Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

No Heat

Caricato da

kaiser_shaikh10 valutazioniIl 0% ha trovato utile questo documento (0 voti)

151 visualizzazioni11 paginenissan altima heat issue

Titolo originale

no heat

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentonissan altima heat issue

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

151 visualizzazioni11 pagineNo Heat

Caricato da

kaiser_shaikh1nissan altima heat issue

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 11

1/11

Classification: Reference: Date:

HA02-002b NTB02-047b September 9, 2003

2002 2003 ALTIMA; POOR HEATER PERFORMANCE

This bulletin amends NTB02-047a. This version updates the Service Procedure. Please discard all

paper copies of the previous version.

APPLIED VEHICLE: 2002 2003 Altima (L31)

IF YOU CONFIRM

Air from the heater on an Applied Vehicle:

Takes a long time to warm up after an engine cold start, or

Output air cools down and is not warm enough while the engine is at idle, or

Output air is not warm enough at any engine speed,

ACTIONS:

1. Perform Coolant Mixture Inspection procedure; on page 3.

NOTE: This will require the use of a new essential tool. See page 4 for tool

information.

2. If needed, perform Coolant Mixture Correction procedure on page 5.

3. Remove all air bubbles from the cooling system by performing Cooling System Bleed

Procedure; starting on page 6.

4. Recheck heater performance. If the heater performance is still poor:

Use the applicable Service Manual (ESM) to diagnose another cause of the incident.

Also, refer to NTB02-048 for possible air mix door malfunction.

IMPORTANT: The purpose of ACTIONS (above) is to give you a quick idea of the work

you will be performing. You MUST closely follow the entire Service Procedure (starting on

page 2) as it contains information that is essential to successfully completing this repair.

2/11

CLAIMS INFORMATION

If only the coolant inspection and system air bleed are done, submit a Primary

Operation (PO) line claim using the following claims coding:

DESCRIPTION OP CODE SYM DIA FRT

Coolant Inspection and

cooling system air bleed only

WX07AA ZL 57 0.4 hrs

OR

If the coolant inspection, coolant replacement and system air bleed are done, submit

a Primary Operation (PO) line claim using the following claims coding:

DESCRIPTION OP CODE SYM DIA FRT

Coolant Inspection, coolant

replacement and cooling

system air bleed

WX12AA ZL 57 0.6 hrs

3/11

SERVICE PROCEDURE

Coolant Mixture Inspection

(63%)

-50 (60%)

-40 (57%)

-30 (53%)

-20 (49%)

TP030384

-10 (44%)

-5 (41%)

+5 (34%)

+10 (30%)

+15 (25%)

+20 (19%)

+25 (12%)

+32 (0%)

PROPYLENE

GLYCOL

0 (38%)

-60

(59%)

(70%)

(64%)

-50 (56%)

-40 (52%)

-34 (50%)

-30 (48%)

-20 (44%)

-10 (38%)

-5 (36%)

+5 (29%)

+10 (25%)

+15 (21%)

+20 (16%)

+25

F

(10%)

+32 (0%)

0 (38%)

-60

ETHYLENE

GLYCOL

FREEZE POINT

1% GLYCOL BY VOLUME

BATTERY

CHARGE

1,400

1,350

1,300

G

O

O

D

F

A

I

R

R

E

C

H

A

R

G

E

1,250

1,150

1,100

1,200

SPECIFIC

GRAVITY

{

Use this

scale.

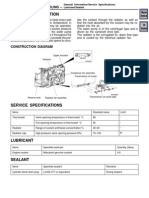

Figure 1

Don t use the old style bulb and disc/ball type hydrometers, or pH test strips. These

devices are not precise enough to provide the readings required for the critical

balance between freeze protection and heater performance.

If the coolant mixture is not between 50-55% ethylene glycol, correct the mixture by

performing the Coolant Mixture Correction procedure on page 5. Then perform

Cooling System Bleed procedure.

If the mixture is between 50-55% ethylene glycol, go to Cooling System Bleed

Procedure (starting on page 6).

If engine coolant and battery tester (refractometer) J-23688 is not available, perform

the Coolant Mixture Correction procedure on page 5. Then perform Cooling System

Bleed procedure starting on page 6.

1. Take a sample of coolant from the radiator and

check the percentage of ethylene glycol.

Use Refractometer (J-23688)engine

coolant and battery tester (see page 4 for

tool information).

The refractometer has the percentage of

ethylene glycol written on the scale

(see Figure 1).

4/11

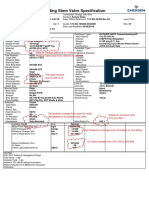

Refractometer J-23688 (Engine Coolant and Battery Tester) Tool Information

Nissan requires coolant and battery tester (refractometer) J-23688 be used for the

Coolant Mixture Inspection procedure in this bulletin.

Refractometer J-23688 is automatically temperature compensated. Other

refractometers may not be temperature compensated, and will not be precise enough to

provide the readings required for the critical balance between freeze protection and

heater performance.

Figure 2

Refractometer J-23688 is an essential tool and will be automatically sent to all Nissan

dealers. It is scheduled to be shipped in late September 2003.

Your dealer non-vehicle account will be charged $131.55 each, plus applicable taxes

and freight.

A separate announcement will be made when this tool is being shipped to dealers.

If a dealer elects to purchase this tool (J-23688) at the regular price from Tech-Mate,

before it is automatically shipped; the essential shipment can be returned for credit.

Contact Tech-Mate for details.

5/11

Coolant Mixture Correction

1. Drain the entire cooling system (radiator, coolant reservoir tank, and cylinder block).

Refer to the applicable Service Manual (ESM), section MA, for coolant drain

locations.

2. Refill the engine cooling system using Genuine Nissan Anti-freeze Coolant, mixed

50/50 with distilled water or de-mineralized water.

Use Engine Coolant Refill Tool #J-45695 to fill the radiator.

Refer to NTB02-011a for Engine Coolant Refill Tool #J-45695 information.

IMPORTANT:

It is very important that the engine cooling system be filled with a mixture that is no

more then 55% coolant (ethylene glycol). Please be precise (accurate) when

measuring.

In most areas it is best to use a 50% coolant / 50% water mixture. The freezing

point of a 50/50 mixture is 34 degrees F.

If freeze protection down to 47 degrees F is needed, a 55% coolant / 45% water

mixture may be used.

To account for spillage during refill, and the extra mixture needed to keep the refill

tool and bleed tool from running dry, we recommend a full mixture: 12 quarts /

3 gallons.

The following measurements will give you 12 quarts / 3 gallons of a 55/45 mixture.

Coolant 6 quarts 19 ounces

Water

\

5 quarts 13 ounces

Total 55/45

mixture

12 quarts or 3 gallons

If a refractometer is available, it is best to recheck the coolant mixture after mixing to

confirm it is within 50 to 55% ethylene glycol.

Engine coolant capacity (without reservoir tank) is:

7.5 liters (7 7/8 quarts) for vehicles equipped with the 4-cylinder engine (QR25DE)

8.1 liters (8 5/8 quarts) for vehicles equipped with the 6-cylinder engine (VQ35DE)

Reservoir tank capacity is:

0.7 liters (3/4 quart) for both the QR25DE and VQ35DE engines

6/11

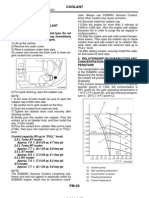

Cooling System Bleed Procedure

Steps 3 through 9 in this procedure describe making and using a cooling system

bleed tool.

However, you can use a commercially available funnel-type coolant refill bleed tool,

such as Lisle Spill-Free Funnel Tool #285-LIS-22150. See Figure 3.

The above tool is available from TECH-MATE by calling 1-800-662-2001 and pressing

option 4 to order.

If a funnel-type tool is used, refer to the instructions that come with the tool for proper

usage.

Figure 3

Remove All Air Bubbles (Bleed) the Cooling System as Follows:

1. Check the coolant level in the radiator (see Figure 4, next page).

a. If the coolant level is up to the radiator filler neck, proceed with step 3 on page 8.

b. If the coolant level is NOT up to the radiator filler neck, perform step 2 on the next

page, and then proceed with step 3 on page on 8.

c. If, for whatever reason, the radiator is drained, use Engine Coolant Refill Tool

#J-45695 to fill the radiator, then proceed with step 3 on page 8.

NOTE: Refer to NTB02-011a for Engine Coolant Refill Tool #J-45695 information.

Radiator

filler neck

Front

Funnel-type

coolant refill

"bleed" tool

TP020205

7/11

2. Slowly fill the radiator and reservoir tank to the specified level (see Figure 4).

Make sure to use a 50/50 coolant mixture.

Pour coolant into radiator filler neck slowly (less than 3 liters3 1/8 quarts per

minute) to allow air in the cooling system to escape.

Gently squeeze the upper radiator hose while filling. This will help purge air from

the system.

Continue to fill until the coolant level stays up at the top of the radiator filler neck.

Figure 4

NOTE:

Use Genuine Nissan Anti-freeze Coolant, mixed 50/50 with distilled water or de-

mineralized water.

Refer to the MA section of the applicable Service Manual (ESM) under

Recommended Fluids and Lubricants for additional information.

Engine coolant capacity (without reservoir tank) is:

7.5 liters (7 7/8 quarts) for vehicles equipped with the 4-cylinder engine (QR25DE)

8.1 liters (8 5/8 quarts) for vehicles equipped with the 6-cylinder engine (VQ35DE)

Reservoir tank capacity is:

0.7 liters (3/4 quart) for both the QR25DE and VQ35DE engines

MAX.

MIN.

Radiator

Coolant level

Coolant filler neck

Overflow

port

RESERVOIR

TP020162

8/11

3. Install a wire under the radiator cap pressure valve to allow air and coolant to flow

through freely (see Figure 5).

NOTE: Make sure the wire you install is at least 2 mm [0.079 in] in diameter. A

wire less than 2 mm in diameter will not allow air to escape quickly and will not

bleed the cooling system properly. Do not use a paper clip or other thin wire for

this operation.

Figure 5

4. After installing the wire in the radiator cap, install the cap on the radiator

5. Disconnect the coolant reservoir hose from the radiator filler neck overflow port.

6. Make a coolant system bleed tool as follows:

a. Obtain a one-gallon plastic bottle (e.g., empty windshield washer fluid bottle, etc.).

NOTE: If available, you can use an old coolant overflow reservoir bottle, as long as

the drain is at the bottom of the bottle.

b. Obtain a length (approximately 3 feet) of rubber hose that will fit onto the radiator

filler neck overflow port.

c. Cut a hole in the bottom of the plastic bottle that is smaller in diameter than the

outside diameter of the rubber hose. It has to seal.

d. Insert the rubber hose into the hole in the bottom of the plastic bottle. There should

be a tight fit (interference fit) between the hose and bottle hole that will prevent

leakage.

e. Connect the other end of the hose to the radiator filler neck overflow port.

7. Fill the modified one-gallon bottle to about full with a 50/50 coolant mixture.

9/11

8. Hang the bottle from the hood latch (see Figure 6).

WARNING: Make sure the hood is properly supported to hold the additional weight of

the bottle filled with coolant mixture.

Figure 6

9. Set the heater controls as follows:

Vehicles with Manual A/C:

A/C off.

Temperature set to full HOT

Mode control set to Floor/Defrost

Fan speed set to HIGH

Vehicles with Automatic A/C:

Temperature set to 90F (30C)

Fan speed set to HIGH

10. Make sure the transmission is in the Park (P) position (for automatic transmission) or

the Neutral (N) position (for manual transmission).

11. Firmly apply the parking brake and place blocks in front of and behind the rear wheels.

12. Raise the front of the vehicle

The bottom of the front bumper fascia needs to be approximately 22 inches (558

mm) from the ground.

This will help air bubbles (that may be caught in the cooling system) to escape.

10/11

13. Run the engine at 1,500 RPM (occasionally revving the engine).

Make sure the coolant level in the plastic bottle does not drop below of the

bottles capacity.

Keep the engine running until the cooling fans turn on (approximately 20 25

minutes), and

Make sure that no more bubbles are seen in the bleed tool (bottle).

To help dislodge air bubbles, gently squeeze the upper radiator hose a few times

while the engine is running.

CAUTION: Watch the coolant temperature gauge to make sure the engine does

not overheat.

14. Shut OFF the engine and allow it to cool to less than approximately 122F (50C).

To reduce the amount of cool-down time, use a fan to blow air across the radiator.

Finish the Coolant Re-filling Procedure as Follows:

15. Crimp the bleed tool hose near the radiator and disconnect it from the filler neck

overflow port

The bleed tool (bottle and hose) will no longer be needed.

16. Carefully remove the radiator cap.

WARNING: Use extreme caution when removing the radiator cap.

17. Reconnect the coolant reservoir hose to the radiator filler neck overflow port.

Confirm the reservoir tank is filled to the MAX level line with the specified coolant

mixture (see Figure 4 on page 7).

Then re-install the reservoir cap.

18. Fill the radiator with the specified coolant mixture to the top of the filler neck (see

Figure 4 on page 7).

11/11

19. Remove the wire from the radiator cap (see Figure 7).

Figure 7

20. Install the radiator cap on the radiator, making sure it is turned to the fully locked

position.

21. Clean/remove excess coolant from the engine and engine compartment.

22. Run the engine and check the cooling system for leaks.

Potrebbero piacerti anche

- Service Bulletin: WarningDocumento11 pagineService Bulletin: Warningninzau100% (1)

- 04 2429GDocumento11 pagine04 2429Gzanella159051Nessuna valutazione finora

- FOCUS Overheating IssueDocumento5 pagineFOCUS Overheating Issueio100% (2)

- Caminhão Spartan - Cooling SystemDocumento17 pagineCaminhão Spartan - Cooling SystemO mecanicoNessuna valutazione finora

- Service - Service Manual Code 950 - 994 - 653 (1) Kubota V2203Documento30 pagineService - Service Manual Code 950 - 994 - 653 (1) Kubota V2203ynadeem100% (4)

- System Pendingin Mesin Aerio Next G Dan Cara Kuras RadiatorDocumento74 pagineSystem Pendingin Mesin Aerio Next G Dan Cara Kuras RadiatorGatotGtToroNessuna valutazione finora

- Engine Cooling System: 1988 Toyota CelicaDocumento12 pagineEngine Cooling System: 1988 Toyota CelicaToua YajNessuna valutazione finora

- 3306 Cylinder Head To Block Joint Repair Procedure (1124, 1101, 1201)Documento24 pagine3306 Cylinder Head To Block Joint Repair Procedure (1124, 1101, 1201)Nick Ildefonso Fuenmayor AntunezNessuna valutazione finora

- Cooling System - Test: SMCS - 1350-040 1350-081Documento14 pagineCooling System - Test: SMCS - 1350-040 1350-081anon_909514915Nessuna valutazione finora

- Cooling System: Systems OperationDocumento6 pagineCooling System: Systems OperationRichard ChuaNessuna valutazione finora

- NTB02 011aDocumento3 pagineNTB02 011aPMNessuna valutazione finora

- Hydroconstant-VariableSpeedDrivesDocumento16 pagineHydroconstant-VariableSpeedDrivesJohn Jairo HoNessuna valutazione finora

- Cooling System Draining and Filling: Glycol UsageDocumento10 pagineCooling System Draining and Filling: Glycol UsageluckinsideNessuna valutazione finora

- Application Bulletin 140Documento12 pagineApplication Bulletin 140Maria DazaNessuna valutazione finora

- Service - Service Manual Code 950 - 994 - 653Documento30 pagineService - Service Manual Code 950 - 994 - 653Victor UribeNessuna valutazione finora

- Cooling System - Test: Testing and AdjustingDocumento11 pagineCooling System - Test: Testing and AdjustingMbahdiro KolenxNessuna valutazione finora

- Water Temperature Regulators (Thermostats) : ReplaceDocumento5 pagineWater Temperature Regulators (Thermostats) : ReplacePedro SchembriNessuna valutazione finora

- Whirpool - 6LBR5132EQ - Manual Servicio PDFDocumento31 pagineWhirpool - 6LBR5132EQ - Manual Servicio PDFAldo TonatoNessuna valutazione finora

- Radiator FlushDocumento7 pagineRadiator FlushmichaelguzziNessuna valutazione finora

- Accent Cooling SystemDocumento14 pagineAccent Cooling Systemflash_24014910Nessuna valutazione finora

- Group 3 Tests and Adjustments: 1 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyDocumento7 pagineGroup 3 Tests and Adjustments: 1 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyPriscila RodriguesNessuna valutazione finora

- d8k Tractor - Power Shift - 66v00001-02084 (Machine) (Hebp1007 - 01) - Sistemas y ComponentesDocumento5 pagined8k Tractor - Power Shift - 66v00001-02084 (Machine) (Hebp1007 - 01) - Sistemas y ComponentesJose MontalvoNessuna valutazione finora

- Manual of 06naDocumento35 pagineManual of 06naKannan Krishnamoorthy100% (8)

- C15 Cooling System OperationDocumento4 pagineC15 Cooling System OperationTakaNessuna valutazione finora

- Cooling System Loader 988GDocumento4 pagineCooling System Loader 988Gpurwa cuteNessuna valutazione finora

- Cooling System - Test: Testing and AdjustingDocumento8 pagineCooling System - Test: Testing and Adjustingsklm123Nessuna valutazione finora

- Air Dryer Manual - 2Documento20 pagineAir Dryer Manual - 2Khasan MuntahaNessuna valutazione finora

- Cooling SystemDocumento6 pagineCooling SystemIsd ServiceNessuna valutazione finora

- Saej 1436 V 002Documento11 pagineSaej 1436 V 002Arun Mangal PandeyNessuna valutazione finora

- 345S Operators Manual: 511bailey Ave PO Box 324 New Hampton, IA 50659 Fax: 1-641-394-6224Documento9 pagine345S Operators Manual: 511bailey Ave PO Box 324 New Hampton, IA 50659 Fax: 1-641-394-6224valangelofNessuna valutazione finora

- Dahatsu Terios CODocumento19 pagineDahatsu Terios COJose M Chire0% (2)

- 2AZ FE CoolingDocumento35 pagine2AZ FE CoolingLuks Fernandez50% (2)

- AC Servicing Guide enDocumento22 pagineAC Servicing Guide enaiigee100% (1)

- Pffy p20 40vkm e SM (Oc404reva)Documento32 paginePffy p20 40vkm e SM (Oc404reva)CallGRNessuna valutazione finora

- Copeland Zr90 300Documento21 pagineCopeland Zr90 300Wilson Javier CubaNessuna valutazione finora

- 2GR FE CoolingDocumento36 pagine2GR FE CoolingLuks FernandezNessuna valutazione finora

- 3126 Air in FuelDocumento4 pagine3126 Air in FuelArnon Rutsalam50% (2)

- GROUP 540 Air Intake System Air Intake System: Fig. 1. Air Cleaner AssemblyDocumento6 pagineGROUP 540 Air Intake System Air Intake System: Fig. 1. Air Cleaner AssemblyDeepti KanadeNessuna valutazione finora

- Cooling System: Shutdown SIS Previous ScreenDocumento10 pagineCooling System: Shutdown SIS Previous ScreenMiharb FinouakefNessuna valutazione finora

- General Information: Engine CoolingDocumento13 pagineGeneral Information: Engine Coolinganonymous2abcNessuna valutazione finora

- Aftercooler - Test: Testing and AdjustingDocumento6 pagineAftercooler - Test: Testing and AdjustingAbdoulaye Boua BERTHENessuna valutazione finora

- 1995 Toyota Camry Cooling System Technical ManualDocumento30 pagine1995 Toyota Camry Cooling System Technical ManualKevin Reilly100% (1)

- 3406C+Industrial+Engines Maintenance+IntervalsDocumento32 pagine3406C+Industrial+Engines Maintenance+Intervalsfoxtrot12100% (1)

- Cooling System Coolant (ELC) ChangeDocumento4 pagineCooling System Coolant (ELC) ChangeAgungNessuna valutazione finora

- Flujo Aceite CajaDocumento4 pagineFlujo Aceite CajaAlirio VilchezNessuna valutazione finora

- ER 58.11startup ProcedureDocumento3 pagineER 58.11startup Proceduredongosuperstar100% (2)

- Daewoo Engine D1146-T-TI Shop ManualDocumento108 pagineDaewoo Engine D1146-T-TI Shop ManualSilas F Pimenta100% (10)

- Know Your Cooling SystemDocumento115 pagineKnow Your Cooling SystemDeividas BNessuna valutazione finora

- Eco İng.a5Documento35 pagineEco İng.a5Edgar Nicolás Paricela VergarayNessuna valutazione finora

- Maintenance Préventive Du SULLAIR 260Documento17 pagineMaintenance Préventive Du SULLAIR 260MMF PLUSNessuna valutazione finora

- 4.3L GM Gas Engine Parts Manual PN 0D3749Documento28 pagine4.3L GM Gas Engine Parts Manual PN 0D3749Da GuruNessuna valutazione finora

- Cooling Fan Motor, Charge Air Cooler, Checking/adjusting High RPMDocumento6 pagineCooling Fan Motor, Charge Air Cooler, Checking/adjusting High RPMAli KuncoroNessuna valutazione finora

- Subaru CoolantDocumento2 pagineSubaru CoolantJames ParkNessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Da EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Valutazione: 3.5 su 5 stelle3.5/5 (3)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDa EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNessuna valutazione finora

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDa EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNessuna valutazione finora

- High-Performance Automotive Cooling SystemsDa EverandHigh-Performance Automotive Cooling SystemsValutazione: 4.5 su 5 stelle4.5/5 (2)

- FusionModule800 Smart Small Data Center V100R001 Hardware Installation Standard Operation Guide (SOP)Documento107 pagineFusionModule800 Smart Small Data Center V100R001 Hardware Installation Standard Operation Guide (SOP)Daniel100% (1)

- Flat Slab BW 2Documento14 pagineFlat Slab BW 2Kuladeep YalamanchiliNessuna valutazione finora

- 1482407553balmerol Ropelube 1000 PdsDocumento2 pagine1482407553balmerol Ropelube 1000 PdsKapil GoyalNessuna valutazione finora

- MS 01 182Documento5 pagineMS 01 182kicsnerNessuna valutazione finora

- The CH2 Building (Melbourne, Australia)Documento8 pagineThe CH2 Building (Melbourne, Australia)Blessing Mukome100% (2)

- Bikesport Micro-Camper PDFDocumento15 pagineBikesport Micro-Camper PDFviocons72Nessuna valutazione finora

- TDS - Plastistrength 770 - ArkemaDocumento2 pagineTDS - Plastistrength 770 - ArkemaOscar Jimenez GonzalezNessuna valutazione finora

- MOS Unit 1-Model QuestionsDocumento11 pagineMOS Unit 1-Model QuestionsBhuvan RockNessuna valutazione finora

- Types of StairsDocumento12 pagineTypes of Stairsfaris danial100% (1)

- Loads On Structures (Case of Two-Way Slabs) : Preliminary DesignDocumento5 pagineLoads On Structures (Case of Two-Way Slabs) : Preliminary DesignMrAlittle Finger100% (1)

- Civil Engineering ProjectDocumento73 pagineCivil Engineering Projectmasihuzzamana100% (1)

- ChatGPT Thermal Mass Role in Enhancing The Energy EfficiencyDocumento2 pagineChatGPT Thermal Mass Role in Enhancing The Energy EfficiencyPanos PanagiotopoulosNessuna valutazione finora

- TC 5 - Earthing and Surge Protection DevicesDocumento71 pagineTC 5 - Earthing and Surge Protection DevicesSHREENIDHI SHARMANessuna valutazione finora

- EE4533 Part II2021Documento100 pagineEE4533 Part II2021Daniel ChaiNessuna valutazione finora

- Asdfasr 2 Q 4235Documento3 pagineAsdfasr 2 Q 4235Claire BernardNessuna valutazione finora

- 5.3. Bearing Capacity of MAT FoundationsDocumento15 pagine5.3. Bearing Capacity of MAT Foundationsnurul100% (1)

- BROAN HD997I Notice Mode Emploi Guide ManuelDocumento24 pagineBROAN HD997I Notice Mode Emploi Guide ManuelbobmoranefrNessuna valutazione finora

- Rme Pec Module 3 - Sept 2015Documento2 pagineRme Pec Module 3 - Sept 2015Bianca SañezNessuna valutazione finora

- Input Datas: N/mm2 N/mm2 DEG KN/m3 KN/m2 DEGDocumento117 pagineInput Datas: N/mm2 N/mm2 DEG KN/m3 KN/m2 DEGradhi_rads89Nessuna valutazione finora

- Superimposed, Reinforced, Built-Up Timber BeamsDocumento16 pagineSuperimposed, Reinforced, Built-Up Timber Beamsmnmusor0% (1)

- CamisaDocumento2 pagineCamisaJuan Roberto López BetanzosNessuna valutazione finora

- Swaner Eco CenterDocumento5 pagineSwaner Eco CenterSteph CrabtreeNessuna valutazione finora

- HIU Brochure - G3 G4 Eco - June 11Documento20 pagineHIU Brochure - G3 G4 Eco - June 11dejanoski_aNessuna valutazione finora

- Celosia Anti RetornoDocumento4 pagineCelosia Anti RetornoEsteban San Martín MaulénNessuna valutazione finora

- NASA/Army Rotorcraft Technology: NI/SIDocumento594 pagineNASA/Army Rotorcraft Technology: NI/SI雷黎明Nessuna valutazione finora

- History of Strength of MaterialsDocumento2 pagineHistory of Strength of MaterialsAshwani Goel100% (1)

- Week 1 Wires and CablesDocumento22 pagineWeek 1 Wires and CablesCourei-FxAlcazarNessuna valutazione finora

- VavDocumento228 pagineVavWJHYYHNessuna valutazione finora

- 2.0 Basic Concepts On ThermodynamicsDocumento17 pagine2.0 Basic Concepts On ThermodynamicsLeo JohnNessuna valutazione finora

- Iqwq-ce1092-Qpqac-00-0001 - 0 -Quality Control Procedure for Civil 土建质量控制程序Documento37 pagineIqwq-ce1092-Qpqac-00-0001 - 0 -Quality Control Procedure for Civil 土建质量控制程序Ali MajeedNessuna valutazione finora