Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Structural Analysis of Landing Strut Madeup of Carbon Fibre Composite Material

Caricato da

Raj Kumar0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

26 visualizzazioni6 pagineStructural Analysis of Landing Strut Madeup of Carbon Fibre Composite Material

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoStructural Analysis of Landing Strut Madeup of Carbon Fibre Composite Material

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

26 visualizzazioni6 pagineStructural Analysis of Landing Strut Madeup of Carbon Fibre Composite Material

Caricato da

Raj KumarStructural Analysis of Landing Strut Madeup of Carbon Fibre Composite Material

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 6

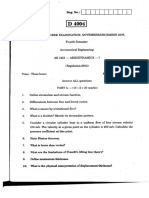

International Journal of Mechanical and Production Engineering (IJMPE), ISSN 2320-2092,

Vol.1, Issue No.1

4

STRUCTURAL ANALYSIS OF LANDING STRUT MADEUP OF CARBON

FIBRE COMPOSITE MATERIAL

Prof.R.Arravind

1

, Dr.M.Saravanan

2

, R.Mohamed Rijuvan

3

, D.Vadivel

4

1

Department of Aeronautical Engineering, Excel College of Engineering & Technology, Tamil Nadu, India

2

Principal, SBM College of Engineering & Technology, Tamil Nadu, India

3

Final Year, B.E Aeronautical Engineering, Excel College of Engineering & Technology, Tamil Nadu, India

4

Final Year, M.E Aeronautical Engineering, Er.P.M.C Tech, Tamil Nadu, India

email id : arravind_r@rediffmail.com, drmsaravanan@yahoo.com , rijuvanaero09@gmail.com,

vadivelaero@gmail.com

ABSTRACT: The landing strut is a structure that supports an helicopter on ground and allows it to take-off,

and land. In fact, landing strut design tends to have several interferences with the helicopter structural

design. Now a day the weight of landing strut has become an important factor. Efforts are being made to

reduce the weight of the helicopter and consequently increase the payload. This paper presents an approach

to optimize the design of landing strut of an Light Compact Helicopter (LCH) made of Carbon Fibre

Composite Material adopted from Aerospace Specification Metals (ASM). First the structural behavior is

tested using the structural analysis when subjected to behavior constraints. Optimization process is carried

out iteratively to minimize thickness of landing strut which results in the minimum weight of landing strut.

1.0 INTRODUCTION:

Each type of helicopter needs a unique

landing strut with a specific structural system, which

can complete the demands described by unique

characteristics associated with each helicopter. The

landing strut is the component that supports a

helicopter and allows it to move on the ground.

Conventional landing strut is one of the types among

the landing strut where the strut legs indeed of

tricycle fashion. The tricycle arrangement has one

strut either back or front and two main strut legs. The

main strut leg comprises a simple single piece of

carbon fibre composite material spring leaf type

which is bolted at the bottom of the fuselage.

The design and development of a landing

strut encompasses several engineering disciplines

such as structures, mechanical systems,

aerodynamics, material science, and so on. The

conventional landing strut design [1] and

development for aerospace vehicles is based on the

availability of several critical components/systems

such as forgings, machined parts, mechanisms, sheet

metal parts, electrical systems, hydraulic systems,

and a wide variety of materials such as carbon fibre

composite materials, steel and titanium, beryllium,

and polymer composites. As the science of materials

is progressing continuously it is natural that the use

of new materials will replace older designs with new

ones. Energy absorption and crashworthy features are

the primary design criteria that govern the

development of landing struts. The impact force on

landing strut has been discussed by Flugge [2]

considering both the landing and taxiing impact

forces and neglected the drag force acting on it. The

crack generation in the landing strut components was

observed by Fujimoto [3] and the basic causes of

damage were found to be processing operations,

latent material defects, mechanical damage and crack

growth developed at corrosion pits. The helicopter

landing strut simulation was analyzed by Derek

Morrison et al. [4] by performing two types of

analysis. The first is kinematic evaluation of front

nose strut and other is the structural study of main

landing strut for a light weight helicopter. The

approach for modeling and simulating landing strut

systems was proposed by James Daniels [5] devolved

a nonlinear model of an A-6 intruder main strut, the

simulation and validation was performed against the

static and dynamic test data. A discussion has been

done on problems facing by the helicopter

community in landing strut dynamics, especially in

shimmy and brake-induced vibration by Jocelyn

Pritchard [6], experimentally validated and

characterized the shimmy and brake-induced

vibration of helicopter landing strut. The design

analysis of Light Landing Strut was presented by

Amit Goyal [7]. In the development phase,

conducting a rigorous non-linear stress and buckling

analysis was carried out and also conducting various

experimentations on different combinations of loads

and orientations. Noam Eliaz et al. [8] discussed

failure of beams of landing strut during operation.

During replacement of a wheel on the helicopter, a

International Journal of Mechanical and Production Engineering (IJMPE), ISSN 2320-2092,

Vol.1, Issue No.1

5

crack was found on the rear axle bore of the left-hand

main landing strut truck beam. The aero structure

analysis on ME 548 was analyzed by Dave Briscoe

[9] verified that the vonmises and deflections of

landing strut and also proved that results given by the

ANSYS and SOLID WORKS software are not same

because of improper meshing of components. The

specific constrained layer damping applications for

cantilever-loaded steel spring landing strut was

investigated by Oraig Gellimore [10]. This work

involves validation of the cost efficient design of

traditional landing strut damping devices when used

in constrained layer damping. The dynamic analysis

of landing strut for critical work conditions by

applying finite element analysis was analyzed by

Jerzy Malachowski [11].The design of light landing

strut by conducting structural analysis and design

optimization was analyzed by Essam Albahkali and

Mohammed Alqhtani [12] by conducting experiments

on landing strut using impact analysis. Review of

literature survey on different types of landing struts

shows that landing strut is analyzed for safety of the

structure and effort was made to identify the faults

occurring in them. However there is limited literature

available on conventional landing strut made of

ASM7075-T6 material. The present study deals with

the structural analysis and optimization of landing

struts leg made of ASM7075-T6 material and the

analysis was carried out using ANSYS (Version 13).

2.0 GEOMETRICAL MODEL:

The undercarriage or landing strut in

aviation is the component that supports an aircraft on

the ground and allows it to land. Conventional

landing strut consists of horizontal struts connected

with parallel struct which possess centre of gravity.

This type of landing strut is most often used in older

generation aviation airplanes and now a day, it is

used in LCH.

The following are assumptions to be considered for

analysis

1. The material is assumed to elastic and

homogenous.

2. The analysis has been carried out with in

elastic limits.

3. Both Solid (pipe element) and shell elements

are used for analysis.

4. Rigid Body Element (RBE3) connection is

used for load transfer.

Figure 2.1: Landing Strut

Figure 2.1 shows the model of landing strut chosen

for analysis which have been used for light compact

helicopter and at present these are used in LCH. The

weight of landing Strut considered for analysis was

taken as 6 kg.

The data required for designing and weight

of landing strut has been taken from Grove

Helicopter Landing Gear Systems Inc, which is a

complete custom landing gear company manufactures

ready to bolt component design for customer

requirements to individual aircrafts and Helicopter.

3.0 FLOW CHAT

4.0 MATERIAL PROPERTIES:

Here we are using the materials for analysis

of helicopter strut is Carbon fibre composite

materials. It having density as 1.6 g/cm

3

, Youngs

Start

Create 3D Cad Model

Clean up the 3D Cad Model

Save the 3D Cad Geometry

Save the 3D Cad Geometry in Neutral

format

Define Material Properties

Solve

Post Processing

Stop

International Journal of Mechanical and Production Engineering (IJMPE), ISSN 2320-2092,

Vol.1, Issue No.1

6

modulus as 70 Gpa and poissons ratio as 0.10.

Carbon fiber, alternatively graphite fiber, carbon

graphite or CF, is a material consisting

of fibers about 510 m in diameter and composed

mostly of carbon atoms. The carbon atoms are

bonded together in crystals that are more or less

aligned parallel to the long axis of the fiber. The

crystal alignment gives the fiber high strength-to-

volume ratio (makes it strong for its size). Several

thousand carbon fibers are bundled together to form

a tow, which may be used by itself or woven into a

fabric. The properties of carbon fibers, such as high

stiffness, high tensile strength, low weight, high

chemical resistance, high temperature tolerance and

low thermal expansion, make them very popular in

aerospace, civil engineering, military, and

motorsports, along with other competition sports.

However, they are relatively expensive when

compared to similar fibers, such as glass fibers or

plastic fibers. Carbon fibers are usually combined

with other materials to form a composite. When

combined with a plastic resin and wound or molded it

forms carbon fiber reinforced plastic (often referred

to as carbon fiber) which has a very high strength-to-

weight ratio, and is extremely rigid although

somewhat brittle. However, carbon fibers are also

composed with other materials, such as with graphite

to form carbon-carbon composites, which have a very

high heat tolerance.

5.0 PROCEDURE:

1. Define Geometry : First of all, we have to

define the geometry and dimension for the

helicopter strut. With the help of obtained

geometry, we have to design 3D model of

the landing strut with the help of CAD

Package softwares like Pro/E, Catia and NX

CAD. After model has been designed, we

have to save the modeled design in the

common format like IGES or STEP.

2. For Analysis of landing strut, here we are

using Ansys Workbench V12.0.1, this

analysis can be also done with the help

Nastran software too.

3. Meshing has been done for the designed

model, here we used tetrahydral element

type for dividing the model into small

number of elements

4. We have define the fixed support and force

acting on the strut. Here we use force as

400N because the load acting on the landing

strut during landing will be around 350N.

5. Then we have to select the result what are

all we need for further studies like

deformation, stress and strain

6.0 LANDING GEAR LOADS:

The design loads applied on aircraft are lift load,

drag load, side load and torsion load. Lift is the

upward force created by the air flow as it passes over

the wing, drag is the retarding force (back ward

force) that limits the aircrafts speed, side load is the

opposing acting in inward direction of gear leg and

torsion load is applied when the air craft structure

rotates. Table 2 shows general design loads

considered to test the landing gears leg.

Table 1: Landing Strut Loads (Design Loads)

Type of Load Value

Landing Load 400 N

With the above all specifications the model

was designed in CATIA (Ver-11), meshed in

HYPERMESH (Ver-12) and the results are viewed in

ANSYS (Ver-12).

Figure 2.2: 3D-meshed model of landing gears leg

Figure 2.2 shows the 3D model of the

landing gears leg which is meshed in HYPERMESH

and applied the boundary conditions. The applied

boundary conditions for the model are as follows,

Fixing the gear leg at bolting portion in all

directions.

The loads such as lift, drag, side and torsion

are applied in respective directions..

International Journal of Mechanical and Production Engineering (IJMPE), ISSN 2320-2092,

Vol.1, Issue No.1

7

Gear leg and axle component are glued to

make a single component.

Figure 2.3: Loads applied on landing gears

leg

The maximum possible loads which are given as

design loads are applied through RBE3 connection at

the axle end spreading to wheel base. The units are

taken in such a way that translational forces are in

newton and torsion moment is represented in newton-

millimeters. The colour code is used to represent the

problem boundary conditions.

7.0 STRUCTURAL ANALYSIS:

There are several types of structural analysis

which play an important role in finding the structural

safety under stress and deformation. From that the

basic structural safety of the component can be found

by analyzing the structure for static and dynamic

loading conditions.

7.1 STATIC ANALYSIS:

A static analysis is used to calculate the

effects of steady loading conditions on a

structure, while ignoring inertia and damping

effects, such as those caused by time-varying

loads. This analysis has been done by applying

static loads and results are presented for the

displacements and vonmises stresses, because

vonmises stress theory is the main failure theory

to find the failure of the components or factor of

safety in the problem.

Fig 7.1 Total Deformation

Fig 7.2 Equivalent Von-Mises Stress

Fig 7.2 Equivalent Von-Mises Elastic Strain

From the above Contour Plots, we can able

to find the place where the maximum stress, strain

and deformation take place.

Results

Plot Deformation Strain Stress

Minimum 0. m 4.6937e-012 m/m 0.32856 Pa

Maximum 4.4192e-004 m 5.6668e-004 m/m 3.9668e+007 Pa

There are two conditions for static analysis:

1) The force is static i.e. there is no variation

with respect to time (dead weight )

2) Equilibrium condition forces

(F

X

,F

Y

,F

Z

)and Moments (M

X

,M

Y

,M

Z

)=0

The FE model must fulfil this condition at each

and every node. The complete model summation of

International Journal of Mechanical and Production Engineering (IJMPE), ISSN 2320-2092,

Vol.1, Issue No.1

8

the external forces and moments is equal to the

reaction forces and moments.

The complete equation to be solved in a linear

static FE solver is F = K * u.

F is the vector of all applied external forces and

moments.

K is the stiffness matrix of the model depending

on material and geometric properties. In a linear

analysis, K is constant.

u is the nodal displacement vector.

8.0 WEIGHT OPTIMISATION OF THE

LANDING GEARS LEG

The static and spectrum results indicate that

the obtained stresses are low when compared to

allowable stresses of the material, hence there is a

possibility for optimization of the landing gears legs

thickness. The model with shell elements is

considered for the analysis. Various regions are

created by splitting and by varying thickness. The

thicknesses are supplied as the real constants which

can be easily optimized based on the optimization

cycle satisfying the design requirements. Totally 11

regions were created with different thickness

parameters for optimization. The analysis is limited

to main landing gear part. Since the axle dimension

depends on wheel diameter and suspension, so the

axle part is not considered for optimization.

In ANSYS optimization the zero-order method which

is an advanced method in sub problem approximation

technique with random design generation type

optimization tool performs multiple loops, with

random design variable obtains values at each loop.

A maximum number of loops with a desired number

of feasible loops can be specified. This tool is useful

for studying the overall design space, and for

establishing feasible design sets for subsequent

optimization analysis.

OPTIMIZATION

Optimization is clearly one of the overall

strengths of Altair and HyperWorks. You may

distinguish optimization methods with respect to its

position in the design phase i.e. concept design

optimization such as topology, topography and free

size optimization, and fine tuning optimization

disciplines such as size or shape optimization.

Alternatively, you can distinguish according to the

design variable i.e. which variable of the system is

modified/altered during the optimization. For

instance, the design variable of a topology

optimization is the elements density, whereas in size

optimization the thickness of a sheet metal may be

varied

Types of Optimization

1. Geometrical Parameters

2. Shape Optimization

Geometrical Parameters

- Optimization for geometry parameters,

work well at the individual component level rather

than with complicated assemblies.

- Software cannot add or remove geometry

on its own but can only play with pre defined

parameters within

specified limits.

Shape Optimization

- Usually restricted to only linear static and

normal mode dynamics.

- Good tool for innovative products (when

the initial shape is not known or fixed).

- Software can give hints for the addition or

removal of geometry.

9.0 CRASH ANALYSIS

1. Structural Crashworthiness Or Full

Dynamic / Impact Simulations:

To find deformation, stress, and energy

absorbing capacity of various structural

components of a vehicle hitting a stationary or

moving object. The component is said to be

crashworthy (safe) if it meets the

plastic strain and energy targets .

Applications: Frontal, Side , Rear, Roof

crush, car hitting a pole / wall etc.

2. Drop Test Simulations:

Drop test is a free fall test carried out to

check the structural integrity of the component .

Applications : Black box of an aircraft,

mobile phone, consumer goods such as TV,

fridge etc

3. Occupant Safety

To find the effects of crash on the human

body and making the ride safe for the driver as

well as the passengers . Several regulations exist

in different countries to ensure a proper

certification.

e.g. : FMVSS (Federal Motor Vehicle Safety

Standards) in the USA, ECE (Economic

Commission of Europe) regulation in Europe. In

Indiea, the ARAI has set up standard procedures

International Journal of Mechanical and Production Engineering (IJMPE), ISSN 2320-2092,

Vol.1, Issue No.1

9

for the Automobile industry and called AIS (

Automotive Industry Standards )

10.0 ADVANTAGES OF FEA

Visualization

Design cycle time

No. of prototypes

Testing

Optimum design

11.0 CONCLUSIONS:

A CAD model of Landing strut for LCH was

made and discretized in to finite element mesh using

HYPERMESH. Design loads were applied through

RBE3 connection in respective directions. Static and

spectrum response analysis were conducted in

ANSYS. The obtained stresses are much lesser than

the allowable stresses of the material. So design

optimization is carried out to reduce the weight of the

component. The landing strut weight was reduced by

iterative process using design optimization analysis

in ANSYS from 6 kg to 4.1538kg for the given

loading conditions. A reduction of 1.8462 kg can be

observed which amounts to almost 30% reduction of

weight.

12.0 REFERENCES:

[1]. Norman, S. C. Aircraft Landing strut Design:

Principle and Practices, AIAA Education Series,

AIAA, Washington, D.C., 1988.

[2]. Flugge W, Landing strut Impact, NACA,

TN2743, 9016, 1952.

[3]. Fujimoto W.T, Gallagher J.P, Summary of

Landing strut Initial Flaws, AFFDL-TR-77-125,

1977.

[4]. Derek Morrison, Gregory Neff and Mohammed

Zahraee, Aircraft landing strut simulation and

analysis, American Society for Engineering

Education Annual Conference, 1997.

[5]. James N. Daniels, A Method for Landing strut

Modeling and Simulation with Experimental

Validation , NASA Contractor Report 201601,

1996.

[6]. Jocelyn I. Pritchard, An Overview of Landing

strut Dynamics, NASA/TM-1999-209143 ARL-TR-

1976.

[7]. Amit Goyal Light Aircraft Main Landing strut

Design and Development, SAS Tech journals pp.

45-50, 2002.

[8]. Noam Eliaz, Haim Sheinkopf, Gil Shemesh and

Hillel Artzi, Cracking in cargo aircraft main landing

strut truck beams due to abusive grinding following

chromium plating, Elsevier Engineering Failure

Analysis, Vol.12, pp. 337347,2005.

[9]. Dave Briscoe,ME 548 Aero structures Final

Project ANSYS Analysis of Landing strut, 2006.

[10]. Oraig Gellimore Constrained layer damping

treatment design for aircraft landing, 2007.

[11]. Jerzy Malachowski Dyanamical analysis of

Landing strut for critical work conditions , 2010.

[12]. Essam Albahkali & Mohammed Alqahtani

Design of Light Landing strut, 2011.

Potrebbero piacerti anche

- (2006) The Material Selection For Typical Wind Turbine BladesDocumento12 pagine(2006) The Material Selection For Typical Wind Turbine BladesmiguelteixeiramaNessuna valutazione finora

- Aircraft Materials QPDocumento3 pagineAircraft Materials QPRaj KumarNessuna valutazione finora

- Important For Wind Turbine Blade PDFDocumento119 pagineImportant For Wind Turbine Blade PDFRaj KumarNessuna valutazione finora

- Lecture NotesDocumento44 pagineLecture NotesRaj KumarNessuna valutazione finora

- Theories of Failure ExplainedDocumento27 pagineTheories of Failure ExplainedRaj Kumar100% (1)

- Materials For Wind PresentationDocumento28 pagineMaterials For Wind PresentationRaj KumarNessuna valutazione finora

- Theories of FailureDocumento77 pagineTheories of FailureAnonymous 6HADGUEXDNessuna valutazione finora

- Fatigue Test Dimension PDFDocumento7 pagineFatigue Test Dimension PDFRaj KumarNessuna valutazione finora

- Wagner BeamDocumento5 pagineWagner BeamRaj Kumar67% (3)

- Study of Tension Field Beams (Wagner Beam) EquationsDocumento5 pagineStudy of Tension Field Beams (Wagner Beam) EquationsRaj KumarNessuna valutazione finora

- C1 Urban - Application English PDFDocumento4 pagineC1 Urban - Application English PDFSudha100% (1)

- Aircraft structures-II 5th UnitDocumento24 pagineAircraft structures-II 5th UnitRaj KumarNessuna valutazione finora

- Chemical - IJCPT - ALLDocumento11 pagineChemical - IJCPT - ALLglobal-marketin8184Nessuna valutazione finora

- NDTDocumento23 pagineNDTRaj KumarNessuna valutazione finora

- 2015 Aero RulesDocumento56 pagine2015 Aero RulesalbertorocoNessuna valutazione finora

- Advanced Som SyllabusDocumento1 paginaAdvanced Som SyllabusRaj Kumar0% (1)

- 2015 Aero RulesDocumento56 pagine2015 Aero RulesalbertorocoNessuna valutazione finora

- Determine crippling stress using Needham's, Gerard's method for structural sectionsDocumento3 pagineDetermine crippling stress using Needham's, Gerard's method for structural sectionsRaj Kumar0% (1)

- Finite Element Analysis Questions and AnswersDocumento14 pagineFinite Element Analysis Questions and AnswersFrancis VimalrajNessuna valutazione finora

- Aircraft Configuration OverviewDocumento128 pagineAircraft Configuration OverviewRaj KumarNessuna valutazione finora

- Evening Session NotesDocumento8 pagineEvening Session NotesRaj KumarNessuna valutazione finora

- AS1 NotesDocumento56 pagineAS1 NotesRaj KumarNessuna valutazione finora

- Wing RotorDocumento42 pagineWing RotorRaj KumarNessuna valutazione finora

- Transformation of Stresses and StrainsDocumento15 pagineTransformation of Stresses and StrainsHüseyin HızlıNessuna valutazione finora

- Torsional Shear Flow in Multi-Cell Beams via Successive CorrectionsDocumento7 pagineTorsional Shear Flow in Multi-Cell Beams via Successive CorrectionsRaj KumarNessuna valutazione finora

- Rajalakshmi Engineering College Department of Aeronautical Engineering Ae 2301 - Flight Dynamics V Sem Question Bank Part ADocumento3 pagineRajalakshmi Engineering College Department of Aeronautical Engineering Ae 2301 - Flight Dynamics V Sem Question Bank Part AVaroon RamNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Crystic PD9359 EN Dec17Documento2 pagineCrystic PD9359 EN Dec17MoutikNessuna valutazione finora

- AL-Nafeay 2021 IOP Conf. Ser. Mater. Sci. Eng. 1094 012141Documento22 pagineAL-Nafeay 2021 IOP Conf. Ser. Mater. Sci. Eng. 1094 012141Thanaraj SanmughamNessuna valutazione finora

- BOQ For Lot6 RoadDocumento4 pagineBOQ For Lot6 RoadZelalem MengistuNessuna valutazione finora

- 03 - Revised MOS - AIR BALANCINGDocumento8 pagine03 - Revised MOS - AIR BALANCINGEditor EditorNessuna valutazione finora

- Helical SpringDocumento2 pagineHelical SpringG. Dancer GhNessuna valutazione finora

- A Methodology To Determine in Situ Rock Mass FailureDocumento8 pagineA Methodology To Determine in Situ Rock Mass FailurerannscribdNessuna valutazione finora

- Non-Dispersible, Antiwashout Underwater Concrete AdmixtureDocumento2 pagineNon-Dispersible, Antiwashout Underwater Concrete AdmixtureghazanfarNessuna valutazione finora

- Soil Stabilization-D WallDocumento12 pagineSoil Stabilization-D WallNisha VermaNessuna valutazione finora

- What Is Packaged Air Conditioner? Types of Packged Air CondtionersDocumento8 pagineWhat Is Packaged Air Conditioner? Types of Packged Air CondtionersCisco StarkNessuna valutazione finora

- PolykenDocumento7 paginePolykenJanllo83Nessuna valutazione finora

- Pedestrian BridgesDocumento7 paginePedestrian BridgesНемања Караклајић100% (1)

- Gelation and Fusion Process of PVC PlastisolDocumento32 pagineGelation and Fusion Process of PVC Plastisolhost1000youtub100% (1)

- Asme B 31.9Documento5 pagineAsme B 31.9jeswin0% (1)

- Wurth Wit Pe 500Documento1 paginaWurth Wit Pe 500Bijaya RaulaNessuna valutazione finora

- Perfomance Rated I-Joits Roof Framing DetailsDocumento10 paginePerfomance Rated I-Joits Roof Framing DetailsCeyanezNessuna valutazione finora

- Salford Journal of Bridge Engineering Jan-18Documento24 pagineSalford Journal of Bridge Engineering Jan-18Swaminathan VivekananthamNessuna valutazione finora

- A Review of The Tensile Strength of Rock: Concepts and TestingDocumento22 pagineA Review of The Tensile Strength of Rock: Concepts and TestingHooman_RostamiNessuna valutazione finora

- SP - Constructions: Industrial Training Report ON Analysis and Design of G+3 Building Using Staad ProDocumento55 pagineSP - Constructions: Industrial Training Report ON Analysis and Design of G+3 Building Using Staad ProSagarKasarla100% (1)

- LSI Cypress LPS Low Pressure Sodium Series Brochure 1987Documento6 pagineLSI Cypress LPS Low Pressure Sodium Series Brochure 1987Alan MastersNessuna valutazione finora

- Iron-carbon phase diagram guideDocumento9 pagineIron-carbon phase diagram guideNagamuthu PandianNessuna valutazione finora

- Rev Quotation 2005Documento4 pagineRev Quotation 2005Sardar ayyan Sardar ayyanNessuna valutazione finora

- Selamawit DegeDocumento95 pagineSelamawit DegeSultan MohammedNessuna valutazione finora

- As Management Tools Settings 2015 enDocumento81 pagineAs Management Tools Settings 2015 enMIRCEA1305Nessuna valutazione finora

- 6 Things You Must Know Before Inspecting TubesDocumento3 pagine6 Things You Must Know Before Inspecting TubesWoodrow FoxNessuna valutazione finora

- Approximate AnalysisDocumento35 pagineApproximate AnalysisSyahir HamidonNessuna valutazione finora

- BS en 00683-2 1997 (En)Documento12 pagineBS en 00683-2 1997 (En)Emanuele MastrangeloNessuna valutazione finora

- Uow009694 Hydraulic Services Design StandardsDocumento37 pagineUow009694 Hydraulic Services Design StandardsstarykltNessuna valutazione finora

- 01-07-2021-1625129537-6-Impact - Ijrhal-14. Ijrhal - Design and Analysis of FlexvatorDocumento4 pagine01-07-2021-1625129537-6-Impact - Ijrhal-14. Ijrhal - Design and Analysis of FlexvatorImpact JournalsNessuna valutazione finora

- CS 457 Revision 1 The Assessment of Composite Highway Bridges and Structures-WebDocumento137 pagineCS 457 Revision 1 The Assessment of Composite Highway Bridges and Structures-Webasaad biqaiNessuna valutazione finora

- Mechanics of Fluids RR 212101Documento8 pagineMechanics of Fluids RR 212101Nizam Institute of Engineering and Technology LibraryNessuna valutazione finora