Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

1.6 - Manual Valvula 788

Caricato da

Denis MarcosDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

1.6 - Manual Valvula 788

Caricato da

Denis MarcosCopyright:

Formati disponibili

Design Specifications

DSV788DVC

May, 2001

DESCRIPTION

The Model 788DVC Digital Control Valve is designed

to provide precise flow rate control and batch delivery

of fluid products when used with an electronic batch

control device such as the PetroCount. The Model

788DVC valve is automatically controlled by the

PetroCount for low flow start-up, high flow rate control,

low flow shutdown, and final shut-off. This also pro-

vides for maximum flowmeter accuracy by maintain-

ing a constant flow rate with varying line pressures.

The Model 788DVC features an external pilot control

loop that consists of a normally-open solenoid pilot, a

normally-closed solenoid pilot, strainer, and opening/

closing speed controls.

DESIGN FEATURES

Precision flow rate and batch control

Modular construction - all internal parts including

seat ring are removable as a cartridge assembly

without removing the valve body from system

piping.

No diaphragms or stuffing boxes

45

0

body design assures high capacity

Positive (bubble-tight) shut-off

Linear control characteristics with uniform response

speed

Automatic check valve-no reverse flow

Fail-safe closes on loss of electrical power

AP (AGGRESSIVE PRODUCTS) OPTION

The AP option valve cylinder incorporates a combi-

nation of seals and O-ring materials to provide opti-

mum performance in aggressive product applications.

This option includes reinforced cylinder heads, stat-o-

seals, washers and gaskets. Specify AP Option at

time of order when used on alcohols, MTBE, TAME

and reformulated fuels.

APPLICATIONS

Batch control with flow limiting capabilities when used

with digital control devices such as the PetroCount or

similar compatible devices.

PRINCIPLE OF OPERATION

The valves are pilot operated on a balanced piston

principle. They are spring biased to a closed position.

Pressure differential overcomes the force of the spring,

causing the main valve to open and establish flow. The

pilot control(s) vary the pressure on the spring side of

the piston for position.

MAXIMUM OPERATING PRESSURE

DIFFERENTIAL (M.O.P.D) ACROSS PI-

LOTS

150 lb. Standard - 150 psid (1,035 kPa)

Optional - 285 psid (1,967 kPa)

300 lb. Standard - 740 psid (5,106 kPa)

FLANGE CONNECTIONS / RATINGS (ANSI)

Valve MAXIMUM WORKING PRESSURE @ 100

o

F

Size 150 lbs. ANSI 300 lbs. ANSI

2" - 8" 285 psi 740 psi

FLANGE CONNECTIONS / RATINGS (DIN)

DIN PN16 DIN PN25 DIN PN40 DIN PN64 (300 lbs.)

Valve MAX. WORKING MAX. WORKING MAX. WORKING MAX. WORKING

Size PRESSURE @ 120

o

CPRESSURE @ 120

o

CPRESSURE @ 120

o

C PRESSURE @ 38

o

C

DN50 - DN300 16 bar 25 bar 40 bar 51 bar

Temperature Range: -20

o

F to 150

o

F (-29

o

C to 66

o

C) Optional 250

o

F (121

o

C)

Model 788DVC

DIGITAL CONTROL VALVES

Page 1 of 8

MATERIALS OF CONSTRUCTION

Main Valve Body

Steel - ASTM-A216-GR-WCB

Main Valve Cylinder

2-4" Stainless Steel

6-8" Steel, Nickel Coated

Main Valve Piston

2-6" Stainless Steel

8" Bronze Standard

Stainless Steel - Optional

Seat Ring

2-6" Stainless Steel

8" Steel, Nickel Coated

O-Rings

Standard - Buna-N

Optional - Other O-Rings are available Neoprene

,

EPR, all Viton, all Buna-N, Kalrez/Teflon ("AP"

Valves)

Other Internal Parts

Stainless Steel

Pilot Valve Strainer/Needle Valve Body

Standard - Steel

Pilot Valve Strainer/Needle Valve Trim

Stainless Steel

Tubing and Fittings

Standard - Steel

Optional - Stainless Steel

SHIPPING WEIGHT AND VOLUME

(Approximate)

Valve

Size

150 - 300 lbs. (ANSI Flanges)

lbs. kgs.

Cubic

Feet

Cubic

Meters

2" 60 27.22 1.66 0.047

3" 105 47.63 2.36 0.067

4" 140 63.5 2.51 0.071

6" 250 113.4 4.84 0.137

8" 465 212 8.94 0.253

STANDARD EQUIPMENT

Pre-wired solenoids (not for CENELEC execution)

Opening and closing speed controls

Self-cleaning strainer (Pilot Inlet)

Stainless steel solenoid pilots

Steel tubing and fittings

UL and CSA Listed

Class I - Group C & D

Class II - Group E, F & G

Explosion Proof Nema Types 7C, 7D, 9E, 9F, 9G

and Waterproof Nema Type 4

CENELEC EEx d II B T3 (Optional)

DOCUMENTATION & APPROVALS

** DC voltage and 440/480 Vac available upon request.

Voltage** Current (Inrush) Current (Holding)

110/50 Vac 0.71 amps 0.37 amps

120/60 Vac 0.65 amps 0.34 amps

220/50 Vac 0.36 amps 0.19 amps

240/60 Vac 0.33 amps 0.17 amps

SOLENOID ELECTRICAL DATA

PRESSURE DROP

Refer to Publication DSVALVEC

v

.

Valve Size 2" 3" 4" 6" 8"

*Cv - gpm 86 186 309 688 1, 296

VALVE CAPACITY DATA

For capacities and pressure drops, please consult Publication

DSVALVEC

v

"Capacity Charts for Valve Sizing."

*C

v

based on wide open valve utilizing water at 60

0

F (15.6

0

C).

OPTIONAL EQUIPMENT

1.Manual Override

2.Valve Position Indicator

3.Stainless Steel Position Indicator - (Visual Only)

4.Position Indicator Switches

5.Thermal Relief

6.Stainless Steel Tubing and Fittings

7. Stainless Steel Piston

8. Pre-wiring for valves with CENELEC solenoids

RECOMMENDED SPARE PARTS

O-Rings

Page 2 of 8

Design Specifications

DSV788DVC

May, 2001

Figure 2 Truck Loading - Single Product/Multiple Blends

Figure 1 Truck Loading - Single Product/Blend

TYPICAL APPLICATIONS

The most common application of the 788DVC control valve is for truck loading. Figures 1 and 2 show the valve

working with Turbines and PetroCount to precisely control flow rates, batch quantities and blend ratio's of various

products being loaded.

Page 3 of 8

Design Specifications

DSV788DVC

May, 2001

OPERATIONAL SEQUENCE

With both solenoids de-energized, the main valve is

closed as shown in Figure 3. The main valve can be

infinitely positioned anywhere between 0-100% open

by digital control of the solenoids. With both solenoids

energized, as shown in Figure 4, the valve begins to

open. It will only open to the programmed flow rate set

in the PetroCount. Normally, the PetroCount is pro-

grammed to digitally control low flow start-up rate,

maximum flow rate, low flow rate before shut-off and

no flow. The PetroCount will automatically energize

and de-energize the solenoids to position the main

valve to limit the required flow rate. When the required

rates are reached the solenoids will be as shown in

Figure 5. This hyraulically locks the main valve piston

in position. Should flow increase, the valve will close

slightly to adjust to the required rate. All of the

positioning is done by digitally controlling the two

sol enoi ds as shown i n Fi gures 3,4

and 5.

Figure 3 Closed or Closing Position

Closed or Closing Position - The normally closed solenoid is

closed. The normally open solenoid is open. Y-Port (P3) to Z-port

(P2) is closed. X-port (P1) and Y-port (P3) pressures are balanced.

The main valve spring being the differential force, closes the

piston and keeps it seated.

Page 4 of 8

Design Specifications

DSV788DVC

May, 2001

Controlling Position - The normally closed solenoid is closed.

The normally open solenoid is closed. Y-Port (P3) to Z-port (P2)

is closed. X-port (P1) to Y-port (P3) is closed.

Note: The product cannot flow to or from the top of the piston (Y-

port). The piston is hydraulically locked in position until the

PetroCount commands the valve to open or close as required to

maintain the desired flow rate.

Opening Position - The normally closed solenoid is open. The

normally open solenoid is closed. Y-Port (P3) is open to Z-port

(P2). X-port (P1) is closed off by the normally open solenoid. The

pressure on the bottom of the piston (P1) is greater than the

pressure at (P3) plus the spring force; (P1 minus P2) is equal to or

greater than the spring force. Therefore, (P1) pressure pushes the

piston open.

Figure 4 Full Open / No Control Figure 5 Controlling Position

Page 5 of 8

Design Specifications

DSV788DVC

May, 2001

DIMENSION A

(ANSI Flanges)

DIMENSION B

(ANSI Flanges)

Valv

Size

150 lbs. 300 lbs. 150 - 300 lbs.

Inches mm Inches mm Inches mm

2" 10 1/4 260 10 1/2 267 10 7/8 276

3" 11 279 13 1/8 333 11 1/4 286

4" 13 330 14 1/2 368 11 1/2 292

6" 17 432 17 7/8 454 13 3/8 346

8" 22 1/4 565 23 1/4 591 17 3/4 451

Dimensions - Model 788DVC (For certified dimension prints, consult factory)

Page 6 of 8

Design Specifications

DSV788DVC

May, 2001

Page 7 of 8

Design Specifications

DSV788DVC

May, 2001

1. Size

2. Flange connections

3. Product, product viscosity, product specific

gravity

4. Minimum and maximum operating temperature

5. Minimum and maximum flow rate

6. Minimum, normal and maximum operating

pressure

7. Control functions to be performed

8. O-Ring material

9. Control pilot materials

10. Tubing material

11. Main valve piston material

12. Voltage Required

ORDERING INFORMATION

When ordering, the following information must

be supplied:

PURCHASE SPECIFICATIONS

These valves shall be hydraulically operated, digitally

solenoid controlled on-off valves using the flowing

stream as the operating medium. The main valve shall

be pressure balanced, single seated, piston operated

with 45

0

body construction. All internal parts, including

cylinder, spring, piston and seat ring shall be removed

as a cartridge assembly without disturbing line con-

nections. The pilot valves shall be direct acting,

solenoid operated, two way valves. Two manual flow

control valves shall be included in the pilot supply line

to provide an adjustable opening and closing rate. The

pilot supply line shall also include a strainer. These

valves shall, in all respects, be similar or equal to a

Model 788DVC digital control valve. There shall be

no diaphragms operating in the main valve.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed

as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicabil ity. We reserve the right to modify or improve

the designs or specifications of such products at any time without notice.

Page 8 of 8

Design Specifications

DSV788DVC

May, 2001

2001 is a registered trademark Printed in USA DAN-DSV788DVC-3M-05/

01

Daniel is a wholly owned subsidiary of Emerson , and a division of Emerson Process Management.

Daniel Division Headquarters - Houston, Texas, USA, Tel: (713) 467-6000, Fax: (713) 827-3880

USA Toll Free 1-888-FLOW-001

Calgary, Alberta, Canada, Tel: (403) 279-1879, Fax: (403) 236-1337

Stirling, Scotland - UK, Mid-East & Africa, Tel: +44 1653-638300, Fax: +44 1653-600425

Singapore - Asia Pacific Tel: +65- 777-8211, Fax: +65 -770-8001

www.daniel.com

Viton is a registered trademark of DuPont Performance Elastomers.

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Probability Theory - VaradhanDocumento6 pagineProbability Theory - VaradhanTom HenNessuna valutazione finora

- A First Etymological Dictionary of BasquDocumento29 pagineA First Etymological Dictionary of BasquDaily MailNessuna valutazione finora

- CNC Milling ReportDocumento15 pagineCNC Milling ReportStarscream Aisyah78% (37)

- OPENING & CLOSING PROGRAM NARRATIVE REPORT (Grade 7)Documento4 pagineOPENING & CLOSING PROGRAM NARRATIVE REPORT (Grade 7)Leo Jun G. Alcala100% (1)

- Howo ModelDocumento54 pagineHowo ModelTry SumantryNessuna valutazione finora

- Biography Worksheet: Name: Gerardo Angeles MartinezDocumento1 paginaBiography Worksheet: Name: Gerardo Angeles MartinezAlejandro AngelesNessuna valutazione finora

- Er6f Abs 2013Documento134 pagineEr6f Abs 2013Calibmatic JobNessuna valutazione finora

- (Word 365-2019) Mos Word MocktestDocumento4 pagine(Word 365-2019) Mos Word MocktestQuỳnh Anh Nguyễn TháiNessuna valutazione finora

- Storage Tanks Overfill Prevention Better PracticesDocumento2 pagineStorage Tanks Overfill Prevention Better PracticesRicardo Bec100% (1)

- Configuring Hyper-V: This Lab Contains The Following Exercises and ActivitiesDocumento9 pagineConfiguring Hyper-V: This Lab Contains The Following Exercises and ActivitiesMD4733566Nessuna valutazione finora

- Typical Cable Laying Details For Direct Buried, Low Tension CablesDocumento9 pagineTypical Cable Laying Details For Direct Buried, Low Tension CableslataNessuna valutazione finora

- Bombas KMPDocumento42 pagineBombas KMPReagrinca Ventas80% (5)

- Flow Through A Converging-Diverging Tube and Its Implications in Occlusive Vascular Disease-IDocumento9 pagineFlow Through A Converging-Diverging Tube and Its Implications in Occlusive Vascular Disease-IRukhsarAhmedNessuna valutazione finora

- Be and Words From The List.: 6B Judging by Appearance Listening and ReadingDocumento3 pagineBe and Words From The List.: 6B Judging by Appearance Listening and ReadingVale MontoyaNessuna valutazione finora

- Swenson 1 Dan Swenson Printing Press: Part One (Timeline)Documento6 pagineSwenson 1 Dan Swenson Printing Press: Part One (Timeline)Dan SwensonNessuna valutazione finora

- Thesis - A Surlyn® Ionomer As A Self-Healing and Self-Sensing Composite - 2011 - UKDocumento194 pagineThesis - A Surlyn® Ionomer As A Self-Healing and Self-Sensing Composite - 2011 - UKAhmedNessuna valutazione finora

- Surge Protection Devices CatalogueDocumento134 pagineSurge Protection Devices CatalogueNguyen Doan QuyetNessuna valutazione finora

- Progressive Muscle Relaxation ExerciseDocumento2 pagineProgressive Muscle Relaxation Exerciseraghu2362704100% (1)

- Modular Heavy Duty Truck TransmissionDocumento6 pagineModular Heavy Duty Truck Transmissionphucdc095041Nessuna valutazione finora

- 19 Uco 578Documento20 pagine19 Uco 578roshan jainNessuna valutazione finora

- Mathematics4 q4 Week4 v4Documento11 pagineMathematics4 q4 Week4 v4Morales JinxNessuna valutazione finora

- ERP Solution in Hospital: Yangyang Shao TTU 2013Documento25 pagineERP Solution in Hospital: Yangyang Shao TTU 2013Vishakh SubbayyanNessuna valutazione finora

- GATE Chemical Engineering 2015Documento18 pagineGATE Chemical Engineering 2015Sabareesh Chandra ShekarNessuna valutazione finora

- Program of ActivitiesDocumento2 pagineProgram of ActivitiesVon Limuel LopezNessuna valutazione finora

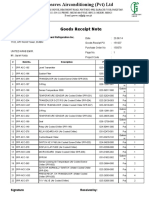

- Goods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateDocumento4 pagineGoods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateSaad PathanNessuna valutazione finora

- EEE301 Digital Electronics Lecture 1 Part 3: Dr. A.S.M. MohsinDocumento6 pagineEEE301 Digital Electronics Lecture 1 Part 3: Dr. A.S.M. MohsinAaa AaaNessuna valutazione finora

- WicDocumento6 pagineWicGonzalo Humberto RojasNessuna valutazione finora

- Human Development and Performance Throughout The Lifespan 2nd Edition Cronin Mandich Test BankDocumento4 pagineHuman Development and Performance Throughout The Lifespan 2nd Edition Cronin Mandich Test Bankanne100% (28)

- Gates Crimp Data and Dies Manual BandasDocumento138 pagineGates Crimp Data and Dies Manual BandasTOQUES00Nessuna valutazione finora

- The Confucian Transformation of Korea: Harvard-Yen Ching Institute Monograph SeriesDocumento456 pagineThe Confucian Transformation of Korea: Harvard-Yen Ching Institute Monograph SeriesAnna D.Nessuna valutazione finora