Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sika MonoTop 620 PDS (CE)

Caricato da

cormolioCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sika MonoTop 620 PDS (CE)

Caricato da

cormolioCopyright:

Formati disponibili

Product Data Sheet

Edition 19/10/2010

Identification no:

01 03 02 05 001 0 000003

SikaMonoTop-620

1 1/4

C

o

n

s

t

r

u

c

t

i

o

n

SikaMonoTop-620

Si k a

MonoTop-620

Cementitious Smoothing Coat/Levelling Mortar & Pore Sealer

Product

Description Sika

MonoTop-620 is a one component cementitious polymer modified mortar.

Uses As a concrete pore sealer/levelling mortar/smoothing coat

Repairing minor defects

Thin layer render

Repairing pores and honeycombed concrete

For exterior and interior use

Characteristics /

Advantages

Pre-bagged for quality

J ust add water

Compatible with Sika

FerroGard

corrosion inhibitor

Compatible with SikaTop

and MonoTop mortars

Overcoatable with Sikagard

coatings

Sprayable by wet spray method

Product Data

Form

Appearance /Colours Grey powder

Packaging 25 kg bag

Storage

Storage Conditions/

Shelf-Life

6 months from date of production if stored properly in original unopened, sealed

and undamaged packaging in dry and cool conditions.

Technical Data

Chemical Base Portland cement, polymer redispersable powder, selected aggregates and

additives.

Density Mixed wet 2.0 kg/litre

Layer Thickness 1.5 mm min. / 5.0 mm max.

BS EN 1504-2 09 0086 CPD - 541325

2 2/4

SikaMonoTop-620

Mechanical / Physical

Properties

Compressive Strength 28 days @ 20

o

C ~30-35 N/mm

2

Flexural Tensile Strength 28 days @ 20

o

C ~4-6 N/mm

2

Bond Strength ~1.5-2.5 N/mm

2

(substrate failure)

E-Modulus ~15.4 kN/mm

2

System

Information

System Structure Sika

MonoTop-620 is part of the Sika

MonoTop Concrete Repair System

Sika

MonoTop-610: Bonding primer and reinforcement coating

Sika

MonoTop-612: Hand and wet spray applied repair mortar

Sika

MonoTop-615: Hand and wet spray high build applied repair mortar

Sika

MonoTop-620: Smoothing coat

Sika

FerroGard

-903: Corrosion inhibitor

Application Details

Consumption This depends on the substrate roughness and thickness of layer applied.

As a guide, ~2.0 kg/m

2

/mm.

Substrate Quality The concrete shall be free from dust, loose material, surface contamination, existing

renders, laitance coatings, oil and other materials which reduce bond or prevent

suction or wetting of the smoothing coat.

Substrate Preparation Delaminated, weak, damaged and deteriorated concrete should be repaired using

MonoTop repair mortars.

High spots can be removed by grinding.

Concrete surface should be cleaned and roughened using suitable abrasive blast

cleaning techniques or high pressure waterblasting [up to 60 mPa (9000 psi)]

techniques to achieve acceptable adhesion to the substrate. Adhesion test average

must be >0.8 N/mm

2

with no single value below 0.5 N/mm

2

for crack bridging

coatings and 1.0 N/mm

2

with no single value below 0.7 N/mm

2

for rigid coatings.

.

Application

Conditions /

Limitations

Substrate Temperature +5C min. / +30C max.

Air Temperature +5C min. / +30C max.

3 3/4

SikaMonoTop-620

Application

Instructions

Mixing Wet Spray Application : 2.5 to 3.5 L of water for 25kg powder

Hand Application: ~4.0 to 4.5 L of water for 25 kg powder

Mixing Time Sika

MonoTop-620 can be mixed with a slow speed (<500 rpm) electric drill

mixer.

Pour the water in the correct proportion into a suitable mixing container. While

stirring slowly, add the powder to the water. Mix thoroughly for at least 3 minutes to

the required consistency.

Application Method /

Tools

Smoothing Coat/Levelling Mortar

The surface should be pre-wetted to a saturated surface dry condition before

application.

Pre-fill surface defects before applying as a smoothing coat.

Apply Sika

MonoTop-620 by spatula or trowel to the required thickness and finish.

Where Sika

MonoTop-620 is to be overcoated, finishing with a moist neoprene

sponge or brush after initial set has taken place is recommended to provide a key

for the coating.

Do not overwork Sika

MonoTop-620 during or after applying. Should Sika

MonoTop-620 mortar be wetted during the initial cure period a white bloom may be

produced on the surface. This however, does not affect the long term properties of

the mortar.

Pore filler:

Tightly trowel over surface and force into pores and other surface defects.

Before overcoating remove excess material from surface while wet and wash down

if necessary when dry to remove any dust deposits which may affect the bond of

subsequent coatings.

Cleaning of Tools Clean all tools and application equipment with water immediately after use.

Hardened/cured material can only be mechanically removed.

Potlife ~35-45 minutes (at +23C)

Notes on Application /

Limitations

Avoid application in direct sun and/or strong wind and/or rain.

Do not add water over recommended dosage.

Apply only to sound, prepared substrates.

Do not add additional water during the surface finishing as this will cause

discoloration and cracking.

Protect freshly applied material from freezing.

Curing Details

Curing Treatment It is essential to cure the repair mortar immediately after application for a minimum

of 3 days to ensure full cement hydration and to minimise cracking. Use polythene

sheeting taped down at the edges or other approved method.

Curing compounds shall not be used if smoothing coat is to be overcoated.

Value Base

All technical data stated in this Product Data Sheet are based on laboratory tests.

Actual measured data may vary due to circumstances beyond our control.

Local Restrictions

Please note that as a result of specific local regulations the performance of this

product may vary from country to country. Please consult the local Product Data

Sheet for the exact description of the application fields.

Health and Safety

Information

For information and advice on the safe handling, storage and disposal of chemical

products, users shall refer to the most recent Material Safety Data Sheet containing

physical, ecological, toxicological and other safety-related data.

4 4/4

SikaMonoTop-620

Legal Notes

The information, and, in particular, the recommendations relating to the application

and end-use of Sika products, are given in good faith based on Sika's current

knowledge and experience of the products when properly stored, handled and

applied under normal conditions in accordance with Sikas recommendations. In

practice, the differences in materials, substrates and actual site conditions are such

that no warranty in respect of merchantability or of fitness for a particular purpose,

nor any liability arising out of any legal relationship whatsoever, can be inferred

either from this information, or from any written recommendations, or from any other

advice offered. The user of the product must test the products suitability for the

intended application and purpose. Sika reserves the right to change the properties

of its products. The proprietary rights of third parties must be observed. All orders

are accepted subject to our current terms of sale and delivery. Users must always

refer to the most recent issue of the local Product Data Sheet for the product

concerned, copies of which will be supplied on request.

The harmonised European standard EN 1504-3 Products and systems for the

protection and repair of concrete structures Definitions, requirements, quality control

and evaluation of conformity Part 3 Structural and non-structural repair specifies

the identification, performance (including durability) and safety of products and

systems to be used to repair concrete surfaces (either building or civil engineering

structures).

Non-structural repair fall under this specification they need to be CE-labelled as per

Annex ZA.2, table ZA.2 conformity 2+and fulfil the requirements of the given

mandate of the EU Construction Products Directive (89/106/CE).

CE Labelling

Water Vapour Permeability Class 1

Capillary Absorption and

Permeability to Water

0.1 kg.m

2

.h

0.5

Adhesion > 1.0 N/mm

2

Dangerous Substances Complies with 5.4

0086

Sika Ltd,

Welwyn Garden City,

Herts AL7 1BQ, UK

09

0086 CPD - 541325

BS EN 1504 -2

Surface Protection Systems

Sika Limited

Watchmead

Welwyn Garden City

Hertfordshire

AL7 1BQ

United Kingdom

Phone +44 1707 394444

Telefax +44 1707 329129

www.sika.co.uk

email: sales@uk.sika.com

Certificate No. EMS 4308 Certificate No. FM 12504

C

o

n

s

t

r

u

c

t

i

o

n

Potrebbero piacerti anche

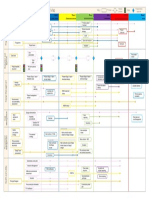

- Ricardo Vargas Pmbok Flow 6ed Color En-A0Documento1 paginaRicardo Vargas Pmbok Flow 6ed Color En-A0murdi.santoso83% (6)

- PD 6547 Guidance To BS en 40-3-1 Lighting ColumnDocumento18 paginePD 6547 Guidance To BS en 40-3-1 Lighting ColumnJoseph Loroy100% (2)

- MEP Concept Design DocumentsDocumento16 pagineMEP Concept Design DocumentssolarstuffNessuna valutazione finora

- Stage 6 - HandOver and Close Out ChecklistDocumento13 pagineStage 6 - HandOver and Close Out ChecklistVirah Sammy ChandraNessuna valutazione finora

- Project Process MapDocumento1 paginaProject Process MapShahrirNessuna valutazione finora

- Sika MonoTop 615 PDS (CE)Documento6 pagineSika MonoTop 615 PDS (CE)Virah Sammy ChandraNessuna valutazione finora

- Flowable Shrinkage Compensated Cementitious Grout: Product DescriptionDocumento4 pagineFlowable Shrinkage Compensated Cementitious Grout: Product DescriptionSerdar AldanmazlarNessuna valutazione finora

- Monotop 412 NFG PdsDocumento4 pagineMonotop 412 NFG PdsJames MizziNessuna valutazione finora

- Semen GroutingDocumento3 pagineSemen GroutingMuhammad Iqbal HimawanNessuna valutazione finora

- SikaTop Armatec 110 EpoCem PDSDocumento6 pagineSikaTop Armatec 110 EpoCem PDSsmartman35Nessuna valutazione finora

- Sikafloor - Proseal-22: Curing and Sealing Compound For Concrete FloorsDocumento4 pagineSikafloor - Proseal-22: Curing and Sealing Compound For Concrete FloorsSholikhinIbnuRamadhanNessuna valutazione finora

- Chapdur 091228Documento4 pagineChapdur 091228priyanithiNessuna valutazione finora

- Sikadur 32Documento3 pagineSikadur 32Matteo BreveglieriNessuna valutazione finora

- Sikagrout - 214: High Performance, Non Shrink, Expanding Cementitious Grouting MortarDocumento3 pagineSikagrout - 214: High Performance, Non Shrink, Expanding Cementitious Grouting MortarSulaim Al KautsarNessuna valutazione finora

- Cem FlexDocumento3 pagineCem FlexJaneshaNessuna valutazione finora

- SikaSeal CrystalDocumento3 pagineSikaSeal CrystalGabo TellezNessuna valutazione finora

- Sika For Flooring WorkDocumento2 pagineSika For Flooring WorkLauw Tjun NjiNessuna valutazione finora

- Sika Monotop®-610: Product Data SheetDocumento3 pagineSika Monotop®-610: Product Data SheetViet LeNessuna valutazione finora

- SikaTop Seal 107 PDS (CE) PDFDocumento4 pagineSikaTop Seal 107 PDS (CE) PDFSed BeelzeNessuna valutazione finora

- Sikagrout® - 214Documento3 pagineSikagrout® - 214Mostafa Hussein AbdouNessuna valutazione finora

- Sika ChapdurDocumento2 pagineSika ChapdurcormolioNessuna valutazione finora

- Sikacrete 08 SCC Id - Pds enDocumento2 pagineSikacrete 08 SCC Id - Pds enMuhammad Zaini GaniNessuna valutazione finora

- Sika Unitherm - 19010 PDFDocumento4 pagineSika Unitherm - 19010 PDFmihaisraduNessuna valutazione finora

- Sikadur - 31 CF Rapid: 2-Part Thixotropic Epoxy AdhesiveDocumento6 pagineSikadur - 31 CF Rapid: 2-Part Thixotropic Epoxy AdhesivevladodjuNessuna valutazione finora

- HT Sikadur 32gelDocumento4 pagineHT Sikadur 32gelQuerubin EboliNessuna valutazione finora

- Sika PDS - E - Sikadur - 42 TH PDFDocumento2 pagineSika PDS - E - Sikadur - 42 TH PDFlwin_oo2435100% (1)

- SikaTop Seal 107 PDS (CE)Documento5 pagineSikaTop Seal 107 PDS (CE)Vladimir StojanovicNessuna valutazione finora

- Sika Grout 214 (HE)Documento3 pagineSika Grout 214 (HE)aselabollegalaNessuna valutazione finora

- Sikatop Armatec 110 EpoCem PDFDocumento2 pagineSikatop Armatec 110 EpoCem PDFDarwin SyahputraNessuna valutazione finora

- Sika Concrete Primer 2011-04-1Documento3 pagineSika Concrete Primer 2011-04-1orgaNessuna valutazione finora

- Sika ChapdurDocumento2 pagineSika ChapdurJim Dry100% (1)

- Sikadur - 42 HS: High Strength Pourable Epoxy GroutDocumento4 pagineSikadur - 42 HS: High Strength Pourable Epoxy GroutMuhammad Azlan AhmadNessuna valutazione finora

- Sika Monotop 610Documento4 pagineSika Monotop 610Peter LodgeNessuna valutazione finora

- Sikaflex Construction DDocumento3 pagineSikaflex Construction Dthe pilotNessuna valutazione finora

- Sika Chapdur Pds enDocumento2 pagineSika Chapdur Pds enIndra KusumaNessuna valutazione finora

- Sikagard 75 Epocem: Superfine Epoxy-Cement Sealing MortarDocumento4 pagineSikagard 75 Epocem: Superfine Epoxy-Cement Sealing MortarAnonymous v1blzDsEWANessuna valutazione finora

- Pds CPD Sikadur22LM UsDocumento2 paginePds CPD Sikadur22LM Uspandavision76Nessuna valutazione finora

- Sika Rep FineDocumento2 pagineSika Rep Finethe pilotNessuna valutazione finora

- Sika RepDocumento3 pagineSika Repsmartman35Nessuna valutazione finora

- Sika Intraplast ZDocumento3 pagineSika Intraplast Zreborn_willyNessuna valutazione finora

- Sikafloor - 2430: 2-Part Epoxy Coloured CoatingDocumento4 pagineSikafloor - 2430: 2-Part Epoxy Coloured Coatingthe pilotNessuna valutazione finora

- Sikaflex 11FCDocumento3 pagineSikaflex 11FCthe pilotNessuna valutazione finora

- Sika MonoTop 438 R - Micro Concrete - PDS PDFDocumento4 pagineSika MonoTop 438 R - Micro Concrete - PDS PDFKrish ChandNessuna valutazione finora

- Dimetcote 9 PDS AIDocumento3 pagineDimetcote 9 PDS AIAmer Y KNessuna valutazione finora

- SikaTop Seal-109 MY 2012-08 - 1Documento3 pagineSikaTop Seal-109 MY 2012-08 - 1Mashithah AhmadNessuna valutazione finora

- Sikaflex Pro 3 WF Pds enDocumento4 pagineSikaflex Pro 3 WF Pds enrydocNessuna valutazione finora

- Sikagrout - 200 PtidDocumento3 pagineSikagrout - 200 Ptidfandy sipataNessuna valutazione finora

- Sikacem Gunit 133Documento2 pagineSikacem Gunit 133the pilotNessuna valutazione finora

- SikaMonoTop 620MY en MY (11 2018) 1 1Documento3 pagineSikaMonoTop 620MY en MY (11 2018) 1 1chanqiming51Nessuna valutazione finora

- Sika PDS - E - SikaGrout - 212 GP PDFDocumento2 pagineSika PDS - E - SikaGrout - 212 GP PDFlwin_oo2435Nessuna valutazione finora

- PDS - SikaGroutŽ Cable PTDocumento3 paginePDS - SikaGroutŽ Cable PTCatalin ToaderNessuna valutazione finora

- Sikagard - 720 Epocem: 3-Part Cement and Epoxy Combination Micro Mortar For Surface SealingDocumento5 pagineSikagard - 720 Epocem: 3-Part Cement and Epoxy Combination Micro Mortar For Surface Sealingthe pilotNessuna valutazione finora

- Sika® Microcrete®-218: Product Data SheetDocumento3 pagineSika® Microcrete®-218: Product Data SheetthowchinNessuna valutazione finora

- Sika PDS E SikaPoro G-230Documento3 pagineSika PDS E SikaPoro G-230lwin_oo2435Nessuna valutazione finora

- Sikadur 30Documento3 pagineSikadur 30Hakiki SaputraNessuna valutazione finora

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryDa EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNessuna valutazione finora

- Mechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsDa EverandMechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsNessuna valutazione finora

- Fibreglass Septic Tanks: SpecificationsDocumento4 pagineFibreglass Septic Tanks: SpecificationsAnonymous 2ZiabUZNessuna valutazione finora

- FINAL Appendix Building Control (Accessibility and Gender Compliance in Buildings) RegulationsDocumento17 pagineFINAL Appendix Building Control (Accessibility and Gender Compliance in Buildings) RegulationsVirah Sammy ChandraNessuna valutazione finora

- Design Calculation of Project Sign Boards Between Island House Interchange andDocumento37 pagineDesign Calculation of Project Sign Boards Between Island House Interchange andVirah Sammy ChandraNessuna valutazione finora

- BS 6297-1988 PDFDocumento50 pagineBS 6297-1988 PDFisempogo100% (1)

- Project Management Professional Certification Program (Pmi - PMP)Documento11 pagineProject Management Professional Certification Program (Pmi - PMP)Virah Sammy ChandraNessuna valutazione finora

- Sika Monotop®-610: Product Data SheetDocumento3 pagineSika Monotop®-610: Product Data SheetVirah Sammy ChandraNessuna valutazione finora

- Dura Grout: A.B.E. Construction ChemicalsDocumento3 pagineDura Grout: A.B.E. Construction ChemicalsVirah Sammy ChandraNessuna valutazione finora

- Sikatop 71 CuringDocumento3 pagineSikatop 71 CuringVirah Sammy ChandraNessuna valutazione finora

- Technical Bulletin Plaste-Fix FinDocumento2 pagineTechnical Bulletin Plaste-Fix FinVirah Sammy ChandraNessuna valutazione finora

- Overview of 49 Processes From PMBOK GuideDocumento11 pagineOverview of 49 Processes From PMBOK GuideVirah Sammy ChandraNessuna valutazione finora

- Format of Curriculum Vitae22012012Documento6 pagineFormat of Curriculum Vitae22012012Virah Sammy ChandraNessuna valutazione finora

- 2019 SMTE Conference Proceedings - 6-9 November 2019 - University of Curtin and The Mauritius Institute of EducationDocumento144 pagine2019 SMTE Conference Proceedings - 6-9 November 2019 - University of Curtin and The Mauritius Institute of EducationVirah Sammy ChandraNessuna valutazione finora

- 8 Wastewater Collection, Treatment and Disposal: 8.1 The ApproachDocumento11 pagine8 Wastewater Collection, Treatment and Disposal: 8.1 The ApproachVirah Sammy ChandraNessuna valutazione finora

- BS 6399-Part2Documento124 pagineBS 6399-Part2Lina NgahNessuna valutazione finora

- BS 648 1964 Schedule of Weights of BuildDocumento51 pagineBS 648 1964 Schedule of Weights of BuildVirah Sammy ChandraNessuna valutazione finora

- Innovative Tower Crane Foundation Designs by Katlkodikara: June 2013Documento5 pagineInnovative Tower Crane Foundation Designs by Katlkodikara: June 2013mmrahman93Nessuna valutazione finora

- Uputstvo Za Advance Steel 2019Documento55 pagineUputstvo Za Advance Steel 2019Zoran SimićNessuna valutazione finora

- Sample Design InformationDocumento1 paginaSample Design InformationVirah Sammy ChandraNessuna valutazione finora

- Crane Footing Design CalculationsDocumento14 pagineCrane Footing Design CalculationsVirah Sammy ChandraNessuna valutazione finora

- Stage 5 - Construction Stage ChecklistDocumento21 pagineStage 5 - Construction Stage ChecklistVirah Sammy ChandraNessuna valutazione finora

- Stage 3 - Developed Design ChecklistDocumento16 pagineStage 3 - Developed Design ChecklistVirah Sammy ChandraNessuna valutazione finora

- Proponent's Eia GuidelinesDocumento19 pagineProponent's Eia GuidelinesVirah Sammy Chandra100% (1)

- Stage 4 - Technical Design ChecklistDocumento23 pagineStage 4 - Technical Design ChecklistVirah Sammy ChandraNessuna valutazione finora

- Workbook Master Your People Skills PDFDocumento164 pagineWorkbook Master Your People Skills PDFVirah Sammy ChandraNessuna valutazione finora

- BLP GuideDocumento68 pagineBLP GuideKarish_J89Nessuna valutazione finora