteroDocumento4 paginePropiñan de Melyor: Javier Martos CarreteroAlejandro ParinoNessuna valutazione finora

- Fixed Versus Floating PointDocumento5 pagineFixed Versus Floating PointAnil AgarwalNessuna valutazione finora

- Olympus Omniscan MX Specifications Spec Sheet 2k19Documento14 pagineOlympus Omniscan MX Specifications Spec Sheet 2k19Aldika KurniawanNessuna valutazione finora

- Chapter 5 Heba Sami-1Documento41 pagineChapter 5 Heba Sami-1Heba SamiNessuna valutazione finora

- Megersa OljiraDocumento106 pagineMegersa Oljiramegersa oljira100% (3)

- Wolf X Ray BrochureDocumento56 pagineWolf X Ray BrochureItzelNessuna valutazione finora

- 2023-06-26Documento21 pagine2023-06-26Cindy GaillatNessuna valutazione finora

- ETECH Module 5 Weeks 6 7Documento20 pagineETECH Module 5 Weeks 6 7Hersley PhynomeNessuna valutazione finora

- Whiplash-Drumset Sheet Music For Drum Group (Solo) Download and Print in PDF or MIDI Free Sheet Music For Whiplash by Hank LevDocumento1 paginaWhiplash-Drumset Sheet Music For Drum Group (Solo) Download and Print in PDF or MIDI Free Sheet Music For Whiplash by Hank LevJimtim LeeNessuna valutazione finora

- SSN Project Report PDFDocumento27 pagineSSN Project Report PDFErlanggaAdinegoroNessuna valutazione finora

- Technical - Havells SylvaniaDocumento27 pagineTechnical - Havells SylvaniaUmeshNessuna valutazione finora

- Bodyflow - P2Ch/-P1Ch: Service ManualDocumento24 pagineBodyflow - P2Ch/-P1Ch: Service ManualLevent yanmazNessuna valutazione finora

- Visual Impaired StudentsDocumento13 pagineVisual Impaired Studentskrezyl Mae LagayadaNessuna valutazione finora

- Oj L 2017 187 Full en TXTDocumento116 pagineOj L 2017 187 Full en TXTDevi PurnamasariNessuna valutazione finora

- Comparation Between 7000pro and Honeywell 6603Documento3 pagineComparation Between 7000pro and Honeywell 6603dediNessuna valutazione finora

- CIS 207 Unit 2 Case Project QuestionsDocumento1 paginaCIS 207 Unit 2 Case Project QuestionsJohnNessuna valutazione finora

- M4K-CF AGV 11mar22Documento2 pagineM4K-CF AGV 11mar22Wallie BillingsleyNessuna valutazione finora

- Be - First Year Fe Engineering - Semester 1 - 2019 - November - Engineering Mathematics I Pattern 2019Documento5 pagineBe - First Year Fe Engineering - Semester 1 - 2019 - November - Engineering Mathematics I Pattern 2019BdhdhshNessuna valutazione finora

- Code FotoDocumento3 pagineCode FotoEsteffany BennHuamNessuna valutazione finora