Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Vapor-Liquid Equilibrium Data for Ethanol-Water and 2-Propanol-Water Systems

Caricato da

JCKARLDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Vapor-Liquid Equilibrium Data for Ethanol-Water and 2-Propanol-Water Systems

Caricato da

JCKARLCopyright:

Formati disponibili

AV for C4C1,F, i n system E gi ves 4.8 ml .

The experi-

mental val ue is about 9 ml. The compound C4C1,F7 occurs

i n the three systems B, D, and E. If i t is assumed that the

P s for the second component i n each of these systems are

approximately equal , the partial molal volumes of C,Cl,F,

at i nfi ni te dilution i n each of these systems shoul d be i n

the ratio of the B-values for thi s compound i n the respec-

ti ve sol uti ons. The partial molal volume of C,C1,F7 i n

C,F,,O should be about three times as l arge as i ts val ue i n

C,Cl,F,. Actually i t is only about twi ce as large. A si mi -

lar si tuati on prevai l s for C,Cl,F, i n mixtures with C,F,,O

when compared with the pentene i n mixture with C,Cl,F,.

The volume change on mixing of the two chlorofluorocar-

bons (system B) seems to be abnormally large. The rati o

of the B-values (by Equation 1) for the C4C1,F7 i n systems

D and E is 1 to 5, and the rati o of the partial molal volumes

for the butane i n these systems at i nfi ni te dilution is .1to

3. However, the ratio of the p s for C,F,,O and n-C7H,, is

probably approximately 1 to 2, so that the partial molal

volume at i nfi ni te dilution for C4C1,F7 i n these sol uti ons

should theoretically be about 1 to 10. As i t was shown

above that the limiting partial molal volume for C4C1,F7 i n

n-C7H16 is about twi ce the theoreti cal , i t may be concluded

that the partial molal volume for C,Cl,F, with the hydro-

carbon al so shows abnormally l arge val ues.

ACTI VI TY COEFFI CI ENTS

The empirical formulas of Scatchard, of Marguler, and of

Van L am rel ati ng acti vi ty coeffi ci ents to composition were

fitted to the experimental val ues i n the three systems (C,

D, and E) which are not i deal . The Van Laar equati ons

were the only ones which gave consi stent rel ati onshi ps for

all three systems. The constants i n these equati ons when

written as

logl,y, - bx:/(ax, +4

log,,y, =abx:/(ax, +x,) (4)

are given i n Tabl e VII.

If these systems all obeyed the theory of Hildebrand (3,

the val ues of A and B should be rel ated to the theoreti cal

V,/V, val ues and the B val ues of Tabl e V by

a =V,/V, ( 5)

Tabl e VII. Van Laar Constants in Equations 3 and 4

System a b

C. CSClaFe(1): CaF160(2) 0.635 0.174

D. C&l$FT(l): CaF160(2) 1.0 0.174

E. C4Cl3F,(1): n-C,Hl&) 0.945 0.246

b =BJ 686 (6)

Equati ons 5 and 6 hold only for system C. For system D, a

is 1.0 i nstead of V,/V, =0.703, and 6866 is 148 i nstead of

the theoreti cal val ue B , =52. For system E, a is 0.945 in-

stead of V,/V, =1*12, and 6866 is 207 as compared to the

theoreti cal val ue of B , =278. In system E the theoreti cal

acti vi ty coeffi ci ents are greater than the experimental

val ues, while i n system D the theoreti cal val ues are too

small. The theoreti cal val ues i n system C are the same as

the experimental val ues.

LI TERATURE CI TED

(1) American Petroleum Institute, Research Project 44, Se-

lected Values of Properties of Hydrocarbons, Camegie In-

stitute of Technology.

(2) Bromiley, E. P., wi ggl e, D., Ind. Eng. Chem. 25, 1136

(3) Broughton, D. B, Breadsley, C. S., Ibid., 47, 838 (1955).

(4) Hildebrand, J. H., Fisher, B B., Benesi, H. A,, J . Am.

(5) Hildebrand, J . H., Scott, R. L., Solubility of Nonelectro-

(6) Ibid., p. 143.

(7) Hipkin, H., Myers, H. S., Ind. Eng. Chem. 46, 2524 (1954).

(8) Newcome, M. M., doctor of philosophy thesis, University of

(9) Oliver, G. D., Blumkin, S., Cunningham, C. W. , 1. Am. Chem.

(1933).

Chem. SOC. 72, 4348 (1950).

lytes, Reinhold, New York, 1950.

Washington, 1954.

SOC. 73, 5722 (1951).

(10) Oliver, G. D., Grisard, J . W., Ibid., 73, 1688 (1951).

(11) wi ggl e, D., Tongberg, C. O., Fenske, M. R., Ind. Eng.

(12) Reed, T. M. 111, Anal. Chem. 30, 221 (1958).

(13) Reed, T. M. III, J . Phys. Chem. 59, 425 (1955).

(14) Ibid., 61, 1213 (1957).

(15) Timmermans, J., dPhysico-Chemical Constants of Pure Or

(16) Yen, L. C., master of science thesis, University of Florida,

Received for review February 6, 1958. Accepted May 23, 1958.

Chem., Anal . Ed. 6, 466 (1934).

ganic Compounds, Elsevier, New York, 1950.

1957.

Vapor-Liquid Equilibrium at High Pressures

The Systems Ethanol-Water and 2-Propanol- Water

FRANK BARR-DAVID and BARNETT F. DODGE

Chemi cal Engi neer i ng Depar t ment , Yal e Uni ver si t y, New Haven, Conn.

Vapor-l i qui d, phase-equilibrium data at el evated tempera-

tures and pressures are necessary for the desi gn of high

pressure di sti l l ati on processes, and i n other fi el ds of mod-

ern chemical engineering. At Y al e University, research be-

ing conducted on the two-phase hydration of olefins has

fostered i nterest i n the vapor-liquid phase equilibria for

the systems ethanol-water and 2-propanol-water; such data

are necessary for the prediction of the equilibrium compo-

si ti ons i n the hydration of ethyl ene and propylene, respec-

tively. The determination of these data will also gi ve ex-

perimental checks on vari ous methods of cal cul ati on of

relevant thermodynamic data, of great i nterest because of

the departure of these systems from ideality. Thi s experi-

mental work, accordingly, adds to the suppl y of fundamen-

tal data, which, when sufficiently complete information is

avai l abl e, will allow accurate thermodynamic prediction of

such reactions.

Previ ous studi es of I.. vapor-liquid phase equilibrium

for the systems ethanol-water and 2-propanol-water are re-

ported i n Tabl e I and of the vapor pressure of 2-propanol i n

Tabl e 11.

The aim of this current experimental work was to enl arge

the amount of data for the ethanol-water system obtai ned

by Griswold, Haney, and Klein (24), and to extend the

study of the isothermal vapor-liquid equilibrium for the

systems ethanol-water and 2-propanol-water up to condi-

ti ons approaching as cl osel y as possi bl e the cri ti cal point

of pure water. The data of the i nvesti gators mentioned were

to be used to check the operation of the equipment.

EXPERI MENTAL DETERMINATION OF

VAP OR-LIQ UID EQU ILI BR IUM DATA

There are si x main methods for determination of vapor-

liquid equilibria: recirculation, static, dynamic flow, dew

VOL. 4, No. 2, APRIL 1959

107

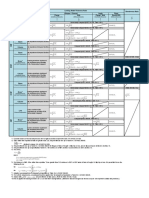

Table I. Previous Studies of Vapor-Liquid Equlllbrium

for Systems Alcohol-Water

Temperature

or Pressure References

760 mm.

(760 mm.

760 mm.

760 mm.-300 p.s.i.a.

Up to 150 p. s. i. a.

75 p.s.i.a.

Up to 15 atm.

SO0 and 60 C.

150 '-275'C.

Up to 300 p.s.i.a.

Subatmospheric

Up to 1450 mm.

A. Ethanol-Water

( 5, 10, 12, 18,

26, 34, 42, 54,

56, 61, 65, 71)

( 5)

(1 )

I sobaric

Remarks

I sobaric

Very low ethanol con-

centrations. Henry's

law not obeyed

I sobaric

I sobaric

I sobaric

I sobaric

Isothermal

Isothermal

Azeotropic composition

Azeotropic compositions

Azeotropic compositions

and temperature

R 2-Propanol-Water

95 mm.-4 atm. ( 78) I sobaric

760 nun. (9, 42, 43, 69) I sobaric

760 mm. (9, 42, 43, 44, Azeotropic compositions

49, 69, 80) and temperatures

(50, 78)

Effect of pressure on

azeotropic composi-

tion and temperature

Tabl e II. Reported Vapor Pr essur e for 2-Propanol

Temperature or Pressure References

350-900 C.

1-8 atm.

( 57)

(78)

and bubble point, differential distillation, and continuous

di sti l l ati on methods.

Detai l s of these methods, and the advantages and disad-

vantages of each, are di scussed by Robinson and Gilliland

(66) and Barr-David (3).

A study of the methods and apparatus used for the de-

termination of vapor-liquid equilibrium shows that only a

few are sui tabl e for the determination of the high pressure

vapor-liquid equilibrium for the systems ethanol-water and

2-propanol-water. Only two methods will be further con-

sidered-the dew and bubble point method, and the recircu-

l ati on method.

The dew and bubble point method has the advantage of

giving volume data as well as the y - x data. There are

two methods by which thi s techni que may be used-namely,

with a constant-mass, variable-volume cell, or with a

variable-mass, constant-volume cell. Further detai l is

given by Barr-David (3). Because of the complexity of the

equipment and other di sadvantages, it was deci ded not to

use this method.

The choi ce then l ay i n adopting an accurate method based

on the use of a recirculation-type sti l l . The operating con-

ditions of high temperature and pressure, as well as opera-

tion with conditions approaching the critical point, greatl y

limited the choice. The theoreti cal advantages claimed for

the vapor-recirculating sti l l were consi dered outweighed

by the i ncrease i n complexity of construction and operation

for thi s type of sti l l . I t is doubtful that data determined

for these systems would be appreciably affected by the

theoretical shortcomings of the liquid-recirculation still.

Vapor-recirculating sti l l s have proved difficult to operate

even at 1-atm. pressure i n gl ass apparatus, i n which the

progress of operation may be watched; the di ffi cul ti es would

be enormously i ncreased i n an all-metal apparatus at condi-

ti ons approaching the cri ti cal point, where the volumes of

each phase are only approximately known. The l arge change

i n properties of each phase at el evated temperatures and

pressures could well cause the still to cease operating in

the desi red manner.

The same can be sai d for many types of liquid-recircu-

l ati ng sti l l s. Some of these are too complex i n constmc-

tion for simple adaptation to high pressures; others, such

as the sti l l of Gi l l espi e (20), may cease operating. Sti l l s

designed for high pressure operation usi ng the construction

of a simple Othmer-type still have been very sati sfactori l y

used by Scheel i ne and Gilliland (68) and Griswold, Andres,

and Klein (23).

The equilibrium still used by the former i nvesti gators

consi sted of a gl ass cylinder seal ed by neoprene packing.

There are limitations to thei r apparatus imposed by the

high-temperature strength of gl ass and the thermal and

chemical stabi l i ty of the seal i ng gasket. These difficul-

ti es were overcome i n a si mpl e still desi gn by Griswold,

Andres, and Klein (23), and used by Griswold, Haney, and

Klein (24) for the study of the system ethanol-water up to

275OC. and pressures up to about 1500 p.s.i. Thi s sti l l

was designed, bearing i n mind the difficulties of high pres-

sure operation. One of these was the greater tendency for

condensate to fl ash as it returns to the sti l l without mixing

with all the liquid i n the sti l l . The vapor densi ty is higher,

and that of the liquid is lower, than at atmospheric pres-

sure. Hence, there is a greater danger of entrainment and

al so of backflow surges of liquid from sti l l to condensate

chamber at higher pressures. The i ncreased solubility of

an i nert gas at the high pressures would have an apprecia-

bl e effect on the equilibrium, and the equipment was de-

signed to operate without inert gas by maintaining condi-

ti ons i n the sti l l by bal anci ng heat input and output.

Their sti l l accordingly has several important features,

A circulation pipe and collar in the heater section, to ensure

adequate mixing of condensate and sti l l liquid before the vapor

is released fromthe boiling liquid.

Ample vapor space above the boiling liquid so that entrain-

ment is negligible.

A condenser, the cooling duty of which can be easi l y varied to

sui t the conditions.

A ball-check valve in the condensate return line to prevent

back-surges during momentary fluctuations of heat input or re-

moval, or while samples are being withdrawn.

Because of the sati sfactory resul ts on the system ethanol-

water obtained by Griswold, Haney, and Klein (24) usi ng

the apparatus j ust described, and other reasons, i t was de-

cided to use an apparatus similar i n principle to that used

by these investigators. However, the constructional detai l

of the present sti l l is entirely different from the still of

Griswold and others. The major changes were the fabrica-

tion of the vessel from commercially avai l abl e high pres-

sure components, wherever available; the use of accepted

high pressure cl osures, such as the cone and the Bridgman-

type cl osures, i nstead of welded joints; the addition of a

siphon-breaker l i ne; the design of the check valve; and the

design of the equipment to operate at higher pressure and

temperature-namely, 3200 p.s.i. and 370' C.

Det ai l s of Const r uct i on of Apparatus. Fi gure 1 shows a

schemati c equipment flowsheet.

Equi l i br i um St i l l . Fi gure 2 shows the equilibrium still

used for thi s study. Omitted from Fi gure 2 for the sake of

clarity are the insulation, el ectri cal windings, and supports.

I n the reboiler, 7, the liquid is heated by means of an external

heater windlag sunounding the leg. Thorough mixing of the re-

tuni ng liquid and liquid in the still is ensured by the circulation

pipe and collar, 8. The vapor formed passes up through the main

body, 9, in which any entrained liquid settles out The vapors

leave the top of the sti l l and pass into a two-section condenser,

which can be cooled by air or water. The main body of the sti l l

and the top fittings are maintained 2' to 3' above the vapor tem-

perature to ensure nearly adiabatic operation of the sti l l and pre-

vent refluxing. The condensed vapor collects in the condensate

chamber, 26, flows through a check valve, 19, and returns by the

vapor-condensate return line 17, to the reboiler. A vent pipe

fromthe check valve to the main vapor space has been added to

prevent siphoning of the liquid from the condensate chamber to

the still.

108

JOURNAL OF CHEMICAL AND ENGINEERING DATA

Fi gur e 1. Schemat i c equi pment f l owsheet

A. Blackhawk pump

B. Mercury-piston pump

C. Gl ass charging funnel

D. Mercury level contact terminals

E. Oil drain

F. Main still

G. Main heater

H. support

I. support

J . Still drain

K. Condenser

L. Cooling fluid connections from

air and water flowmeters

M. Condensate chamber

N. Phase sampling connections

0. Mercury reservoir

P. 0-500 p.s.i. Hei se gage

Q. 0-3500 p.s.i. Hei se gage

R. Vent

S. Manometer

T. Sample bomb evacuation connection

U. To vacuum pump

The reboiler, 7, main body, 9, and top plug, 15, were con-

strutted from AIS1 4130 steel. The rest of the equipment was

fabricated fromstai nl ess steel.

The thermocouple wells, 12 and 13, are constructed from Y,-

inch outside diameter tubing. Because of the small cross sec-

tion of the metal of the thermowell, the length, and the fact that

at the connection between the thermowell and the wall the tem-

perature is only 2' to 3OC. above the temperature to be meas-

ured by the thermocouple, the error introduced in the temperature

read by the thermocouple due to conduction along the thermowell

is entirely negligible.

In the check valve, 19, the !&,-inch steel ball was replaced by

a conical aluminum float, which required a pressure difference

of about '6 inch of water for opening. The steel ball required

excessive pressure for operation. In the sti l l design of Griswold

and others (23). the check-valve design would have required

large pressure differences for operation, which must have led to

operation in a manner not desired as critical conditions were

approached,

The location of the liquid sampling line is important, for the

liquid phase sampled should be liquid in equilibrium with the

vapor-that is, liquid fromnear the surface of the liquid in the

reboiler, and not liquid contaminated with returning vapor con-

densate. The problem was solved by a '/,-inch outside diameter

tube, 3, which terminated at about the circulation collar.

Thermocouples were inserted into the thermowells, 12 and 13,

and wall thermocouples were attached to the outside wall of the

main sti l l body at four points, 16. Other thermocouples were at-

tached at the top thermocouple tee, 14, and at the condensate

chamber, 27.

The main heating element fits around the outside of the re-

boiler. The auxiliary winding consi sts of three sections, the

winding on the main body, on the top fittings, and on about 3

inches of the vapor line, 22, fromthe tee to the support.

The insulated supports for the sti l l were designed to obviate

any complications in the adiabatic operation of the sti l l caused

by heat l eaks through the supports. The main support is under-

neath the reboiler. The auxiliary support for stability is attached

to the sloping vapor line, 22, at the top of the still. There are

no connections to the main body of the still to cause refluxing.

The entire apparatus is insulated by means of 85% magnesia

light-weight steam-pipe insulation.

After assembly, the equipment was tested repeatedly to 3500

p.s.i. hydraulically and to 2500 p.s.i. gas pressure.

The volume of the equilibrium sti l l was measured by filling

with water and found to be 2900 ml.

1 2 3 4 s 1

SCALE, INCHES

Fi gur e 2. Charging assembl y

1. Drain

2. 'A6 inch valve

3. Liquid sample line

4. '& inch tee

5. 'A6 x % inch reducer

6. Liquid charging l i ne

7. Reboiler

8. Circulation pipe and collar

9. Main body

10. Pl ug in place of Fenwal thermoswitch

11. Special thermocouple assembly

12,13. Thermocouple wells

14. Thermocouple

15. Top plug of sti l l

16,27. Wall thermocouples

17. Vapor condensate return line

18. Special cross

19. Special check valve

20. Syphon break line

21. 'A6 x % X 'A6 X

22. Vapor line

23. Condenser

24. Cooling fluid inlet connections

25. Line to pressure gages, vent, evacuation line

26. Condensate chamber

28. 9/6 x 946 x inch tee

29. Vapor sample l i ne

inch cross

Charging Assembly. The function of the charging assem-

bly is to enabl e liquid of any desi red composition to be in-

j ected i nto the equilibrium still when the l atter is at the

operating condi ti ons of high temperature and pressure. Oil

from a hand-operated Blackhawk pump is used to di spl ace

mercury i n a liquid-piston pump, which i n turn di spl aces

the desi red l i qui d through to the liquid charging l i ne (6,

Fi gure 2) of the main equilibrium still. The l evel of mer-

VOL. 4, No. 2, APRIL 1959

109

cury in the lower of the liquid-piston pump vessel s is kept

between l i mi ts by means of el ectri cal contacts which oper-

ate el ectri cal warning lights. The amount of oi l pumped,

and thus the amount of liquid i nj ected into the equilibrium

sti l l , is measured by means of a gage gl ass on the Black-

hawk pump. The upper vessel of the liquid-piston pump

may be refilled with liquid by means of a graduated gl ass

funnel.

Accessory Equi pmn. The complete arrangement of sti l l

and accessori es is shown i n the schemati c equipment flow-

sheet (Figure 1). The pressure is measured by two Hei se

gages, of pressure ranges 0 to 500 and 0 to 3500 p.s.i., re-

spectively. Two gages were necessary to gi ve the desi red

accuracy of pressure measurement. The accuracy claimed

by the manufacturers of the Hei se gages is 0.5% above 20%

of full scale, and 0.2% of full scale below 20% of full

scale, but may be much better. Thi s accuracy was satis-

factory for thi s experimental work. The pressure i n the

sti l l is transmitted by l i ne, 25 (Figure 2) to a mercury res-

ervoir, then to the Hei se gages.

The sampl e bombs were two small vessel s of about 30-

ml. capaci ty each, made of stai nl ess steel . The seals in

both these bombs are made of si l i cone rubber O-rings. The

standard %-inch cone connecti ons used for connection of

the sampling bombs proved easy to seal and withstood

thousands of attachments and detachments without leaking.

L i ne 25 (Fi gure 2), connects to a valve, which i sol ates

the high pressure of the equilibrium still. The other si de

of thi s val ve is a vent and evacuation system.

The temperatures at vari ous

parts of the equilibrium sti l l are obtained by iron-con-

stantan thermocouples which are numbered i n Fi gure 1.

Thermocouple 1 is the most important junction, for thi s

gi ves the temperature of the liquid-vapor equilibrium SYS-

tern. Thermocouple 2 gi ves the temperature of the vapor

l eavi ng the main body; i n general thi s thermocouple shows

a temperature 1 ' to 3'C. greater than that of thermocouple

1. Wal l thermocouples 3, 4, 5, 6, and 7 should show a tem-

perature 2' to 3'C. above the temperature of thermocouple

1, so that no refluxing can possi bl y occur within the main

body of the sti l l . It is important, however, that the wall of

the sti l l not be substanti al l y hotter than the vapor within

the sti l l , or else vaporization of liquid spl ashes hitting the

wal l s of the sti l l will occur, l eadi ng to erroneous composi-

tions. Thermocouple 8 was used to check that the conden-

sate was cold enough to ensure complete condensation of

the vapor, and not fractional condensation.

The electromotive forces developed by the thermocouples

were read from a L eeds & Northrup K2 potentiometer. The

K-2 tri pl e range potentiometer gave more than sufficient a c

curacy and precision for thi s work. The accuracy of the

e.m.f. measurement i s far greater than the accuracy of the

calibration of the thermocouples.

The thermocouples were cal i brated up to 200'C. with a

National Sureau of Standards calibrated mercury-in-glass

thermometer and at the freezing point of l ead usi ng NRS

certified lead. The accuracy of the temperature measure-

ment was considered to be to about 0.5'C. The precision

of the temperature measurements was probably at l east

0.02OC. The operation of the equipment is descri bed i n

detai l by Barr-David (3).

The operation of the

still was checked by a study of the 200'C. ethanol-water

vapor-liquid isotherm and a comparison of the resul ts with

the work of Griswold, Haney, and Klein (24). The y - x

data showed excellent agreement, although the work of

Griswold and others i ncl udes only fi ve experimental points.

I nitially, because of i nsuffi ci entl y preci se temperature con-

trol, the pressure data scattered, but with the K-2 potenti-

ometer the desi red temperature precision was obtained.

The data for thi s isotherm were obtained for a wide range

of boil-up rates. No effect of boil-up rate could be de-

Temperature Measurement.

Check on Oper at i on of Equi pment .

tected. The amount of entrainment expected at a maximum

boil-up rate (2200 watts) was cal cul ated from the data given

by Souders and Brown (72) and found to be negligible.

The operation of the still for a liquid volume from 400

to 1000 ml. was checked. No effect of liquid l evel was

found.

A survey of ethanol avai l abl e showed

that very pure grades were avai l abl e from many manufac-

turers, and that they were all equally sui tabl e for this

work. Two grades of U. S. I ndustrial Chemi cal s Co. ethanol

were used. No di fference between the grades could be

detected in the resul ts of the experimental determinations.

Most work was performed usi ng pure ethanol alcohol abso-

l ute, U. S. P. 200-proof. Experimental determinations gave

the densi ty at 20'C. to be 0.78979 gram per cc., which

corresponds to 99.8 weight % of alcohol. Limited experi-

mental work was done al so with pure ethanol alcohol U. S. P.

190-proof. Thi s had a densi ty of 0.81083 gram per CG. at

2OoC., which corresponds to 92.64 weight % of alcohol.

No further purification of the ethanol was attempted.

Very pure 2-propanol was avai l abl e from several manu-

facturers, "Isopropyl alcohol, Baker anal yzed reagent."

supplied by the J . T. Baker Chemical Co. was used for

thi s study. Experimental determination of the speci fi c

gravity gave 0.78764, corresponding to 99.5 weight % of

alcohol. No further purification was attempted with the

2-propanol used for the equilibrium determinations.

The 2-propanol used for the vapor-pressure determination

was rendered as anhydrous as possi bl e. Riddick and Toops

(64) summarize the methods that have been used for thi s

preparation. The 2-propanol for thi s study was prepared i n

a manner similar to that used by Maryott (48). Thi s in-

volved dehydration using magnesium, which is claimed to

be superior to calcium oxi de and many other materials.

The 2-propanol was allowed to stand over magnesium tum-

i ngs for 2 weeks, then refluxed for 10 hours with fresh

magnesium turnings, followed by di sti l l ati on at a reflux

ratio of 10 to 1. A center cut boiling at 82.3 'C. was col-

lected. This material had a speci fi c gravity 2Oo/2O0C. of

0.78644, corresponding to 99.95 weight % of 2-propanol.

Density is an accurate method of

anal ysi s of ethanol-water and 2-propanol-water mixtures.

The densi ty of ethanol-water mixtures at 2OoC. is given by

Perry (58), Hodgman and Holmes (27), and the National

Bureau of Standards 19 (73). The density of 2-propanol-

water mixtures at 20'C. is given by Lebo (43), which is

ci ted by Perry (60) and I nternational Critical Tabl es. For

thi s work, the speci fi c gravity of 2-propanol-water mixtures

published by the Enjay Co., Inc. (17) was used.

Equi pment Used for Densi t y Det er mi nat i on. A multitude

of devi ces has been used for defining a volume so that the

filling and weighing of the vessel are reproducible and con-

venient. The accuracy, advantages, and di sadvantages of

various types of pycnometers are di scussed by Weissberger

(76). The pycnometers used for thepresent work have been

described by Lipkin and others (46) and were obtained

commercially (Catalog No. 5437, 10-ml . pycnometer type

B, Ace Gl ass Co., Vineland, N.J .)

All weighings were performed on an Ainsworth Chain-

Weight balance, capabl e of a precision to at least 0.1 mg.

Tests were conducted to ensure proper operation of the bal-

ance and to cal i brate the rider and chain. High quality

lacquered brass wei ghts were used for the weighings. The

weights were cal i brated agai nst NBS cal i brated Cl ass M

weights. These wei ghts were al so used for the calibration

of the rider and chain of the balance.

All weighings were corrected for buoyancy of the air, as

given by Drucker (16) and Diehl and Smith (13).

The densi ti es were determined at 20C. by thermostating

the pycnometers i n a water bath controlled to 20' *

0.01OC. by means of a mercury regulator. The densi ty

val ues recorded i n this work are accurate to at l east four

figures. The equilibrium compositions of the phases in

Mat er i al s Used.

Anal yses of Sampl es.

110

JOURNAL OF CHEMICAL AND ENGINEERING DATA

thi s study have been reported to three si gni fi cant figures.

Thus substanti al l y no error i n the fi nal resul ts may be at-

tributed to the method of anal ysi s.

SUMMARY OF RESULTS

The i sotherms at 150, 200, 250, 275", 300, 325O,

and 35OoC. were studi ed i n the ethanol-water system. The

pressure-temperature composition data are reported i n

Tabl e 111and graphically presented i n Fi gures 3 and 4.

The vapor-liquid equilibria of 2-propanol-water were

studi ed at the 150, 200, 250m, 275", and 30OoC. iso-

therms. The pressure-temperature-composition data are re-

ported i n Tabl e I V and are shown graphically i n Fi gures 5

and 6. Extensi ve decomposition of the 2-propanol i nto pro-

pene prevented the determination of any equilibrium data

at higher temperatures.

The vapor pressure of pure 2-propanol is given i n Tabl e

V and is graphically presented as a referencesubstance

plot in Fi gure 7.

For the ethanol-water system, cri ti cal data for the mix-

ture have been given by Griswold and others (24 and White

(77). White's data consi st of limited cri ti cal temperature

data, at vari ance with those of Griswold, and have not

been used i n thi s work. The method used by Griswold for

the measurements of the cri ti cal properti es could l ead to

smal l i naccuraci es i n these measurements. The method

used for the measurement of the cri ti cal temperature-seal-

i ng glass tubes about one third full of liquid at room tem-

perature and observing the meni scus as the tubes are

heated-will gi ve the cri ti cal temperature only if the tubes

contai n the cri ti cal volume of the mixture. Griswold re-

ports that the tubes filled with liquid-that is, the bubbl e

point l i ne was reached and therefore the tubes contai ned

too much material and the temperatures reported will be

low. Similarly no attempt was made to introduce the criti-

cal volume into the bomb used for the cri ti cal pressure

measurements. Because of the l arge densi ty vari ati ons

with smal l temperature changes near the critical point, the

val ues reported are probably cl ose to the trueval ues. The

cri ti cal l ocus from Griswold's data is plotted on Fi gure 3,

and shows good agreement with the present data. The

Table 1 1 1 . Experimental Vapor-Liquid Equi l i bri um Data Ethanol-Water

Mole Fraction Mole Fraction Pressure, Mole Fraction Mole Fraction Pressure,

Ethanol in Liquid Ethanol in Vapor P. S. I. A. Ethanol in Liquid Ethanol in Vapor P. S.I. A.

At 150C. At 25OoC.

0.018

0.048

0.084

0.155

0.184

0.232

0.264

0.326

0.340

0.463

0.572

0.648

0.717

0.781

0.862

0.923

0.966

0.023

0.032

0.048

0.066

0.088

0.112

0.157

0.214

0.295

0.345

0.391

0.479

0.49 1

0.580

0.689

0.824

0.934

0.009

0.034

0.063

0.098

0.135

0.172

0.223

0.285

0.339

0.402

0.463

0.565

0.673

0.702

0.705

0.159

0.288

0.367

0.438

0.458

0.490

0.503

0.528

0.535

0.600

0.658

0.704

0.749

0.797

0.862

0.919

0.96 1

At 2OO0C.*

0.134

0.175

0.2 19

0.262

0.299

0.337

0.381

0.424

0.466

0.495

0.528

0.579

0.586

0.641

0.719

0.828

0.929

At 25OoC.

0.044

0.135

0.206

0.264

0.306

0.340

0.376

0.417

0.446

0.487

0.530

0.605

0.690

0.715

0.715

81

91

102

113

117

120

122

122

123

130

133

135

135

139

143

143

143

260

271

288

300

313

329

3 39

359

364

385

38 1

407

3%

412

422

437

428

592

665

718

764

795

827

858

892

910

940

965

1003

1032

1038

1037

0.737

0.756

0.79

0.007

0.033

0.065

0.105

0.149

0.201

0.273

0.348

0.374

0.414

0.455

0.490

0.512

0.006

0.030

0.057

0.091

0.128

0.178

0.246

0.330

0.350

0.007

0.035

0.063

0.084

0.121

0.161

0,190

0.008

0.033

0.052

0.085

0.740

0.756

0.79

At 275OC.

0.029

0.112

0.177

0.233

0.277

0.322

0.377

0.429

0.44 1

0.465

0.486

0.490

0.512

At 30OoC.

0.024

0.087

0.138

0.186

0.276

0.315

0.330

0.350

0.228

At 325OC.

0.018

0.075

0.114

0.134

0.173

0.191

0.192

At 35OoC.

0.016

0.05 7

0.074

0.085

1040

1040b

1040=

890

985

1060

1120

1173

1220

1282

1345

1363

1392

1421

1430'

1456d

1283

1382

1470

1555

1634

1720

1785

1820'

1870d

1798

1937

2032

2085

2185

2250

2278

2475

2620

2691

2752d

aPressure readings inaccurate because of inadequate tempera-

bCompositions equal, either single phase or azeotrope.

CCritical point estimated from Figure 3.

dpoint in single-phase region.

ture control.

111

VOL. 4, No. 2, APRIL 1959

I 200 r -

h - . , -

,

0

MOL E FRACTI OH ET HA NOL

Fi gur e 3. Pr essur e-composi t i on i sot herms of et hanol -wat er

l ocus has been used to esti mate the cri ti cal composition of

the mixture for the 275' and 300' isotherms, and thus to

establ i sh the limiting compositions on the y - x curves

(Fi gure 4).

Comparison of the ethanol-water equilibria of thi s work

with those of Griswold and others (24), shows that the

pressures reported i n the l atter experimental data are

higher than those found i n the present experimental work.

The discrepancy can be explained by the error of the tem-

perature measurements; because in each set of data the ac-

I t MOLE FRACTION ETHANOL IN LIQUID

Fi gur e 4. y , x i sot her ms of et hanol -wat er

I

X l O

1 1 I I 1 I

I 1

100

0

0 01 0 2 0 3 0 4 0 5 06 0 7 0 8 09

MOLE FRACTION 2-PROPANOL

Fi gur e 5. Pr essur e-composi t i on i sot herms o f

2-propanol -wat er

curacy of the temperature is about 0.5' C., the combined

error of 1C. could expl ai n the pressure discrepancy.

The y - x data, however, are relatively i nsensi ti ve to

small temperature changes, and good agreement should be

expected. Comparison shows that the two sets agree well

at 200'; at 150' and 250' the vapor compositions for the

respecti ve liquid compositions reported by Griswold lie a

l i ttl e below those of the present work, while at 275' Gris-

wold's data are considerably l ess than those of thi s work.

A possi bl e explanation for Griswold's low val ues at the

higher temperatures (275') could lie i n the fact that he

charged insufficient material (600 ml.) to the vapor-liquid

equilibrium still to maintain the l evel of the liquid i n the

sti l l necessary so that the liquid sampl e should consi st of

liquid only and not one enriched i n more vol ati l e component

because of contamination of the liquid sample by vapor.

A study of these resul ts for the two systems 2-propanol-

water and ethanol-water shows a great similarity i n the

data, as would be expected. A s the degree of mutual sol-

ubility of comparable systems decreases-for example, i n

thi s case for the systems of water with al cohol s of increas-

ing number of carbon atoms-the y - x curves at atmos-

pheric pressure show: for methanol a concavity upward;

for ethanol a homogeneous azeotrope; for 2-propanol a more

pronounced homogeneous azeotrope; for butanol immiscibil-

i ty over part of the composition rat'ge and a heterogeneous,

azeotrope; and for higher al cohol s, an i ncreasi ng range of

immiscible section.

The effect of pressure on any one system is to decrease

the differences between the components. Thus as the pres-

sure is i ncreased for the systems studi ed, the concavity

112

JOURNAL OF CHEMICAL AND ENGINEERING DATA

a , M E %TION P~PWPbNOL IN LI QUI D

Fi gur e 6. y, x i sot her ms of Zpropanol-water

Mole Fraction

2-Propanol in Liquid

0.004

0.0 10

0.014

0.026

0.050

0.104

0.164

0.253

0.267

0.378

0.495

0.570

0,588

0.661

0.710

0.745

0.818

0.90 5

0.941

0.017

0.024

0.036

0.052

0.072

0.105

0.151

0.201

0.389

0.521

0.599

0.610

0.650

0.682

0.706

0.788

0.862

0.934

0.011

0.025

0.037

0.056

upward decreases, and, at high pressures, the y - x curves

are convex upward to the cri ti cal point of the mixture. The

effect of pressure on the azeotrope will be di scussed latea.

A vapor-liquid equilibrium sti l l is known to gi ve inac-

curate resul ts at conditions approaching the critical point.

I ndeed, the whole operation of the still ceases; at the criti-

cal point the boil-up rate becomes i nfi ni te and the density

difference between the phases becomes zero, and thus en-

trainment becomes infinite. J ust how far below the cri ti cal

point of the mixture entrainment becomes significant has

not been demonstrated, but i t probably i s not appreci abl e

at condi ti ons reasonably removed from the critical point,

because of the big changes i n the densi ti es of the phases

and the heat of vaporization of the mixture, with a smal l

temperature decrease from the cri ti cal temperature. For

these reasons, it was not possi bl e to establ i sh accuratel y

the shape of the pressure-cornposition curves and p - x

curves, i n the region of the cri ti cal point. The critical

l ocus for the 2-propanol-water system i n Fi gure 6 has been

drawn through the si ngl e phase experimental points, and is

only approximate; the amount of material i n the sti l l may

not have been the quantity required to gi ve the cri ti cal vol-

ume, although thi s amount was esti mated approximately

from the general i zed charts and the pseudoreduced condi-

ti ons computed usi ng Kay's rul e (35).

Hougen and Watson (29) state that, for all except pure

compounds or mixtures of compounds differing l i ttl e i n

Tobl e IV. Exper i monkl Vapor-Li qui d Equi l i bri um Data 2.Propanol-Water

Mole Fraction Pressure, Mole Fraction Mole Fraction Press we ,

2-Propanol in Vapor P.S.LA. 2-Propanol in Liquid 2-Propanol in Vapor P.S.I.A.

At 150OC.

0.094

0.151

0.233

0.315

0.382

0.435

0.461

0.501

0.490

0.527

0.574

0.611

0.621

0.667

0.699

0.726

0.788

0.880

0.923

At 200OC.

0.145

0.198

0.253

0.297

0.336

0.363

0.390

0.413

0.495

0.564

0.613

0.618

0.648

0.673

0.69 1

0.762

0.837

0.917

At 25O0C.

0.078

0.148

0.181

0.222

75

80

88

98

112

117

120

124

124

127

131

1 32

132

132

133

132

131

128

125

268

286

30 5

321

339

349

361

369

394

402

407

404

406

403

404

397

389

379

625

678

714

7 52

0.077

0.116

0.175

0.251

0.380

0.489

0.541

0.605

0.638

0.669

0.702

0.738

0.026

0.034

0.050

0.067

0.087

0.119

0.158

0.200

0.223

0.247

0.262

0.280

0.291

0.295

0.310

0.353

0.369

0.419

0.003

0.015

0.095

0.142

0.195

0.273

At 250OC.

0.267

0.304

0.339

0.380

0.448

0.521

0.557

0.612

0.638

0.669

0.702

0.738

At 275OC.

0.114

0.148

0.184

0.211

0.243

0.270

0.293

0.319

0.330

0.342

0.353

0.359

0.366

0.379

0.379

0.395

0.394

0.4 19

At 30O0C.

0.018

0.210

0.222

0.253

0.267

0.273

.s Single phase.

'Vapor sample gassy. Data in error.

dE30th samples gassy. Data in error.

Slightly gassy vapor sample.

791

825

855

890

930

950

960

960

960'

952'

945'

941"

IOOP

10476

1085b

1 I 22b

11566

1190

1232

1261

1275

1289

12%

1310

1318

1323

1325

1345

1350

13484

1290c

1358d

1690d

1699

1753

1791R

~~ ~~ -~

113

VOL. 4, No. 2, APRIL 1959

Tabl e V. Vapor Pressure of 2-Propanol

Temp., Pressure,

0 C. P. S I. A.

144.3

150.0

175.0

200.0

216.3

225.0

108.9

126.7

233.2

389.5

54 2

650

MOLE FRACTION Z- FUORI I OL In LIWIO

Fi gur e 9. y, x i sobar s of 2-pr opanol -wat er

Fi gur e 7. Vapor pr essur e of pur e 2-propanol

Reference substance aster

0 Wilson and Simons

0 Petrohol Data Book

This work

physical properties, the pseudocritical temperature and

pressure [using Kay's rule (391 are l ess than the true criti-

cal temperature and pressure. This is not true for ei ther

of the systems studi ed here; the pseudocritical properties

for mixtures rich i n ethanol are considerably higher than

the true critical properties.

The presence of a maximum pressure azeotrope is re-

sponsi bl e for the flat maximum on the pressure-composition

pl ots at 150' and 200'C. The liquid l i ne (upper l i ne) and

the vapor l i ne (lower l i ne) lie so cl ose together for the al-

cohol-rich end of the pressure-composition diagram that on

Figure 5 they appear as a si ngl e line.

At 25OoC. for both systems, the shape of the curves

shows that the azeotropic composition i s approximately the

HOLE FRACTION ETWNOL IN Ll i Nl D

Fi gur e 8. y, x i sobar s of et hanol -wat er

114

critical composition-that is, the curves reach a maximum

with a zero sl ope on the pressure-composition diagram; and

on the y - x diagram, they become tangent to the 45' line.

I t is not possi bl e to establ i sh whether or not the azeotropes

exi st at thi s temperature. I sobaric y - x pl ots for the sys-

tems have been prepared and presented in Figures 8 and 9.

Al so plotted on these figures are the 1-ab. vapor-liquid

equilibrium data. From Fi gure 9, i t can be seen that for

liquid compositions below 0.05 mole fraction of 2-propanol,

the vapor-liquid equilibria are substantially the same for

thi s experimental work at 100 p.s.i.a. as for Wilson and

Simon's work (78) at 1 atm. Thi s result is unexpected, and

O l I I I I

,so PO0 E50 300 350

T, TEYPERI TURE, .C

Fi gur e 10. Pr essur e-t emper at ur e di agr am of et hanol -wat or

JOURNAL OF CHEMICAL AND ENGINEERING DATA

i ndi cates i naccuracy i n one of these sets of data. There

is no reason to bel i eve that refluxing occurred i n the still

while the present data were bei ng taken, a cause of rich

vapor composition, as the external wall temperatures of

the still were maintained 2' to 5'C. above the l i qui d

temperature.

For comparison with other systems, pressure-temperature

diagrams were constructed and are presented i n Fi gures 10

and 11. Because of the crowding together of the border

curves it is difficult to i ncl ude many compositions on thi s

type of plot. Thi s p , t, x, y space figure so formed is typi cal

of many systems exhibiting a maximum pressure homogene-

ous azeotrope. Similar remarks apply to the ethanol-water

system.

Starting with the vapor-pressure curve of pure alcohol,

the addition of water resul ts i n an extremely narrow border

curve which lies completely above the vapor pressure

curve for the al cohol (not shown i n diagrams). A s the water

content is i ncreased, the dew and bubbl e point curves

merge i nto a si ngl e l i ne for the azeotropi c composition,

which represents the maximum pressure possi bl e at any

temperature. As the water content is further i ncreased, the

space fi gure becomes curved and skewed, so that the upper

part of the border curves lies below, and the lower part,

above the vapor pressure curve for the alcohol. Eventual l y

a composition is reached where the border curves lie com-

pl etel y between the vapor pressure curve of the alcohol

and the curvefor pure water. Thi s skewi ng of the p , t , x, y

space, as shown i n the region rich i n alcohol, is character-

istic of systems whose components form a maximum-pres-

sure azeotrope which persi sts up to the cri ti cal tempera-

ture, as has been pointed out by Kay and Rambosek (36).

These rel ati ons can also be seen by studying the pressure-

compo si ti on diagram s.

These systems do not exhi bi t any maximum or minimum

cri ti cal temperature or pressure, as can be seen from the

cri ti cal loci i n Fi gures 10 and 11. The cri ti cal l ocus for

the 2-propanol-water system (Fi gure 11) is ody approximate

because of the limited data avai l abl e from thi s experimental

work.

The apparently sharp-pointed boundary curves on the

pressuretemperature diagrams, or on the pressure-composi-

tion diagrams, i ndi cate that the cricondentherm, the cri ti cal ,

and the point of maximum pressure coincide, and any zones

of retrograde condensation are absent, or very small. P r e

vi ous work by Griswold and others (24) for the ethanol-

water system also l ed to thi s conclusion.

A more detai l ed di scussi on about the limiting shape of

the various l i nes is given by Barr-David (2).

Al ternati ve pressuretemperature pl ots were attempted to

improve the cl earness of these graphs. A plot of log pres-

sure vs. reciprocal temperature gave a series of al most

strai ght l i nes. As with the previous pl ots, the l i nes crowded

together and became confusing. A better way of presenti ng

the data was to use a referencesubstance plot, and to pl ot

the logarithm of the ratio of total pressure in the system to

the vapor pressure of water, agai nst the vapor pressure of

water at the same temperature, as a reference substance.

At condi ti ons removed from the cri ti cal of ei ther compo-

nent, thi s shoul d be a seri es of straight l i nes. As cri ti cal

condi ti ons are approached, the l i nes become curved. Thi s

method of plotting was found to be too sensi ti ve and the

data points were scattered.

Other methods of correlation of the vapor-liquid equilib-

rium data have been proposed. Othmer and Gilmont (52)

claim that a logarithmic plot of the mole fraction i n the va-

por vs. the total pressure, with mole fraction i n the l i qui d

as parameter yi el ds a seri es of strai ght l i nes for many bi-

nary mixtures including ethanol-water over l i mi ted ranges

[Otsuki and Williams (%)I. Fi gures 12 and 13 show such

plots. Over the extended range of the work, the l i nes are

sl i ghtl y curved, the curvature i ncreasi ng as cri ti cal condi-

ti ons are approached.

Azeot r opi c Behavi or , The behavior of the azeotrope for

the system 2-propanol-water is particularly i nteresti ng, be-

T, TEMPERPTURE, .C.

Fi gur e 11. Pr essur e-t emper at ur e di agram of

2-propanol -wat er

7.

0 1 - z

5 :

5 :

5

A 0 1

7. -1 x

w 01-

9

I -

; o o o -

Y

Y

I

0 oe

-

I I 1 I I I I

DO 100 200 100 1000 ZOW 8000 5 I O 10

0 01

TOTAL PRESSURE, PBIA

Fi gur e 12. y, p di agr am at const ant x o f

et hanol -wat er

TOTA L ~ n c s a u ~ c PSIA

Fi gur e 13. y, p di agram at const ant x of

2-propanol -wat er

VOL. 4, No. 2, APRIL 1959

115

Tabl e VI. Ef f ect of Pressure on Azeotrope 2-Propanol-Water

Pressure, Boiling Point, Composition

P.S.I. A. 'C. M.F. 2-PrOH Reference

59.7 120.45 0,6950 Wilson and Simons (78)

14.69 80.10 0.6870 Wilson and Simons (78)

7.35 63.90 0.6750 Wilson and Simons (78)

3.67 49.33 0.6705 Wilson and Simons (78)

1.83 36.00 0.6670 Wilson and Simons (78)

14.69 80.4 0.681 Lebo (43)

14.69 80.3 0.687 Lecat ( 44)

14.69 80.37 0.6854 Young and Fortley ( 80)

14.69 80.3 0.678 Schumaker and Hunt (69)

14.69 ... 0.6835 Langdon and Keyes (42)

14.69 80.16 0.6813 Btunjes and Bogart (9)

31.8 0.658 Miller and Graves (50)

59.4 0.675 Miller and Graves (50)

80.3 0.681 Miller and Graves (50)

124.6 0.684 Miller and Graves (SO)

151.1 0.671 Miller and Graves (SO)

171.6 0.662 Miller and Graves ( So )

185.0 0.652 Miller and Graves (50)

195.6 0.646 Millgr and Graves (50)

204.8 0.639 Miller and Graves ( 50)

132 150 0.6775 This work

405 200 0.6435 This work

960 250 0.64 This work

Fi gur e 14. Cor r el at i on of azeot r opi c t emperat ures, pres-

sures, and composi t i ons of Zpr opanol -wat er

cause i t is the only system reported i n which the azeotropic

composition passes through a maximum with i ncreasi ng

pressure. The azeoti opi c compositions from thi s experi-

mental work were determined by l arge scale y - x pl ots and

are reported i n Tabl e VI. From the experimental data i t

appears that the azeotropic Composition is approximately

the cri ti cal composition at 25OoC. The present data show

good agreement with those of other investigators.

Othmer and Ten Eyck (55) have i ndi cated a method of

correlating the azeotropi c temperatures, pressures, and

compositions for vari ous binary systems. The azeotropi c

pressure when plotted agai nst the vapor pressure of water

as a reference substance, at the same temperature on a l og-

arithmic plot yi el ds a straight line. Fi gure 14 shows for

these present data thi s l i ne to be almost straight, the cur-

vature probably being due to the extended range of these

data. Othmer al so claims that the azeotropic composition

vs. the vapor pressure of water at the same temperature

yi el ds a straight l i ne, as he i l l ustrated for the system

ethanol-water [Otsuki and Williams (56)l; but i n thi s pl ot

the composition scale is so compressed as to yield a hori-

zontal, straight line. Fi gure 14 shows such a plot for the

system 2-propanol-water, with an extended logarithmic

composition scale. The plot is far from a strai ght line.

The azeotropic compositions for the ethanol-water sys-

tem could not be determined with any degree of accuracy

because of the shape of the plots. For this reason no at-

tempt has been made to correl ate the azeotropic data of

thi s system with that reported in the literature.

Vapor Pressure of 2-Propanal. For determining limiting

val ues of many of the previ ous graphs, and for thermody-

namic cal cul ati ons, the vapor pressure of pure 2-propanol

was measured. The data are summarized in Tabl e V and

presented as a reference-substance plot in Fi gure 7. Thi s

plot shows the excel l ent agreement between the present

work, the data given by Wilson and Simons (78) and the

val ue of the critical pressure given i n the Petrohol data

book (17).

Decomposi t i on Test s. During the study of the low alcohol-

concentration end of the 250' and 275' isotherms of the 2-

propanol-water system, traces of gas were found to be dis-

sol ved i n the vapor sample. Thi s gas formed smal l bubbl es

in the pycnometers, and care had to be taken to avoid er-

rors from thi s cause i n the densi ty determinations. The

gas formation was evident only for the di l ute concentration

range-namel y, 0.15 mole fraction of 2-propanol i n the re-

boiler, or less. At 300' l arge amounts of gas were formed

for concentrations of 2-propanol i n the reboiler of 0.15

mole fraction or less, the l owest concentration tested being

0.01 mole fraction of 2-propanol. The extent of gas forma-

tion was sufficient to prevent experimental vapor-liquid

equilibrium data from being col l ected i n thi s range. The

higher concentration range of the 2-propanol-water isotherm

at 300' up to the cri ti cal composition (0.273 mole fraction)

did not show gas formation at all, and the data were col-

l ected satisfactorily. No attempts were made to measure

the vapor-liquid equilibria for thi s system at any higher

temperatures.

The gas was identified, by i ts infrared spectrum and by

i ts power of decolorizing a solution of bromine i n chloro-

form, to be propene. Because hydrogen and acetone can

easi l y form from the dehydrogenation of 2-propanol i n the

presence of the correct catal ysts, the absence of dehydro-

genation was confirmed by the infrared spectrum and by 2,4-

dinitrophenylhydrazine. The infrared spectrum also showed

diisopropyl ether to be present.

Apparently the decomposition was a simple dehydration

reaction. 2-Propanol is known to dehydrate and propene to

hydrate with greater ease than ethanol and ethylene, r e

spectively. Because only the more dilute propanol solu-

ti ons decomposed, and the stronger solutions, the decom-

position of which is more thermodynamically favorable, did

not decompose, the reaction was considered to be catal yzed

by the oxi de on the A.I.S.I. 4130 steel wal l s of the sti l l , or

by the steel i tsel f, rather than to be a homogeneous reaction.

Thi s was confirmed by a seri es of decomposition tests.

These decomposition tests were conducted as follows.

A seri es of gl ass tubes containing aqueous sol uti ons of 2-

propanol ranging i n concentration from 0.01 to 1.0 mole

fraction of 2-propanol was sealed. Some tubes contained

pi eces of A.I.S.I. 4140 steel, previously cl eaned and com-

pl etel y freed from oxide by boiling i n a strong aqueous so-

lution of hydrochloric acid. These tubes were pl aced i n a

high-pressure steel bomb, some di l ute propanol was added

to the bomb outsi de the tubes to maintain approximately

equal pressures on both si des of the gl ass tubes, and the

bomb was heated to 320'C. for 10 hours and then cooled.

The 2-propanol solution (0.1 mole fraction) which was

pl aced in the steel bomb (Type 410 stai nl ess steel) out-

si de the gl ass tubes was extensively decomposed i nto pro-

pene, and much propene had polymerized to a yellow, oi l y

polypropene. None of the sampl es of 2-propanol i n the

gl ass tubes was found to be decomposed. Apparently

neither the glass (which was heavily etched by the aqueous

sol uti ons on both si des) nor the oxi defree steel is a cata-

l yst for the dehydration of 2-propanol i nto propene.

Although no evidence of gas formation was found during

the determination of the vapor-liquid equilibria of ethanol-

water, similar tests were conducted usi ng ethanol sol uti ons

i n seal ed gl ass tubes, some containing A.I.S.I. 4140 steel.

Once agai n no decomposition of the sol uti ons i nsi de the

gl ass tubes occurred. Very slight decomposition of the 0.1

116

JOURNAL OF CHEMICAL AND ENGINEERING DATA

mole fraction ethanol solution i n the steel bomb did occur,

a smal l amount of gas (presumed to be ethylene) col l ecti ng

in the steel bomb.

From these tests it was concluded that the oxi de formed

on A. I. S. I. 4140 and similar steels is an acti ve catal yst for

the decomposition of di l ute 2-propanol sol uti ons. The

catal yst is acti ve only i n sol uti ons containing less than

0.15 mole fraction of 2-propanol i n the liquid phase (at

250" thi s corresponds to about 0.33 mole fraction i n the

vapor phase). The decomposition is slow at 250' and

275", but is fast and extensi ve at 300C. No tests were

made to determine i n which phase the catal yst was acti ve,

nor were tests conducted to determine the catal yti c prop

erties of austeni ti c stai nl ess steel i n thi s dehydration

reaction. Possi bl y a still made of 300-seri es stai n-

less steel would have permitted the experimental work in

the 2-propanol-water system to be continued to higher

temperatures.

THERMODYNAMIC ANALYSIS OF DATA

Theor et i cal Consi der at i ons Based on' Gi bbs-Duhem Equa-

t i on, Vapor-liquid equilibrium data may i n pri nci pl e be

checked for thermodynamic consi stency by means of the

Gibbs-Duhem equation. For isothermal data a pressure-

correction term is necessary, as the commonly presented

si mpl e form of thi s equation hol ds for constant pressure

and constant temperature, which for binary sol uti ons is not

permitted by the phase rule. The error i n omitting the

pressure term becomes great as the critical state of one of

the components is approached. A form of the Gibbs-Duhem

equation, for the liquid phase of a binary solution, sui tabl e

for isothermal data, is given by I bl and Dodge (31), and

may be written:

x dl n f (1 - x ) d l n c v,,, dp

dx dx RT dx

+ =- -

If suffi ci ent information is avai l abl e, the necessary

quanti ti es i n Equation 1 may be cal cul ated, and the data

may be checked by graphical differentiation at vari ous

compositions. I t is convenient to use an i ntegrated form

of the Gibbs-Duhem equation to obvi ate the need for graph-

ical differentiation. A sui tabl e form is:

1 -

l n F x f /x dx =In fa/fw -- J p e v, dp (2)

RT

p w

Without the correction term for the variation i n pressure,

thi s equation can be put i n the form:

r l

(3)

Thi s is the equation used by Redl i ch and others (62) for

testi ng experimental data.

An i ntegrated equati on such as Equation 2 can be used

only below the cri ti cal temperature of both components of

the solution; above the critical temperature of one compo-

nent the equation cannot be i ntegrated over the composi-

tion range x =0 to x =1.

The most common method of correlating vapor-liquid

equilibria by the Gibbs-Duhem equation is to make use

of the sol uti ons given by van L aar (41), Margules (47), or

Scatchard and Hamer (67). A review of these rel ati ons is

given by Wohl (79) and their application to speci fi c cases

is given by Carl son and Colburn (If). For a rel i abl e ther-

modynamic check one must use equati ons such as 2 or 3,

but when the experi ments are made at el evated pressures

thi s i nvol ves di ffi cul ti es which make the resul ts unreliable.

The problem of testi ng vapor-liquid equilibrium data re-

sol ves i nto cal cul ati on of the various terms i n the Gibbs-

Duhem equation. Di ffi cul ti es arise i n the cal cul ati on of

the fugaci ti es of the components i n the solution for associ -

ating compounds at high pressure, because of insufficient

information. Because at equilibrium the fugacity of a com-

ponent i n the vapor phase is equal to the fugacity of the

component i n the liquid phase, the fugaci ti es of the com-

ponents i n the vapor solution are computed, and used i n

the equati ons involving liquid-phase fugacities.

Methods of Cal cul at i on of Fugaci t i es. The fugacity of a

component i n a solution may be defined by the expression:

- 1 P -

R T i

I n f =- ( VI - V,)dp +In fI yI

(4)

If necessary P-V-T data are avai l abl e, the fugacity of the

components i n the solution may be exactl y eval uated by

such an expression. Because of the very meagre amount

of P-V-T data avai l abl e for gas mixtures at vari ous composi-

ti ons, such methods are of l i ttl e value, and for thi s reason

many attempts have been made to use the data on the in-

dividual components to predict those for the mixture.

Two general methods of attack on the problem have been

used. One i nvol ves the development of an equation of state

for the mixture, which is then used to i ntegrate the thermo-

dynamic expressi on for the fugacity. The other approach

is based on empirical rul es such as the Lewi s and Randal l

fugacity rule or the use of a pseudocri ti cal pressure and

temperature of the mixture combined with the use of gener-

al i zed properti es to obtain the fugacity of a mixture, and

from thi s component fugaci ti es are obtai ned by the relation

for partial molal quantities.

Equat i ons of St at e. In thi s method the equati ons of state

for the pure components are used, the constants being com-

bined i n some manner, so that the resul tant equation of

state is val i d for the mixture. Substitution of the equation

of state for the mixture i nto an equation such as 4 gi ves

the required fugaci ti es.

Three commonly used equati ons of state are those of van

der Waals, Reattie-Bridgeman (4) and Benedi ct, Webb, and

Rubin (6, 7). Methods of combination of the constants of

equati ons of state are given by Dodge (14). However, the

choi ce of method of combining constants is semiempirical,

and no guiding rul es can be given as to the best method i n

all cases.

Thi s method of cal cul ati on of fugaci ti es of components

of a binary sol uti on can never be stri ctl y appl i ed in the

case of vapor-liquid equilibrium, because each component

is necessari l y stabl e i n only one phase when pure at the

temperature and pressure of the solution. I t is still con-

si dered val i d to combine the constants, even though one

component does not exi st as vapor under the conditions.

L i ttl e work has been done to test the validity of thi s

extrapolation.

Gilliland (21) proposed a method of treating the compres-

si bi l i ty of gas mixtures that is based on the use of an

equation of state of the linear-isometric form and on vari-

ous schemes for combining the constants. The fugacity

equati on based on thi s method is given by Gilliland and

Sullivan (22). Kritschewsky (38) states that thi s rul e for

fugaci ty gi ves better agreement with the true fugaci ti es at

high pressures than ei ther Bartl ett's rule or the L ewi s and

Randall rule. The l i near i sometri c rul e is complicated to

use and does not hold as the saturati on l i ne is approached,

which is the very region of i nterest i n vapor-liquid equilib-

rium cal cul ati ons.

More recentl y a simple equation of state has been pro-

posed by Redl i ch and Kwong (a), whose constants can be

determined from the cri ti cal pressure and temperature of

the substance. Redlich, Kister, and Turnquist (62) show

how the constants of thi s equation may be combined to give.

the fugacity of a component i n a solution, and present

graphs which greatly simplify the cal cul ati on of the fugacity.

Calculation of the fugaci ti es

by assuming i deal solution is probably the most widely

used method. Thi s method is commonly cal l ed theL ewi s and

L ewi s and Randall Rule.

VOL. 4, No. 2, APRIL 1959

117

Randall (45) rule.

rul e, i t will be consi dered i n some detail.

Because of the extensi ve use of thi s

Because volume is an extensi ve property,

- - -

v =VaXe +VbXb +. . . 4- v n n x

An i deal solution is one so defined that the partial molal

volumes are independent of composition up to the pres-

sures of the solution and i n the range of temperatures

which i ncl udes the temperature under consideration. If the

vari ous components of an i deal solution are stabl e i n the

pure state at the pressure and temperature of the solution,

then

-

v =VI

the molal volume of pure i at p and t . Then Equation 5 b e

comes

( 7)

v = vexe +VbXb +. . . vnxn

or the volumes are additive.

For the reasons previously stated i n considering the

equati ons of state for the components, Equation 7 can

never be stri ctl y applied i n the case of vapor-liquid equi-

librium because one component does not exist as a gas

under the conditions. In practi ce the necessary information

is extrapolated to gi ve the information required.

Substitution of 6 i n 4 gi ves

r, =Y, f ,

Equation 8 represents the L ewi s and Randall fugacity

rule. The fugacity of the pure component, f,, at the tem-

perature and pressure of the solution may be obtained from

P-V-7 data for pure i, or from general i zed correlations.

I t must be remembered that Equation 8 stri ctl y appl i es

only when the volumes are addi ti ve over the complete pres-

sure range, from zero pressure up to the pressure of the ex-

perimental data, and the pure component is stabl e as a gas

at the pressure and temperature of the solution. Thi s can

be readily seen from Equation 4.

The error i n the L ewi s and Randall rul e is the val ue of

the integral i n thi s equation, and i t can be seen that over

the pressure range from zero pressure up to the pressure p

of the solution, F, must be equal to vl.

To summarize the condi ti ons for a solution to be i deal

for all compositions, Equation 6, 7, or 8 must be val i d for

all pressures up to the pressure of the solution, and over

the range of temperatures which i ncl udes the temperature of

the solution. However, a solution can behave i deal l y at a

certain composition if these equati ons hold over the com-

position range which i ncl udes the composition under ques-

tion, the temperature range which i ncl udes the temperature

of the solution, and for all pressures up to the pressure of

the solution. Van Ness (74) gi ves a more complete discus-

si on of the i deal solution and the condi ti ons of its validity.

I t is concluded by Gilliland and Sullivan (22) that the

L ewi s and Randall rule can gi ve l arge errors at high pres-

sure, and, as an approximate criterion for most mixtures, i t

is not l i kel y to be sati sfactory at pressures greater than

0.6 ti mes the cri ti cal pressure of the component i n ques-

tion. Hougen and Watson (30) state that the rule is satis-

factory for pseudoreduced pressures of less than 0.8. Thi s

is much less limiting than the restriction imposed by

Gilliland and Sullivan, and would permit the use of thi s

rul e at pressures far i n excess of the cri ti cal pressure for

a component i n solution with another component with a

much higher cri ti cal pressure. The fugaci ti es computed i n

the range permitted by Hougen and Watson's criterion must

be i n error under these circumstances.

A method often employed for the

cal cul ati on of fugaci ti es is to cal cul ate the fugacity of the

mixture by means of correl ati ons developed for pure gases,

using the pseudoreduced temperature and pressure of the

Partial Molal Method.

mixture, eval uated by combination of the cri ti cal constants

of the pure components.

The fugacity of the mixture is defined by the equation:

(9)

The concept of fugacity of a mixture differs from the

concept of fugacity of a component-that is, an escapi ng

tendency. A similar physical meaning cannot be applied to

the concept, I t is best regarded as a si mpl e method of ex-

pressi ng the integral above.

The fugacity of any component in the gaseous mixture is

then cal cul ated by the relation

The differentiation may be performed graphically on a

plot of f, vs. the number of moles of the component.

The need for carrying out the graphical differentiation

has been removed by a modification of Gamson and Watson

(19), while J offe (32) showed that the general i zed charts

for gases may be used for calculation with a method si mi -

l ar to that of Gamson and Watson. The procedure devel-

oped by J offe is the most convenient of the partial molal

techni ques and probably gi ves the most sati sfactory method

for calculation of the fugaci ti es of components i n a solu-

tion, except when partial molal volume data for the mixture

are available.

Assuming (1) that f, is a function of p , 7, and the y' s

f

but that the fugacity coefficient -E is a function only of p R

P

and 7, ; (2) that the generalized correlation for fugacity

coefficient of a gas is valid; and (3) that Kay's rul e may

be used for the calculation of the pseudocritical pressure

and temperature of the mixture, the following equati on is

obtained:

In his development, Joffe assumed that Q was a function onl y

of p R and TR. Bretton ( 8 ) pointed out the error on t hi s and gave

a more logical derivation leading to the same final equation as

obtained by Joffe.

Bartl ett's Rule. Bartlett's rule of addi ti ve pressures

states that

P Yi Pi +YaPa (12)

where p i and p a are taken at the molal concentration of the

mixture.

Kritschewsky (38) has shown that combination of Equa-

ti ons 12 and 4 gi ves the fugacity equation, referred to by

Gilliland and Sullivan (22) as Bartl ett's rule.

..

- "m - p i )

In f, =In ylfl +

RT

where

v, =molal volume of mixture

Kritschewsky's Rule. Kritschewsky (37, 39) has pro-

posed an improvement for Bartl ett's rule of addi ti ve pres-

sures by adding a correction term that is a function of the

pressures and the compositions, but not the temperature.

Thi s rule, and the fugacity equation derived from it, are

given by Gilliland and Sullivan (22). Thi s method has the

great di sadvantage of requiring that P- V- T data for one mix-

ture composition be known.

The

thermodynamic consi stency of some of the experimental

Ther modynami c Consi st ency of Exper i ment al Dat a.

118

JOURNAL OF CHEMICAL AND ENGINEERING DATA

Fi gur e 15. Fugaci t i es of component s i n sol ut i on

2-propanol-water, 200 O C.

Alcohol Water

0 0 Computed using method of Joffe

8 8 Computed using method of Redlich et af.

(D 0 Computed using ideal solutions

data of this research was tested by means of the Gibbs-

Duhem equation, expressed in the form of Equati on 2.

Lack of P-V-T data for the ethanol-water and Z-propanol-wa-

ter systems precl udes the exact thennodynamic calculation

of the fugaci ti es of components i n solution. I t is therefore

necessary to resort to other methods of cal cul ati on out-

l i ned i n the previous section. Because of the i nconcl usi ve

resul ts due to questi onabl e assumpti ons made, the con-

si stency of the 200' isotherm for the 2-propanol-water

system was the only one tested. The di sadvantages and

the assumpti ons involved i n the vari ous methods are

di scussed.

Calculation of Fugaci t i es. The 200' i sothen for the

2-propanol-water system has been computed usi ng the

L ewi s and Randal l rule. The resul ts are presented graph-

i cal l y i n Fi gure 15.- Thi s graph was extrapolated to give

limiting val ues of (fi/xt). The assumpti ons made in thi s

computation are known to be not valid. Although the pres-

sures involved are less than 0.6 ti mes the cri ti cal pres-

sure of the component i n question, the limit imposed by

Gilliland and Sullivan (22), the volumes of the components

of the solution are not addi ti ve or the conditions pre-

viously stated because of the associ ated nature of each

component, and i nterassoci ati on of the two molecular spe-

cies. Furthermore, some m r is introduced by the use of

the generalized fugacity coefficient pl ot of Hougen and

Watson (28) for the evaluation of the fugaci ti es of the pure

components.

The fugacity data were cal cul ated al so by the method

proposed by J offe (33). Thi s method probably is the most

satisfactory approach, but the val ues obtained for the

fugaci ti es are still i n question, because of the assump

ti ons involved-namely, that the generalized correlations

for gases are valid, and that Kay's rul e may be used for

calculation of the pseudocritical temperature and pressure.

Both assumpti ons are known to be incorrect. The val ues

obtained are al so presented i n Fi gure 15. These were

computed using the general i zed charts of Hougen and

Watson (28).

Another method used for the calculation of the fugaci ti es

was that proposed by Redlich, Kister, and Tumqui st (62)

based on the Redl i ch and Kwong (63) equation of state.

Thi s method of cal cul ati on assumes that the Redl i ch and

Kwong equation of state hol ds for both components and

that the method of combination of the constants of the

equations of state is valid. Again with the 2-propanol-

water system the extent of deviation from these assump

ti ons is unknown. The resul ts for the 200C. isotherm are

summarized i n Fi gure 15.

Examination of Figure 15 shows fair agreement between

the three methods of cal cul ati on of fugacity. 3ecause

some of the assumpti ons which are open to doubt, such as

the l aw of corresponding states, used for these cal cul ~t

ti ons are common to all three methods, t hi s result i s not

too surprising. The fugacity of 2-propanol i n 2-propanol-

rich mixtures is probably greatly i n error, because, i n the

case of the fugacity computed by assuming i deal solutions,

the integral term i n Equati on 4 is omitted. This integral is

by no means negligible i n the case of conditions approach-