Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Flow Control Valves QV-06: Pressure Compensated, Two Way, ISO 4401 Size 06

Caricato da

DANIZACHDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Flow Control Valves QV-06: Pressure Compensated, Two Way, ISO 4401 Size 06

Caricato da

DANIZACHCopyright:

Formati disponibili

QV-06/1 QV-06/6 QV-06/11 QV-06/16 QV-06/24

1,5 6 11 16 24

50

24

Assembly position / location Any position

Subplate surface finishing Roughness index ,flatness ratio 0,01/100 (ISO 1101)

Ambient temperature -20C to +70

Fluid Hydraulic oil as per DIN 51524 ... 535; for other fluids see section 1

Recommended viscosity 15 100 mm

2

/s at 40C (ISO VG 15 100)

Fluid contamination class ISO 19/16, achieved with in line filters at 25 m value and 25 75 (recommended)

Fluid temperature -20C +60C (standard and /WG seals) -20C +80C (/PE seals)

3 3 5 6,5 8

24

250

www.atos.com

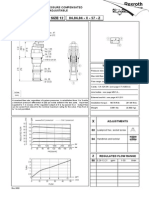

Flow control valves type QV-06

pressure compensated, two way, ISO 4401 size 06

Table C210-6/E

QV are flow control valves with pressu-

re compensator : the controlled flow

rate is independent of pressure varia-

tions.

They are usually supplied with a built-in

check valve to allow the free flow in

the opposite direction.

The flow is regulated by turning a gra-

duate micrometer knob . Clockwise

rotation increases the flow regulation.

Optional versions with locking key

on the adjustment knob are available

on request.

ISO 4401 size 06.

Fl ow up to 1,5; 6; 11; 16; 24 l /mi n

(depending on models).

Pressure up to 250 bar.

Valves designed to operate in hydrau-

lic systems with hydraulic mineral oil or

synthetic fluid having similar lubricating

characteristics.

QV

Pressure compensated

flow control valve

1

C210

06

Maximum adjustable flow rate:

1 = 1,5 l/min

6 = 6 l/min

11 = 11 l/min

16 = 16 l/min

24 = 24 l/min

Options:

/K = with lock key for the setting knob

/V = without by-pass check valve

/ /K **

Size:

06

/*

Synthetic fluids:

WG = water-glycol

PE = phosphate ester

MODEL CODE

2 HYDRAULIC CHARACTERISTICS

Valve model

Max regulated flow [I/min]

Min regulated flow [cm

3

/min]

Max flow BA through check valve [l/min]

Regulating p [bar]

Max flow on port A [l/min]

Max pressure [bar]

Hydraulic symbols

with check valve without check valve

QV-06 QV-06/*/K

6

Series number

3 MAIN CHARACTERISTICS OF FLOW CONTROL VALVES TYPE QV-06

www.atos.com www.atos.com

QV-06

4 DIAGRAMS based on mineral oil ISO VG 46 at 50C

6 MODULAR PLATES TYPE BHQ

4.1 Regulation diagram

1 = QV-06/1

2 = QV-06/6

3 = QV-06/11

4 = QV-06/16

5 = QV-06/24

4.2 Q/p diagram through the check valve

for free flow BA

6 = QV-06/*

Setting [notch on the knob] Flow [l/min]

F

l

o

w

[

l

/

m

i

n

]

D

i

f

f

e

r

e

n

t

i

a

l

p

r

e

s

s

u

r

e

[

b

a

r

]

The modular plates type BHQ allow the assembling of valves type QV-06 in a modular stack with other components having ISO 4401 size 06 mounting surface.

See below for model code and functional sketches; see section 5 for dimensions and example of assembly.

Available also version for water-glycol and for phosphate ester (add respectively /WG and /PE at the end of the model code).

The plates type BHQ are supplied with 4 fastening bolts M5x60 (8 for BHQ-012 and BHQ-022) to fix one (or two) QV-06 which are supplied without fastening

bolts.

7 MOUNTING PLATES TYPE BA

Valve

BA-202/Q

BA-204/Q

BA-302/Q

Ports A, B, P, T underneath;

Ports P, T underneath; Ports A, B on lateral side

Ports A, B, P, T underneath;

G 3/8 1,2

G 3/8 25,5 1,2

G 1/2 30 1,8

Subplate model Ports location

Ports

A, B, P, T

Counterbore

[mm]

A, B, P, T

Mass

[Kg]

The plates type BA-***/Q are supplied with 4 fastening bolts M5x60 because QV-06 are supplied without fastening bolts.

10/05

5

4

6

3

2

1

BHQ-011

BHQ-023

BHQ-013

BHQ-024

BHQ-014

BHQ-012

BHQ-016

BHQ-022

5 DIMENSIONS [mm]

Option /K

Mass: 1,2 Kg

ISO 4401: 2005

Mounting surface: 4401-03-02-0-05

(see note 1)

Fastening bolts:

4 socket head screws M5x70 class 12.9

Tightening torque = 8 Nm

Seals: 2 OR 117

Diameter of ports A, B: = 7 mm

= Flow control valve type QV-06

Note that the valve(s) is (are) mounted:

on side port A for BHQ-011, BHQ-013, BHQ-016 and BHQ-023

on side port B for BHQ-014 and BHQ-024

on both sides for BHQ-012 and BHQ-022

= Modular plate type BHQ, see section 6

= Closing element. This element can be on side port A or side port

B depending on models. It is not present on BHQ-011, BHQ-016,

BHQ-012 and BHQ-022

= Directional valve type DH (ISO 4401 size 06)

ASSEMBLY IN MODULAR STACK

see section 6

note 1: the manifold interface has to be provided only of the A and B ports.

The valve cannot be installed on manifolds with ISO 4401-AB-03 interface

with P and T ports.

X

view from X

Potrebbero piacerti anche

- Flow control valves QV-06 pressure compensatedDocumento2 pagineFlow control valves QV-06 pressure compensatedCristhian CañizaresNessuna valutazione finora

- Check Valve Data SheetDocumento5 pagineCheck Valve Data SheetshahganNessuna valutazione finora

- Vickers Counterbalance Valve CBV 10Documento2 pagineVickers Counterbalance Valve CBV 10rafarodrig6Nessuna valutazione finora

- DGMPC 5 Check Valve Eaton Vickers PDFDocumento10 pagineDGMPC 5 Check Valve Eaton Vickers PDFsandyread4uNessuna valutazione finora

- Reductores - d140 - HG KGDocumento4 pagineReductores - d140 - HG KGDANIZACHNessuna valutazione finora

- Pressure Relief Valves ARE: Direct Operated, in Line Mounting - G 1/4" and G 1/2" Threaded PortsDocumento4 paginePressure Relief Valves ARE: Direct Operated, in Line Mounting - G 1/4" and G 1/2" Threaded PortsmfbayatNessuna valutazione finora

- Hydraulic Directional Control and Check ValvesDocumento28 pagineHydraulic Directional Control and Check ValvestunradotNessuna valutazione finora

- Valvula Reductora de PresionDocumento4 pagineValvula Reductora de PresionCristhian CañizaresNessuna valutazione finora

- Directional Seat ValvesDocumento4 pagineDirectional Seat ValvesMiron GabrielNessuna valutazione finora

- 7-EN 520-D - D5S 2-PortDocumento16 pagine7-EN 520-D - D5S 2-Portabuzer1981Nessuna valutazione finora

- SDM 080 eDocumento28 pagineSDM 080 eseaqu3stNessuna valutazione finora

- K290Documento6 pagineK290longoluiNessuna valutazione finora

- Valvulas XT PDFDocumento4 pagineValvulas XT PDFIsidro Gomez GarciaNessuna valutazione finora

- Hydraulic directional control valves guideDocumento112 pagineHydraulic directional control valves guideAldo Alonso GuemezNessuna valutazione finora

- Elec Grs Pumps 203seriesDocumento5 pagineElec Grs Pumps 203serieschand_yelNessuna valutazione finora

- SDM 141 eDocumento28 pagineSDM 141 eseaqu3stNessuna valutazione finora

- Screw Pump Relief ValvesDocumento12 pagineScrew Pump Relief ValvesEtemadiNessuna valutazione finora

- Valves BarendsenDocumento63 pagineValves BarendsenidontlikeebooksNessuna valutazione finora

- Automatically Balanced Combination Valves Ab-Qm: Data SheetDocumento12 pagineAutomatically Balanced Combination Valves Ab-Qm: Data SheetbatazivoNessuna valutazione finora

- Directional control valves guideDocumento108 pagineDirectional control valves guidemgkalfas100% (2)

- 3/2 Directional Control Valves for Single-Acting CylindersDocumento9 pagine3/2 Directional Control Valves for Single-Acting CylindersMohan ArumugavallalNessuna valutazione finora

- 219 BUnloadingreliefvalve 1Documento4 pagine219 BUnloadingreliefvalve 1kulkarni278Nessuna valutazione finora

- Variable Displacement Pump Closed Loop Circuit: T E C H N I C A L C A T A L O GDocumento44 pagineVariable Displacement Pump Closed Loop Circuit: T E C H N I C A L C A T A L O GSocaciu VioricaNessuna valutazione finora

- SD 18 eDocumento32 pagineSD 18 eseaqu3stNessuna valutazione finora

- 7-En 5150-B - CarDocumento15 pagine7-En 5150-B - Carabuzer1981Nessuna valutazione finora

- SD 25 eDocumento20 pagineSD 25 eseaqu3stNessuna valutazione finora

- Modular Throttle Valve NG4, Type QTM2Documento2 pagineModular Throttle Valve NG4, Type QTM2LibinNessuna valutazione finora

- SD 6 eDocumento16 pagineSD 6 eseaqu3stNessuna valutazione finora

- Valve configuration and solenoid directional valvesDocumento8 pagineValve configuration and solenoid directional valvesFabinhoTowerNessuna valutazione finora

- Check Valves Guide: Pilot Operated & Direct Acting ModelsDocumento24 pagineCheck Valves Guide: Pilot Operated & Direct Acting Models2267airportNessuna valutazione finora

- SL030 PDFDocumento2 pagineSL030 PDFchidambaram kasiNessuna valutazione finora

- A35769EDocumento44 pagineA35769Ealsief1951Nessuna valutazione finora

- SDM140EDocumento36 pagineSDM140Eseaqu3stNessuna valutazione finora

- SD 14 eDocumento12 pagineSD 14 eseaqu3stNessuna valutazione finora

- NIMCO CV300newDocumento24 pagineNIMCO CV300newBruno SamaeianNessuna valutazione finora

- 221 Deceleration and Check ValveDocumento4 pagine221 Deceleration and Check Valvekulkarni278Nessuna valutazione finora

- SD 11 eDocumento12 pagineSD 11 eseaqu3stNessuna valutazione finora

- KladivarDocumento107 pagineKladivaranta77Nessuna valutazione finora

- SD 5 eDocumento12 pagineSD 5 eseaqu3stNessuna valutazione finora

- SDM 102 eDocumento24 pagineSDM 102 eseaqu3stNessuna valutazione finora

- H Series Motorised Valves GuideDocumento4 pagineH Series Motorised Valves GuidedoplocopoNessuna valutazione finora

- Series R5U Characteristics: Pilot Operated Pressure Unloading ValveDocumento5 pagineSeries R5U Characteristics: Pilot Operated Pressure Unloading ValveHarinderNessuna valutazione finora

- Filtro RexrothDocumento12 pagineFiltro RexrothduhgrandoNessuna valutazione finora

- DPC 38 eDocumento12 pagineDPC 38 ejbsb1Nessuna valutazione finora

- Three Way Valve Technical OverviewDocumento8 pagineThree Way Valve Technical OverviewWalter JosephNessuna valutazione finora

- SD 16 eDocumento20 pagineSD 16 eseaqu3stNessuna valutazione finora

- 2-Way Flow Control Bosch-RexrothDocumento12 pagine2-Way Flow Control Bosch-RexrothKemal GokovicNessuna valutazione finora

- Pressure ReliefDocumento124 paginePressure ReliefFrancis5801Nessuna valutazione finora

- D1VW UkDocumento8 pagineD1VW UksureshllsNessuna valutazione finora

- Re 22058Documento16 pagineRe 22058ShortcutterNessuna valutazione finora

- ATOSs Valves DHI-0711Documento4 pagineATOSs Valves DHI-0711Cardoso MalacaoNessuna valutazione finora

- Re26892 2003-02Documento10 pagineRe26892 2003-02DANIZACHNessuna valutazione finora

- HPB Brochure 0708Documento12 pagineHPB Brochure 0708musaluddinNessuna valutazione finora

- Beta Hand BookDocumento67 pagineBeta Hand BookColin MonkmanNessuna valutazione finora

- Nks Press Gauge GVDocumento4 pagineNks Press Gauge GVAndrew PutrayudhaNessuna valutazione finora

- BuTech ball valves introductionDocumento51 pagineBuTech ball valves introductionvankarpNessuna valutazione finora

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerDa EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerValutazione: 5 su 5 stelle5/5 (1)

- Gas Well Deliquification: Solutions to Gas Well Liquid Loading ProblemsDa EverandGas Well Deliquification: Solutions to Gas Well Liquid Loading ProblemsNessuna valutazione finora

- 305 TransmissionDocumento2 pagine305 TransmissionDANIZACHNessuna valutazione finora

- Baldor MotorsDocumento124 pagineBaldor Motorsangel_basualdoNessuna valutazione finora

- Nema Chart 04Documento1 paginaNema Chart 04zguy360Nessuna valutazione finora

- Hsr-300e - CC PATINES LINEALES THKDocumento26 pagineHsr-300e - CC PATINES LINEALES THKDANIZACHNessuna valutazione finora

- Allround Line Floor 100 250kNDocumento4 pagineAllround Line Floor 100 250kNDANIZACHNessuna valutazione finora

- Valvula de Acc Manual - E150Documento4 pagineValvula de Acc Manual - E150DANIZACHNessuna valutazione finora

- Valvula Tn10 - Dke E025Documento4 pagineValvula Tn10 - Dke E025DANIZACHNessuna valutazione finora

- Check en Linea - c406Documento2 pagineCheck en Linea - c406DANIZACHNessuna valutazione finora

- Check d180 - HR KRDocumento4 pagineCheck d180 - HR KRDANIZACHNessuna valutazione finora

- Alivio - d120 - HM - KMDocumento4 pagineAlivio - d120 - HM - KMDANIZACHNessuna valutazione finora

- Valve configuration and solenoid directional valvesDocumento8 pagineValve configuration and solenoid directional valvesFabinhoTowerNessuna valutazione finora

- En - b1 - 070 PATINES LINEALESDocumento2 pagineEn - b1 - 070 PATINES LINEALESDANIZACHNessuna valutazione finora

- Pump Magnun SeriesDocumento63 paginePump Magnun SeriesDANIZACHNessuna valutazione finora

- Aloy High Pressure Filters 20 BarDocumento2 pagineAloy High Pressure Filters 20 BarDANIZACHNessuna valutazione finora

- Sun - Hydraulics CatalogDocumento44 pagineSun - Hydraulics CatalogAndreea75% (4)

- 742Documento52 pagine742DANIZACHNessuna valutazione finora

- Series 34Documento10 pagineSeries 34DANIZACHNessuna valutazione finora

- Single and double acting hydraulic cylinders specificationsDocumento1 paginaSingle and double acting hydraulic cylinders specificationsDANIZACHNessuna valutazione finora

- Basic Training: Motors, Gears & DrivesDocumento80 pagineBasic Training: Motors, Gears & DrivesDANIZACH50% (2)

- Pump Polaris SeriesDocumento47 paginePump Polaris SeriesDANIZACHNessuna valutazione finora

- Pump KappaDocumento112 paginePump KappaDANIZACHNessuna valutazione finora

- Catalogo Componentes 2007Documento39 pagineCatalogo Componentes 2007DANIZACHNessuna valutazione finora

- Gear flow dividers technical specifications and application guideDocumento20 pagineGear flow dividers technical specifications and application guideDANIZACHNessuna valutazione finora

- 742Documento52 pagine742DANIZACHNessuna valutazione finora

- 4 - Way Directional Control Valve "HPV4": FeaturesDocumento2 pagine4 - Way Directional Control Valve "HPV4": FeaturesDANIZACHNessuna valutazione finora

- 040404X57ZDocumento1 pagina040404X57ZDANIZACHNessuna valutazione finora

- Baldor MotorsDocumento124 pagineBaldor Motorsangel_basualdoNessuna valutazione finora

- Re26892 2003-02Documento10 pagineRe26892 2003-02DANIZACHNessuna valutazione finora

- Absorb Shock and Reduce Vibration with Flexible Grid CouplingsDocumento18 pagineAbsorb Shock and Reduce Vibration with Flexible Grid CouplingsRafo Vega GuerovichNessuna valutazione finora

- MPHDocumento16 pagineMPHDANIZACHNessuna valutazione finora

- Illustration 29 07 2017 PDFDocumento1 paginaIllustration 29 07 2017 PDFGlenn D. KleinNessuna valutazione finora

- Technical Standards & Specifications Including Safety Standards For City or Local Natural Gas Distributions NetworksDocumento91 pagineTechnical Standards & Specifications Including Safety Standards For City or Local Natural Gas Distributions Networkspravesh sharma80% (5)

- Safety Relief Valve - Norriseal WellMark 2600Documento6 pagineSafety Relief Valve - Norriseal WellMark 2600ace4200Nessuna valutazione finora

- Pump Performance Datasheet: Operating Conditions LiquidDocumento4 paginePump Performance Datasheet: Operating Conditions LiquidMansoor Ahamed Abbas100% (1)

- Ies-Industrial Engineering Services: Hydraulic Test ReportDocumento7 pagineIes-Industrial Engineering Services: Hydraulic Test ReportMD Shadikul Huq ShezanNessuna valutazione finora

- Spare Parts DC Pro XT V.en Rev.14Documento31 pagineSpare Parts DC Pro XT V.en Rev.14serkan çakmakNessuna valutazione finora

- SAT - Centrifugal Pump For TDUDocumento4 pagineSAT - Centrifugal Pump For TDUNIKHIL JOHRI100% (4)

- PED 2014-68-EU Guidelines en v4Documento235 paginePED 2014-68-EU Guidelines en v4Zarra FaktNessuna valutazione finora

- Pneumatics PDFDocumento138 paginePneumatics PDFfurkan84Nessuna valutazione finora

- Van Cong Ty Chim Ydk Apt2Documento2 pagineVan Cong Ty Chim Ydk Apt2Le NghiNessuna valutazione finora

- VA1 YEA 02100 I I1 PID 0001 - RevA PDFDocumento7 pagineVA1 YEA 02100 I I1 PID 0001 - RevA PDFAnonymous JtYvKt5XENessuna valutazione finora

- A.T.E QP April May 2018Documento2 pagineA.T.E QP April May 2018Sumanth Vn100% (1)

- Vacuum-Assisted Power Brakes: Adama University Faculity of Tte Department of Automobile TechnologyDocumento5 pagineVacuum-Assisted Power Brakes: Adama University Faculity of Tte Department of Automobile TechnologyElias WeldeyohansNessuna valutazione finora

- Wilo SD TDV: Suction Diffusers & Triple Duty ValvesDocumento2 pagineWilo SD TDV: Suction Diffusers & Triple Duty ValvesilieoniciucNessuna valutazione finora

- Motor Graco 311238 Part ListDocumento48 pagineMotor Graco 311238 Part Listmanuel solano gomezNessuna valutazione finora

- KSB Pumps Co. Eta ChromeDocumento2 pagineKSB Pumps Co. Eta ChromeHuzaifa KhanNessuna valutazione finora

- 3340F322 Lionn Auto SoftwaresDocumento2 pagine3340F322 Lionn Auto SoftwaresLIONN ONESOLUTIONNessuna valutazione finora

- Flojet 2100Documento4 pagineFlojet 2100Luis Panti EkNessuna valutazione finora

- Hydrocontrol STRDocumento4 pagineHydrocontrol STRMoe KimoNessuna valutazione finora

- WW Procedure 2Documento14 pagineWW Procedure 2Samir BrahimNessuna valutazione finora

- MSS SP-6 2012Documento7 pagineMSS SP-6 2012ISRAEL PORTILLO100% (1)

- Selection guide for coiled tubing and casing cuttersDocumento5 pagineSelection guide for coiled tubing and casing cuttersSusin LimNessuna valutazione finora

- Pressure Relif ValaveDocumento9 paginePressure Relif Valaveom pawarNessuna valutazione finora

- Ps Og A Range en D Avril2022Documento3 paginePs Og A Range en D Avril2022asifNessuna valutazione finora

- Hydraulic and Pneumatic Tools GuideDocumento4 pagineHydraulic and Pneumatic Tools GuideShishir VardeNessuna valutazione finora

- Chapter 3 Part 1Documento26 pagineChapter 3 Part 1Yohannes EndaleNessuna valutazione finora

- Knife Gate Valve Testing ProceduresDocumento2 pagineKnife Gate Valve Testing ProceduresmehtahemalNessuna valutazione finora

- 07a3ec02 Fluid Mechanics and Hydraulic Machinery PDFDocumento8 pagine07a3ec02 Fluid Mechanics and Hydraulic Machinery PDFfotickNessuna valutazione finora

- Applications of Navier-Stokes EquationDocumento2 pagineApplications of Navier-Stokes Equationsoumya100% (1)

- 1100-ME-DST-001 - Rev.1A - Data Sheet Hari Pig Launcher (1194-V-101)Documento6 pagine1100-ME-DST-001 - Rev.1A - Data Sheet Hari Pig Launcher (1194-V-101)Didi Hadi RiantoNessuna valutazione finora