Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PLC Program Development Guide

Caricato da

Radwa EL-Mahdy0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

148 visualizzazioni19 pagineThis document contains coding style guidelines for PLC programming, to improve readability, maintainability and

the consistency of PLC programs. It describes simple rules which allow to get meaninful quality indicators from

the first day of development.

Titolo originale

Plc Program Development Guide

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document contains coding style guidelines for PLC programming, to improve readability, maintainability and

the consistency of PLC programs. It describes simple rules which allow to get meaninful quality indicators from

the first day of development.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

148 visualizzazioni19 paginePLC Program Development Guide

Caricato da

Radwa EL-MahdyThis document contains coding style guidelines for PLC programming, to improve readability, maintainability and

the consistency of PLC programs. It describes simple rules which allow to get meaninful quality indicators from

the first day of development.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 19

PLC programs development guidelines

Itris Automation Square

January 20th 2012 - Version 1.6.7

http://www.automationsquare.com

PLC programs development guidelines

2/19 January 20th 2012 - Version 1.6.7

Contents

1 Document purpose 5

2 Document structure 6

2.1 Rules classication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Presentation of each rule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Coding Rules 7

3.1 Naming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1.1 PLCs common Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2.1 PLCs common Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Writing code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3.1 PLCs common Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3.2 Unity Pro specic rules (Schneider Electric). . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.4.1 PLCs common Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.5 Useful Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.5.1 Useful information for all PLCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.6 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.6.1 Unity Project Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 Annexes 17

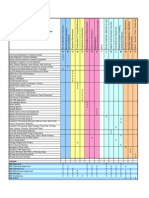

4.1 Summary of Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Document history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3/19

PLC programs development guidelines

4/19 January 20th 2012 - Version 1.6.7

Chapter 1

Document purpose

This document contains coding style guidelines for PLC programming, to improve readability, maintainability and

the consistency of PLC programs. It describes simple rules which allow to get meaninful quality indicators from

the rst day of development.

All rules in this document are checked automatically with PLC Checker, which supports PL7 PRO and Unity

Pro from Schneider Electric, STEP7 from Siemens and Rockwell Automation RSLogix 5000 PLCs.

This document was written by IAS seasoned consultants, based on analysis results of many codes used by

Itris Automation Squares customers in several industries and using various ranges of PLCs. It also reects some

best practices from other computer engineering domains such as embedded systems, which have been applying

standard sets of programming guidelines for years.

5/19

Chapter 2

Document structure

2.1 Rules classication

The rules described in this document are classied into several categories: Naming, Comments, Writing and Struc-

ture. The last part of this document also provides useful information which are not only about coding rules, but also

allow improvements of the programs quality. The last part is about the rules on the options of the PLC workbench.

Each category is divided into two parts:

1) The rules that may be applied independently of the PLC for which the program is developed.

2) The rules that are only relevant for a specic PLC or that need to be adapted in order to be applicable.

2.2 Presentation of each rule

The rules are numbered according to their implementation in PLC Checker. For each rule, we nd an identical

structure made up of a title, an explanation of the rule, a justication of its importance and, when relevant, a code

example to facilitate understanding of the rule.

6/19

Chapter 3

Coding Rules

3.1 Naming

The elements manipulated in PLCs have mnemonics. Elements are, for example, variables, routines (sections,

subroutines, FCs . . . ) or function blocks (FB). The purpose of this section is to make sure that the symbols follow

rules ensuring readability, maintainability and allow for greater code perenity. Generally, the libraries elements are

excluded from naming verication. Of course, when the workbench allows this, we dont recommend to change

the elements names dened in the libraries.

3.1.1 PLCs common Rules

N.1 - All program elements should have a mnemonic

All programs elements should have a mnemonic (program, modules, variables, DFB, FB, OB, SR, routine, Add-

On)..

Comment : When all programs elements have a mnemonic, maintenance is easier and it is easier to understand

program content. Moreover, not using mnemonic makes an implicit link between a code and an hardware imple-

mentation.

N.2 - Elements names length should be in a given range

The names of program elements must contain at least 3 characters and no more than 15 characters.

Comment : A minimum number of characters ensures more meaningful naming. A maximum number of

characters allows:

In Schneider Unity, Schneider PL7pro and Rockwell RSLogix : to avoid the mnemonics being truncated in

display or export, . . .

In Siemens Step7: to improve readability

N.3 - Topological physical address should not be used as part of a mnemonic

The mnemonics shall not contain a reference to their physical address (for instance, MW2, FB4. . . ).

Comment : The reference to the physical address of the entity in the code may have bad properties : read-

ability is worse, and it may induce dangerous confusion. It should be noted that with the evolution of software

workbenches, referencing the elements names by their physical address is not necessary anymore. Eventhough

such a reference to the physical address may be unintentional, it is prohibited.

Example :

7/19

PLC programs development guidelines

Physical ad-

dress

Mmnemonics comment

%MW23 Cde 23 Never link the naming of the variable to its physical address

N.4 - Debug mnemonics should not be part of the nal program

Some mnemonics (test, toto, titi, tata, tutu, to delete , todo,. . . ) are forbidden, and the comments should not con-

tain debug expressions (like: to do later, to delete, todo)

Comment : Leave debug items in the nal program reduces its readability and may have different behavior

than expected. The list of prohibited elements is congurable (of course, it is language specic).

N.5 - Special or graphical characters are prohibited in mnemonics

The special characters set (e.g : ` a, e, c. . . ), space and accents are prohibited in the mnemonics names. Only al-

phanumerical characters and the underscore are allowed.

Comment : Using special characters, may generate some problems of portability to future workbench version

and / or to other platforms. It also reduces the readability in an international context. Finally, the restriction to only

alphanumerical characters ensures a better distinction between variable names.

Example :

depart := true;

# .... Lines of code

depart := false; #Using the special charactere, leads to a confusion between mnemonics.

N.6 - The programming language keywords should not be used as mnemonics

Programming language keywords (for example if, set, start. . . ) should not be used as mnemonics. But it is

possible that mnemonics contain a keyword. Most cases are handled by PLC workbench, but there are exceptions.

Comment : Using keywords as mnemonics lowers program readability and portability.

Example :

start := true; # mistaken mnemonic, "start" is a language keyword

start_motor := true; # Correct mnemonic

3.2 Comments

In addition to good naming practices, it is important to follow rules when commenting programs. In fact, the more

explicit and detailed the comments are, the more the code will be understandable. Generally, the standard library

elements comments are not checked.

8/19 January 20th 2012 - Version 1.6.7

PLC programs development guidelines

3.2.1 PLCs common Rules

C.1 - All program elements should have a comment

All program elements must be commented (Program, Section, Modules, Variables, DFB, FB, OB, SR).

Comment : If all the program elements are commented signicantly, it is easier to read and understand the

program, therefore its maintenance is less costly.

C.2 - Comments should be longer than a given number of characters

The comments of program elements must contain a minimum number of characters (7 for variables, 15 for codes)

to avoid insignicant comments.

Comment : Having a minimum length ensures that the comments are more meaningful.

C.3 - Each network should have a comment

The networks must be commented. This rule is specic to some languages of the IEC61131 standard. Also please

note that the concept of network is not always present in PLC vendor IDEs.

Comment : In addition to a good overall rate of comments, its important to ensure that comments are well

distributed within the program. Such a rule is also a guide that ensures consistency when copy/pasting code sec-

tions.

C.4 - Comments should not contain comment start marker

Comments should not contain comment start marker (e.g, / *, ( *).

Comment : The presence of a comment start marker is often a symptom of a forgotten comment end marker,

which can lead to commenting out of a part of program and thus a non intended behavior.

Example:

/* Any comment with the end marker has been forgotten

Critical_section_that_must_be_executed_which_is_found_in_the comment();

/* <- The start marker comment is commented because the end marker of the previous comment has been

forgotten */

3.3 Writing code

3.3.1 PLCs common Rules

E.1 - All variables should be written before being read

Except for physical and communication inputs and system variables, all variables should be written before being

read during a PLC cycle.

Comment : a variable that is read before being written, can increase program latency. Efcient code should

respect during one PLC cycle the following diagram:

inputs reading -> processing -> update the outputs.

January 20th 2012 - Version 1.6.7 9/19

PLC programs development guidelines

In addition, make sure that the variables that are never written in the code have been initialized, otherwise they are

updated by other ways.

In some cases it is justied to ignore this rule:

variables that were initialized in the database,

variables updated by a communications link,

state variables that store the value of a previous PLC cycle.

Example:

if urgentAlarme then

alarmeTreatement();

end if;

# ...

urgentAlarme := presenceDefault AND ...;

In this example, the call of the alarm function alarmTraitement happens during the next PLC cycle, which

increases the average response time. This delay is around one PLC cycle.

E.2 - The parameters of the user functional blocks should be used correctly

This rule is divided into three sub-rules :

E.2.a and b - Inputs of the user functional blocks should be read and not written.

E.2.c and d - Inputs/Outputs of the user functional blocks should be read and written.

E.2.e - Outputs of the user functional blocks should be written before being read.

Comment : Parameters incorrectly used are evidence of unnished code or a code that still contains unnecessary

elements of correct behavior. In some PLCs, misusing parameters may generate undesirable and potentially dan-

gerous effects, such as data corruption. Please note that checking whether private parameters of user blocks are

used is done by the rule S7.

3.3.2 Unity Pro specic rules (Schneider Electric).

E.U.1 - The functions of the Unity obsolete libraries should not be used

In a new Unity Pro PLC Project, the functions of the obsolete libraries should not be used.

Comment : In Unity, some libraries are obsolete and exist to ensure backward compatibility with previous

versions of Schneider PLCs. In new applications, the usage of the functions of those libraries must be avoided for

future portability problems. Furthermore, some of those functions can make the code nondeterministic (ex: shifts

on signed integers shl int, shlz int, shr int, shrz int, rol int, ror int).

10/19 January 20th 2012 - Version 1.6.7

PLC programs development guidelines

3.4 Structure

3.4.1 PLCs common Rules

S.1 - Backward jumps are forbidden

Backward jumps are forbidden.

Comment : Using a backward jump can trigger an innite loop, which can lead to a PLC shutdown. Moreover,

in general, jumps make the code less understandable and therefore their maintenance is more complex.

Example: Example of jump which triggers an innite loop

Figure 3.1: Example of jump which triggers an innite loop

S.2 - A variable should be elaborated only in one routine

A variable should be elaborated only in one routine.

Comment : A simple and clear code architecture facilitates understanding of the code and therefore its main-

tenance. Moreover, multiple variable elaborations can lead to erratic behavior of the code.

S.3 - A variable should be written from one task only

A variable should be written from one task only.

Comment : writing a variable from several tasks leads to an nondeterministic behavior, such as a potential

access conict.

S.4 - A physical output should be written only once per PLC cycle

A physical output should be written only once per PLC cycle.

Comment : Multiple output writing may lead to problems of dependability. Also, a code where the outputs

are written more than once is less easy to understand and maintain. It should be noted that writing in a loop is

considered as multiple writing and therefore constitutes a violation of this rule.

Example:

January 20th 2012 - Version 1.6.7 11/19

PLC programs development guidelines

if very_complicated_condition then

Critical_Output := TRUE;

end if;

#.... much later in the program

if another_very_complicated_condition then

Critical_Output := FALSE;

end if;

In the case where the output is not controlled where it should be, it is very difcult to identify which affectation is

executed

S.5 - Variables should not be localized

Variable memory mapping should be reserved to variables which elaboration or consumption is done out of the

program : communication tags, I/O variables, special function variables. All internal variables should not be

localized.

Detailed explanation : Using localized variables constraints program evolutivity, due to a more rigid memory

organization. It reduces portability, as memory organization varies from one PLC to another. So the code cannot

be reused in another application, as in the other application the given memory zone may be reserved for other

purposes. Moreover, it may lead to memory organization mistakes in which several variables will be saved in the

same memory cells. This bug may be silent during a long time and be encountered late in the development or in

the production cycle.

S.6 - DFB/FBs instances should be called only once

Comment : A functional block instance owns its variables used to save the FB state between two consecutive

cycles. Each FB execution should modify those variables to show the state evolution. When executed more than

once, it looks like the cycle is progressing twice quicker than the other instances.

Often used more than once, the same instance is the result of a cut and paste not updated.

It may lead to bugs hard to discover.

S.7 - Declared variables should be used

Variables and dened types should be used, except for reserve variables. Reserve variables shall not be used.

Comment : Variables (except reserves) and unused types are often a sign of a forgotten treatment or incomplete

database cleaning. When reserve variables are used this is often the sign of a forgotten renaming.

S.8 - Variables location shall not overlap

The overlapping variables are to be checked.

Comment : Localized variables that overlap are equivalent to an implicit transfer of value between each other.

This is sometimes a difculty to code readability. It is also sometimes a localization error.

S.9 - Complexity measure

Complexity of the code shall be assessed. Loops (for, repeat, while), jumps and a high level of imbrication are

criteria of code complexity.

Comment : Parts of program are more complicated than others. This is specially the case when execution

sequential ow is often cut. This rule searches for some root causes for ow discontinuation, like loops, backward

goto and high complex instructions nested level.

12/19 January 20th 2012 - Version 1.6.7

PLC programs development guidelines

S.10 - SCADA Limitations

SCADA software doesnt support structures arrays. Such constructions shall be avoided for portability purposes.

Comment : When using a SCADA which doesnt support array of structures, it is important to not build a PLC

database based on these arrays of structures. This rule is used here to detect this kind of construction.

3.5 Useful Information

3.5.1 Useful information for all PLCs

I.1 - Comments rate

It is recommended that the code contains a minimum percentage of comments.

Comment : Itris Automation Square recommends a rate of 30% (# of commented instructions / total # of

instructions). Such a minimum rate of comments ensures that the development was carried taking into account the

maintainability of the code, and ensuring that it will be easy to understand when evolution is needed.

I.2 - Code in the comments

It is very important to check the possible presence of code as comments.

Comment : Commenting out code is a typical test and debug strategy. The nal program should not contain

commented out code as maintenance technicians may be confused.

I.3 - Dead code

Provision shall be made against the presence of dead code in the program. \ \

Clarication : Dead code affects the readability and maintainability of the program and can be a symptom of a

functional problem. Please note that when PLC Checker detects unreferenced functions and parts of isolated code

after an unconditional jump, the completeness of the detection is not guaranteed (for example, dead code related

to the evaluation of an expression).

I.4 - List of locked elements

The locked elements are not scanned by PLC Checker, they should be identied for manual review.

Comment : In applications where the major part of the code is locked, it is important to know it.

I.5 - Cyclomatic number v(G)

A cyclomatic number gives information about complexity. It is important to keep it reasonably low.

Comment : A cyclomatic number counts the number of different paths that can be executed in a routine. The

higher this number is, the more difcult it is to validate the correct behavior of the routine. In such a case, the

routine should be divided in subroutines. Each of them having a cyclomatic number below the given threshold.

I.6 - Essential Complexity ev(G)

Essential complexity gives information about unstructured instructions. It is important to keep it reasonably very

low.

Comment : Essential complexity counts the number of different unstructured instructions in a routine. The

higher this number is, the more difcult it is to validate the correct behavior of the routine. Most of the time,

unstructured instructions can normally be replaced by structured instructions.

January 20th 2012 - Version 1.6.7 13/19

PLC programs development guidelines

I7 - Source Line of Code count

The source line of code counts number of instructions in a POU. It is important to keep it under control.

Comment : Very big procedure or function blocks may be difcult to test, to read and to maintain. It may be

better to split a very big procedure into two or more procedures of reasonable size.

I8 - Sequential Function Chart (SFC) steps count

This is the count of steps in a given SFC.

Comment : This rules returns the number of steps found by SFC. This number may be further used to detect

complex SFCs or to give an overview of the relative size of SFCs.

I9 - SFC branches count

This number sums the number of branches in each AND/OR divergence found in a given SFC.

Comment : This rule calculates the number of branches available in a given SFC. This count gives information

about SFC complexity. This number is equivalent to the v(G) applied to imperative coding languages.

I10 - Copy/Paste detection ratio

This number detects the percentage of code which is redundant.

Comment : Reusing the code by copying code is not a good practice. Maintenance and evolution are more

expensive to perform because modications and corrections should be applied at each copy/paste instance. More-

over, the manual copy/paste is error prone : after doing the copy/paste, code should be modied. When code is not

modied correctly, it introduces subtle bugs hard to discover.

3.6 Options

3.6.1 Unity Project Options

O.U.1 - SFC : Multiple Token should not be Allowed

In the language extensions tab of project settings, the check-box Allow multiple token shall be deactivated.

Comment : The only purpose of the multiple token mode is to ensure backward compatibility with previous

versions of Schneider PLCs. It should not be used in new projects because it can make the code indeterministic.

SFC code with Multi Token is not compliant with IEC 61131-3.

Example: In the following SFC code, if the condition A is always true, after several PLC cycles, all steps

are simultaneously active.

14/19 January 20th 2012 - Version 1.6.7

PLC programs development guidelines

Figure 3.2: indeterministic SFC in multi-token mode

O.U.2 - SFC : Keep previous steps in active state should not be Allowed

In the language extensions tab of project settings, the check-box SetSteps: keep previous step(s) in active state

shall be deactivated.

Comment : This option is only available if the Allow multiple token check-box is activated - see O.U.1.

O.U.3 - SFC : Parallel branches: allow jump in/out should not be Allowed

In the language extensions tab of project settings, the check-box Parallel branches: allow jump in/out shall be

deactivated.

Comment : This option is only available if the Allow multiple token check-box is activated - see O.U.1.

O.U.4 - SFC : Only one evolutions by divergence of sequence selection

In the language extensions tab of project settings, the check-box Allow multiple evolutions by divergence of se-

quence selection shall be deactivated.

Comment : This option is only available if the Allow multiple token check-box is activated - see O.U.1.

O.U.5 - ST : Jump and label should not be Allowed

In the language extensions tab of project settings, the check-box Allow Jump and label shall be deactivated.

Comment : In general, usage of jumps reduces the readability of the code and therefore its maintainability.

O.U.6 - Identiers: leading digits in names should not be Allowed

In the language extensions tab of project settings, the check-box Allow leading digits shall be deactivated.

January 20th 2012 - Version 1.6.7 15/19

PLC programs development guidelines

Comment : In general, usage of leading digits in names reduces the readability and portability of the program.

O.U.7 - Identiers: the standard (IEC) character set shall be used in names

In the language extensions tab of project settings, the check-box standard shall be deactivated.

Comment : In general, usage of the non standard (IEC) character set in names , reduces the readability and

portability of the program.

O.U.8 - Graphical languages (FBD/LD): Usage of ST expressions should not be Allowed

In the language extensions tab of project settings, the check-box Usage of ST expressions shall be deactivated.

Comment : In general, usage of ST expressions in FBD reduces the readability of the program.

O.U.9 - Upload information: Upload information with comments and animation tables

In the Build tab of project settings (project generation settings) the following check-boxes shall be activated:

1. Include in the Upload information,

2. Comments (Variables and types) in the Upload information,

3. Animation tables in the Upload information

Comment : If the PLC memory allows, the storage of all upload information ensures a smooth restoration of the

source of the project from the PLC, thus improving the long term maintainability (lost backup issues).

O.U.10 - Ladder Diagram : Right-justify coils

In the Editors tab of project settings, the check-box Right-justify coils for Ladder Diagram (LD) shall be acti-

vated.

Comment : Right-justify coils allow a better readability of the program.

16/19 January 20th 2012 - Version 1.6.7

Chapter 4

Annexes

4.1 Summary of Rules

This annexe summarizes all the rules and useful information contained in this document.

Naming rules

N.1 - Non-specic - All elements of the program must be named

N.2 - Non-specic - Elements name length should be in a given range

N.3 - Non-specic - Topological physical address should not be used as part of a mnemonic

N.4 - Non-specic - Testing mnemonics should not be part of the nal program

N.5 - Non-specic - Special or graphical characters are prohibited in mnemonics

N.6 - Non-specic - The programming language keywords should not be used as mnemonics

Commenting rules

C.1 - Non-specic - All program elements should have a comment

C.2 - Non-specic - Comments should be longer than a given number of characters

C.3 - Non-specic - Each network should have a comment

C.4 - Non-specic - Comments should not only contain the comment start marker

Writing rules

E.1 - Non-specic - All variables should be written before being read

E.2.a, E.2.b - Non-specic - Inputs of the user functional blocks should be read and not written.

E.2.c, E.2.d - Non-specic - Inputs/Outputs of the user functional blocks should be read and written.

E.2.e - Non-specic - Outputs of the user functional blocks should be written before being read.

E.U.1 - SE Unity - The functions of the Unity obsolete libraries should not be used

17/19

PLC programs development guidelines

Structure rules

S.1 - Non-specic - Backward jumps are forbidden

S.2 - Non-specic - A variable should be elaborated only in one routine

S.3 - Non-specic - A variable should be written from one task only

S.4 - Non-specic - A physical output should be written only once per PLC cycle

S.5 - SE Unity - Variable should not be localized

S.6 - Non-specic - DFB/FBs instances should be called once

S.7 - Non-specic - Declared variables should be used

S.8 - Non-specic - Variables location doesnt overlap

S.9 - Non-specic - Complexity measure

S.10 - Non-specic - SCADA Limitations

Informations Utilities

I.1 - Non-specic - Comments rate

I.2 - Non-specic - Code in the comments

I.3 - Non-specic - Dead code

I.4 - Non-specic - List of locked elements

I.5 - Cyclomatic number v(G)

I.6 - Essential Complexity ev(G)

I.7 - Source Line of Code count

I.8 - SFC steps count

I.9 - SFC branches count

I.10 - Copy/Paste detection ratio

Options

O.U.1 - SE Unity - SFC : Multiple Token should not be Allowed ===

O.U.2 - SE Unity - SFC : Keep previous steps in active state should not be Allowed ===

O.U.3 - SE Unity - SFC : Parallel branches: allow jump in/out should not be Allowed ===

O.U.4 - SE Unity - SFC : Only one evolutions by divergence of sequence selection ===

O.U.5 - SE Unity - ST : Jump and label should not be Allowed ===

O.U.6 - SE Unity - Identiers: leading digits in names should not be Allowed ===

O.U.7 - SE Unity - Identiers:Using the standard (IEC) character set in names ===

O.U.8 - SE Unity - Graphical languages (FBD/LD): Usage of ST expressions should not be Allowed ===

O.U.9 - SE Unity - Upload information: Upload information with comments and animation tables ===

O.U.10 - SE Unity - Ladder Diagram : Right-justify coils ===

18/19 January 20th 2012 - Version 1.6.7

PLC programs development guidelines

4.2 Document history

Date Changes

2010

Jul 12th

Initial version

2010

Dec

21th

Add Options chapter

2011

Nov

9th

Add description for rules S5, S6, S7, S8, S9, S10, I5, I6, I7, I8, I9, I10

2011

Nov

21th

Add version number. Texts Corrections. Extend EU1 rule to all functions of the obsolete libraries

2012

Jan

20th

Proofreading and corrections (grammar, spelling) by Pauline

January 20th 2012 - Version 1.6.7 19/19

Potrebbero piacerti anche

- 2001 Ford F150 ManualDocumento296 pagine2001 Ford F150 Manualerjenkins1100% (2)

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosDa EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosValutazione: 5 su 5 stelle5/5 (1)

- User Manual ControlLogix 5580Documento164 pagineUser Manual ControlLogix 5580Nixius0% (1)

- PLC 5 Quick Ref PDFDocumento172 paginePLC 5 Quick Ref PDFfellskevNessuna valutazione finora

- 1756-pm006 - En-P - Sequential Function ChartsDocumento82 pagine1756-pm006 - En-P - Sequential Function Chartsjediael.pjNessuna valutazione finora

- PLC 2012Documento108 paginePLC 2012Qais Alsafasfeh100% (2)

- Phy Mock SolDocumento17 paginePhy Mock SolA PersonNessuna valutazione finora

- PLC Programming Using SIMATIC MANAGER for Beginners: With Basic Concepts of Ladder Logic ProgrammingDa EverandPLC Programming Using SIMATIC MANAGER for Beginners: With Basic Concepts of Ladder Logic ProgrammingValutazione: 4 su 5 stelle4/5 (1)

- TECH NOTE QuantumX EtherCAT Integration Beckhoff TwinCAT. HBMDocumento11 pagineTECH NOTE QuantumX EtherCAT Integration Beckhoff TwinCAT. HBMEnrique de AguileraNessuna valutazione finora

- RSLogix 5000 Studio 5000 Features v16 v30Documento147 pagineRSLogix 5000 Studio 5000 Features v16 v30abdelatif ZinaiNessuna valutazione finora

- RSLogix5000 V17 20080620Documento39 pagineRSLogix5000 V17 20080620Rinalyn-Oscar Gamboa MagtibayNessuna valutazione finora

- Six Months Industrial Automation SyllabusDocumento9 pagineSix Months Industrial Automation SyllabusWilliam SmithNessuna valutazione finora

- L01 - Introduction To Studio 5000 Logix DesignerDocumento11 pagineL01 - Introduction To Studio 5000 Logix DesignerjaysonlkhNessuna valutazione finora

- Allen Bradley Network - Update PDFDocumento164 pagineAllen Bradley Network - Update PDFChí NghĩaNessuna valutazione finora

- TwinCAT IO System ManualDocumento29 pagineTwinCAT IO System Manualdennis_packiaraj3063Nessuna valutazione finora

- STG sg2Documento162 pagineSTG sg2Radwa EL-MahdyNessuna valutazione finora

- PLC 2 Unity ReferenceDocumento698 paginePLC 2 Unity ReferenceRodolfo BelchiorNessuna valutazione finora

- Uh 60 ManualDocumento241 pagineUh 60 ManualAnonymous ddjwf1dqpNessuna valutazione finora

- TcPlcControl PDFDocumento249 pagineTcPlcControl PDFpaull2002Nessuna valutazione finora

- RSLogix 500 EtherNet-IP Logic Examples PDFDocumento4 pagineRSLogix 500 EtherNet-IP Logic Examples PDFchapsboiNessuna valutazione finora

- Usingcontrol MatlabDocumento1.626 pagineUsingcontrol MatlabGjergjiNessuna valutazione finora

- TwinCAT Getting StartedDocumento60 pagineTwinCAT Getting StartedKarlo JurecNessuna valutazione finora

- PLC programmable logic controller A Clear and Concise ReferenceDa EverandPLC programmable logic controller A Clear and Concise ReferenceNessuna valutazione finora

- Programming Recommendation For PLC S7 300 enDocumento41 pagineProgramming Recommendation For PLC S7 300 enauduserNessuna valutazione finora

- SIMATIC S7 + TIA Function BlocksDocumento109 pagineSIMATIC S7 + TIA Function BlocksVladimirAgeevNessuna valutazione finora

- CoDeSysVisualization ABBDocumento568 pagineCoDeSysVisualization ABBgersonjaraguasemfaceNessuna valutazione finora

- Getting Started With Your DeltaV SystemDocumento222 pagineGetting Started With Your DeltaV SystemMiguel Alvarez100% (1)

- Antifraud PlaybookDocumento60 pagineAntifraud PlaybookDani UsmarNessuna valutazione finora

- Scada System PDFDocumento74 pagineScada System PDFglizNessuna valutazione finora

- RS Logix Sample For VFDDocumento9 pagineRS Logix Sample For VFDJoe ElectricneutronNessuna valutazione finora

- ST Programming PDFDocumento446 pagineST Programming PDFJaime LledóNessuna valutazione finora

- TwinCAT IEC61131-3Documento176 pagineTwinCAT IEC61131-3Nigo VillanNessuna valutazione finora

- The Codesys Visualization: Supplement To The User Manual For PLC Programming With Codesys 2.3Documento67 pagineThe Codesys Visualization: Supplement To The User Manual For PLC Programming With Codesys 2.3veintimillaaNessuna valutazione finora

- Flip The Coin - EbookDocumento306 pagineFlip The Coin - EbookAjesh Shah100% (1)

- 10-PLC Software Engineering Handbook 3QPL4H v1 4Documento62 pagine10-PLC Software Engineering Handbook 3QPL4H v1 4Anonymous dPUUgoNessuna valutazione finora

- TIA Portal WinCC RT Advanced OPC DA ServerDocumento2 pagineTIA Portal WinCC RT Advanced OPC DA Serverdavid_diaz_sNessuna valutazione finora

- T360-21 Simple Reports - RevBDocumento28 pagineT360-21 Simple Reports - RevBKan Chora100% (1)

- FactoryTalk® View Site Edition User's GuideDocumento702 pagineFactoryTalk® View Site Edition User's Guidemistiano100% (2)

- Motors and LoadsDocumento24 pagineMotors and Loadsmanukjoy007Nessuna valutazione finora

- Certified Automation Professional A Complete Guide - 2020 EditionDa EverandCertified Automation Professional A Complete Guide - 2020 EditionNessuna valutazione finora

- PLC To Deltav Systems MigrationDocumento14 paginePLC To Deltav Systems MigrationzacriasNessuna valutazione finora

- Example of PLC Program PDFDocumento2 pagineExample of PLC Program PDFMia0% (1)

- ControlLogix Selection GuideDocumento88 pagineControlLogix Selection Guideronnell_naidooNessuna valutazione finora

- Tutorial 02 PLC PDFDocumento23 pagineTutorial 02 PLC PDFTete GoriNessuna valutazione finora

- InTouchHMI2020 RevADocumento646 pagineInTouchHMI2020 RevAReiser Anthony Flores Roca100% (1)

- EtherCAT Device Protocol PosterDocumento1 paginaEtherCAT Device Protocol Posterkroenen SSNessuna valutazione finora

- Function Block ProgrammingDocumento180 pagineFunction Block ProgrammingSyed SaifuddinNessuna valutazione finora

- Sylabus Spring2015 Robt308 IndustrialAutomationDocumento6 pagineSylabus Spring2015 Robt308 IndustrialAutomationBauyrzhan Du FromageNessuna valutazione finora

- Studio 5000 Application Code Manager Webinar 20170912Documento15 pagineStudio 5000 Application Code Manager Webinar 20170912Savio Fernandes100% (1)

- Loading Parameters Into Siemens G120 Variable Frequency DriveDocumento4 pagineLoading Parameters Into Siemens G120 Variable Frequency DrivemiltonNessuna valutazione finora

- Series 8 PLC ProgrammingDocumento314 pagineSeries 8 PLC ProgrammingbhlebarovNessuna valutazione finora

- PlantPAx HMI Security ConfigurationDocumento1 paginaPlantPAx HMI Security ConfigurationjaysonlkhNessuna valutazione finora

- EtherCAT Workbench ManualDocumento38 pagineEtherCAT Workbench Manualslu9900Nessuna valutazione finora

- CPU 410 en en-USDocumento422 pagineCPU 410 en en-USHammad AshrafNessuna valutazione finora

- User Manual For PLC ProgrammingDocumento458 pagineUser Manual For PLC ProgrammingSusanta royNessuna valutazione finora

- Interaction of Process Design and Control: Ref: Seider, Seader and Lewin (2004), Chapter 20Documento34 pagineInteraction of Process Design and Control: Ref: Seider, Seader and Lewin (2004), Chapter 20josejuanramos100% (1)

- Vijeo Quick Start Tutorial V710Documento86 pagineVijeo Quick Start Tutorial V710idris_pmNessuna valutazione finora

- Indralogic 1 Operating and ProgrammingDocumento384 pagineIndralogic 1 Operating and ProgrammingCristopher EntenaNessuna valutazione finora

- Vijeo Citect User GuideDocumento1.108 pagineVijeo Citect User GuideLucia Cosanzeana100% (1)

- Beckhoff Twincat Manual PDFDocumento40 pagineBeckhoff Twincat Manual PDFuskov_oleg100% (1)

- Training Document For InTouchDocumento27 pagineTraining Document For InTouchthakur941264191950% (2)

- RSLOGIX5000 Programming A Clear and Concise ReferenceDa EverandRSLOGIX5000 Programming A Clear and Concise ReferenceNessuna valutazione finora

- Process Control System A Complete Guide - 2020 EditionDa EverandProcess Control System A Complete Guide - 2020 EditionNessuna valutazione finora

- Supervisory control and data acquisition Third EditionDa EverandSupervisory control and data acquisition Third EditionNessuna valutazione finora

- Solar Power For Sustainable Offshore Petroleum Exploration and Production in AfricaDocumento10 pagineSolar Power For Sustainable Offshore Petroleum Exploration and Production in AfricaRadwa EL-MahdyNessuna valutazione finora

- S7 300 First Time User enDocumento68 pagineS7 300 First Time User enLeonardo AlencastreNessuna valutazione finora

- Model Answer Winter 2015Documento38 pagineModel Answer Winter 2015Vivek MalwadeNessuna valutazione finora

- DevOps Reference CardDocumento2 pagineDevOps Reference CardIntizarchauhanNessuna valutazione finora

- Key Performance Indicators - KPIsDocumento6 pagineKey Performance Indicators - KPIsRamesh Kumar ManickamNessuna valutazione finora

- Evolis SDK Use Latest IomemDocumento10 pagineEvolis SDK Use Latest IomempatrickNessuna valutazione finora

- Electromagnetism WorksheetDocumento3 pagineElectromagnetism WorksheetGuan Jie KhooNessuna valutazione finora

- Brochure GM Oat Technology 2017 enDocumento8 pagineBrochure GM Oat Technology 2017 enArlette ReyesNessuna valutazione finora

- Nikasil e AlusilDocumento5 pagineNikasil e AlusilIo AncoraioNessuna valutazione finora

- Lakh Only) Being The Amount Covered Under The Aforesaid Dishonoured Cheque, and So AlsoDocumento2 pagineLakh Only) Being The Amount Covered Under The Aforesaid Dishonoured Cheque, and So AlsoShivam MishraNessuna valutazione finora

- Bulletin PDFDocumento2 pagineBulletin PDFEric LitkeNessuna valutazione finora

- Course DescriptionDocumento54 pagineCourse DescriptionMesafint lisanuNessuna valutazione finora

- 02 Chapter 2 - Corporate Governance MechanismDocumento19 pagine02 Chapter 2 - Corporate Governance MechanismHanis ZahiraNessuna valutazione finora

- Lecture 12 Health Management Information SystemDocumento14 pagineLecture 12 Health Management Information SystemKamran SheikhNessuna valutazione finora

- IbmautomtiveDocumento38 pagineIbmautomtiveMeltz NjorogeNessuna valutazione finora

- Chapter 1 4Documento76 pagineChapter 1 4Sean Suing100% (1)

- ProjectDocumento33 pagineProjectPiyush PatelNessuna valutazione finora

- JCIPDocumento5 pagineJCIPdinesh.nayak.bbsrNessuna valutazione finora

- Hydraulics and PneumaticsDocumento6 pagineHydraulics and PneumaticsRyo TevezNessuna valutazione finora

- Bathinda - Wikipedia, The Free EncyclopediaDocumento4 pagineBathinda - Wikipedia, The Free EncyclopediaBhuwan GargNessuna valutazione finora

- Abc Uae Oil and GasDocumento41 pagineAbc Uae Oil and GasajayNessuna valutazione finora

- Reference by John BatchelorDocumento1 paginaReference by John Batchelorapi-276994844Nessuna valutazione finora

- Taxation Law 1Documento7 pagineTaxation Law 1jalefaye abapoNessuna valutazione finora

- Transposable Elements - Annotated - 2020Documento39 pagineTransposable Elements - Annotated - 2020Monisha vNessuna valutazione finora

- ICU General Admission Orders: OthersDocumento2 pagineICU General Admission Orders: OthersHANIMNessuna valutazione finora

- Lotus Exige Technical InformationDocumento2 pagineLotus Exige Technical InformationDave LeyNessuna valutazione finora

- Wins Salvacion Es 2021Documento16 pagineWins Salvacion Es 2021MURILLO, FRANK JOMARI C.Nessuna valutazione finora