Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Engine Pressure Sensor Open or Short PDF

Caricato da

NydRomGDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Engine Pressure Sensor Open or Short PDF

Caricato da

NydRomGCopyright:

Formati disponibili

Shutdown SIS

Previous Screen

Welcome: r080nr1

Product: WHEEL LOADER

Model: 966H WHEEL LOADER A6D

Configuration: 966H Wheel Loader A6D00001-UP (MACHINE) POWERED BY C11 Engine

Troubleshooting

C11 and C13 Engines for Caterpillar Built Machines

Media Number -RENR9318-11 Publication Date -01/12/2013 Date Updated -12/12/2013

i02402329

Engine Pressure Sensor Open or Short Circuit - Test

SMCS - 1439-038-PX

System Operation Description:

Use this procedure to troubleshoot any suspect problems with the following sensors:

Fuel pressure sensor

Engine oil pressure sensor

Atmospheric pressure sensor

Right turbo inlet pressure sensor

Intake manifold pressure sensor

Use this procedure to troubleshoot the system when one of the following diagnostic codes is active or

easily repeated:

94-03 Fuel Pressure open/short to +batt

94-04 Fuel Pressure short to ground

100-03 Engine Oil Pressure open/short to +batt

100-04 Engine Oil Pressure short to ground

274-03 Atmospheric Pressure open/short to +batt

274-04 Atmospheric Pressure short to ground

Pgina 1 de 14 966H Wheel Loader A6D00001-UP (MACHINE) POWERED BY C11 Engine(SEBP3...

03/03/2014 https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw...

275-03 Right Turbo Inlet Pressure open/short to +batt

275-04 Right Turbo Inlet Pressure short to ground

1785-03 Intake Manifold Pressure Sensor voltage high

1785-04 Intake Manifold Pressure Sensor voltage low

The 5 volt sensor supply provides power to all 5 volt sensors. The Electronic Control Module (ECM)

supplies 5.0 0.2 VDC to terminal A of each sensor connector. The sensor return from the ECM

connector goes to terminal B of each sensor connector. The sensor supply is output short circuit

protected. A short circuit to the battery will not damage the circuit inside the ECM.

Pull-up Voltage

The ECM continuously outputs a pull-up voltage on the circuit for the sensor signal wire. The ECM

uses this pull-up voltage in order to detect a problem in the signal circuit. When the ECM detects the

presence of a voltage that is above a threshold on the signal circuit, the ECMwill generate a 03

diagnostic code for the sensor.

If the sensor is disconnected at the sensor connector, the presence of pull-up voltage at the sensor

connector indicates that the wires from the sensor connector to the ECMare OK. If the sensor is

disconnected at the sensor connector, the absence of pull-up voltage at the sensor connector indicates

a problem in the signal wire. If the sensor is disconnected at the sensor connector and the voltage at

the sensor connector is different from pull-up voltage, the signal wire may be shorted to another wire

in the harness.

Pgina 2 de 14 966H Wheel Loader A6D00001-UP (MACHINE) POWERED BY C11 Engine(SEBP3...

03/03/2014 https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw...

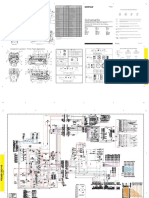

Illustration 1 g01203122

Schematic for the engine pressure sensors

Test Step 1. Inspect the Electrical Connectors and the Wiring

Remove electrical power from the engine ECM. A.

Pgina 3 de 14 966H Wheel Loader A6D00001-UP (MACHINE) POWERED BY C11 Engine(SEBP3...

03/03/2014 https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw...

Illustration 2 g01200216

Locations of the pressure sensors (typical left side engine view)

(1) Atmospheric pressure sensor

(2) Fuel pressure sensor

(3) Intake manifold pressure sensor

(4) Engine oil pressure sensor

(5) J2/P2 ECM connectors

(6) J1/P1 ECM connectors

Pgina 4 de 14 966H Wheel Loader A6D00001-UP (MACHINE) POWERED BY C11 Engine(SEBP3...

03/03/2014 https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw...

Illustration 3 g01142856

Air filter assembly

(7) Right turbo inlet pressure sensor

Thoroughly inspect connector (5) and (6). Also, thoroughly inspect the connectors for sensors

(1), (2), (3), (4) and (7). Refer to Troubleshooting, "Electrical Connectors - Inspect" for details.

B.

Pgina 5 de 14 966H Wheel Loader A6D00001-UP (MACHINE) POWERED BY C11 Engine(SEBP3...

03/03/2014 https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw...

Pgina 6 de 14 966H Wheel Loader A6D00001-UP (MACHINE) POWERED BY C11 Engine(SEBP3...

03/03/2014 https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw...

Illustration 4 g01024457

P2 ECM connector

(P2-15) Intake manifold pressure sensor

(P2-17) Sensor return

(P2-28) Engine oil pressure sensor

(P2-40) Fuel pressure sensor

(P2-57) Atmospheric pressure sensor

(P2-72) Sensor supply

Pgina 7 de 14 966H Wheel Loader A6D00001-UP (MACHINE) POWERED BY C11 Engine(SEBP3...

03/03/2014 https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw...

Illustration 5 g01145897

P1 ECM connector

(P1-2) Sensor supply

(P1-3) Sensor return

Pgina 8 de 14 966H Wheel Loader A6D00001-UP (MACHINE) POWERED BY C11 Engine(SEBP3...

03/03/2014 https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw...

(P1-15) Right turbo inlet pressure sensor

Illustration 6 g01159881

Sensor connector

(A) Sensor supply

(B) Sensor return

(C) Signal

Perform a 45 N (10 lb) pull test on each of the wires in the ECM connector and on each of the

wires in the pressure sensor connectors.

C.

Check the allen head screw for each of the ECM connectors and the machine connectors for the

proper torque. Refer to Troubleshooting, "Electrical Connectors - Inspect" for the correct torque

values.

D.

Check the harness and wiring for abrasions and for pinch points from each of the pressure

sensors back to the ECM.

E.

Expected Result:

All connectors, pins, and sockets are completely coupled and/or inserted. The harness and wiring are

free of corrosion, of abrasion, and of pinch points.

Results:

OK - The harness and wiring appear to be OK. Proceed to Test Step 2.

Pgina 9 de 14 966H Wheel Loader A6D00001-UP (MACHINE) POWERED BY C11 Engine(SEBP3...

03/03/2014 https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw...

Not OK - There is a problem in the connectors and/or wiring.

Repair: Repair the connectors or wiring and/or replace the connectors or wiring. Ensure that all

of the seals for each of the connectors are properly in place and ensure that the connectors are

completely coupled. Verify that the repair eliminates the problem.

STOP

Test Step 2. Check the Supply Voltage at the Sensor Connector

Remove electrical power from the engine ECM. A.

Disconnect the harness connectors for the following sensors: B.

Fuel pressure sensor

Engine oil pressure sensor

Intake manifold pressure sensor

Atmospheric pressure sensor

Right turbo inlet pressure sensor

Restore electrical power to the engine ECM. C.

Note: The original diagnostic code may not stay active. An open circuit diagnostic code for the

sensor supply may become active when all of the sensors are disconnected. Ignore the active

codes at this time and continue with this test step.

Note: Be sure to wiggle the harness during the following measurements in order to reveal an

intermittent condition.

Measure the voltage between terminals A and B at each sensor connector on the engine harness. D.

Remove electrical power from the engine ECM. E.

Connect all of the sensors. F.

Expected Result:

Each voltage measurement is 5.0 0.2 VDC.

Results:

OK - Each voltage measurement is 5.0 0.2 VDC. The voltage is correct at the sensor

connectors. Proceed to Test Step 3.

Not OK - The voltage is not 5.0 0.2 VDC. The voltage is incorrect.

Repair: Perform the diagnostic functional test Troubleshooting, "5 Volt Engine Pressure

Sensor Supply Circuit - Test".

Pgina 10 de 14 966H Wheel Loader A6D00001-UP (MACHINE) POWERED BY C11 Engine(SEB...

03/03/2014 https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw...

STOP

Test Step 3. Check for Active Diagnostic Codes

Connect Caterpillar Electronic Technician (ET) to the service tool connector. A.

Restore electrical power to the engine ECM. B.

Note: Wait at least 30 seconds so that any codes may become active.

Monitor the active diagnostic code screen on Cat ET. Look for an active diagnostic code for an

engine pressure sensor.

C.

Determine if the problem is related to an open circuit diagnostic code 03 or a short circuit

diagnostic code 04.

D.

Expected Result:

No diagnostic codes are active.

Results:

OK - No diagnostic codes are active for the engine pressure sensors.

Repair: The problem may have been related to a faulty connection in the harness. Carefully

reinspect the connectors and wiring. Refer to Troubleshooting, "Electrical Connectors -

Inspect".

STOP

Not OK - A 03 diagnostic code is active at this time. Proceed to Test Step 5.

Not OK - A 04 diagnostic code is active at this time. Proceed to Test Step 4.

Test Step 4. Disconnect the Suspect Sensor in Order to Create an Open Circuit

Remove electrical power from the ECM. A.

Disconnect the harness connector of the sensor with the 04 diagnostic code. B.

Restore electrical power to the ECM. C.

Use Cat ET to check for active diagnostic codes. Wait at least 30 seconds for activation of the

diagnostic codes. Check for an active 03 diagnostic code for the disconnected sensor.

D.

Remove electrical power from the ECM. E.

Expected Result:

A 04 diagnostic code was active before the sensor was disconnected. A 03 diagnostic code became

active after the sensor was disconnected.

Results:

Pgina 11 de 14 966H Wheel Loader A6D00001-UP (MACHINE) POWERED BY C11 Engine(SEB...

03/03/2014 https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw...

OK - A 04 diagnostic code was active before the sensor was disconnected. A 03 diagnostic

code became active after the sensor was disconnected.

Repair: Temporarily connect a new sensor to the harness, but do not install the new sensor in

the engine. Verify that there are no active diagnostic codes for the sensor. If there are no active

diagnostic codes for the sensor, permanently install the new sensor. Clear any logged diagnostic

codes.

STOP

Not OK - When the sensor is disconnected, a 04 diagnostic code remains active for the suspect

sensor. There is a short circuit between the sensor harness connector and the ECM. Leave the

sensor disconnected. Proceed to Test Step 6.

Test Step 5. Create a Short at the Suspect Sensor Connector

Remove electrical power from the engine ECM. A.

Fabricate a jumper wire that is long enough to connect two terminals at the sensor connector.

Crimp connector sockets to each end of the jumper wire.

B.

Install the jumper wire between terminal B (sensor return) and terminal C (sensor signal) on the

harness side of the connector for the suspect sensor.

C.

Restore electrical power to the engine ECM. D.

Note: Wait at least 30 seconds for activation of the diagnostic code.

Monitor the "Active Diagnostic Codes" screen on Cat ET before installing the jumper wire and

after installing the jumper wire.

E.

Check for an active short circuit diagnostic code 04 while the jumper wire is installed.

Remove electrical power from the engine ECM. F.

Remove the jumper wire. G.

Expected Result:

A 04 diagnostic code was active when the jumper wire was installed. A 03 diagnostic code became

active when the jumper wire was removed.

Results:

OK - A 04 diagnostic code was active when the jumper wire was installed. A 03 diagnostic

code became active when the jumper wire was removed.

Repair: The engine harness and the ECM are OK. Temporarily connect a new sensor to the

harness, but do not install the new sensor in the engine. Verify that there are no active

diagnostic codes for the sensor. If there are no active diagnostic codes for the sensor,

permanently install the new sensor. Clear any logged diagnostic codes.

STOP

Pgina 12 de 14 966H Wheel Loader A6D00001-UP (MACHINE) POWERED BY C11 Engine(SEB...

03/03/2014 https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw...

Not OK - The 03 diagnostic code remains active with the jumper in place. There is a problem

in the circuit between the ECM and the sensor connector. There may be a problem with the

ECM. Proceed to Test Step 6.

Test Step 6. Test the Operation of the ECM

Remove electrical power from the engine ECM. A.

Fabricate a jumper wire that is long enough to connect one of the terminals at the ECM

connector to the engine ground stud. Crimp a connector socket to one end of the jumper wire.

B.

Disconnect the appropriate ECMconnector for the signal wire of the suspect sensor. C.

Remove the signal wire for the suspect sensor from the ECMconnector. D.

Install the jumper wire into the terminal location of the suspect sensor's signal wire at the ECM

connector.

E.

Connect the ECMconnectors. F.

Check the operation of the ECM by creating an open at the ECM: G.

Hold the loose end of the jumper wire away from any components in order to create an

open circuit condition.

a.

Restore electrical power to the engine ECM. b.

Note: Wait at least 30 seconds so that any codes may become active.

Monitor the "Active Diagnostic Code" screen on Cat ET. c.

Check the suspect sensor for an active 03 diagnostic code.

Remove electrical power from the engine ECM. d.

Check the operation of the ECM by creating a short circuit at the ECM: H.

Connect the jumper wire to the engine ground stud. a.

Restore electrical power to the engine ECM. b.

Note: Wait at least 30 seconds so that any codes may become active.

Monitor the "Active Diagnostic Code" screen on Cat ET. c.

Check the suspect sensor for an active 04 diagnostic code while the jumper wire is

installed.

d.

Remove electrical power from the engine ECM. e.

Remove the jumper wire. Return all wiring to the original configuration. I.

Expected Result:

Pgina 13 de 14 966H Wheel Loader A6D00001-UP (MACHINE) POWERED BY C11 Engine(SEB...

03/03/2014 https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw...

A 03 diagnostic code is active when the sensor signal wire is removed from the ECM connector. A 04

diagnostic code is active when the signal wire is connected to the engine ground stud.

Results:

OK - A 03 diagnostic code is active when the sensor signal wire is removed from the ECM

connector. A 04 diagnostic code is active when the signal wire is connected to the engine

ground stud.

Repair: The ECM is operating properly. The problem is in the harness wiring between the

ECM and the sensor connector. If the code is active for more than one sensor, the problem is

most likely in the return wire for the sensor. Repair the return wire for the sensor or replace the

harness.If the code is only active for one sensor, the problem is most likely in the signal wire

for the sensor. Repair the signal wire for the sensor.

STOP

Not OK - One of the following conditions exists: The 03 diagnostic code is not active when the

sensor signal wire is disconnected. The 04 diagnostic code is not active when the wire jumper is

installed.

Repair: Replace the ECM. Refer to Troubleshooting, "Replacing the ECM". Verify that the

problem is resolved.

STOP

Copyright 1993 - 2014 Caterpillar Inc.

All Rights Reserved.

Private Network For SIS Licensees.

Mon Mar 3 17:37:40 EST 2014

r080nr1

Pgina 14 de 14 966H Wheel Loader A6D00001-UP (MACHINE) POWERED BY C11 Engine(SEB...

03/03/2014 https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw...

Potrebbero piacerti anche

- 5 Volt Engine Pressure Sensor Supply Circuit - TestDocumento8 pagine5 Volt Engine Pressure Sensor Supply Circuit - TestGustavo GarzaNessuna valutazione finora

- Speed Control (Switch) - Test (RENR5096)Documento4 pagineSpeed Control (Switch) - Test (RENR5096)Josip MiškovićNessuna valutazione finora

- 5 Volt Engine Pressure Sensor Supply Circuit - TestDocumento12 pagine5 Volt Engine Pressure Sensor Supply Circuit - TestMartin Carhuaz Acuna100% (1)

- Injector Solenoid Circuit - Test (RENR5096)Documento7 pagineInjector Solenoid Circuit - Test (RENR5096)Josip MiškovićNessuna valutazione finora

- Sensores 3500B EUIDocumento32 pagineSensores 3500B EUICesar Ego-Aguirre Calderon100% (3)

- CAT - 3516H Engine Cranks But Does Not StartDocumento4 pagineCAT - 3516H Engine Cranks But Does Not Startwagner_guimarães_1100% (1)

- Enine Timing Clibration Engine Speed Timing Sensor Calibrate RENR9319Documento8 pagineEnine Timing Clibration Engine Speed Timing Sensor Calibrate RENR9319Khaled Kamel100% (2)

- C11 Valves and InjDocumento7 pagineC11 Valves and Injraymon1191Nessuna valutazione finora

- Fuel Pump Timing TipsDocumento2 pagineFuel Pump Timing Tips032359rwNessuna valutazione finora

- C15 Fuel System OperationDocumento7 pagineC15 Fuel System OperationTaka100% (1)

- CAT - G3516H Oil Pressure Is Low PDFDocumento5 pagineCAT - G3516H Oil Pressure Is Low PDFwagner_guimarães_1Nessuna valutazione finora

- CAT - 3516H Coolant Temperature Is HighDocumento5 pagineCAT - 3516H Coolant Temperature Is Highwagner_guimarães_1Nessuna valutazione finora

- Fuel System: Systems OperationDocumento11 pagineFuel System: Systems OperationNy Romero100% (2)

- Valve Lash - AdjustDocumento4 pagineValve Lash - AdjustHugo Cipriani100% (1)

- 3500C Timing CalibrationDocumento2 pagine3500C Timing Calibrationharikrishnanpd3327100% (1)

- Cylinder Cutout TestDocumento3 pagineCylinder Cutout TestPILAR MARTINEZ100% (1)

- C32 MOTOR CAT Electronic Unit Injector - TestDocumento2 pagineC32 MOTOR CAT Electronic Unit Injector - TestFreddy Villegas100% (1)

- 3500 Event Code ListDocumento10 pagine3500 Event Code Listharikrishnanpd3327Nessuna valutazione finora

- 3500 Engine Controls - Electronic Unit Injection (Slides) PDFDocumento101 pagine3500 Engine Controls - Electronic Unit Injection (Slides) PDFSaul Leonidas Astocaza Antonio100% (12)

- Troubleshooting Fuel Dilution of Engine Oil PDFDocumento2 pagineTroubleshooting Fuel Dilution of Engine Oil PDFmanu luvungaNessuna valutazione finora

- Caterpillar C9 Engine SpecsDocumento3 pagineCaterpillar C9 Engine SpecsIvan Aditya100% (1)

- Engine Monitoring System Display Overview: Información de Servicio GeneralDocumento17 pagineEngine Monitoring System Display Overview: Información de Servicio GeneralmanuelNessuna valutazione finora

- Engine Speed - Test SMCS-1907-038 - I02637941Documento9 pagineEngine Speed - Test SMCS-1907-038 - I02637941EstoqueNessuna valutazione finora

- 05 EUI Engine ControlDocumento96 pagine05 EUI Engine ControlHải Lưu MinhNessuna valutazione finora

- 3512C HD Fuel Injector AdjustmentDocumento5 pagine3512C HD Fuel Injector Adjustmentharikrishnanpd3327100% (2)

- Transmission Pressures - Test and AdjustDocumento8 pagineTransmission Pressures - Test and Adjustjuankielec100% (3)

- Troubleshooting Cat PDFDocumento215 pagineTroubleshooting Cat PDFmisaelandres1100% (3)

- Herramienta Cat ET CaterpillarDocumento44 pagineHerramienta Cat ET Caterpillarramiro rodriguez100% (2)

- 1.troubleshoot Engine Crank But Cant StartDocumento3 pagine1.troubleshoot Engine Crank But Cant StartsyahrilNessuna valutazione finora

- Engine Monitoring System (G3516B)Documento9 pagineEngine Monitoring System (G3516B)victor.cipriani100% (2)

- Engine Oil Pressure - Test 966H - 01Documento7 pagineEngine Oil Pressure - Test 966H - 01Freddy QuispeNessuna valutazione finora

- 3500 Series Engines Hydramechanical Protective SystemDocumento18 pagine3500 Series Engines Hydramechanical Protective SystemEbied Yousif AlyNessuna valutazione finora

- Air Fuel Ratio ControlDocumento6 pagineAir Fuel Ratio Controlmiguel oswaldo gonzalez benitezNessuna valutazione finora

- Schematic - 131675901 3512 Electronico PDFDocumento2 pagineSchematic - 131675901 3512 Electronico PDFkhanghanh2017 a0% (1)

- REHS1438-09 Installation and Initial Start-Up Procedure For G3500C and G3500E Generator Set Engines PDFDocumento52 pagineREHS1438-09 Installation and Initial Start-Up Procedure For G3500C and G3500E Generator Set Engines PDFvoivod667% (3)

- Testing For Excessive Cylinder Blowby in 3500 EnginesDocumento10 pagineTesting For Excessive Cylinder Blowby in 3500 EnginesPILAR MARTINEZNessuna valutazione finora

- C-15 Electronic Unit Injector - AdjustDocumento4 pagineC-15 Electronic Unit Injector - AdjustCEVegaONessuna valutazione finora

- C13, C15, and C18 Engines Acceleration Is Poor or Throttle ResDocumento4 pagineC13, C15, and C18 Engines Acceleration Is Poor or Throttle ResRaphael ThornerNessuna valutazione finora

- Dynamometer Testing of Caterpillar EnginesDocumento98 pagineDynamometer Testing of Caterpillar EnginesSixto Guarniz Anticona100% (1)

- 3408E/3412E ENGINE CONTROLS: Technical PresentationDocumento168 pagine3408E/3412E ENGINE CONTROLS: Technical PresentationVicTor CarrAnzaa100% (6)

- ET TrainingDocumento10 pagineET TrainingStalin Paul Rodriguez LeonNessuna valutazione finora

- 3500B Gen-Set Eng. TroubleshootingDocumento156 pagine3500B Gen-Set Eng. TroubleshootingNeil Summer100% (12)

- ATA/J1939 Diagnostic Code Quick Reference: Refer To Troubleshooting Manual For Recommended Service ProceduresDocumento9 pagineATA/J1939 Diagnostic Code Quick Reference: Refer To Troubleshooting Manual For Recommended Service ProceduresM. ShaatNessuna valutazione finora

- G3516CDocumento154 pagineG3516Cratheesh50% (2)

- Troubleshooting 3412 4BZ PDFDocumento18 pagineTroubleshooting 3412 4BZ PDFMounir SerguineNessuna valutazione finora

- Cat C7 .Documento4 pagineCat C7 .dionymackNessuna valutazione finora

- 3406E, C12, C15 and C18 Marine Engines CaterpillarDocumento9 pagine3406E, C12, C15 and C18 Marine Engines CaterpillarRakhi Kishore50% (2)

- 3500 Diagnostic Codes ListDocumento11 pagine3500 Diagnostic Codes Listharikrishnanpd3327100% (1)

- Caterpillar - Troubleshooting For c175-16 & c175-20 Engines For Caterpillar Built MachinesDocumento224 pagineCaterpillar - Troubleshooting For c175-16 & c175-20 Engines For Caterpillar Built MachinesRolando Daclan82% (17)

- P-530 G3516BDocumento5 pagineP-530 G3516Bmuhammad arifNessuna valutazione finora

- ElectronicComponent INPUT, OUPUTDocumento48 pagineElectronicComponent INPUT, OUPUTtaller avansys100% (2)

- CAT - 3516H Engine OverspeedsDocumento3 pagineCAT - 3516H Engine Overspeedswagner_guimarães_1Nessuna valutazione finora

- Fuel Rack Solenoid - TestDocumento6 pagineFuel Rack Solenoid - TestAdolfo Dario SaavedraNessuna valutazione finora

- Systems Operation Troubleshooting Testing and Adjusting: Emcp 3Documento148 pagineSystems Operation Troubleshooting Testing and Adjusting: Emcp 3Inot Depression Side93% (14)

- D399 Operation SystemDocumento64 pagineD399 Operation SystemNOUR ZAINNessuna valutazione finora

- Cat 3512B/3516BDocumento2 pagineCat 3512B/3516Bmohammad hazbehzad100% (2)

- Engine Pressure Sensor TestDocumento11 pagineEngine Pressure Sensor Testsamsularief03100% (1)

- 5 Volt Engine Pressure Sensor Supply Circuit - Test: TroubleshootingDocumento7 pagine5 Volt Engine Pressure Sensor Supply Circuit - Test: TroubleshootingsyahrilNessuna valutazione finora

- MID 039 - CID 0544 - FMI 08: TroubleshootingDocumento4 pagineMID 039 - CID 0544 - FMI 08: TroubleshootingNerminTurkenceNessuna valutazione finora

- Diagrama Electrico de Transmcion 160HDocumento4 pagineDiagrama Electrico de Transmcion 160HJuan CarlosNessuna valutazione finora

- 20-F201007-SC-010 R0 - Design Calculation of Foam Tank and Fire Pump ShedDocumento187 pagine20-F201007-SC-010 R0 - Design Calculation of Foam Tank and Fire Pump ShedSaravan KumarNessuna valutazione finora

- Integrating Theory, Experiments, and FEA To Solve Challenging Nonlinear Mechanics ProblemsDocumento17 pagineIntegrating Theory, Experiments, and FEA To Solve Challenging Nonlinear Mechanics ProblemsBodieTechNessuna valutazione finora

- ManualDocumento31 pagineManualextremtigerNessuna valutazione finora

- Question Bank-JavaDocumento3 pagineQuestion Bank-Javarachana saiNessuna valutazione finora

- Tefnol 1Documento11 pagineTefnol 1Moustapha Salem MansourNessuna valutazione finora

- Kluang (A) S2 STPM 2019Documento9 pagineKluang (A) S2 STPM 2019Rex KalNessuna valutazione finora

- S3 3 TrigonometryDocumento81 pagineS3 3 TrigonometryEugene ChoongNessuna valutazione finora

- Degree of Kinematic IndeterminacyDocumento8 pagineDegree of Kinematic IndeterminacyshahrukhNessuna valutazione finora

- Differential EquationDocumento17 pagineDifferential EquationAashika DhareNessuna valutazione finora

- Javascript Date ObjectDocumento5 pagineJavascript Date Objectshivi08Nessuna valutazione finora

- Slides Prepared by John S. Loucks St. Edward's University: 1 Slide © 2003 Thomson/South-WesternDocumento34 pagineSlides Prepared by John S. Loucks St. Edward's University: 1 Slide © 2003 Thomson/South-WesternHRish BhimberNessuna valutazione finora

- Abb Sas GeneralDocumento43 pagineAbb Sas Generalsabill arasyidNessuna valutazione finora

- 07a80809 OperationsresearchDocumento11 pagine07a80809 OperationsresearchSharanya ThirichinapalliNessuna valutazione finora

- Hofman NotesDocumento114 pagineHofman NotesNoelia PizziNessuna valutazione finora

- Method Statement For Fabrication of Concrete StairsDocumento10 pagineMethod Statement For Fabrication of Concrete StairsDenver Vera MendozaNessuna valutazione finora

- Contoh SRSDocumento46 pagineContoh SRSFatur RachmanNessuna valutazione finora

- Amta5 8 Applying Tungsten Inert Gas Tig Welding TechniquesDocumento115 pagineAmta5 8 Applying Tungsten Inert Gas Tig Welding TechniquesAbu RectifyNessuna valutazione finora

- Statics and Mechanics of Materials 3Rd Edition Full ChapterDocumento41 pagineStatics and Mechanics of Materials 3Rd Edition Full Chapterjason.rabil982100% (29)

- Deflection of BeamsDocumento109 pagineDeflection of BeamsNadir Khattak Jr.100% (1)

- Schiotz TonometerDocumento9 pagineSchiotz TonometerDR_LUBYNessuna valutazione finora

- College Level Math Practice TestDocumento17 pagineCollege Level Math Practice TestHarsha Kasaragod100% (1)

- A Deep Dive Into The Latest HPC SoftwareDocumento38 pagineA Deep Dive Into The Latest HPC SoftwareSundar NilNessuna valutazione finora

- MagPi70 PDFDocumento100 pagineMagPi70 PDFDaniel TuarezNessuna valutazione finora

- Shaft Alignment: Your Photo HereDocumento75 pagineShaft Alignment: Your Photo HereMahmoud Elghandour0% (1)

- Delamination With AbaqusDocumento13 pagineDelamination With AbaqusSchmetterling TraurigNessuna valutazione finora

- Vdocuments - MX - Catalogo Maquinas Despiezables de Feedback PDFDocumento4 pagineVdocuments - MX - Catalogo Maquinas Despiezables de Feedback PDFHelder NascimentoNessuna valutazione finora

- "Fabrication of Impact Testing Machine": Diploma in Mechanical Engineering ProgrammeDocumento59 pagine"Fabrication of Impact Testing Machine": Diploma in Mechanical Engineering ProgrammemanjaNessuna valutazione finora

- QuesTeksFerriumC61C64andC6 PDFDocumento23 pagineQuesTeksFerriumC61C64andC6 PDFEmily MillerNessuna valutazione finora

- Whats A Job in Linux: $ Sleep 100 & (1) 1302 $Documento2 pagineWhats A Job in Linux: $ Sleep 100 & (1) 1302 $Viraj BhosaleNessuna valutazione finora

- Vinco Lesson Plan CO2 2022 EditedDocumento8 pagineVinco Lesson Plan CO2 2022 EditedAdrianalover RescofanaticsNessuna valutazione finora