Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Nss Calculator

Caricato da

Zoebair100%(1)Il 100% ha trovato utile questo documento (1 voto)

346 visualizzazioni4 pagineBEP Flow is 3400gpm @ 230' and requires an NPSH of 12 feet. The Suction Energy ratio is the calculated SE divided by the high Suction Energy value for a particular pump design. The chart below shows the NPSH margin required to meed a certain level of pump reliability.

Descrizione originale:

Copyright

© © All Rights Reserved

Formati disponibili

XLSX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoBEP Flow is 3400gpm @ 230' and requires an NPSH of 12 feet. The Suction Energy ratio is the calculated SE divided by the high Suction Energy value for a particular pump design. The chart below shows the NPSH margin required to meed a certain level of pump reliability.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLSX, PDF, TXT o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

346 visualizzazioni4 pagineNss Calculator

Caricato da

ZoebairBEP Flow is 3400gpm @ 230' and requires an NPSH of 12 feet. The Suction Energy ratio is the calculated SE divided by the high Suction Energy value for a particular pump design. The chart below shows the NPSH margin required to meed a certain level of pump reliability.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLSX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 4

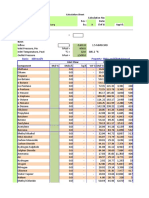

Enter the required data in the highlighted cells Enter the required data in the highlighted cells

Pump RPM (N) 1770 Impeller Eye Diameter " (De)

BEP Flow (Q)* 3400 Pump RPM (N)

NPSHr @ BEP 12 Suction Specific Speed (Nss)

Specific Gravity (SG)

S = 16,008 SE =

* For double suction pumps enter 1/2 the BEP flow. Pump Type

Values of S greater than 9,000 may require a greater NPSH margin.

Refer to the chart below for acceptable operating ranges. 1 or 2- Vane Sewage*

End Suction

Double Suction

Vertical Turbine

* Also any impeller with less than 15 vane overlap

Instructions:

If the impeller eye diameter is not known it can be approximated as follows:

End Suction Pump - Suction nozzle diameter x 0.90

Horizontal Split Case Pump - Suction nozzle x 0.75

The chart below shows the minimum stable flow for various The example used in both calculators is a dry pit non-clog with a 10" suction

specific speeds and suction specific speeds. and a two vane, 17.5" impeller. BEP flow is 3400gpm @ 230' and requires

an NPSH of 12 feet.

The chart below shows the NPSH margin required to meed a certain level

of pump reliability. The suction energy ratio is the calculated SE divided

by the high suction energy value for a particular pump design.

S = N Q / NPSHr

0.75

Suction Specific Speed (S or Nss)

Suction Energy (SE)

SE = De x N x S x SG

Suction Calculators Joe Evans www.PumpEd101.com

Window of Operation

Enter the required data in the highlighted cells

Impeller Eye Diameter " (De) 9

Pump RPM (N) 1770

Suction Specific Speed (Nss) 16008

Specific Gravity (SG) 1

255,007,440

Pump Type High Suction Energy Very High Suction Energy

1 or 2- Vane Sewage* 100,000,000 150,000,000

End Suction 160,000,000 240,000,000

Double Suction 120,000,000 180,000,000

Vertical Turbine 200,000,000 300,000,000

* Also any impeller with less than 15 vane overlap

Instructions:

If the impeller eye diameter is not known it can be approximated as follows:

End Suction Pump - Suction nozzle diameter x 0.90

Horizontal Split Case Pump - Suction nozzle x 0.75

The example used in both calculators is a dry pit non-clog with a 10" suction

and a two vane, 17.5" impeller. BEP flow is 3400gpm @ 230' and requires

an NPSH of 12 feet.

The chart below shows the NPSH margin required to meed a certain level

of pump reliability. The suction energy ratio is the calculated SE divided

by the high suction energy value for a particular pump design.

Suction Energy (SE)

SE = De x N x S x SG

Joe Evans www.PumpEd101.com

Potrebbero piacerti anche

- Zero Water DischargeDocumento5 pagineZero Water Dischargehemendra499Nessuna valutazione finora

- Pipe thickness calculationDocumento1.287 paginePipe thickness calculationShantanu JalgaonkarNessuna valutazione finora

- Engineering Design Calculation - Dennis Kirk Centrifugal Fan Performance CharacteristicsDocumento1 paginaEngineering Design Calculation - Dennis Kirk Centrifugal Fan Performance CharacteristicsAnonymous EarAM2100% (1)

- ScreenDocumento2 pagineScreenMeena Munim0% (1)

- Water HammerDocumento3 pagineWater HammerSrinivas ReddyNessuna valutazione finora

- GEMI Equations ToolDocumento10 pagineGEMI Equations TooljnmanivannanNessuna valutazione finora

- Valve CV Sizing Liquids GasesDocumento24 pagineValve CV Sizing Liquids GasesRicardo RamosNessuna valutazione finora

- PUMP DESIGNDocumento2 paginePUMP DESIGNmoh. rusli bahtiarNessuna valutazione finora

- Mixer (So3 Jadi H2so4)Documento6 pagineMixer (So3 Jadi H2so4)Evi SiswantoNessuna valutazione finora

- LMP Pump Consulting Friction Loss 2.6Documento1 paginaLMP Pump Consulting Friction Loss 2.6LorettaMayNessuna valutazione finora

- ATFE Installation Costing for Xylene Distillation ProjectDocumento27 pagineATFE Installation Costing for Xylene Distillation ProjectPrathmesh GujaratiNessuna valutazione finora

- CO2 Condenser 02-03-2023-15 PMDocumento37 pagineCO2 Condenser 02-03-2023-15 PMahmad santosoNessuna valutazione finora

- Centrifugal Pump Affinity Law DemonstrationDocumento2 pagineCentrifugal Pump Affinity Law DemonstrationidlidlidlidlNessuna valutazione finora

- RELIEF VALVE PARAMETERSDocumento6 pagineRELIEF VALVE PARAMETERSMa AlNessuna valutazione finora

- Water Hammer: Design CriteriaDocumento3 pagineWater Hammer: Design CriteriamazharimechNessuna valutazione finora

- 62577A Calculation of Orifice Coefficient Si UnitsDocumento18 pagine62577A Calculation of Orifice Coefficient Si UnitsUary Buza RegioNessuna valutazione finora

- Desuperheater Boiler Feed Water RequirementDocumento2 pagineDesuperheater Boiler Feed Water Requirementmehul10941Nessuna valutazione finora

- Valve Sizing CalculationDocumento7 pagineValve Sizing CalculationSteve Wan100% (1)

- Pump SizingDocumento31 paginePump SizingTuấn VũNessuna valutazione finora

- Siphon dosing calculations for company projectDocumento2 pagineSiphon dosing calculations for company projectfaridhassaniNessuna valutazione finora

- Cavitation-Pump-Pipe-Skid CalcDocumento56 pagineCavitation-Pump-Pipe-Skid CalcOltun KAYANessuna valutazione finora

- Pump specifications and sizing for sewage treatment plantDocumento3 paginePump specifications and sizing for sewage treatment plantbharathNessuna valutazione finora

- Industrial VillageDocumento35 pagineIndustrial VillageRajani jirelNessuna valutazione finora

- Reactor Geometry and Agitator SizingDocumento26 pagineReactor Geometry and Agitator SizingNeeraj BhallaNessuna valutazione finora

- Insulation Thickness by UOPDocumento4 pagineInsulation Thickness by UOPOmar EzzatNessuna valutazione finora

- FLB Tank Pump Calculation 7/28/1998 P1: Document No.: Title: Sign Date Made by Rev: Checked by Contract No.: QX0032Documento3 pagineFLB Tank Pump Calculation 7/28/1998 P1: Document No.: Title: Sign Date Made by Rev: Checked by Contract No.: QX0032Ekundayo JohnNessuna valutazione finora

- Pressure Loss - SwitchyardDocumento1 paginaPressure Loss - Switchyardkarthikraja21Nessuna valutazione finora

- Line Sizing GuidelinesDocumento2 pagineLine Sizing GuidelinesHarryBouterNessuna valutazione finora

- Waymouth CalculationDocumento8 pagineWaymouth CalculationSURJYA TAMULINessuna valutazione finora

- Gear Pump Design SheetDocumento3 pagineGear Pump Design SheetJagankumarNessuna valutazione finora

- ParalDocumento9 pagineParalTahirJabbarNessuna valutazione finora

- Data Solution: C F L DDocumento27 pagineData Solution: C F L DJMVNessuna valutazione finora

- Calculation of Friction Losses, Power, Developed Head and Available Net Positive Suction Head of A PumpDocumento11 pagineCalculation of Friction Losses, Power, Developed Head and Available Net Positive Suction Head of A Pumpthanh_79Nessuna valutazione finora

- Calculate Diesel Generator SizeDocumento2 pagineCalculate Diesel Generator SizeFuad Al-AwzariNessuna valutazione finora

- Centrifugal Pumps Excel Data Calculation'Documento30 pagineCentrifugal Pumps Excel Data Calculation'Anoif Naputo AidnamNessuna valutazione finora

- Air Eliminator Datasheet PDFDocumento2 pagineAir Eliminator Datasheet PDFbecpavanNessuna valutazione finora

- Process Calculation For FREYLIT CPI Oil SeparatorDocumento4 pagineProcess Calculation For FREYLIT CPI Oil SeparatorRajdeepsinhNessuna valutazione finora

- Control Valve Sizing - EnggcyclopediaDocumento4 pagineControl Valve Sizing - EnggcyclopediaazitaggNessuna valutazione finora

- Rms B C HesaplamaDocumento21 pagineRms B C HesaplamayilmazerolNessuna valutazione finora

- Properties of liquid hydrocarbons in pumpsDocumento1 paginaProperties of liquid hydrocarbons in pumpsmahesh_eilNessuna valutazione finora

- Horizontal Cylindrical Tank Volume and Level CalculatorDocumento5 pagineHorizontal Cylindrical Tank Volume and Level CalculatorWaleed EmaraNessuna valutazione finora

- Piping CalculationsDocumento3 paginePiping CalculationsAkhilesh Dhar DiwediNessuna valutazione finora

- SP SP VP V PR) : Velocity Pressure Method Calculation SheetDocumento6 pagineSP SP VP V PR) : Velocity Pressure Method Calculation SheetAnkit LonareNessuna valutazione finora

- Basis: Basis: 100 Mol/h Property: GPSA and Elliott ManualDocumento6 pagineBasis: Basis: 100 Mol/h Property: GPSA and Elliott ManualsterlingNessuna valutazione finora

- Water Hammer pressure calculations for pipes of different diametersDocumento3 pagineWater Hammer pressure calculations for pipes of different diametersSrinivas ReddyNessuna valutazione finora

- Friction Factor CalculationsDocumento1 paginaFriction Factor Calculationseco protectionNessuna valutazione finora

- Modified Vyas formula for S.D.P. treatment of organic and aqueous wasteDocumento11 pagineModified Vyas formula for S.D.P. treatment of organic and aqueous wasteNITIN P SHAHNessuna valutazione finora

- Line Size Calculation For Cooling Water Pipes: Pipe Size Provided Is OKDocumento40 pagineLine Size Calculation For Cooling Water Pipes: Pipe Size Provided Is OKjitendra shindeNessuna valutazione finora

- Salt Water CalculationsDocumento13 pagineSalt Water CalculationsHsein WangNessuna valutazione finora

- Air Receiver Sizing CalculationDocumento1 paginaAir Receiver Sizing CalculationAziz HaqueNessuna valutazione finora

- Density of WaterDocumento5 pagineDensity of WaterJean Pajuelo0% (1)

- KRTK 100-400/454UEC2-S data sheetDocumento5 pagineKRTK 100-400/454UEC2-S data sheetGhassan ABO ALINessuna valutazione finora

- DRYER CALCULATIONSDocumento4 pagineDRYER CALCULATIONSOmprakaash MokideNessuna valutazione finora

- Economic Diameter CalDocumento28 pagineEconomic Diameter CaldsdeshpandeNessuna valutazione finora

- Final HP Heater by Kerns MethodDocumento5 pagineFinal HP Heater by Kerns Methodbb84sharmaNessuna valutazione finora

- Calculation AgitatorDocumento3 pagineCalculation AgitatorKrishnaAgarwalNessuna valutazione finora

- Design of AgitatorDocumento3 pagineDesign of AgitatorManish PatelNessuna valutazione finora

- Clickable List: E - HydraulicsDocumento9 pagineClickable List: E - Hydraulicssaeed65Nessuna valutazione finora

- Pneumatic - Book (5-17) PDFDocumento13 paginePneumatic - Book (5-17) PDFibnu100% (1)

- Chapter 9 Pump SelectionDocumento40 pagineChapter 9 Pump SelectionDuke ThibbotuwawaNessuna valutazione finora

- 90 Series (ET1590) InstructionsDocumento24 pagine90 Series (ET1590) InstructionsZoebairNessuna valutazione finora

- International Standard: Hydraulic Turbines, Storage Pumps and Pump-Turbines - Model Acceptance TestsDocumento9 pagineInternational Standard: Hydraulic Turbines, Storage Pumps and Pump-Turbines - Model Acceptance TestsZoebairNessuna valutazione finora

- 1 12 (End)Documento17 pagine1 12 (End)ZoebairNessuna valutazione finora

- ENZX TechDocumento30 pagineENZX TechZoebairNessuna valutazione finora

- Spring-Supported Thrust BearingsDocumento4 pagineSpring-Supported Thrust BearingsZoebairNessuna valutazione finora

- Installation and Operating Procedures: Manual Grease InterceptorsDocumento8 pagineInstallation and Operating Procedures: Manual Grease InterceptorsZoebairNessuna valutazione finora

- Structures and Mechanisms Classifications GuideDocumento1 paginaStructures and Mechanisms Classifications GuideminakirolosNessuna valutazione finora

- Appendix B - 20100903 - 145453Documento25 pagineAppendix B - 20100903 - 145453AkoKhalediNessuna valutazione finora

- TurbinesDocumento19 pagineTurbinesSamarakoon BandaNessuna valutazione finora

- Type of ThreadDocumento13 pagineType of ThreadVils ArabadzhievaNessuna valutazione finora

- Ratle Enm Reply Tecnical Prebid Points 080212Documento42 pagineRatle Enm Reply Tecnical Prebid Points 080212ZoebairNessuna valutazione finora

- Quality Conference TTL KUDocumento6 pagineQuality Conference TTL KUZoebairNessuna valutazione finora

- CA6NMDocumento2 pagineCA6NMjoene3Nessuna valutazione finora

- 1 Technical Data Sheets TurbineDocumento7 pagine1 Technical Data Sheets TurbineZoebairNessuna valutazione finora

- 8.4 Basic Size Drawing, With Pump: Alfa Laval Ref. 557913 Rev. 0Documento1 pagina8.4 Basic Size Drawing, With Pump: Alfa Laval Ref. 557913 Rev. 0ZoebairNessuna valutazione finora

- Datasheet TurbineDocumento2 pagineDatasheet TurbineZoebairNessuna valutazione finora

- Solutions EngDocumento6 pagineSolutions EngZoebairNessuna valutazione finora

- Calculate The Number of Extinguishers Needed in A BuildingDocumento3 pagineCalculate The Number of Extinguishers Needed in A BuildingZoebairNessuna valutazione finora

- INDIGENOUS MANUFACTURERS OF SMALL HYDRO TURBINESDocumento6 pagineINDIGENOUS MANUFACTURERS OF SMALL HYDRO TURBINESZoebairNessuna valutazione finora

- PJPR0 V 200 Ucturing 0 Data 0 SheetDocumento3 paginePJPR0 V 200 Ucturing 0 Data 0 SheetZoebairNessuna valutazione finora

- Scada SystemDocumento1 paginaScada SystemZoebairNessuna valutazione finora

- 1 - Layout of H-FrancisDocumento1 pagina1 - Layout of H-FrancisZoebairNessuna valutazione finora

- ANDRITZ HYDRO Valves Ensure Lifetime Safety and Reliability in Hydropower PlantsDocumento3 pagineANDRITZ HYDRO Valves Ensure Lifetime Safety and Reliability in Hydropower PlantsZoebairNessuna valutazione finora

- Load AcceptanceDocumento2 pagineLoad AcceptanceZoebairNessuna valutazione finora

- Construction Specification 71-Water Control Gates: Instructions For UseDocumento2 pagineConstruction Specification 71-Water Control Gates: Instructions For UseZoebairNessuna valutazione finora

- CEE 331: Fluid Mechanics, Homework Set 2, SolutionsDocumento7 pagineCEE 331: Fluid Mechanics, Homework Set 2, SolutionsZoebairNessuna valutazione finora

- PJPR0 V 200 Ucturing 0 Data 0 SheetDocumento3 paginePJPR0 V 200 Ucturing 0 Data 0 SheetZoebairNessuna valutazione finora

- ANDRITZ HYDRO Valves Ensure Lifetime Safety and Reliability in Hydropower PlantsDocumento3 pagineANDRITZ HYDRO Valves Ensure Lifetime Safety and Reliability in Hydropower PlantsZoebairNessuna valutazione finora

- 3DS Net OrthoGen For Intergraph CADWorx Plant ProfessionalDocumento2 pagine3DS Net OrthoGen For Intergraph CADWorx Plant ProfessionalThanadkitBunkaewNessuna valutazione finora

- 3 Tables Friction Loss AquacultureDocumento10 pagine3 Tables Friction Loss AquacultureZoebairNessuna valutazione finora

- Mod Exam Mah PDFDocumento3 pagineMod Exam Mah PDFjaja riveraNessuna valutazione finora

- ME 406 The Logistic Map: 1. IntroductionDocumento32 pagineME 406 The Logistic Map: 1. IntroductionsustrasNessuna valutazione finora

- 9709 s14 QP 12Documento4 pagine9709 s14 QP 12Abrar JahinNessuna valutazione finora

- Comparitive Study of Various Watermarking TechniquesDocumento7 pagineComparitive Study of Various Watermarking TechniquesHitanshi SachdevaNessuna valutazione finora

- Everything You Need to Know About AC Drives and VFDsDocumento31 pagineEverything You Need to Know About AC Drives and VFDsAnonymous FKMfvCbNessuna valutazione finora

- Production and CostsDocumento110 pagineProduction and CostsramandeepkaurNessuna valutazione finora

- Alfa Laval Flow Transmitter Product LeafletDocumento4 pagineAlfa Laval Flow Transmitter Product LeafletsanjeevNessuna valutazione finora

- Linear Algebra Resupply Date Iv. Direct Sum Vs DimensionDocumento7 pagineLinear Algebra Resupply Date Iv. Direct Sum Vs Dimension詹子軒Nessuna valutazione finora

- Acceleration and DecelerationDocumento28 pagineAcceleration and DecelerationCt RahayuNessuna valutazione finora

- (Ggplot2 Data Visualization) Alboukadel Kassambara - Guide To Create Beautiful Graphics in R-STHDA (2013) PDFDocumento238 pagine(Ggplot2 Data Visualization) Alboukadel Kassambara - Guide To Create Beautiful Graphics in R-STHDA (2013) PDFGrasiela SantanaNessuna valutazione finora

- Anel Peralta Participation Activity 2Documento7 pagineAnel Peralta Participation Activity 2Indira AlfonsoNessuna valutazione finora

- Mid Term Past Papers 701Documento4 pagineMid Term Past Papers 701Ahmad HassanNessuna valutazione finora

- Why Visual APL? APL - The Next GenerationDocumento26 pagineWhy Visual APL? APL - The Next GenerationaaNessuna valutazione finora

- SF-2200H Operating ManualDocumento36 pagineSF-2200H Operating ManualuripssNessuna valutazione finora

- Activity 1 (Activity Guide)Documento3 pagineActivity 1 (Activity Guide)Ronel AlbanNessuna valutazione finora

- Inverse Circular FunctionDocumento1 paginaInverse Circular FunctionDharmendra SankhlaNessuna valutazione finora

- (Mathematical Logic) : Jhjeong@kyungpook - Ac.krDocumento68 pagine(Mathematical Logic) : Jhjeong@kyungpook - Ac.krJ-in KimNessuna valutazione finora

- (-/2 Points) SCALCET8 2.7.JIT.003.MI.: Details My Notes Ask Your Teacher Practice AnotherDocumento4 pagine(-/2 Points) SCALCET8 2.7.JIT.003.MI.: Details My Notes Ask Your Teacher Practice Anotherbilal5202050Nessuna valutazione finora

- Dynamic Response Factor As Per As 1170.2Documento2 pagineDynamic Response Factor As Per As 1170.2Zarna ModiNessuna valutazione finora

- Math 323: Solutions To Homework 9Documento8 pagineMath 323: Solutions To Homework 9AlbertoAlcaláNessuna valutazione finora

- Christoph Reinhart: L12 Thermal Mass and Heat FlowDocumento64 pagineChristoph Reinhart: L12 Thermal Mass and Heat FlowT N Roland BourgeNessuna valutazione finora

- Yasmin Schulberg Mid Year TranscriptDocumento1 paginaYasmin Schulberg Mid Year Transcriptapi-405077147Nessuna valutazione finora

- Chapter 3 2D Simulations GuideDocumento23 pagineChapter 3 2D Simulations GuideTran Van TienNessuna valutazione finora

- Mabalacat Math 9 Quarterly Exam Covers Exponents, RadicalsDocumento3 pagineMabalacat Math 9 Quarterly Exam Covers Exponents, RadicalsMailyn ElacreNessuna valutazione finora

- Lecture Notes On Matroid Intersection: 6.1.1 Bipartite MatchingsDocumento13 pagineLecture Notes On Matroid Intersection: 6.1.1 Bipartite MatchingsJoe SchmoeNessuna valutazione finora

- Chapter 9 - Areas of Parallelograms and Triangles Revision NotesDocumento8 pagineChapter 9 - Areas of Parallelograms and Triangles Revision NotesHariom SinghNessuna valutazione finora

- Integral Calculus SYLLABUSDocumento2 pagineIntegral Calculus SYLLABUSCAHEL ALFONSONessuna valutazione finora

- Good LabDocumento23 pagineGood Labglories_Nessuna valutazione finora

- 6.045 Class 7: Computability Theory FundamentalsDocumento53 pagine6.045 Class 7: Computability Theory FundamentalsMuhammad Al KahfiNessuna valutazione finora