Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Analyse and Design of Truss by STADPro

Caricato da

Suvajit Bisai0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

163 visualizzazioni18 pagineThe document provides steps to analyze and design a steel truss using STAAD Pro software. The steps include:

1) Creating a model of the truss by defining the geometry, member properties, loads and supports

2) Performing an analysis on the model by running the STAAD engine

3) Viewing the results of the analysis, including reactions, member forces and displacements

4) Checking the design of the truss members against code requirements.

Descrizione originale:

staad pro guide for truss

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThe document provides steps to analyze and design a steel truss using STAAD Pro software. The steps include:

1) Creating a model of the truss by defining the geometry, member properties, loads and supports

2) Performing an analysis on the model by running the STAAD engine

3) Viewing the results of the analysis, including reactions, member forces and displacements

4) Checking the design of the truss members against code requirements.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

163 visualizzazioni18 pagineAnalyse and Design of Truss by STADPro

Caricato da

Suvajit BisaiThe document provides steps to analyze and design a steel truss using STAAD Pro software. The steps include:

1) Creating a model of the truss by defining the geometry, member properties, loads and supports

2) Performing an analysis on the model by running the STAAD engine

3) Viewing the results of the analysis, including reactions, member forces and displacements

4) Checking the design of the truss members against code requirements.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 18

Design and Analysis of Truss Using Staad Pro

Analysis and Design of Truss using Staad Pro

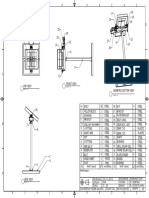

The above figure shows a truss from several truss supposed to cover certain area.As shown the

truss has a cantilever part ,its span equals 4 meters.The proposed truss depth is 3 m.The loads are

shown as concentrated on tuss joints.The values of its load case are shown .

Use all the data you take in steel course to design and analyze steel truss.

Main Steps Of Modeling Truss in STAAD PRO

Entering Job information

Building model geometry

Defining member properties ,sections

Assigning Loads(Load Cases and combination)

Defining Pre-Analysis Print out,analysis type and Post-Analysis print out

Defining Design Requirements

Note :To see the image clearly click the image.

How to Start Staad Pro

The Pic below shows how to start Staad Pro

Click the picture to enlarge

In New File select

1. Truss

2. Units (here KN and mm in this example)

The staad Graphical interface will appear as

shown in below picture

1-Entering Job Information

2-Building Model (structure) Geometry

Defining Truss Geometry

One of the methods that you can construction lines and then draw on these lines the truss

members

Noting that the no. of construction lines is excluding Ist line..

After clicking Snap Node/Beam ,use the

mouse and connect between nodes created at the intersections of construction lines

How to see Diagram Labels(Nodes Numbers,Beam Numbers etc)

Node and beam labels are a way of identifying

the entities we have drawn on the screen, and very useful when dealing with the output results

3. Defining member properties, sections

Property

In which we can define or choose sections properties of the members of the truss.

Spec.:

In which we can define or choose members specifications.

Support:

In which we can define the supports properties (restraints).

Load:

In which we can define the applied loads, load cases, load combinations.

Material

In which we can define the material properties (ex. E, density, etc.)

Assume Preliminary Sections:

Using The Canadian Steel Tables

All Top and Bot chords are one size L 55*55*3

All Diagonals and verticals are one size L 45 * 45* 3

Assigning the sections created to the model

Supports

By clicking on the support icon the shown window will appear. We have to create new kinds of

supports

Use the mouse and click on the nodes according to its support type as shown below

4. Defining Loads

The creation and assignment of load cases involves the following two steps:

1. First, we will be creating all 3-load cases.

2. Then, we will be assigning them to the respective members/nodes

For example

Dead Load Case can be Load Case No.1

Live Load Case can be Load Case No. 2 and Wind Load is the Case No.3

Also, we can define load combinations according to required.

For example, we can create a load combination

1.25 D.L. + 1.5 L.L + 0.8 W.L.

and In Dead Load Create the Self weight as

In each Load Case Creat the Nodal Loads on

truss as specified before.Make sure of the direction of forces acording to global coordinates

After Creating the commond of (Perform

Analysis-Check);We have to assign the members that want to be this type of analysis for it.

Click Assign and then use the cursor and choose all the members,thus all the members should

be highlighted as shown below.

Pre-Print

To add the Pre-Print Commond click" Define Commands"

For example here we have choosen to print the

support reactions,member forces,joint displacements

Post Print Commands

Support reactions

Analysis results

Member Forces

Max Forces

Add which property you need and then use cursor to ASSIGN to which member in the truss

6-Defining Design Requirements

Steps

1. To Specify steel design parameters,go to Design/Steel page from the left side of the

screen.Make sure that under the Current Code selections on the top right hand side ,Canadian is

selected.

There are many Design Commands in the

STAAD Design subroutine.Here,we will use only to Check Code,regarding adequacy of

members.

7-Analysis & Viewing Results

STAAD Performs Analysis and Design simultaneously. In order to Perform Analysis and

Design,select the Run Analysis option from the Analyze menu

When you select the Run Analysis option from

the Analyze menu,the following dialog box appears.We are presented with the choice of 2

engines.the STAAD engine and the STARDYNE Advanced Analysis engine.The

STARDYNE Analysis engine is suitable for advanced problems such as Buckling

Analysis,ModaL Extraction using various method ,etc

STAAD engine is suitable for this tutorial. Click on th Run Analysis button.

The soloving process is shown in pop up

screen.

Visualization of Some Results

Note

Generally,in any program ,try to make some checks about the shapes of

defletions,BMD,SFD.Also check the level of reactions. Just to make sure that there is no

significant nput error.

Viewing The OutPut File

During the analysis process,STAAD creates an Output file .This file provides important

information on whether the analysis was performed properly.

For example,if STAAD.Pro encounters an instability problem during the nalysis process,it will

be reported in the output file.

Alternatively ,we can select the File/View/Output File/STAAD Output option from the top

menu.

The Output File

Its name is <>

As shown for example ,below are the results of the steel design check.

Potrebbero piacerti anche

- Staad Pro BasicsDocumento49 pagineStaad Pro BasicsSteven SebastianNessuna valutazione finora

- STAAD - Slab Design: Method 1: As Suro Mentioned, This Method Involves Specifying Design Parameters SuchDocumento6 pagineSTAAD - Slab Design: Method 1: As Suro Mentioned, This Method Involves Specifying Design Parameters Suchsivasan10006098Nessuna valutazione finora

- Staad Basics: - Notes On The Effective Use of Staad-Pro Rel 3.1Documento17 pagineStaad Basics: - Notes On The Effective Use of Staad-Pro Rel 3.1kardels100% (14)

- Staad Lecture PDFDocumento3 pagineStaad Lecture PDFJohn SewNessuna valutazione finora

- Footings Design ProcedureDocumento19 pagineFootings Design ProcedureJanakiram GoudNessuna valutazione finora

- Tekla, Strucures, Hints, And, TipsDocumento5 pagineTekla, Strucures, Hints, And, Tipsrk_gprkavi2011Nessuna valutazione finora

- 5-Design of Raft FoundationDocumento2 pagine5-Design of Raft FoundationheshamNessuna valutazione finora

- Staad - Pro2007 FullCourseDocumento353 pagineStaad - Pro2007 FullCourseEon ErLobNessuna valutazione finora

- Design of Raft FoundationDocumento3 pagineDesign of Raft FoundationBikram BhusalNessuna valutazione finora

- ETABS ExampleDocumento40 pagineETABS ExampleRaj ShahNessuna valutazione finora

- Seismic Analysis and Design of R.C.C Tall Building With Shear WallDocumento9 pagineSeismic Analysis and Design of R.C.C Tall Building With Shear WallNaveen JatavNessuna valutazione finora

- TR.31.2.10 IS - 1893 (Part 1) 2016 Codes - Lateral Seismic LoadDocumento5 pagineTR.31.2.10 IS - 1893 (Part 1) 2016 Codes - Lateral Seismic LoadsvnNessuna valutazione finora

- CE6686 - Design of RCC and Composite StructuresDocumento12 pagineCE6686 - Design of RCC and Composite StructuresSabarinath MuruganNessuna valutazione finora

- Water Tank DesignDocumento9 pagineWater Tank DesigncadetpalangNessuna valutazione finora

- Channel Bed Slope, S 1/200 From Figure H4-1, We Know That:-When H 310 MM Then, Q 22.7 X 10 M /sDocumento4 pagineChannel Bed Slope, S 1/200 From Figure H4-1, We Know That:-When H 310 MM Then, Q 22.7 X 10 M /sFendy RoynNessuna valutazione finora

- P MemberDocumento4 pagineP MemberrkukgNessuna valutazione finora

- Areva T& D India Limited: Design of Circular Sump Input DataDocumento2 pagineAreva T& D India Limited: Design of Circular Sump Input DatajatinNessuna valutazione finora

- StaadPro FAQDocumento250 pagineStaadPro FAQJose Luis Velasco CadavidNessuna valutazione finora

- Sambungan Sewerage TableDocumento3 pagineSambungan Sewerage TableAmyra MiaNessuna valutazione finora

- Seismic Analysis and Design of Multistoried Steel Structure Using IS 1893:2016Documento14 pagineSeismic Analysis and Design of Multistoried Steel Structure Using IS 1893:2016Shantanu DateraoNessuna valutazione finora

- Technical Report StaadDocumento48 pagineTechnical Report StaadochukoikoghoNessuna valutazione finora

- Slab-On-Grade Reinforcing DesignDocumento9 pagineSlab-On-Grade Reinforcing DesignAdam GreenlawNessuna valutazione finora

- Column LoadsDocumento3 pagineColumn LoadsV.m. RajanNessuna valutazione finora

- Intze Tank-75kL Design 16M STAGING - SBC 8TON PER SMTDocumento25 pagineIntze Tank-75kL Design 16M STAGING - SBC 8TON PER SMTMUKESH RAJENDRANessuna valutazione finora

- DBR How To MakeDocumento15 pagineDBR How To Maketanmay271100% (1)

- Load - Calculation For Dead LoadDocumento6 pagineLoad - Calculation For Dead LoadSandesh PrajapatiNessuna valutazione finora

- RCC Retaining WallDocumento3 pagineRCC Retaining Wallsuganthi1711Nessuna valutazione finora

- Reinforcement: V, F: Project: Staircase Design - STC 1Documento4 pagineReinforcement: V, F: Project: Staircase Design - STC 1zzweirdozzNessuna valutazione finora

- Tutorial SheetsDocumento5 pagineTutorial SheetsMr.A.R. VimalNessuna valutazione finora

- STAAD GuideDocumento8 pagineSTAAD GuideFerdinand DagaNessuna valutazione finora

- 2.pile - Cap.design ColumnsDocumento9 pagine2.pile - Cap.design Columnstaha abu el hanaNessuna valutazione finora

- Analysis and Design of (G+100) Storied Building by Using SoftwareDocumento3 pagineAnalysis and Design of (G+100) Storied Building by Using SoftwareInternational Journal of Innovations in Engineering and ScienceNessuna valutazione finora

- Etabs Check ListDocumento6 pagineEtabs Check ListLokeswar SahaNessuna valutazione finora

- Staadpro2006 Module-1 WorkbookDocumento32 pagineStaadpro2006 Module-1 Workbooksaistructure3500Nessuna valutazione finora

- Seismic Design Steps: Er.T.Rangarajan, B.E, M.SC (Struct - Engg), Consulting Structural EngineerDocumento16 pagineSeismic Design Steps: Er.T.Rangarajan, B.E, M.SC (Struct - Engg), Consulting Structural EngineercivilsadiqNessuna valutazione finora

- Computer Aided Analysis and Design of Multi-Storeyed BuildingsDocumento66 pagineComputer Aided Analysis and Design of Multi-Storeyed BuildingsPeter Saxena100% (1)

- Wind Load IS875Documento30 pagineWind Load IS875Pranjal Pareek100% (2)

- A. Pile Capacity CalculationDocumento24 pagineA. Pile Capacity CalculationAzizi RazakNessuna valutazione finora

- Annular Raft Under 1250 Cum OHRDocumento1 paginaAnnular Raft Under 1250 Cum OHRanirban dasNessuna valutazione finora

- The Boundary Element Method for Plate AnalysisDa EverandThe Boundary Element Method for Plate AnalysisNessuna valutazione finora

- Lecture Notes on Reinforced Concrete DesignDa EverandLecture Notes on Reinforced Concrete DesignNessuna valutazione finora

- Discrete Element Method to Model 3D Continuous MaterialsDa EverandDiscrete Element Method to Model 3D Continuous MaterialsNessuna valutazione finora

- Design and Analysis of Truss Using Staad ProDocumento18 pagineDesign and Analysis of Truss Using Staad Progautamshankar67% (3)

- Software Application Lab ManualDocumento87 pagineSoftware Application Lab ManualKiran M S100% (1)

- Staad Tut1Documento58 pagineStaad Tut1gundulp100% (1)

- StaadDocumento47 pagineStaadDaniel RhinoNessuna valutazione finora

- Sacs MarcieladewaDocumento15 pagineSacs MarcieladewajachoijachoiNessuna valutazione finora

- Staad ProDocumento24 pagineStaad Proammigalla swethaNessuna valutazione finora

- Computer Application in Civil EngineeringDocumento21 pagineComputer Application in Civil EngineeringSangeetha AnguchamyNessuna valutazione finora

- Lesson 2 - Simple Continuous Beam AnalysisDocumento6 pagineLesson 2 - Simple Continuous Beam AnalysisGunabalasingam JeneevanNessuna valutazione finora

- STEEL Designer ManualDocumento27 pagineSTEEL Designer ManualDeveloperNessuna valutazione finora

- STAAD-PRO-tutorial ExampleDocumento50 pagineSTAAD-PRO-tutorial ExampleAmir MushtaqNessuna valutazione finora

- Design of Steel Truss STAADDocumento50 pagineDesign of Steel Truss STAADrebtagg100% (12)

- Tehnical University Gheorghe Asachi From Iasi Faculty of Civil Engineering Master IseDocumento26 pagineTehnical University Gheorghe Asachi From Iasi Faculty of Civil Engineering Master IseIon IovitaNessuna valutazione finora

- Finite Element Method Using Pro ENGINEER and ANSYSDocumento11 pagineFinite Element Method Using Pro ENGINEER and ANSYSsunil481Nessuna valutazione finora

- PDS StructuralEnterprise LTR 0517 LR FDocumento7 paginePDS StructuralEnterprise LTR 0517 LR FcristinelbNessuna valutazione finora

- Solidworks NotesDocumento27 pagineSolidworks NotesCadcam CentreNessuna valutazione finora

- Master Series Design NotesDocumento11 pagineMaster Series Design NotesGE MutaiNessuna valutazione finora

- Delhimetrophaseiii, TBM 1: Project No.: S-839Documento2 pagineDelhimetrophaseiii, TBM 1: Project No.: S-839Suvajit BisaiNessuna valutazione finora

- Bore Hole Owner DetailsDocumento1 paginaBore Hole Owner DetailsSuvajit BisaiNessuna valutazione finora

- Delhimetrophaseiii, TBM 1: Project No.: S-839Documento2 pagineDelhimetrophaseiii, TBM 1: Project No.: S-839Suvajit BisaiNessuna valutazione finora

- UK Report0025 PDFDocumento2 pagineUK Report0025 PDFSuvajit BisaiNessuna valutazione finora

- Bore Hole Details From Palam Station To CC - 1Documento1 paginaBore Hole Details From Palam Station To CC - 1Suvajit BisaiNessuna valutazione finora

- MS - Borewell Removal (Rev.0) NDS30Documento17 pagineMS - Borewell Removal (Rev.0) NDS30Suvajit BisaiNessuna valutazione finora

- ITA-Working Group Research - Guidelines For Design of Shield Tunnel LiningDocumento49 pagineITA-Working Group Research - Guidelines For Design of Shield Tunnel LiningrasanavaneethanNessuna valutazione finora

- Cutterhead Torque ModelingDocumento11 pagineCutterhead Torque ModelingSuvajit BisaiNessuna valutazione finora

- Determinate and Indeterminate Structures - FilesDocumento8 pagineDeterminate and Indeterminate Structures - FilesSuvajit BisaiNessuna valutazione finora

- Grouting PDFDocumento22 pagineGrouting PDFSuvajit BisaiNessuna valutazione finora

- Cant Deficiency, Curving Speeds and TiltDocumento20 pagineCant Deficiency, Curving Speeds and TiltSuvajit Bisai100% (1)

- FetchDocumento38 pagineFetchshashankniecNessuna valutazione finora

- Basso - 2001 - Neurobiological Relationships Between Ambient Ligh PDFDocumento11 pagineBasso - 2001 - Neurobiological Relationships Between Ambient Ligh PDFVíctor MJNessuna valutazione finora

- BM 2 Operations Management and TQM NewDocumento9 pagineBM 2 Operations Management and TQM NewEly GragasinNessuna valutazione finora

- Paul Brunton - WikipediaDocumento3 paginePaul Brunton - WikipediaShabd_MysticNessuna valutazione finora

- Case Study: Question 1)Documento2 pagineCase Study: Question 1)Hoai CoiNessuna valutazione finora

- Human Resource Management in Banking Sector in STATE BANK OF INDIA by PrinceDocumento83 pagineHuman Resource Management in Banking Sector in STATE BANK OF INDIA by Princemayur pawarNessuna valutazione finora

- Product PolyolDocumento1 paginaProduct PolyolAgung SiswahyuNessuna valutazione finora

- Week 3 Lecture SlidesDocumento23 pagineWeek 3 Lecture SlidesMike AmukhumbaNessuna valutazione finora

- Dictum Giftideas 2012Documento40 pagineDictum Giftideas 2012Alexandre LetellierNessuna valutazione finora

- BOSS GLOBAL CONCEPTS LTD - AML Policy-UpdatedDocumento46 pagineBOSS GLOBAL CONCEPTS LTD - AML Policy-UpdatedtwaseemdttNessuna valutazione finora

- WAP Push and MMS For Android Rev6Documento4 pagineWAP Push and MMS For Android Rev6Shruti MahadikNessuna valutazione finora

- IB SL P1 Math Book Exam-MateDocumento375 pagineIB SL P1 Math Book Exam-MatePang Hua TanNessuna valutazione finora

- 曼昆《经济学原理第三版》宏观分册原版中英文双语PPT课件Chap 25Documento76 pagine曼昆《经济学原理第三版》宏观分册原版中英文双语PPT课件Chap 25Jia Wei MiaoNessuna valutazione finora

- Understanding The Internet of Things Definition, Potentials, and Societal Role of A FasDocumento19 pagineUnderstanding The Internet of Things Definition, Potentials, and Societal Role of A FasSteven GarcíaNessuna valutazione finora

- Air ConditionerDocumento131 pagineAir ConditionerRahul AnsariNessuna valutazione finora

- ENGLISH PAGE - Verb Tense Exercise 3Documento1 paginaENGLISH PAGE - Verb Tense Exercise 3Eka BeradzeNessuna valutazione finora

- AVSEC Awareness Ground StaffDocumento12 pagineAVSEC Awareness Ground Staffanon_823464996100% (2)

- Impact of Phragmanthera Capitata (Sprenge.) Balle On Pod and Beans Production of Two Cocoa Clones in Nkoemvone Seed Fields (South Cameroun) - JBES @scribdDocumento9 pagineImpact of Phragmanthera Capitata (Sprenge.) Balle On Pod and Beans Production of Two Cocoa Clones in Nkoemvone Seed Fields (South Cameroun) - JBES @scribdInternational Network For Natural SciencesNessuna valutazione finora

- Afloat 2Documento256 pagineAfloat 2Matthaios SkantrzourakisNessuna valutazione finora

- C C C !" # # $C% & #'C%Documento12 pagineC C C !" # # $C% & #'C%Sneha ShahNessuna valutazione finora

- Getting A Number From A Textbox: Computer Programming 1 Inputting From TextboxesDocumento1 paginaGetting A Number From A Textbox: Computer Programming 1 Inputting From TextboxesZarif ZulkafliNessuna valutazione finora

- P3A Taking Order BeveragesDocumento2 pagineP3A Taking Order BeveragesRavi KshirsagerNessuna valutazione finora

- Ethnography Discussion QuestionsDocumento2 pagineEthnography Discussion Questionsapi-235718856100% (1)

- 5 Energy ManagementDocumento1 pagina5 Energy ManagementDibyo SetiawanNessuna valutazione finora

- Homework3 Yasser El Mehdi DIBDocumento1 paginaHomework3 Yasser El Mehdi DIBYasser DibNessuna valutazione finora

- CSR ReportDocumento13 pagineCSR Reportrishabh agarwalNessuna valutazione finora

- Machine Elements in Mechanical Design Solution PDFDocumento309 pagineMachine Elements in Mechanical Design Solution PDFazkonaNessuna valutazione finora

- LSA Syllabus (E-Next - In)Documento3 pagineLSA Syllabus (E-Next - In)FIT160-Singh PratikNessuna valutazione finora

- Using Techniques On Seeking, Screening, and Seizing OpportunitiesDocumento8 pagineUsing Techniques On Seeking, Screening, and Seizing OpportunitiesJustine Evasco RubiaNessuna valutazione finora

- PHTH 211 Lecture 1 Regulation of Body FunctionsDocumento33 paginePHTH 211 Lecture 1 Regulation of Body Functionsmaatela7sasNessuna valutazione finora

- PsychosesDocumento32 paginePsychosesAnonymous zxTFUoqzklNessuna valutazione finora