Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

10-Combustion Lab Unit Liquid Burner

Caricato da

Renu SekaranCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

10-Combustion Lab Unit Liquid Burner

Caricato da

Renu SekaranCopyright:

Formati disponibili

Faculty of Chemical & Natural Resources Engineering

BKG3741

Fuel and Combustion Lab

Experiment 7

COMBUS!O" L#B U"! $

G#S BU%"E% & L!'U!( BU%"E%

"ame

Matri) "o*

Group

+ro,ram

Se)tion

(ate

Sem* 11 $ Session -.1-/-.13

BKG3741 0 Fuel and Combustion Lab Sem !!$-.1-/-.13

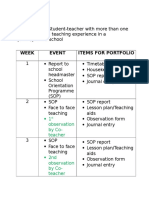

!"%O(UC!O" $ C41- COMBUS!O" L#BO%#O%2 U"!

This unit enables studies into many aspects of combustion and burner

operation using the optional burners or any suitable commercially

available oil or gas burner up to 150 kW.

The four large observation windows fitted in the frame mounted, water

cooled, combustion chamber provide an excellent flame

demonstration facility. The full instrumentation and safety features

allow supervised student operation over a wide range of airfuel

ratios and different fuels.

Figure 1: !"#$ !ombustion %aboratory &nit

1*. OB3EC!4ES

!n5esti,ation o6 #ir/Fuel %atio and Stoi)7iometri) Condition*

'ny hydrocarbon fuel has a condition of perfect combustion, in which

the oxygen is consumed. The stoichiometric airfuel ratio is different

for each fuel depending on its chemical composition. This experiment is

to set the burner to a mid range of fuel flow, which remains constant,

2

BKG3741 0 Fuel and Combustion Lab Sem !!$-.1-/-.13

and then alter the airfuel ratio throughout the range possible to

achieve combustion.

-*.GE"E%#L (ESC%!+!O"

-*1 Unit Constru)tion

Figure 2: !ontrol (anel %ayout !"#$

1. )ain *witch +. Water ,low *witch

$. -urner (ower *upply #. Water .utlet Temperature

/. -urner .n

10. Water Temperature

!ontrol

". -urner .n.ff

11. Water Temperature

!ontrol

5. -urner %ockout 1$. .il ,lowmeter

0. Temperature 1ndicator 1/. 2as ,lowrate Timer

3. !ooling Water ,lowmeter

3

1

2

3

4

5

6 7 8 9 10

11 12 13

BKG3741 0 Fuel and Combustion Lab Sem !!$-.1-/-.13

Figure 1: !"#$ !ombustion %aboratory &nit

4

F

i

g

u

r

e

3

:

*

c

h

e

m

a

t

i

c

4

i

a

g

r

a

m

5

2

a

s

-

u

r

n

e

r

BKG3741 0 Fuel and Combustion Lab Sem !!$-.1-/-.13

3*. O+E%#!"G +%OCE(U% 0 G#S & O!L BU%"E%

3*1 O+E%#!"G +%OCE(U%E 0 G#S BU%"E%

3*. O+E%#!"G +%OCE(U%E 0 O!L BU%"E%

5

F

i

g

u

r

e

4

:

*

c

h

e

m

a

t

i

c

4

i

a

g

r

a

m

5

.

i

l

-

u

r

n

e

r

BKG3741 0 Fuel and Combustion Lab Sem !!$-.1-/-.13

3*1 SE!"G U+ O!L BU%"E%

1. ,it the gas burner onto the four mounting studs with

four )+ nuts. 6nsure the gasket is not over tighten

78ust more than finger tight9.

$. !onnect and screw the 3 pin plug to the burner power

socket.

/. (lug the $ pin plug flow meter sensor lead to the socket

at control panel.

". :emove the blanking cap from oil pump and unscrew

the hose coupling at right sided vertical plate of the

frame. %oosely screw hose to the oil pump suction port.

5. (lace the drip tray under the burner on the hori;ontal

plate of the frame.

0. 6nsure fuel in the tank is sufficient for the test.

3*- S#%!"G 8E O!L BU%"E%

1. *witch on the main isolator and main switch on the

panel. 7 1nstrumentation should light9

$. Turn on main isolating valve and the valve at rear unit

for water supply. *lowly turn the cooling water flow

control anticlockwise until $00 gs. -oth two lamps

change to green.

/. 6nsure to set the dial of the water temperature control

at +0<! or above.

". Turn the three way valve to the desired fuel tank

position.

5. .pen the isolating valve at the front of the unit.

0. *=uee;e the priming pump for few times to purge the

line and then tighten the coupling.

3. *et the burner air control damper at position no 1>$.

+. (ress the green burner onoff button 1. The burner fan

will start.

#. 1gnition spark will be heard, gently s=uee;e the priming

pump and the burner should light up and then release

the priming pump.

10. The pump pressure will indicate the delivery pressure

and the green burner on lamp will illuminate

3*3 EME%GE"C2 SO+ FO% 8E O!L BU%"E%

1. (ress the red burner onoff button . on the control

panel.

3*4 S8U!"G (O9" 8E O!L BU%"E%

6

BKG3741 0 Fuel and Combustion Lab Sem !!$-.1-/-.13

1. Turn off the oil isolating valve.

$. Turn off the water flow at cooling water flow valve,

water isolating valve and the main valve.

/. *witch off the unit at main switch on the control panel.

4*. Sa6et: Measures

&nit should be operated in a well ventilated area and sited well

away from inflammable or heat sensitive material.

4o not allow the unit to run with the gas control valve open if no

flame has been established.

The gas burner control system is more complex than the oil

burner due to potentially ha;ardous and explosive nature of the

fuel. *pecial care need to be taken during handling this system.

7

C41-$ OBSE%4#!O"S O!L

(ate; Fuel; Stoi)7iometri) #/F; <b: 5olume= %elati5e (ensit:; <SG=

Burner; Stoi)7iometri) #/F; <b: mass= #mbient emperature; <C=

#mbient +ressure; <mbar= "o>>le 1*3? / -*. Us,al/7r

ES "O* 1 - 3 4 ? @ 7 A 1 1.

(ump (ressure 7 psi9

,an 4amper *etting 7?o9

4iffuser *etting 7?o9

,uel ,low :ate 1ndicated 7%@r9

!ooling Water ,lowrate 7gs9

!ooling Water 1nlet Temp. t1 7!9

!ooling Water .utlet Temp. t$ 7!9

'ir 1nlet Temperature t/ 7!9

6xhaust Temperature t" 7!9

.$ 7A9

!.$ 7A9

!. 7ppm9

6xcess 'ir 7A9

,lame Temperature t5 7!9

,lame !olor

,lame %ength 7cm9

*moke ?o

BKG3741 0 Fuel and Combustion Lab Sem !!$-.1-/-.13

6fficiency ?ett 7A9

C41-$ (E%!4E( %ESULS O!L

(ate; Fuel; Stoi)7iometri) #/F; <b: 5olume= (ensit: o6 Gas; <B,/m

3

=

Burner; Stoi)7iometri) #/F; <b: mass= #mbientemperature; <C=

#mbient +ressure; <mbar= "o>>le 1*3? / -*. Us,al/7r

ES "O* 1 - 3 4 ? @ 7 A 1 1.

!orrected ,uel ,low :ate 7%@r9

',l :atio 7by Bolume9 7volvol9

'ir ,low :ate 7by Bolume9 7%@r9

)ass ,uel ,low :ate 7kg@r9

', :atio 7by mass9 7kgkg9

'ir ,low :ate 7by mass9 7kg@r9

@eat 1nput 7Cin 9 7kW9

,lue 5 &seful a 7kW9

,lue 5 &nburnt b 7W9

,lue 5 Bapor c 7kW9

Total @eat to ,lue 7kW9

dD 7aEbEc9

@eat to Water e 7kW9

@eat .utput 7Cout9 D7dEe9 7kW9

4ifference

7Cin 5Cout9Cin 7A9

9

@*. EC+E%!ME"

@*1 +ro)edure 6or Oil Burner;

1. 6nsure the 1./5 &*gallhr no;;le is fitted.

$. *tart the gas burner firing.

/. *et constantly the oil pump pressure for the wide range

of airfuel ratio 7 approximately 50 kW heat input, + -ar,

100 psi on the 1./ &*gallhr no;;le9

". 'd8ust the cooling water flow and then keep it constant

for outlet temperature 7T

$

9 between 00 and +0 <!.

5. 'd8ust the damper to the minimum which sustain

combustion

0. 'llow conditions to stabili;e and record the readings on

the observation sheet.

3. 1ncrease the air damper position by one graduation.

+. 'gain, allow the condition to stabili;e and record the

readings.

#. 1ncrease the air flow in stages until maximum setting is

reached or combustion cannot be sustained.

10. *hut down the burner.

11. (rocess the readings as given on the 4erived :esults

*heet.

The .

$

, !.

$

and !. values are obtained from the standard

air analy;er supplied.

@*3* #nal:sis & (is)ussions;

1. (lot the graphs for 6xcessive 'ir 7A9 Bs. 0

$

and !.

$

7A9.

$. !omplete the calculation in the tables for both mass and

volume.

/. !omments on the finding of the airfuel ratio for the

combustion.

BKG3741 0 Fuel and Combustion Lab Sem !!$-.1-/-.13

Sample Cal)ulation

2as ,low :ate 7Bolume9

@r $.50m

1""

/00

Time7*ec9

/00

/

= =

'ir ,uel :atio 7Bolume9

*toichiometric ', by volume D $" F 1

6xcess 'ir 7 9 D "#.3 A 7from 'naly;er9

/5.#/ 1

100

"#.3

$" 1

100

G

tric *toichiome =

+ =

+

'ir ,uel :atio 7Bolume9 D /5.#/ F 1

'ir ,low :ate 7Bolume9

D 2as ,low :ate x ',

vol

2as ,low :ate 7)ass9

D Bolume 2as ,low :ate x 4ensity of ,uel

'ir ,uel :atio 7)ass9

D 15.0 F 1

$/./5 1

100

"#.3

15.0 1

100

G

tric *toichiome =

+ =

+

'ir ,uel :atio 7)ass9 D $/./5F 1

'ir ,low :ate 7)ass9

D 2as ,low :ate x ',

vol

@eat 1nput

D

)ass 2as ,low :ate x 2ross !alorific Balue 7,uel9

=

s

hr

/,000

1

kg

kH

50,000

hr

kg

".5

=

s

hr

/,000

1

hr

kH

$$5,000

= 0$.5kW

s

kH

0$.5 =

11

BKG3741 0 Fuel and Combustion Lab Sem !!$-.1-/-.13

#tta)7ment

,uel *toichiometri

c ', by

Bolume

*toichiometri

c ', by

)ass

Theoritica

l

)aximum

!.

$

7A9

2ross

!alorifi

c Balue

7)HIg

9

!hemica

l

,ormula

?atural

2as

#.+1 F 1 13.10 F 1 11.+ 55.00 !@

"

(ropane $" F 1 1.0 F 1 1/.+ 50.00 !

/

@

+

-utane /0 F 1 1".+ F 1 1".1 "#.5 !

"

@

10

Ierosen

e

#."+ F 1 1".3 F 1 15." "0.$ >

2as .il #.+$ F 1 1"." F 1 15." "5.5 >

!onversion ,actor

10 mm @

$

0 D 1 cm @

$

0 D 1 mbar

1 ft

/

D 0.0$+/$ m

/

1 1mperial gallon D ".5"0 %itre

1 &* gallon D /.3+5 %itre

.il ,lowmeter !orrection ,actor

D 4isplay x 1.1 7 Ierosene9

D 4isplay x 1.0 72as .il9

!p

g

for 6xhaust gas taken as 1.15 kHkgI 7 for 350 6!9

Typical Balues of density 7Igm

/

9

1tem 4ensity

Ierosene 3#0

2as .il +/5

(ropane 1.+5

-utane $."5

?atural 2as 0.0+

)olecular Weight of .

$

D /$

)olecular Weight of @

$

D $

)olecular Weight of ! D 1$

)olecular Weight of ?

$

D $+

)olecular Weight of @

$

. D 1+

'ir D 3# A ?

$

, $1 A 0

$

7 by volume9

30.3 A ?

$

, $/./ A .

$

7by mass9

12

BKG3741 0 Fuel and Combustion Lab Sem !!$-.1-/-.13

13

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Science Form 1Documento15 pagineScience Form 1Renu SekaranNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- For Section A, Write Your Answer in The Answer Sheet Provided in Page 12Documento12 pagineFor Section A, Write Your Answer in The Answer Sheet Provided in Page 12Renu SekaranNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Cell As A Unit of LifeDocumento40 pagineCell As A Unit of LifeRenu SekaranNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Lesson Plan (Subject: SCIENCE)Documento3 pagineLesson Plan (Subject: SCIENCE)Renu SekaranNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Wesley Methodist School Klang MONTHLY TEST 1 (2019) Chemistry Form 4 Total: 50 MarksDocumento8 pagineWesley Methodist School Klang MONTHLY TEST 1 (2019) Chemistry Form 4 Total: 50 MarksRenu SekaranNessuna valutazione finora

- Lesson Plan Format 27-1Documento4 pagineLesson Plan Format 27-1Renu SekaranNessuna valutazione finora

- Lesson Plan Format 24-2 (Opal)Documento3 pagineLesson Plan Format 24-2 (Opal)Renu SekaranNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Intensive 4 Page 2Documento1 paginaIntensive 4 Page 2Renu SekaranNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Lesson Plan (Subject: SCIENCE)Documento2 pagineLesson Plan (Subject: SCIENCE)Renu SekaranNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Lesson Plan Format 27-1 (Opal)Documento4 pagineLesson Plan Format 27-1 (Opal)Renu SekaranNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- E E:sl: Et Isl If:: I Ii:i I Il", 3:p:r I Et:sfDocumento1 paginaE E:sl: Et Isl If:: I Ii:i I Il", 3:p:r I Et:sfRenu SekaranNessuna valutazione finora

- Intensive 4 Page 4Documento1 paginaIntensive 4 Page 4Renu SekaranNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- 1 PGDIPEDU (UAB) MyVLE Practicum SlideDocumento17 pagine1 PGDIPEDU (UAB) MyVLE Practicum SlideRenu SekaranNessuna valutazione finora

- MODE 2: For Student-Teacher With Less Than One: 1 Observation by Co-TeacherDocumento4 pagineMODE 2: For Student-Teacher With Less Than One: 1 Observation by Co-TeacherRenu SekaranNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Intensive 3 Page 2Documento1 paginaIntensive 3 Page 2Renu SekaranNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Form 2 - Page 1Documento1 paginaForm 2 - Page 1Renu SekaranNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Form 1 Assessment OCTOBER 2015 Form 1 Science: (Duration: 25 Minutes)Documento8 pagineForm 1 Assessment OCTOBER 2015 Form 1 Science: (Duration: 25 Minutes)Renu SekaranNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- MODE 1: For Student-Teacher With More Than One: 1 Observation by Co-TeacherDocumento4 pagineMODE 1: For Student-Teacher With More Than One: 1 Observation by Co-TeacherRenu SekaranNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Chapter 2b Molecular Diffusion in LiquidDocumento12 pagineChapter 2b Molecular Diffusion in LiquidRenu SekaranNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Ductulator: S.P. Loss (Per 100 FT.) (In. of W.C.) Width (In.) X Duct Velocity Height (In.) (FPM)Documento8 pagineDuctulator: S.P. Loss (Per 100 FT.) (In. of W.C.) Width (In.) X Duct Velocity Height (In.) (FPM)joabjim8392Nessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- PMSM 2012Documento62 paginePMSM 2012Sreerag Kunnathu Sugathan100% (3)

- CE142P 2 Lab Report 1 Soberano PDFDocumento14 pagineCE142P 2 Lab Report 1 Soberano PDFqwert qwertyNessuna valutazione finora

- AssignmentME LawDocumento2 pagineAssignmentME LawMatthew AquinoNessuna valutazione finora

- Strida Folding Bike - Personal Tips and Facts From The CreatorDocumento8 pagineStrida Folding Bike - Personal Tips and Facts From The CreatorGeorg100% (2)

- KinematicsDocumento7 pagineKinematicsNicole WheelerNessuna valutazione finora

- Ipc 9521Documento4 pagineIpc 9521ashu0470Nessuna valutazione finora

- Syllabus Mechanical Qaqc Course Sdlinc 9600162099Documento3 pagineSyllabus Mechanical Qaqc Course Sdlinc 9600162099Sridurgha Lakshmi Inc SDLINC NDT QA QC INSTITUTE100% (3)

- Welding Symbols and NomenclatureDocumento17 pagineWelding Symbols and Nomenclaturesa saNessuna valutazione finora

- Design of Forming ToolsDocumento22 pagineDesign of Forming ToolskunwarNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Datasheet Crx-10iaDocumento1 paginaDatasheet Crx-10iaGuillaume RICHARDNessuna valutazione finora

- Slab Analysis of Ring Rolling AssumingConstantShearFrictionDocumento7 pagineSlab Analysis of Ring Rolling AssumingConstantShearFrictionMatteo Dalla Vecchia100% (1)

- Powerpoint Images: Failures Resulting From Static LoadingDocumento11 paginePowerpoint Images: Failures Resulting From Static LoadingKTMONessuna valutazione finora

- Moment VectorDocumento9 pagineMoment VectorGlen GulayNessuna valutazione finora

- Outdoor Unit Indoor Unit: Excellent Ecodan's Heating Performance, Even at Low Outdoor Temperature!Documento19 pagineOutdoor Unit Indoor Unit: Excellent Ecodan's Heating Performance, Even at Low Outdoor Temperature!Ивайло СтояновNessuna valutazione finora

- Common Rail System Diesel Engine Technology PDFDocumento26 pagineCommon Rail System Diesel Engine Technology PDFFedima100% (1)

- Farooqi Mohammed Yousuf Saudi Arabia 17.00 YrsDocumento5 pagineFarooqi Mohammed Yousuf Saudi Arabia 17.00 YrsKirkD'costaNessuna valutazione finora

- Thermo Dyanmics 2Documento2 pagineThermo Dyanmics 2xcalliber404Nessuna valutazione finora

- Mathematical Model of Systems:: Rotational Mechanical System Transfer FunctionDocumento11 pagineMathematical Model of Systems:: Rotational Mechanical System Transfer Functionchardo santosNessuna valutazione finora

- Army TM 9-2320-361-20p Air Force To 36a12-1b-1114Documento1.188 pagineArmy TM 9-2320-361-20p Air Force To 36a12-1b-1114wetface100% (1)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Experiment No.1 ObjectiveDocumento4 pagineExperiment No.1 ObjectivealiNessuna valutazione finora

- Overall DimensionDocumento1 paginaOverall DimensionjanetNessuna valutazione finora

- General Notes:: Isometric PlanDocumento1 paginaGeneral Notes:: Isometric PlanAeron Acio0% (1)

- D348 INDUSTRIAL & MARINE ENGINES CaterpillarDocumento32 pagineD348 INDUSTRIAL & MARINE ENGINES Caterpillarjosef67% (3)

- SENR33120001 621E and 627E Tractor-Scraper Hydraulic System (SENR3312)Documento2 pagineSENR33120001 621E and 627E Tractor-Scraper Hydraulic System (SENR3312)CEVegaONessuna valutazione finora

- Euro IV BH117L Trans ManualDocumento748 pagineEuro IV BH117L Trans ManualOlga PlohotnichenkoNessuna valutazione finora

- Flange TableDocumento0 pagineFlange TablemkstngrNessuna valutazione finora

- Fluid Flow Through Randomly Packed Columns and Fluidized BedsDocumento6 pagineFluid Flow Through Randomly Packed Columns and Fluidized BedsalexramquiNessuna valutazione finora

- ASME PTC 22 (Gas Turbine Test Code)Documento46 pagineASME PTC 22 (Gas Turbine Test Code)Nanang Hanani Wijaya100% (5)

- Treadmill 93T-04 - THH100000 - PARTS LISTDocumento19 pagineTreadmill 93T-04 - THH100000 - PARTS LISTpowerliftermiloNessuna valutazione finora

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactDa EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactValutazione: 5 su 5 stelle5/5 (5)

- It's Elemental: The Hidden Chemistry in EverythingDa EverandIt's Elemental: The Hidden Chemistry in EverythingValutazione: 4 su 5 stelle4/5 (10)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincDa EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincValutazione: 3.5 su 5 stelle3.5/5 (137)

- Well Integrity for Workovers and RecompletionsDa EverandWell Integrity for Workovers and RecompletionsValutazione: 5 su 5 stelle5/5 (3)