Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Structural Framing Design Appraisal

Caricato da

timsykiDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Structural Framing Design Appraisal

Caricato da

timsykiCopyright:

Formati disponibili

iii

Design Appraisal

Structural Framing

Structural Framing consists of 40mm deep open grating that span onto trimmers (254 x 102 x 28 UB

for the two floors, and 254 x 102 x 22 UB for the roof). Each trimmers span a length of 3350mm and

transfers its load to the main floor Beam B1 and Roof beam B2 (610 x 229 x 113 UB). Some of the

main beam frame into the columns (356 x 406 x 287 UC), while a few other rest on Beam B3 (610 x

309 x 149 UB)., which in turn transfer the beam loads to the columns. Beam B3 is larger than the main

roof beam because of increase moment from the reaction of beams (B1 and B2) acting in between the

columns. In addition, diagonal (all CHS) are used to support axial loads computed from the truss

analysis. Unlike scheme 1, the length of the diagonals here is longer, thus much attention paid to

ensure section chosen do not buckle. A schedule of the members is shown in Table 1.

The main members are designed for in place condition, and checked for other Sea transportation,

lifting and load out. In addition, the trunions that would be used to connected this module to the

existing structure is also designed. 70mm thick Gusset plate with a hole diameter of 402mm to

accommodate the trunnion which is 400mm diameter. In addition, the padeye on the module which

would be lifted are assessed for it suitability. Unlike scheme 1, the padeyes are at a greater spacing of

20m. For this reason, sling length is increased, which implies that more headroom would be required if

the module is to be lifted.

Load Transfer

Load is typically transferred from the floor to the trimmers, and then to the main beams. The beams in

turn transfer their load to the truss columns, and these in turn transfers the load to the module support

which is in this case the trunnions connected to the existing structure.

Wind loading has not been analysed at this conceptual stage mainly because the design is for an open

module. Nevertheless, the structure has the robustness to conveniently support horizontal load as the

maximum wind load if the module is completely enclosed (i.e 1.4-KN/m

2

x 20m x 10m = 280-KN) is

much lower than typically loads designed for in this module.

The roof and the floor construction is provided with 244 x 12.5 CHS horizontal bracing. This provides

lateral support since open floor gratings do not provide lateral restraint. They can also act to resist

wind load.

Stability

The module is provided with vertical and horizontal bracing capable of resisting any destabilizing force

in any of the load condition.

Load Out Condition

Mammoet trailer would be used to load out the module. The floor beams (at level 1) has been

assessed for capacity for reverse bending, and is very fit. Nevertheless, lateral restraints would be

added to the bottom flange to minimize the effect of lateral torsional buckling.

Lift Condition

The module will be lifted by 4 padeyes located at 20,000mm centres. The lift would be done with a

spreader beam. On account of the long distance between padeyes, sling height is increased. This is

not desirable where the hook headroom is limited.

Sea Transportation

The module would be transported on a standard barge to the offshore location where it would be

mount. The module has been checked using roll force (0.7 x gravity)

iv

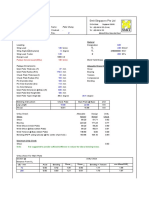

Table 1- Member utilized for Scheme 2

Member Member Description Quantity Length (m) Mass/m (Kg/m) Members Weight

Beam B1 610 x 229 x 113 UB 10 7.00 113 7,910.00

Beam B2 610 x 229 x 113 UB 5 7.00 113 3,955.00

Beam B3 610 x 305 x 149 UB 6 20.00 149.2 17,904.00

Beam B4 610 x 305 x 179 UB 6 7.00 179 7,518.00

Diagonal D1 406 x 16 WT CHS 6 12.04 154 11,124.96

Diagonal D2 406 x 16 WT CHS 2 12.21 154 3,760.68

Diagonal D3

(Horizontal Bracing)

244 x 12.5 WT CHS 9 9.70 71.5 6,241.95

Column C1 356 x 406 x 287 UC 8 10.00 287.1 22,968.00

Floor Trimmers @

1200mm c/c

254 x 102 x 28 UB 10 20.00 28.3 5,660.00

Roof Trimmers @

1200mm c/c

254 x 102 x 22 UB 5 20.00 22 2,200.00

89,242.59 Kg

Table 2- Scheme 1

Beam B1 686 x 254 x 125 UB 6 7 125.2 5,258.40

Beam B2 686 x 254 x 125 UB 3 7 125.2 2,629.20

Beam B3 686 x 254 x 125 UB 6 7 125.2 5,258.40

Beam B4 686 x 254 x 125 UB 6 20 125.2 15,024.00

Diagonal D1 324 x 10 WT CHS 18 7.07 77.4 9,849.92

Diagonal D2 324 x 10 WT CHS 6 8.6 77.4 3,993.84

Diagonal D3

(Horizontal Bracing)

219 x10WT CHS

12 8.6

51.6

5,325.12

Column C1 356 x 368 x 129 UC 10 10 129 12,900.00

Floor Trimmers @

1200mm c/c

305 x 165 x 46 UB 10

20

46.1

9,220.00

Roof Trimmers @

1200mm c/c

305 x 165 x 40 UB 5

20

40.3

4,030.00

73,488.88 Kg

Scheme 2 has estimated structural materials weight of 890-KN compared to Scheme-1 that is

about 730-KN (not including finishing, E+I, welds/bolts equipment; Just main members like beams,

columns and trusses). It is at least 150-KN heavier than Scheme 1.

Detailed calculation are presented in subsequent pages

Potrebbero piacerti anche

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityDa EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNessuna valutazione finora

- 16542Documento7 pagine16542Cnc CamNessuna valutazione finora

- Live Load Distribution Factor CalculationsDocumento5 pagineLive Load Distribution Factor CalculationsBunkun15Nessuna valutazione finora

- Master Series Student InstallationDocumento6 pagineMaster Series Student InstallationekaNessuna valutazione finora

- Facilities On Offshore Installations: Guide For Building and ClassingDocumento209 pagineFacilities On Offshore Installations: Guide For Building and ClassingKarthick VenkatswamyNessuna valutazione finora

- Beam 20031213Documento8 pagineBeam 20031213John AlexanderNessuna valutazione finora

- Composite - Design ProjectDocumento6 pagineComposite - Design ProjectSomen DasNessuna valutazione finora

- USD T BeamDocumento10 pagineUSD T BeammanowarNessuna valutazione finora

- 0488a0vvgc001 06Documento73 pagine0488a0vvgc001 06AlienshowNessuna valutazione finora

- SPACE GASS Revit Structure LinkDocumento6 pagineSPACE GASS Revit Structure LinkozbuildNessuna valutazione finora

- Effect of Carbon Content and Temperature on Fatigue Properties of Steel AlloysDocumento10 pagineEffect of Carbon Content and Temperature on Fatigue Properties of Steel AlloysRizki FebriyantoNessuna valutazione finora

- DNV Os C102Documento133 pagineDNV Os C102Wilson Barreta JuniorNessuna valutazione finora

- Eccentric Column BucklingDocumento10 pagineEccentric Column BucklingMukeshChopraNessuna valutazione finora

- Shear Failure of Bolted Joints Lab ReportDocumento1 paginaShear Failure of Bolted Joints Lab Reportboo huNessuna valutazione finora

- Hydrodynamic Model of The Impact of A Solid On IceDocumento6 pagineHydrodynamic Model of The Impact of A Solid On IceYaoke WenNessuna valutazione finora

- Anchor ForceDocumento14 pagineAnchor ForceAdi Mulyadi100% (1)

- Ansys Analysis-Trolley Beam 3T1Documento13 pagineAnsys Analysis-Trolley Beam 3T1Ye Wint ThuNessuna valutazione finora

- Rules For Classification: ShipsDocumento23 pagineRules For Classification: ShipsMuhammad Nurazim100% (1)

- #160 Lifting Fixture 38tons 020807Documento14 pagine#160 Lifting Fixture 38tons 020807halder_kalyan9216Nessuna valutazione finora

- FOUNDATION ANALYSISDocumento14 pagineFOUNDATION ANALYSISJuli NirwantoNessuna valutazione finora

- GRI DurlonTechnicalHandbookDocumento30 pagineGRI DurlonTechnicalHandbookFrank RamirezNessuna valutazione finora

- Maheswaran Jeron PDFDocumento228 pagineMaheswaran Jeron PDFRohan KarandeNessuna valutazione finora

- CEN301 Steel 03 JLJDocumento62 pagineCEN301 Steel 03 JLJFanisNessuna valutazione finora

- FEA Analysis For Hull MEG Storage Tank T-5601AB - Rev 01Documento52 pagineFEA Analysis For Hull MEG Storage Tank T-5601AB - Rev 01jahiranazriNessuna valutazione finora

- Tolerance Chart: (Maximum Permissible Error)Documento3 pagineTolerance Chart: (Maximum Permissible Error)arufatoNessuna valutazione finora

- All Page PDFDocumento24 pagineAll Page PDFsskamalakannanNessuna valutazione finora

- Tutorials Pad Footing Nta 5 (2012&2013)Documento3 pagineTutorials Pad Footing Nta 5 (2012&2013)Host FredyNessuna valutazione finora

- Substantial Changes To ANSI/AISC 360 in The 2022 Edition That Appear in Public Review One Draft Dated August 3, 2020Documento8 pagineSubstantial Changes To ANSI/AISC 360 in The 2022 Edition That Appear in Public Review One Draft Dated August 3, 2020phamminhquangNessuna valutazione finora

- Columns DesignDocumento60 pagineColumns DesignifsrebraNessuna valutazione finora

- Astm 358Documento7 pagineAstm 358Willy SastraleksanaNessuna valutazione finora

- Combined Footing Using Mathcad PrimeDocumento6 pagineCombined Footing Using Mathcad PrimeYan YanNessuna valutazione finora

- Computer Aided Engineering Space Gass Tutorial Questions (Beam Frames Trusses)Documento9 pagineComputer Aided Engineering Space Gass Tutorial Questions (Beam Frames Trusses)April IngramNessuna valutazione finora

- Pedestal Crane AnalisistDocumento40 paginePedestal Crane AnalisistMuhsiin AliiNessuna valutazione finora

- Example 4Documento4 pagineExample 4dane05Nessuna valutazione finora

- Basics of Tank Seismic OCRDocumento35 pagineBasics of Tank Seismic OCRmario_gNessuna valutazione finora

- Stresses in Machine MemberDocumento18 pagineStresses in Machine MemberK ULAGANATHANNessuna valutazione finora

- Litewalk Steel GratingDocumento2 pagineLitewalk Steel GratingDr Bugs TanNessuna valutazione finora

- CR4 - Thread - How To Calculate Flat Plate Thickness of Flat Bottom Storage Tank - PDFDocumento3 pagineCR4 - Thread - How To Calculate Flat Plate Thickness of Flat Bottom Storage Tank - PDFInamullah KhanNessuna valutazione finora

- Ace Tut 02 Turbulent BackstepDocumento22 pagineAce Tut 02 Turbulent BackstepHilario de JesusNessuna valutazione finora

- Din 4024Documento13 pagineDin 4024Muhammad HassanNessuna valutazione finora

- WRC 297 RWE NODE 6340 25febDocumento4 pagineWRC 297 RWE NODE 6340 25febnamasralNessuna valutazione finora

- Weightor & Load Cell ALEDocumento2 pagineWeightor & Load Cell ALEzackysipNessuna valutazione finora

- Froude-Krylov Force CoefficientDocumento20 pagineFroude-Krylov Force CoefficientLazaros NtoanidisNessuna valutazione finora

- Welded JointsDocumento30 pagineWelded JointsOmkar Kumar JhaNessuna valutazione finora

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part4-Blow Out Strength in TensionDocumento3 pagineConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part4-Blow Out Strength in TensionVenu GopalNessuna valutazione finora

- Paper CT4 Load Assumptions For Pitch System Manj 041Documento5 paginePaper CT4 Load Assumptions For Pitch System Manj 041mbreuking6943Nessuna valutazione finora

- Astm C1196Documento6 pagineAstm C1196Lorenzo GambassiNessuna valutazione finora

- Comp 2Documento9 pagineComp 2YYo YudiNessuna valutazione finora

- 2400 Tema DCDocumento7 pagine2400 Tema DCMasoodMiyanNessuna valutazione finora

- Attachment-5 API 6AF FLANGE - 2 Inch Node 3Documento2 pagineAttachment-5 API 6AF FLANGE - 2 Inch Node 3BhaumikNessuna valutazione finora

- Padeye Design AnalysisDocumento8 paginePadeye Design AnalysisMyatmyat SwewinNessuna valutazione finora

- NozzleproDocumento20 pagineNozzleprossmith2007Nessuna valutazione finora

- Lifting Appliances Guide Oct18Documento234 pagineLifting Appliances Guide Oct18Melvin Leong100% (1)

- Stress Strain Laws - Lect05Documento16 pagineStress Strain Laws - Lect05Manoj VermaNessuna valutazione finora

- Type 1 New Jersey' Style Median Barrier: Product No: 7-0070Documento17 pagineType 1 New Jersey' Style Median Barrier: Product No: 7-0070EiflaRamosStaRitaNessuna valutazione finora

- Paper 118 Guidelines For Prequalification and Design of Post-Installed and Cast-In Anchors in Australia - 2Documento11 paginePaper 118 Guidelines For Prequalification and Design of Post-Installed and Cast-In Anchors in Australia - 2Tarek AbulailNessuna valutazione finora

- Ansys Solution Fall03 PDFDocumento83 pagineAnsys Solution Fall03 PDFGuru75Nessuna valutazione finora

- Buckling Fatigue AnalysisDocumento55 pagineBuckling Fatigue AnalysisHarshit Garg100% (2)

- ISCHP13 ProceedingsDocumento368 pagineISCHP13 ProceedingstimsykiNessuna valutazione finora

- Reservoirs - Ch. 5 - PrefabricationDocumento27 pagineReservoirs - Ch. 5 - PrefabricationtimsykiNessuna valutazione finora

- Lecture 5Documento21 pagineLecture 5timsykiNessuna valutazione finora

- Report 4Documento21 pagineReport 4timsykiNessuna valutazione finora

- Reservoirs - Ch. 1 - Introduction To ReservoirDocumento2 pagineReservoirs - Ch. 1 - Introduction To ReservoirtimsykiNessuna valutazione finora

- MATLAB LA Intro 2015 Rev1Documento39 pagineMATLAB LA Intro 2015 Rev1timsykiNessuna valutazione finora

- Case study CIE5130 - Design of cylindrical reservoirsDocumento1 paginaCase study CIE5130 - Design of cylindrical reservoirstimsykiNessuna valutazione finora

- Chapter 7 Hardening ConcreteDocumento43 pagineChapter 7 Hardening ConcretetimsykiNessuna valutazione finora

- Prestressed Cylindrical Reservoir: Dundation Angth of Piles Ross-Section Piles Earing CapacityDocumento1 paginaPrestressed Cylindrical Reservoir: Dundation Angth of Piles Ross-Section Piles Earing CapacitytimsykiNessuna valutazione finora

- 2015 Multidimensional Linear Regression Examples Error Propagation Rev3Documento8 pagine2015 Multidimensional Linear Regression Examples Error Propagation Rev3timsykiNessuna valutazione finora

- Multidimensional Linear Regression Examples 2015Documento8 pagineMultidimensional Linear Regression Examples 2015timsykiNessuna valutazione finora

- Summary Introduction To Offshore Engineering Oe4606 Complete Lecture 1 16Documento102 pagineSummary Introduction To Offshore Engineering Oe4606 Complete Lecture 1 16timsyki100% (1)

- QuestionsDocumento7 pagineQuestionstimsykiNessuna valutazione finora

- Solution Mult LA Exercise1 2015Documento3 pagineSolution Mult LA Exercise1 2015timsykiNessuna valutazione finora

- 2015 Solution Exercises MLR Error PropagationDocumento8 pagine2015 Solution Exercises MLR Error PropagationtimsykiNessuna valutazione finora

- Chapter 8 Imposed Deformations - ApplicationsDocumento19 pagineChapter 8 Imposed Deformations - ApplicationstimsykiNessuna valutazione finora

- Summary Introduction Transport and Logistic Engineering Lecture 2 4Documento9 pagineSummary Introduction Transport and Logistic Engineering Lecture 2 4timsykiNessuna valutazione finora

- Spring 2014 Question Hour: Learning Units 5-8 + Exam: - Consequentialism Deontological Ethics Virtue Ethics Care EthicsDocumento3 pagineSpring 2014 Question Hour: Learning Units 5-8 + Exam: - Consequentialism Deontological Ethics Virtue Ethics Care EthicstimsykiNessuna valutazione finora

- Handbook To Learn MatlabDocumento79 pagineHandbook To Learn MatlabtimsykiNessuna valutazione finora

- Summary Lecture 1 6 Plus FormulasDocumento13 pagineSummary Lecture 1 6 Plus FormulastimsykiNessuna valutazione finora

- Summary Introduction Transport and Logistic Engineering Lecture 2 4Documento9 pagineSummary Introduction Transport and Logistic Engineering Lecture 2 4timsykiNessuna valutazione finora

- Answer Examination Wb3420 November 2013 Question 4Documento1 paginaAnswer Examination Wb3420 November 2013 Question 4timsykiNessuna valutazione finora

- Exam Introduction Transport Engineering and Logistics Technique November 7 2013 AnswersDocumento4 pagineExam Introduction Transport Engineering and Logistics Technique November 7 2013 AnswerstimsykiNessuna valutazione finora

- Verification and Implementation of Strut-And-Tie Model inDocumento281 pagineVerification and Implementation of Strut-And-Tie Model inrpatel5509Nessuna valutazione finora

- Building Structure ReadingDocumento7 pagineBuilding Structure ReadingtimsykiNessuna valutazione finora

- Drawings of reservoir wall reinforcementDocumento2 pagineDrawings of reservoir wall reinforcementtimsykiNessuna valutazione finora

- Emp Unit-1 Communication SkillsDocumento14 pagineEmp Unit-1 Communication SkillsSaraswathi GopalNessuna valutazione finora

- Types and Forms of CommunicationDocumento22 pagineTypes and Forms of CommunicationayeshaNessuna valutazione finora

- OhmDocumento15 pagineOhmRhonnel Manatad Alburo88% (17)

- Safety and Arming Device Timer 6-7-1976Documento5 pagineSafety and Arming Device Timer 6-7-1976nguyenhNessuna valutazione finora

- Temp Gradient For Warping Stress in Rigid PavementDocumento9 pagineTemp Gradient For Warping Stress in Rigid PavementAmul KotharkarNessuna valutazione finora

- Chlorine (Free or Total) Manual For Test Kits CN-70, CN-70F, CN-70TDocumento6 pagineChlorine (Free or Total) Manual For Test Kits CN-70, CN-70F, CN-70TDemétrius Ivo FernandesNessuna valutazione finora

- Meinrad 2018 All Symbols With NumbersDocumento4 pagineMeinrad 2018 All Symbols With NumbersXer N. AcostaNessuna valutazione finora

- Dav Public School, Berhampur, Odisha Summer Holiday HomeworkDocumento3 pagineDav Public School, Berhampur, Odisha Summer Holiday HomeworkOmNessuna valutazione finora

- AGITAN Defoamer Technologies PDFDocumento15 pagineAGITAN Defoamer Technologies PDFMarco Lopez100% (1)

- Toms2003 A Nonlinear Finite Element Analysis of The Periodontal Ligament Under Orthodontic Tooth LoadingDocumento9 pagineToms2003 A Nonlinear Finite Element Analysis of The Periodontal Ligament Under Orthodontic Tooth LoadingPuttnaree NiteNessuna valutazione finora

- Sae Technical Paper Series 2015-36-0353: Static and Dynamic Analysis of A Chassis of A Prototype CarDocumento12 pagineSae Technical Paper Series 2015-36-0353: Static and Dynamic Analysis of A Chassis of A Prototype CarGanesh KCNessuna valutazione finora

- Adjustment: - Electronic Modulated Air SuspensionDocumento2 pagineAdjustment: - Electronic Modulated Air SuspensionThar KyiNessuna valutazione finora

- Laptop Power SequenceDocumento16 pagineLaptop Power SequenceDelwar Hossain90% (10)

- Law As A Command of SovereignDocumento12 pagineLaw As A Command of SovereignAdv BL Dewasi100% (2)

- Earthquake Faults and Tectonic Plate Boundaries ExplainedDocumento21 pagineEarthquake Faults and Tectonic Plate Boundaries ExplainedAngelo RemeticadoNessuna valutazione finora

- "Smart Attendance Using F Ttendance Management Using Face Recognition" Anagement SystemDocumento13 pagine"Smart Attendance Using F Ttendance Management Using Face Recognition" Anagement Systemamer HNessuna valutazione finora

- Individual tone frequencies have hidden qualitiesDocumento7 pagineIndividual tone frequencies have hidden qualitiesArnauNessuna valutazione finora

- Lorry AirBrakesDocumento3 pagineLorry AirBrakesEnache CristinaNessuna valutazione finora

- JURNAL PENCONG IJAS FixDocumento12 pagineJURNAL PENCONG IJAS Fixmasri ridwanNessuna valutazione finora

- AssignmentDocumento15 pagineAssignmentWahab MirzaNessuna valutazione finora

- Sap - HR Standard Operating Procedure: Facility To Reset Password of ESSDocumento6 pagineSap - HR Standard Operating Procedure: Facility To Reset Password of ESSPriyadharshanNessuna valutazione finora

- BBK SMP123HDT2 SMP124HDT2 Service ManualDocumento25 pagineBBK SMP123HDT2 SMP124HDT2 Service ManualdanielNessuna valutazione finora

- Components of GlobalizationDocumento26 pagineComponents of GlobalizationGiyan KhasandraNessuna valutazione finora

- Tutorial Quartus II Simulation VHDLDocumento27 pagineTutorial Quartus II Simulation VHDLHeitor B. S. BezerraNessuna valutazione finora

- Duplichecker Plagiarism Report 3Documento3 pagineDuplichecker Plagiarism Report 3Mushfiqur RahmanNessuna valutazione finora

- Kamran Afzal ResumeDocumento2 pagineKamran Afzal ResumeChelsea ElizabethNessuna valutazione finora

- Introspective Hypnosis Class - 052017 - Antonio Sangio (2745)Documento62 pagineIntrospective Hypnosis Class - 052017 - Antonio Sangio (2745)sandra100% (4)

- Bashar Discusses Monatomics, White Powder Gold and Ormus MineralsDocumento32 pagineBashar Discusses Monatomics, White Powder Gold and Ormus MineralsFlorin V. Iagaru100% (6)

- 5054 s09 QP 1Documento20 pagine5054 s09 QP 1Hany ElGezawyNessuna valutazione finora

- Directory of Importers Associations Worldwide 2009Documento57 pagineDirectory of Importers Associations Worldwide 2009Thanh Tam75% (12)