Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tufropes Brochure

Caricato da

NirmalKalubowilaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Tufropes Brochure

Caricato da

NirmalKalubowilaCopyright:

Formati disponibili

TUFNETS

Infrastructure

Indore

Silvassa

HDPE TWISTED NETS

Ply

Runnage

(mtrs/kg)

Breaking

Strength

(kgf)

6 Ply

3445

9 Ply

HDPE BRAIDED NETS

Size (mm)

Runnage

(mtrs/kg)

Breaking

Strength

(kgf)

10.75

1.2

983

17

2305

16.00

1.5

833

33

12 Ply

1685

21.00

1.8

623

46

15 Ply

1360

25.70

2.0

450

63

18 Ply

1120

30.50

2.5

398

65

21 Ply

970

35.50

3.0

283

83

24 Ply

850

39.80

3.5

223

12

27 Ply

750

44.50

4.0

210

160

30 Ply

674

49.00

5.0

121

255

36 Ply

565

58.00

6.0

93

283

42 Ply

480

67.50

7.0

81

296

45 Ply

450

72.00

60 Ply

335

100.50

90 Ply

225

150.00

120 Ply

165

190.00

180 Ply

110

260.00

Nets are Made up of 500 Denier Twine

Tolerance : Runnage: +/- 8% & Breaking Strength : +/-10%

Test Condition for Breaking Strength: Temp. 18 C to 25 C

MUMBAI

FACTORY

Head Office

Tufropes has two manufacturing plants near Mumbai, India and one plant

located in Indore, India. Our machines are from renowned manufacturers and

we use the highest quality raw materials. Not only are the standards of our

physical capital extremely high, but our human capital as well is extremely

qualified. Our employees are constantly innovating to produce technically

superior synthetic ropes and nets and using their expertise to benefit our

customers.

Customers first choice

Quality Management

In our quest for excellence, we place great emphasis on quality. Our quality

control team inspects all raw materials and products at each stage to ensure

the best quality and consistency. Our ropes meet national and international

specifications as well as customers specifications. We inspect our products for

denier, linear density, breaking strength, weight, length, UV resistance, colour

shade, abrasion as well as any characteristic specified by the customer. Tufropes

also provides third party certification from Bureau Veritas, Germanischer

Lloyd, Russian Register of Shipping and Lloyd Register of Shipping.

Achievements

Nets are Made up of 380 Denier Twine

Tolerance : Runnage: +/- 8% & Breaking Strength : +/-10%

Test Condition for Breaking Strength: Temp. 18 C to 25 C

Tufropes efforts to serve our international clients have been recognized by the

Government of India which has awarded us with Star Exporter certification.

Tufropes has also been a consistent recipient of the Second Best Exporter of

Ropes award from the Government of India.

Premium Range of Nets

TUFLINE NETS - Higher strength HDPE Nets

High abrasion resistance and high knot breaking strength as compared

to normal HDPE braided nets.

Nominal Dia (mm)

Runnage (meters/kg)

1.2

800.67

53.09

2.0

370.47

105.26

2.5

287.25

130.22

3.0

255.03

155.17

3.5

189.93

210.07

4.0

155.03

240.02

4.5

119.46

300.36

5.0

100.00

352.99

5.5

84.00

453.27

6.0

59.73

625.23

7.0

48.32

700.54

36.91

875.23

8.0

Global Market

Tufropes caters to the varied requirements of markets across the globe. Please

see the map below for our global market presence.

Breaking Strength (kgf)

Nets are made up of 380 Denier Twine

Tolerance: Runnage: +/- 8% and Breaking Strength: +/- 10%

Test condition for breaking strength: Temp 18 C to 25C

Delivering products of

outstanding quality

507, Embassy Center, Nariman Point, Mumbai 400 021, India.

Tel: +91-22-40502600 Fax: +91-22-22844167

email: tufropes@vsnl.com Website: www.tufropes.com

Introduction

8 - STRAND PLAITED ROPES

Made from Polypropylene fibre

Tufropes, an ISO 9001:2000 certified organization, was established in 1993 with

the aim to manufacture high quality synthetic ropes and nets. The company

has grown steadily and is presently Indias leading exporter of synthetic ropes,

nets and rope articles. Currently our products are exported to more than 62

countries. With growth in volumes, Tufropes has attained a high degree of cost

proficiency. Our clients trust us for the quality of our products, our flexibility in

manufacturing ropes and nets to meet our customers specific requirements

and our reliability in providing timely delivery and competitive prices. We, at

Tufropes, always strive for excellence and our customers trust is paramount

to us.

3 - STRAND LAID ROPES

ROPE

SIZE

(mm)

CARGO NETS

TUF FILM

SUPERTUF

TUF LINE

NYLO TUF

TUF PET

TUF FLEX

PP Rope

High tenacity PP

rope

PE Rope

Nylon Rope

Polyester Rope

PP/Polyester

mixed rope

Weight

Breaking

Strength

Weight

Breaking

Strength

Weight

Breaking

Strength

Weight

Breaking

Strength

Weight

Breaking

Strength

Weight

Breaking

Strength

Kgs/100m

Kgf

Kgs/100m

Kgf

Kgs/100m

Kgf

Kgs/100m

Kgf

Kgs/100m

Kgf

Kgs/100m

Kgf

ROPE

SIZE

(mm)

CIR

(inch)

SUPERTUF

NYLO TUF

TUF FLEX

High Tenacity PP rope

Nylon Rope

PP/Polyester mixed rope

Size (metres)

Mesh Rope (mm)

Rim Rope (mm)

Mesh Size (sq mm)

Weight

Breaking Strength

Weight

Breaking Strength

Weight

Breaking Strength

2.5 x 2.5

12

16

150

Kgs/100m

Kgf

Kgs/100m

Kgf

Kgs/100m

Kgf

2.5 x 2.5

12

18

200

24

25.90

9900

35.50

12000

31.90

12000

2.5 x 2.5

14

24

200

28

3.1/2

35.45

13200

48.50

15800

43.40

15800

2.5 x 2.5

18

24

200

32

45.90

16800

63.00

20000

56.50

20000

3.0 x 3.0

10

12

100

36

4.1/2

58.64

20600

80.00

24900

71.40

24900

3.0 x 3.0

12

16

125

40

71.82

25700

99.00

30000

88.40

30000

3.0 x 3.0

12

16

300

44

5.1/2

90.00

31800

120.00

35800

108.00

35800

3.0 x 3.0

12

18

200

48

104.00

36600

142.00

42000

128.00

46290

3.0 x 3.0

14

24

200

52

6.1/2

122.00

42100

166.00

48800

150.00

54300

3.0 x 3.0

18

24

200

56

142.00

52000

193.00

56000

172.00

62800

3.0 x 3.0

20

28

200

60

7.1/2

163.20

59500

221.00

63800

199.00

72000

3.0 x 3.0

20

28

225

64

185.00

67550

252.00

72000

225.00

82600

3.6 x 3.6

12

16

125

72

234.00

84500

319.00

89900

285.00

102000

3.6 x 3.6

12

16

150

80

10

290.00

104000

394.00

109800

352.00

125500

3.6 x 3.6

12

16

200

88

11

351.00

125000

477.00

130800

502.00

156000

3.6 x 3.6

20

28

225

96

12

417.00

148000

568.00

153900

598.00

185000

4.0 x 4.0

12

16

150

104

13

490.00

173500

666.00

182140

701.00

216000

4.0 x 4.0

12

16

300

112

14

570.00

201000

772.00

210200

813.00

250000

4.0 x 4.0

12

18

200

120

15

650.00

230000

887.00

240200

933.00

286000

4.0 x 4.0

14

24

200

128

16

740.00

258850

1010.00

272140

1060.00

325400

136

17

840.00

291000

1140.00

306220

1200.00

365000

144

18

940.00

321500

1280.00

344200

1345.00

405000

160

20

1152.00

390300

1580.00

422400

1660.00

500000

ALL CONSTRUCTIONS AS PER TUFROPES STANDARDS (MEDIUM SOFT LAY)

WARNING : THE MINIMUM BREAKING FORCE SHOULD NEVER BE CONSIDERED AS THE SAFE WORKING LOAD OF THE ROPE

FOR THE METHOD OF CALCULATING SAFE WORKING LOAD PLEASE REFER FACTOR OF SAFETY = BREAKING FORCE / 6

GANGWAY NETS

Made from Polypropylene fibre

0.74

214

0.74

240

0.81

200

1.05

360

1.18

300

0.90

315

Size (metres)

Mesh Rope (mm)

Rim Rope (mm)

Mesh Size (sq mm)

1.70

602

1.70

680

1.82

400

2.25

760

2.70

600

2.00

700

0.61 x 3.05

100

3.00

1060

3.00

1200

3.27

700

4.00

1390

4.80

1020

3.80

1330

1.22 x 4.88

100

10

4.55

1560

4.55

1800

4.90

1100

6.20

2130

7.60

1600

5.50

1980

1.52 x 3.05

100

12

6.59

2210

6.59

2700

7.20

1500

8.90

3040

11.00

2300

8.00

2850

3.00 x 3.00

18

24

200

14

9.00

3050

9.00

3600

9.50

2100

12.20

4180

14.80

3200

10.90

3895

4.00 x 16.00

10

150

16

11.59

3770

11.59

4500

12.80

2800

15.80

5380

19.50

4100

14.10

5035

5.00 x 10.00

10

150

18

14.80

4810

14.80

5800

16.10

3500

20.00

6880

24.50

5100

17.80

6365

5.00 x 15.00

10

150

20

18.00

5800

18.00

6900

20.00

4300

24.50

8450

30.30

6300

22.10

7885

22

22.00

6960

22.00

8400

24.30

5100

30.00

10400

36.70

7600

26.80

9500

24

26.00

8130

26.00

9900

29.50

6100

35.50

12000

43.70

9100

31.90

12000

28

35.50

10700

35.50

13200

39.30

8200

48.50

15800

59.40

12200

43.40

15800

32

46.00

13500

46.00

16800

52.50

10700

63.00

20000

77.80

15700

56.50

20000

36

58.50

16930

58.50

20600

66.00

13500

80.00

24900

98.20

19400

71.40

24900

40

72.00

20510

72.00

25700

78.50

16300

99.00

30000

121.50

24000

88.40

30000

48

104.00

28610

104.00

36600

115.00

22800

142.00

42000

175.00

33500

128.00

46290

56

142.00

37850

142.00

52000

157.00

30400

193.00

56000

238.00

44800

172.00

62800

60

163.00

43280

163.00

59500

180.00

34500

221.00

63800

273.00

49800

199.00

72000

ALL CONSTRUCTIONS AS PER TUFROPES STANDARDS (MEDIUM SOFT LAY)

WARNING : THE MINIMUM BREAKING FORCE SHOULD NEVER BE CONSIDERED AS THE SAFE WORKING LOAD OF THE ROPE

FOR THE METHOD OF CALCULATING SAFE WORKING LOAD PLEASE REFER FACTOR OF SAFETY = BREAKING FORCE / 6

Special Products

Tuf Lead: Lead core ropes are manufactured from fiber wrapped lead lines to

make the ropes as heavy as manila ropes. Ideal for fishing net bottom lines,

these ropes have high ultra-violet light resistance.

Anchor Lines: Anchor lines are available in hank and coil forms and are made

from soft medium lay ropes. With a high quality SS Thimble on one side and

a soft loop on the other, these anchor lines are easy to handle and attach to

anchor kits.

NYLON TAILS

Size (mm)

Size (cir)

Effective Length (metres)

MBL(kgf)

Weight (kgs)

48

11

47863

25

56

11

63466

34

64

11

81649

45

72

11

103358

57

80

10

11

125753

71

88

11

11

152244

88

The tails have an eye loop of 1.8 metres at both the ends.

Potrebbero piacerti anche

- Design of Compliant TowerDocumento50 pagineDesign of Compliant TowerEvi Susanti50% (2)

- Bearing Pressure Calculation Rev 3Documento5 pagineBearing Pressure Calculation Rev 3hutuguoNessuna valutazione finora

- Stone ColumnsDocumento15 pagineStone Columnsanurag hazarikaNessuna valutazione finora

- Ufc 4 152 01Documento167 pagineUfc 4 152 01bhavdip_shahNessuna valutazione finora

- Upn (Unp) European Standard U Channels, Upn Steel Profile Specifications, Dimensions, PropertiesDocumento3 pagineUpn (Unp) European Standard U Channels, Upn Steel Profile Specifications, Dimensions, PropertiesshankerNessuna valutazione finora

- C917 PDFDocumento9 pagineC917 PDFDIAZCORDOBANessuna valutazione finora

- Synthetic Webbing & Round Sling Acceptance CriteriaDocumento3 pagineSynthetic Webbing & Round Sling Acceptance CriteriarustamriyadiNessuna valutazione finora

- Zone Load TestDocumento8 pagineZone Load TestMohammadAsadNessuna valutazione finora

- ACI Method of Mix DesignDocumento18 pagineACI Method of Mix DesignRana Talal RaziNessuna valutazione finora

- Bollard GuideDocumento8 pagineBollard GuideCtr YlNessuna valutazione finora

- CTU Code SpanishDocumento145 pagineCTU Code SpanishBryan Salazar López100% (1)

- En1991.1-Forklift LoadsDocumento2 pagineEn1991.1-Forklift LoadsColin TanNessuna valutazione finora

- Cranes and Derricks, 4th Edition .Page400Documento1 paginaCranes and Derricks, 4th Edition .Page400danilolbg2903Nessuna valutazione finora

- Analysis Traffic LoadingDocumento67 pagineAnalysis Traffic LoadingMohamed MuayidNessuna valutazione finora

- Nilex Woven Geotextile SpecificationsDocumento1 paginaNilex Woven Geotextile SpecificationsAbdullah BasalamahNessuna valutazione finora

- EPA Wind CalculatorDocumento1 paginaEPA Wind CalculatorSandip SenguptaNessuna valutazione finora

- FREYSSISOL - MSE Wall Construction ManualDocumento105 pagineFREYSSISOL - MSE Wall Construction ManualUzmaNaumanNessuna valutazione finora

- Lifting Lug Stress - Typ FactorsDocumento1 paginaLifting Lug Stress - Typ FactorsDipak ZopeNessuna valutazione finora

- Karakteristik KendaraanDocumento23 pagineKarakteristik KendaraanMiftachul DimasNessuna valutazione finora

- Check Soil Bearing CapacityDocumento4 pagineCheck Soil Bearing CapacityKelvin LauNessuna valutazione finora

- Idlers - Medium To Heavy Duty PDFDocumento28 pagineIdlers - Medium To Heavy Duty PDFEd Ace100% (1)

- Astm C 127 PDFDocumento7 pagineAstm C 127 PDFNikolay DrumevNessuna valutazione finora

- BS 4942-3Documento12 pagineBS 4942-3dantorrelio89Nessuna valutazione finora

- c187 Normal ConsistencyDocumento2 paginec187 Normal ConsistencyJoshua Ian Gallardo Aban100% (1)

- Cadwell High Capacity Spreader Beam A - SB - 22-23Documento2 pagineCadwell High Capacity Spreader Beam A - SB - 22-23AbderraoufAffesNessuna valutazione finora

- Dynamic FormulaDocumento53 pagineDynamic FormulaDeni MaulanaNessuna valutazione finora

- Concrete Mix Design (Grade M60)Documento2 pagineConcrete Mix Design (Grade M60)புருஷோத்தமன் சரவணன்Nessuna valutazione finora

- BS-1881-110 CONCRETE Making Test Cylinders From Fresh Con PDFDocumento12 pagineBS-1881-110 CONCRETE Making Test Cylinders From Fresh Con PDFAshraf TomizehNessuna valutazione finora

- Specifications & Load Charts: 40 Ton Tele-Boom Crawler CraneDocumento16 pagineSpecifications & Load Charts: 40 Ton Tele-Boom Crawler CraneLauren'sclub EnglishBimbel Sd-smaNessuna valutazione finora

- 05 Mazier Retractable Core BarrelsDocumento1 pagina05 Mazier Retractable Core BarrelsJuan100% (1)

- 1) Marshal Mix DesignDocumento43 pagine1) Marshal Mix DesignعزNessuna valutazione finora

- ExxonmobilDocumento3 pagineExxonmobillim kang haiNessuna valutazione finora

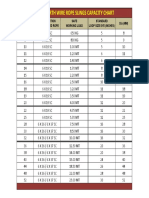

- Wire Rope Sling Capacity Chart PDFDocumento1 paginaWire Rope Sling Capacity Chart PDFMehul Paghdal0% (1)

- Bs 1881 - 112 (1983) PDFDocumento11 pagineBs 1881 - 112 (1983) PDFAdesina AlabiNessuna valutazione finora

- D 1241 - 00Documento3 pagineD 1241 - 00Milu OberoiNessuna valutazione finora

- Audibert Re-Examination of Py Curve FormulationDocumento8 pagineAudibert Re-Examination of Py Curve Formulationjianqiang liu100% (2)

- Excel Sheet For Sieve Analysis of Aggregate and To Calculate Fineness ModulusDocumento6 pagineExcel Sheet For Sieve Analysis of Aggregate and To Calculate Fineness Modulusmersed123Nessuna valutazione finora

- Astm c128 FaDocumento4 pagineAstm c128 FakinlaychengNessuna valutazione finora

- Abuja Plate Load TestDocumento22 pagineAbuja Plate Load TestKhattar Aoun100% (1)

- Product Data Sheet Sheave and Frame Assemblies PDFDocumento1 paginaProduct Data Sheet Sheave and Frame Assemblies PDFCraciun PaulNessuna valutazione finora

- AASHTO Pot BearingsDocumento4 pagineAASHTO Pot BearingsJithesh.k.sNessuna valutazione finora

- C1582C1582M-Aditivos Inhibidores de CorrosionDocumento10 pagineC1582C1582M-Aditivos Inhibidores de CorrosionAnthony López HuamanNessuna valutazione finora

- BS 4550-0 1978 - General IntroductionDocumento8 pagineBS 4550-0 1978 - General IntroductionAhmed BabikirNessuna valutazione finora

- H Beam ASTMDocumento6 pagineH Beam ASTMWong JowoNessuna valutazione finora

- Understanding To Equivalent Frame MethodDocumento4 pagineUnderstanding To Equivalent Frame MethodNikhil KumbharNessuna valutazione finora

- PLT Test (Astm d1196)Documento113 paginePLT Test (Astm d1196)Rango SantosoNessuna valutazione finora

- Concrete Coring (Eng)Documento2 pagineConcrete Coring (Eng)crescentmooon100% (1)

- H Beams in Accordance With JISDocumento3 pagineH Beams in Accordance With JISaselabollegalaNessuna valutazione finora

- Flakiness & Elongation Index Calibration Procedure PDFDocumento3 pagineFlakiness & Elongation Index Calibration Procedure PDFRAJESHNessuna valutazione finora

- Lashing SystemDocumento3 pagineLashing SystemAekJay100% (1)

- d6347 d6347m 05Documento18 pagined6347 d6347m 05Kanwar P SinghNessuna valutazione finora

- 21a Pallet Load Testing To en ISO 8611Documento1 pagina21a Pallet Load Testing To en ISO 8611Debreteni FlorinNessuna valutazione finora

- N2XCYDocumento5 pagineN2XCYRinda_RaynaNessuna valutazione finora

- We Bring Forth High Quality Galvanized Corrugated SheetsDocumento9 pagineWe Bring Forth High Quality Galvanized Corrugated SheetsCHRISTIAN F. MAYUGANessuna valutazione finora

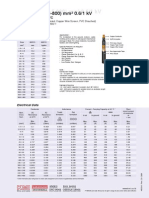

- LT Power Cable - Data SheetDocumento9 pagineLT Power Cable - Data SheetAnagha DebNessuna valutazione finora

- Deflection Mid SpanDocumento39 pagineDeflection Mid SpanPhasin ChitutsahaNessuna valutazione finora

- Grid Coupling PDFDocumento6 pagineGrid Coupling PDFsgupta_615796100% (1)

- Mapower Calculation & AllocationDocumento109 pagineMapower Calculation & AllocationSuresh GaneshNessuna valutazione finora

- Annexure 1 - Product Profile of ShreeSatya GroupDocumento10 pagineAnnexure 1 - Product Profile of ShreeSatya GroupRohan HajelaNessuna valutazione finora

- KIARATEX Technical Data Sheet Non Woven Prod SpecDocumento1 paginaKIARATEX Technical Data Sheet Non Woven Prod Specnw__ayNessuna valutazione finora

- Chapter 4.7-OnDocumento42 pagineChapter 4.7-OnBelayneh Tadesse100% (3)

- GFNDocumento19 pagineGFNAl Amin ZubirNessuna valutazione finora

- Hydraulic Shovel: Engine BucketDocumento32 pagineHydraulic Shovel: Engine BucketJulio CRNessuna valutazione finora

- Positive Displacement PumpsDocumento48 paginePositive Displacement PumpsSteve Carwell100% (6)

- NGR PDFDocumento4 pagineNGR PDFmanicheNessuna valutazione finora

- Coolant DatasheetDocumento2 pagineCoolant DatasheetTerminal TruckNessuna valutazione finora

- Steel Members DesignDocumento195 pagineSteel Members DesignStephen JamesNessuna valutazione finora

- DirectionalControlValves NACHIDocumento47 pagineDirectionalControlValves NACHICarlos Mauricio Guerrero Aguilar100% (1)

- Fs-1030 Quick G... R Jam (Eng)Documento1 paginaFs-1030 Quick G... R Jam (Eng)paliouras11Nessuna valutazione finora

- 345 Prakash2014Documento17 pagine345 Prakash2014xDiego MNessuna valutazione finora

- Matter and Its PropertiesDocumento3 pagineMatter and Its PropertiesCynthiaNessuna valutazione finora

- Process Flow Chart of Woven Dyeing - Textile FlowchartDocumento5 pagineProcess Flow Chart of Woven Dyeing - Textile FlowchartGOWTHAM CHANDRUNessuna valutazione finora

- 1100KVA Cat Engine PDFDocumento6 pagine1100KVA Cat Engine PDFosanebiNessuna valutazione finora

- Hot Work PermitDocumento17 pagineHot Work Permituday0% (1)

- Amount of Substance: WWW - CHEMSHEETS.co - UkDocumento38 pagineAmount of Substance: WWW - CHEMSHEETS.co - UkAsaph AharoniNessuna valutazione finora

- To Pirnt Comflor 46Documento2 pagineTo Pirnt Comflor 46MohammedNessuna valutazione finora

- File 16081432951056215326Documento50 pagineFile 16081432951056215326aayasirNessuna valutazione finora

- Equilibrium Staged OperationsDocumento11 pagineEquilibrium Staged OperationsdeeptankNessuna valutazione finora

- BR PDFDocumento240 pagineBR PDFMisha KulibaevNessuna valutazione finora

- 【Hail Netting】-Technical DATA SHEET - Raschel -TriangleDocumento1 pagina【Hail Netting】-Technical DATA SHEET - Raschel -TriangleVipul AgrawalNessuna valutazione finora

- US10727540Documento47 pagineUS10727540orli20041Nessuna valutazione finora

- FM9, VT2206PTDocumento6 pagineFM9, VT2206PTSherzad Chem67% (3)

- Cassida Fluid HFDocumento3 pagineCassida Fluid HFrinthusNessuna valutazione finora

- BO1001-41120-EEC102 - 448220633 - Cable Trays and Conduits Technical Specification - ESEDocumento31 pagineBO1001-41120-EEC102 - 448220633 - Cable Trays and Conduits Technical Specification - ESEfernando romeroNessuna valutazione finora

- Distillation Column Tray Selection & Sizing - 1 - Separation TechnologiesDocumento30 pagineDistillation Column Tray Selection & Sizing - 1 - Separation TechnologiesHuzefa Calcuttawala0% (1)

- Introduction To ANSYS Mechanical: Workshop 5.1 Linear Structural AnalysisDocumento20 pagineIntroduction To ANSYS Mechanical: Workshop 5.1 Linear Structural AnalysisAjay Chacko100% (1)

- Auto Detailing GuideDocumento46 pagineAuto Detailing Guidemcourchaine13100% (4)

- History of TextileDocumento11 pagineHistory of TextileRavi SinghNessuna valutazione finora

- Hyrax Cable Oil - LAB Based IEC 867-Class I (SDS)Documento11 pagineHyrax Cable Oil - LAB Based IEC 867-Class I (SDS)atenguezNessuna valutazione finora

- Umicore BrazeTec Principles of BrazingDocumento28 pagineUmicore BrazeTec Principles of BrazingsboergertNessuna valutazione finora