Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

IPS Grooved Couplings

Caricato da

Vijayakumar S.P.0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

98 visualizzazioni2 paginePJE Coupling

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoPJE Coupling

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

98 visualizzazioni2 pagineIPS Grooved Couplings

Caricato da

Vijayakumar S.P.PJE Coupling

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

The American Society of Mechanical Engineers (ASME) established

the B31 Pressure Piping Code Committees to promote safety in pres-

sure piping design and construction through published engineering

criteria. The basic consideration of the Codes is safety, however, the

Codes are not designed to replace competent engineering design or

judgement. Most importantly, the Codes do not approve, rate, or

endorse any items of construction; proprietary devices, or activity.

The Codes do not put a limit on conservatism and, conversely, the

Codes also allow for designs that are capable of more rigorous engi-

neering analysis which justifies less conservative designs. A final point

of importance is that the Codes strive to keep abreast of all current

technologies regarding improvements to materials, fabrication, and any

other new developments in the piping industry. They are not intended

to limit the introduction of new products. Numerous sections of the B31

Codes provide the necessary guidelines to analyze new or nontraditional

products so that sound engineering judgments can be made regarding

Code conformance.

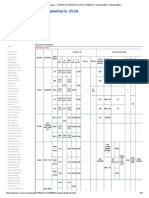

Victaulic Standard IPS couplings and grooved end fittings may be

utilized on ASME B31.1 Power Piping Code applications within their

published temperature and pressure parameters. ASME B31.1 des-

ignates the use of mechanical joints, specifically grooved joints that

use gaskets as method of leak resistance under Paragraph 100.2,

Definitions, which defines a Mechanical Joint as:

A joint for the purpose of mechanical strength or leak resistance,

or both, where the mechanical strength is developed by threaded,

grooved, rolled, flared, or flanged pipe ends, or by bolts, pins, and

compounds, gaskets, rolled ends, caulking or machined and mated

surfaces. These joints have particular application where ease of

disassembly is desired.

Grooving is acknowledged as an acceptable pipe end preparation

under Paragraph 102.4.2 Threading and Grooving. Grooving is further

addressed under Paragraph 104.7.1 which permits the use of materials

manufactured in accordance with the standards listed in Table 126.1.

Table 126.1 includes both ASTM A536 and ASTM A-395 ductile irons.

Victaulic couplings and fittings are manufactured from ductile iron

that conforms to these two specifications. Table 126.1 also includes

American National Standard/American Water Works Association, ANSI/

AWWA C-606 - Standard for Grooved and Shouldered End Joints.

ANSI/AWWA C-606 was proposed in 1971 and initially published in

1978 as the first national standard for grooved and shouldered end pipe

joints. C-606 covers materials of construction, general design, groov-

ing specifications and testing procedures for the grooved pipe joining

method. Victaulic standard grooved couplings meet the requirements of

ANSI/AWWA C-606 for use on grooved end fittings and pipe grooved in

accordance with this standard.

Paragraph 106 - Fittings, Bends, and Intersections permits grooved end

fittings under Paragraphs 106.1 (A) and 106.1 (B).

Paragraph 106.1 (A) states:

Threaded, flanged, grooved and shouldered, socket-welding,

buttwelding, compression, push-on, mechanical gland, and solder-

joint fittings made in accordance with the applicable standards

in Table 126.1 may be used in power piping systems within the

material, size, pressure, and temperature limitations of those

standards, and within any further limitations specified in this

Code.

Paragraph 106.1 (B) refers to Paragraph 104.7 for a method of

qualification. Paragraph 104.7.2 (A) states:

Extensive and successful performance experience under compara-

ble service conditions with similarly proportioned components of the

same or similar material may be used as a basis of acceptability.

Couplings, while specifically qualified by the inclusion of ANSI/AWWA

C-606, are similarly permitted under Paragraph 118 - Sleeve Coupled

and Other Proprietary Joints which states:

Coupling type, mechanical gland type, and other proprietary joints

may be used where experience or tests have demonstrated that

the joint is safe for the operating conditions, and where adequate

provision is made to prevent separation of the joint.

Victaulic grooved products have over 80 years of proven successful

installation performance under a large variety of service conditions. In

addition, Victaulic grooved joints will provide excellent qualifying working

pressures based on temperatures and pressures within their published

parameters in accordance with Section I, A-22 of the American Society

of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code.

Extensive testing is performed on all Victaulic products before and after

they are made available to the piping industry. Victaulic is an ISO 9001

certified company, which has stringent requirements for quality systems,

design control, process control, traceability, inspection, measurement,

and testing of our products.

A piping system properly designed and installed utilizing Victaulic

flexible and rigid couplings is ideal for accommodating both primary

and secondary stresses. Flexible couplings provide for both deflection

and axial movement at each coupling joint. The available deflection and

axial movement can then be used to virtually eliminate any secondary

thermal piping stresses. Both flexible and rigid couplings have proven

performance benefits in reducing primary stresses such as seismic and

induced system vibration. The rigid coupling also provides sufficient

joint rigidity to allow hanger spacing to ASME B31.1 hanger spacing

requirements. To assist design engineers, Victaulic provides published

engineering design data and suggested methods for accommodat-

ing thermal movement and vibration attenuation in a piping system.

Request 26.01, 26.02 and 26.03. Both flexible and rigid coupling

hanger spacing requirements can be found on page 5 of Section 26.01.

The use of Victaulic couplings and fittings for B31.1 applications should

also be reviewed by the piping system designer for the specific applica-

tion. Victaulic grooved end products will be acceptable on applications

within the scope of the published limitations. Services such as hot and

cold fluids, compressed air, and non-combustible gases are permitted

provided the system temperature is within our published temperature

range for the gasket utilized, and the system pressure is at or less than

the published working pressure.

26.06_1

Conformance of IPS Grooved Couplings and Fittings to

ASME B31.1 Power Piping Code (2004) Requirements

26.06 IPS GROOVED COUPLINGS AND FITTINGS B31.1 CODE

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. 2006 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

REV_C

26.06

Conformance of IPS Grooved Couplings and Fittings to

ASME B31.1 Power Piping Code (2004) Requirements

26.06 IPS GROOVED COUPLINGS AND FITTINGS B31.1 CODE

WCAS-6J7S75

UPDATED 5/2006

26.06 1657 REV C

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. 2006 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

US & WORLD HEADQUARTERS

P.O. Box 31

Easton, PA 18044-0031 USA

4901 Kesslersville Road

Easton, PA 18040 USA

1-800-PICK-VIC (1-800-742-5842)

1-610-559-3300

1-610-250-8817 (fax)

pickvic@victaulic.com

CANADA

905-884-7444

905-884-9774 (fax)

viccanada@victaulic.com

EUROPE

32-9-381-15-00

32-9-380-44-38 (fax)

viceuro@victaulic.be

UNITED KINGDOM

44 (0) 1438741100

44 (0) 1438313883 (fax)

viceuro@victaulic.be

CENTRAL AND SOUTH AMERICA

1-610-559-3300

1-610-559-3608 (fax)

vical@victaulic.com

ASIA PACIFIC

86-21-54253300

86-21-54253671 (fax)

vicap@victaulic.com

MIDDLE EAST

971-4-883-88-70

971-4-883-88-60 (fax)

www.victaulic.com

Potrebbero piacerti anche

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDa Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsValutazione: 4 su 5 stelle4/5 (1)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerDa EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerValutazione: 5 su 5 stelle5/5 (1)

- Nuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresDa EverandNuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresValutazione: 5 su 5 stelle5/5 (1)

- R 015987Documento63 pagineR 015987shaffeti100% (2)

- All-in-One Manual of Industrial Piping Practice and MaintenanceDa EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceValutazione: 5 su 5 stelle5/5 (1)

- Pressure Vessels Field Manual: Common Operating Problems and Practical SolutionsDa EverandPressure Vessels Field Manual: Common Operating Problems and Practical SolutionsValutazione: 4 su 5 stelle4/5 (12)

- Color Code For Piping Material IdentificationDocumento7 pagineColor Code For Piping Material IdentificationMcmiltondmordomNessuna valutazione finora

- MSC RD 19440 PDFDocumento13 pagineMSC RD 19440 PDFJairo WilchesNessuna valutazione finora

- Pressure Req DesignDocumento12 paginePressure Req DesignAbhinav PathakNessuna valutazione finora

- Pipe Support Reference 8-29-14Documento108 paginePipe Support Reference 8-29-14HITESHNessuna valutazione finora

- ASME B31.3 Process Piping Code (2020) Compliance Vic-Press For Schedule 10SDocumento5 pagineASME B31.3 Process Piping Code (2020) Compliance Vic-Press For Schedule 10SKarthikeyan LNessuna valutazione finora

- Pipe Stress Analysis Scope and Specifications For Clients, Engineers and ContractorsDocumento4 paginePipe Stress Analysis Scope and Specifications For Clients, Engineers and ContractorsUmesh TiwariNessuna valutazione finora

- Manual Arc Welding of Titanium Alloy Hardware Process SpecificationDocumento20 pagineManual Arc Welding of Titanium Alloy Hardware Process SpecificationFaiz NanafiNessuna valutazione finora

- ASME B31 - Standards of Pressure PipingDocumento3 pagineASME B31 - Standards of Pressure PipingRachit OzaNessuna valutazione finora

- 06 PIPING Design Basis PDFDocumento8 pagine06 PIPING Design Basis PDFKatamaneni Koteswararao100% (2)

- Vessels For High Pressure Dust CollectorsDocumento4 pagineVessels For High Pressure Dust CollectorsWade ColemanNessuna valutazione finora

- ASME B31.9 Building Services Piping Code (2011) ComplianceDocumento3 pagineASME B31.9 Building Services Piping Code (2011) ComplianceАнж БжлNessuna valutazione finora

- Sa 134Documento6 pagineSa 134edisson_barreraNessuna valutazione finora

- Ductwork SystemsDocumento28 pagineDuctwork SystemsSurekanth ManikkavasagamNessuna valutazione finora

- Revised RCSC Specification-Simplified, Clarified, AndImprovedDocumento5 pagineRevised RCSC Specification-Simplified, Clarified, AndImprovedCarlos Javier Goez TarraNessuna valutazione finora

- American Society of Mechanical EngineersDocumento4 pagineAmerican Society of Mechanical Engineersb3 qualNessuna valutazione finora

- Piping TutorialDocumento46 paginePiping Tutorialjtkh1972100% (1)

- Power Piping: ASME Code For Pressure Piping, 831Documento6 paginePower Piping: ASME Code For Pressure Piping, 831ammarashraf91Nessuna valutazione finora

- Revised RCSC Specification-Simplified, Clarified, Andimproved PDFDocumento5 pagineRevised RCSC Specification-Simplified, Clarified, Andimproved PDFfarhadmrt6923Nessuna valutazione finora

- B61-15 Standard Specification For Steam or Valve Bronze CastingsDocumento3 pagineB61-15 Standard Specification For Steam or Valve Bronze CastingsislamakthamNessuna valutazione finora

- ABSA Newsletter Provides Updates on Safety Standards and RegulationsDocumento4 pagineABSA Newsletter Provides Updates on Safety Standards and RegulationsMas Arman TewoNessuna valutazione finora

- Piping Design Plant LayoutDocumento23 paginePiping Design Plant Layoutluxvij100% (1)

- Awwa C200 PDFDocumento23 pagineAwwa C200 PDFangel darioNessuna valutazione finora

- Chapter 5 Code Design - Pressure VesselDocumento11 pagineChapter 5 Code Design - Pressure VesselEDWARD T CHENJERAINessuna valutazione finora

- ASME Secc II A SA-134 Specification For Pipe, Steel, ElectriDocumento5 pagineASME Secc II A SA-134 Specification For Pipe, Steel, ElectriEduardo ArrietaNessuna valutazione finora

- Basic Mechanical Materials and Methods 0606 (PDF Library)Documento17 pagineBasic Mechanical Materials and Methods 0606 (PDF Library)nifilimNessuna valutazione finora

- Architectural, Mechanical, and Electrical Component Design RequirementsDocumento18 pagineArchitectural, Mechanical, and Electrical Component Design RequirementsEnrique AbayNessuna valutazione finora

- SF6 Gas Insulated 72.5 kV Switchgear Technical SpecsDocumento232 pagineSF6 Gas Insulated 72.5 kV Switchgear Technical Specscrazy devil100% (1)

- TSSA Fittings Guideline 1Documento10 pagineTSSA Fittings Guideline 1juda823Nessuna valutazione finora

- ASME VIII Div 1 ReportDocumento12 pagineASME VIII Div 1 ReportAmir Zamri100% (2)

- CODES and STANDARDS PDFDocumento10 pagineCODES and STANDARDS PDFemnptn2667Nessuna valutazione finora

- 240K C2 CS 50 009 0TDocumento78 pagine240K C2 CS 50 009 0TYeims LozanoNessuna valutazione finora

- PV Newsletter April2021Documento32 paginePV Newsletter April2021Tushar MangratiNessuna valutazione finora

- 02 Samss 008Documento11 pagine02 Samss 008inatt101Nessuna valutazione finora

- The API 579 Fitness-for-Service Standard - The Current State of Technology and A Ten Year Look AheadDocumento32 pagineThe API 579 Fitness-for-Service Standard - The Current State of Technology and A Ten Year Look AheadthiagopontualNessuna valutazione finora

- Welding Code IndexDocumento6 pagineWelding Code IndexAkhilesh KumarNessuna valutazione finora

- 24 Steel PipesDocumento11 pagine24 Steel Pipeselynah mistiolaNessuna valutazione finora

- API 6A RadiographyDocumento4 pagineAPI 6A RadiographyminakshissawantNessuna valutazione finora

- ASME Vessel Standard SuncorDocumento71 pagineASME Vessel Standard SuncorChristopher BrownNessuna valutazione finora

- Enbridge Pipeline Repair Workplan WeldingDocumento23 pagineEnbridge Pipeline Repair Workplan WeldingJesus MaestreNessuna valutazione finora

- Ref Book HV Bushings CH 2 StandardsDocumento19 pagineRef Book HV Bushings CH 2 StandardsShahid IqbalNessuna valutazione finora

- 04 Samss 003Documento4 pagine04 Samss 003Moustafa Bayoumi100% (1)

- 32 Samss 004Documento44 pagine32 Samss 004brkmech50% (2)

- ASME Sec VIII the most common code for oil & gas pressure vesselsDocumento13 pagineASME Sec VIII the most common code for oil & gas pressure vesselsShieeplNessuna valutazione finora

- ASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasDocumento9 pagineASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasShieeplNessuna valutazione finora

- ASME Sec VIII the most common code for oil & gas pressure vesselsDocumento14 pagineASME Sec VIII the most common code for oil & gas pressure vesselsShieeplNessuna valutazione finora

- ASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasDocumento11 pagineASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasShieeplNessuna valutazione finora

- ASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasDocumento19 pagineASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasShieeplNessuna valutazione finora

- Astm A105 A105m 21Documento5 pagineAstm A105 A105m 21miraclemj35Nessuna valutazione finora

- (Process Industry Practices) Piping Flexibility OrgDocumento9 pagine(Process Industry Practices) Piping Flexibility OrgMursid Lafaliana Nuari100% (3)

- Piping Codes and Standards GuideDocumento13 paginePiping Codes and Standards Guidesuruchi shrivastavaNessuna valutazione finora

- Ownership Matrix Click For Copy of Word (Native) FileDocumento5 pagineOwnership Matrix Click For Copy of Word (Native) FileToniNessuna valutazione finora

- SECTION 13 05 41 Seismic Restraint Requirements For Non-Structural Components Part 1 - General 1.1 DescriptionDocumento6 pagineSECTION 13 05 41 Seismic Restraint Requirements For Non-Structural Components Part 1 - General 1.1 DescriptionAnonymous P73cUg73LNessuna valutazione finora

- Aws CatalogDocumento43 pagineAws CatalogDesmond Chin100% (1)

- SECTION 23 22 13 Steam and Condensate Heating PipingDocumento33 pagineSECTION 23 22 13 Steam and Condensate Heating PipingLILISNessuna valutazione finora

- Edc - Piping StandardsDocumento11 pagineEdc - Piping StandardsSrikrishnan KrishNessuna valutazione finora

- Portaria 455 de 2010Documento38 paginePortaria 455 de 2010Vijayakumar S.P.Nessuna valutazione finora

- f1c1 CVT Continuously Variable Transmission Service and Repair ManualDocumento58 paginef1c1 CVT Continuously Variable Transmission Service and Repair ManualVijayakumar S.P.Nessuna valutazione finora

- Total Head of Pump PDFDocumento4 pagineTotal Head of Pump PDFJerome GarciaNessuna valutazione finora

- Low Voltage Vs High Voltage TestingDocumento6 pagineLow Voltage Vs High Voltage TestingjunpamsNessuna valutazione finora

- Alstra Oil Filled USADocumento16 pagineAlstra Oil Filled USAVijayakumar S.P.Nessuna valutazione finora

- Recommended Unit Symbols, SI Prefixes, and Abbreviations: A VIIDocumento3 pagineRecommended Unit Symbols, SI Prefixes, and Abbreviations: A VIIAlexander WijesooriyaNessuna valutazione finora

- India Rarest PicturesDocumento49 pagineIndia Rarest PicturesPraveen Kumar NaiduNessuna valutazione finora

- Cam Espuma AnsulDocumento4 pagineCam Espuma AnsulElianaRosalesCabreraNessuna valutazione finora

- 01 Vacuum ComponentsDocumento84 pagine01 Vacuum ComponentsNick LaveryNessuna valutazione finora

- Bondstrand 2400 Series Product Data: Uses and ApplicationsDocumento4 pagineBondstrand 2400 Series Product Data: Uses and ApplicationsChristopher Kenneth ChoaNessuna valutazione finora

- 0200191200r5 Manual, 1forn TouchPower™ T5 Series RedundancyDocumento63 pagine0200191200r5 Manual, 1forn TouchPower™ T5 Series RedundancyNur RahmatNessuna valutazione finora

- APCO Silent Check PDFDocumento8 pagineAPCO Silent Check PDFtanvir04169Nessuna valutazione finora

- Tme CsiDocumento1 paginaTme CsiSimone FioccolaNessuna valutazione finora

- Operating, Installation & Maintenance Manual FOR Series 210 MK - Ii Sample ProbeDocumento44 pagineOperating, Installation & Maintenance Manual FOR Series 210 MK - Ii Sample ProbeSenterver Equipos IndustrialesNessuna valutazione finora

- Equivalent Standards - A - SA516-70, A - SA515-70, ST52-3, S355J2+N, SAILMA 350HI, SAILMA 450HIDocumento10 pagineEquivalent Standards - A - SA516-70, A - SA515-70, ST52-3, S355J2+N, SAILMA 350HI, SAILMA 450HIPuneet BahriNessuna valutazione finora

- Qty. Description TP 100-200/4 A-F-B-BAQE-MX3: Company Name: Created By: Phone: DateDocumento7 pagineQty. Description TP 100-200/4 A-F-B-BAQE-MX3: Company Name: Created By: Phone: Dateabhishek yadavNessuna valutazione finora

- Valvula Diafragma AquamaticDocumento59 pagineValvula Diafragma AquamaticderbisNessuna valutazione finora

- Spare Parts Catalogue: (Export)Documento75 pagineSpare Parts Catalogue: (Export)visugue_26Nessuna valutazione finora

- Repacking HT 400Documento113 pagineRepacking HT 400RODRIGONessuna valutazione finora

- MN PV 001 Installation Operation and Maintenance Manual Pig Valve Model F PDocumento17 pagineMN PV 001 Installation Operation and Maintenance Manual Pig Valve Model F PbalajiNessuna valutazione finora

- FS 2004D Rev.08Documento26 pagineFS 2004D Rev.08Shakeel AhmedNessuna valutazione finora

- VIS30Documento4 pagineVIS30Chali AndresNessuna valutazione finora

- Prueba de Presion en TuberiasDocumento78 paginePrueba de Presion en TuberiaswilberNessuna valutazione finora

- 2011 Catalogo RaccordiDocumento27 pagine2011 Catalogo Raccordisimonetta_nardiNessuna valutazione finora

- TP MP Guide System UpdateDocumento18 pagineTP MP Guide System UpdateWangwen ZhaoNessuna valutazione finora

- Jupiter 150 PDFDocumento73 pagineJupiter 150 PDFRonar TOLITS PajulasNessuna valutazione finora

- Ful Flo Catalog 2015Documento52 pagineFul Flo Catalog 2015arminNessuna valutazione finora

- HT Howard - Cylinder Liner Fitting For Cars, Motorcycles, Vans, Classic and Modern EnginesDocumento3 pagineHT Howard - Cylinder Liner Fitting For Cars, Motorcycles, Vans, Classic and Modern EnginesAndrés Alejandro PereiraNessuna valutazione finora

- Alfa Laval TZ-82F Tank Cleaning MachineDocumento2 pagineAlfa Laval TZ-82F Tank Cleaning MachineSamo SpontanostNessuna valutazione finora

- Stainless Steel Butterfly Valves for Chemical IndustriesDocumento6 pagineStainless Steel Butterfly Valves for Chemical IndustriesRiswanda HimawanNessuna valutazione finora

- 1334p Addendumno1 15460 SuDocumento10 pagine1334p Addendumno1 15460 Suwael72Nessuna valutazione finora

- 3 QUOTATION Anthony 12 DecDocumento12 pagine3 QUOTATION Anthony 12 DecKasarachi AmadiNessuna valutazione finora

- ISO 15348 2002 Metal Bellows Expansion Joints PDFDocumento8 pagineISO 15348 2002 Metal Bellows Expansion Joints PDFFernando GómezNessuna valutazione finora

- Pegler Gate ValveDocumento10 paginePegler Gate ValveJeffry GabilanNessuna valutazione finora

- GS-4500 Instrumentation Design and Installation SpecificationDocumento76 pagineGS-4500 Instrumentation Design and Installation SpecificationSmart LauNessuna valutazione finora

- Slam-Shut Valves: Type BM5Documento12 pagineSlam-Shut Valves: Type BM5RinnoNessuna valutazione finora