Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

M & E QC Plan - 0063b REV. 0

Caricato da

Anonymous 3eHGEDbxTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

M & E QC Plan - 0063b REV. 0

Caricato da

Anonymous 3eHGEDbxCopyright:

Formati disponibili

XYZ

Page 1 of 2

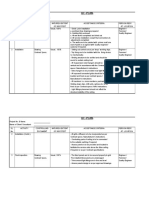

QC~PLAN.

Project No. & Name: Name of Client/ Consultant: SL ACTIVITY CONTROLLING NATURE & EXTENT ACCEPTANCE CRITERIA - Establish position of pipe inlets with respect to fixtures - Pipe supports provided as per the horizontal & vertical spacing requirement / drawing - Pipes laid to uniform / specified gradient - Clean outs provided at change of direction of flow - Access cover provided in walls, ducts & ceilings where access caps are fixed - Fire couplers provided where pipe passes from ceilings and walls from plant room - Pipe end covered while unattended - Rippling, throating & reduction in bore diameter avoided while bending - Fixed not greater than as follows: Pipe dia Vertically Horizontally 35 mm 1.2 m 0.5 m 40 mm 1.2 m 0.5 m 55 mm 1.2 m 0.9 m 110 mm 1.8 m 0.9 m - Pipe gradient Pipe Dia Gradient 35 mm 40 mm 1 : 40 55 mm 75 mm 1 : 60 110 mm 1 : 100

Above Ground Drainage

Doc. No. M & E QC~Plan- 063b/ REV. 0 PERSON RESP. AT LOCATION Engineer/ Foremen/ Quality Engineer RECORD Above Ground Drainage M & E QC~Plan063b-01/ REV. 0

No. 1 Installation

DOCUMENT OF INSP./TEST Drawing Visual, 100% Contract Specs. Mfr.'s instructions BS 8000 Part 13

2 Bending (for metal pipes) 3 Pipe supports

Drawing Visual, 100% Contract Specs. BS 8000 Part 13 Drawing Visual, 100% Contract Specs. Mfr.'s instructions BS 8000 Part 13

Engineer/ Foremen/ Quality Engineer Engineer/ Foremen/ Quality Engineer

Above Ground Drainage M & E QC~Plan063b-01/ REV. 0 Above Ground Drainage M & E QC~Plan063b-01/ REV. 0

225436444.xls.ms_office

Date: January 26, 2001

XYZ

Page 2 of 2

QC~PLAN.

Project No. & Name: Name of Client/ Consultant: SL ACTIVITY CONTROLLING NATURE & EXTENT ACCEPTANCE CRITERIA - Additional pipe supports provided - Pipes dropping from plant rooms fire coupler provided - Clean out provision provided Type Jointing Cast iron pipes Cold / lead caulking Galvanized Bolted flanges / gaskets pipes Copper pipe - UPVC

Above Ground Drainage

Doc. No. M & E QC~Plan- 063b/ REV. 0 PERSON RESP. AT LOCATION Engineer/ Foremen/ Quality Engineer Engineer/ Foremen/ Quality Engineer RECORD Above Ground Drainage M & E QC~Plan063b-01/ REV. 0 Above Ground Drainage M & E QC~Plan063b-01/ REV. 0

No. 4 Suspended floor drains

5 Pipe Jointing

DOCUMENT OF INSP./TEST Drawing Visual, 100% Contract Specs. Mfr.'s instructions BS 8000 Part 13 Drawing Visual, 100% Contract Specs. BS 8000 Part 13

6 Pipe sleeves

7 Inspection & Testing

Drawing Contract Specs. BS 8000 Part 13 Drawing Contract Specs. BS 8000 Part 13

Visual, 100%

Leak Test , 100%

Capillary soldering Compression fittings using ring seals & solvent cement Polyethylene & Compression fittings using Polypropylene ring seals by fusion welding - Pipe ends straight cut square, chamfered, burr removed before jointing using rubber seal rings - Spigot end & socket end cleaned while using solvent (for UPVC Pipes) - Follow pipe manufacturer's instructions & use recommended lubricants / solvents - Pipes crossing through beams / walls / floors Engineer/ shall be provided sleeves of same material Foremen/ Quality Engineer - Water testing done for ordinary pipe work. Engineer/ Static head not to exceed 2 m & without loss Foremen/ for 15 minutes Quality Engineer Quality Engineer: Date: Engineer / Foremen: Date:

Above Ground Drainage M & E QC~Plan063b-01/ REV. 0 Above Ground Drainage M & E QC~Plan063b-01/ REV. 0

Work Location: Remarks:

225436444.xls.ms_office

Date: January 26, 2001

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Invoice PDFDocumento2 pagineInvoice PDFAshish SinghNessuna valutazione finora

- NQA ISO 45001 Implementation GuideDocumento36 pagineNQA ISO 45001 Implementation GuideAnonymous 3eHGEDbx100% (11)

- Elec Wiring Regs 2007 Rev 01Documento240 pagineElec Wiring Regs 2007 Rev 01Anonymous 3eHGEDbxNessuna valutazione finora

- Historical Record Dimensions and PropertiesDocumento145 pagineHistorical Record Dimensions and PropertiesAnonymous 3eHGEDbxNessuna valutazione finora

- RSM311Documento7 pagineRSM311sch123321Nessuna valutazione finora

- Vision Elevators Company ProfileDocumento8 pagineVision Elevators Company ProfileMotlatjo RakgothoNessuna valutazione finora

- Container DimensionsDocumento1 paginaContainer Dimensionsmanoj983100% (1)

- National Gypsum Steel StudPartitionsDocumento9 pagineNational Gypsum Steel StudPartitionsAnonymous 3eHGEDbxNessuna valutazione finora

- Acoustic Brochure PDFDocumento6 pagineAcoustic Brochure PDFAnonymous 3eHGEDbxNessuna valutazione finora

- Steel Window Service: Scale Drawn CheckedDocumento1 paginaSteel Window Service: Scale Drawn CheckedAnonymous 3eHGEDbxNessuna valutazione finora

- MOUNT - Fixing PlatesDocumento8 pagineMOUNT - Fixing PlatesAnonymous 3eHGEDbxNessuna valutazione finora

- Pub 100427Documento5 paginePub 100427Engr Nabeel AhmadNessuna valutazione finora

- Xyz Company: PurposeDocumento3 pagineXyz Company: PurposeAnonymous 3eHGEDbxNessuna valutazione finora

- Purpose: Method Statement M & E No.: M & E Mst-004/ Rev 0 Page 1 of 4 Title: LV Switchgear Installation and TestingDocumento4 paginePurpose: Method Statement M & E No.: M & E Mst-004/ Rev 0 Page 1 of 4 Title: LV Switchgear Installation and TestingAnonymous 3eHGEDbxNessuna valutazione finora

- M & e MST - 038 Rev. 0Documento3 pagineM & e MST - 038 Rev. 0Anonymous 3eHGEDbxNessuna valutazione finora

- M & e MST - 036 Rev. 0Documento3 pagineM & e MST - 036 Rev. 0Anonymous 3eHGEDbxNessuna valutazione finora

- Xyz Company: PurposeDocumento3 pagineXyz Company: PurposeAnonymous 3eHGEDbxNessuna valutazione finora

- Xyz Company: PurposeDocumento5 pagineXyz Company: PurposeAnonymous 3eHGEDbxNessuna valutazione finora

- 018 Insitu FlooringDocumento4 pagine018 Insitu FlooringAnonymous 3eHGEDbxNessuna valutazione finora

- 021-Suspended CeilingDocumento4 pagine021-Suspended CeilingAnonymous 3eHGEDbxNessuna valutazione finora

- M & E QC Plan - 0063b REV. 0Documento4 pagineM & E QC Plan - 0063b REV. 0Anonymous 3eHGEDbxNessuna valutazione finora

- 051 GlazingDocumento2 pagine051 GlazingAnonymous 3eHGEDbxNessuna valutazione finora

- 015-Roofing, Insulation &water ProofingDocumento4 pagine015-Roofing, Insulation &water ProofingAnonymous 3eHGEDbxNessuna valutazione finora

- 019-Carpentary, Joinery & General FixingDocumento2 pagine019-Carpentary, Joinery & General FixingAnonymous 3eHGEDbxNessuna valutazione finora

- FeltDocumento8 pagineFeltadhityaNessuna valutazione finora

- Fosroc Grouting BrochureDocumento9 pagineFosroc Grouting Brochurehareesh13hNessuna valutazione finora

- Transportation SystemsDocumento14 pagineTransportation SystemsJohn Michael ManinangNessuna valutazione finora

- Unit Load Devices Control ManualDocumento32 pagineUnit Load Devices Control Manualphilippe8brunoNessuna valutazione finora

- Road NetworkDocumento4 pagineRoad NetworkEvan RobertsNessuna valutazione finora

- NRMCA Pervious Concrete Construction ChecklistDocumento20 pagineNRMCA Pervious Concrete Construction ChecklistVirginiaEPONessuna valutazione finora

- Dubai International AirportDocumento19 pagineDubai International AirportelcivilengNessuna valutazione finora

- Introduction To Railway Engineering and An Overview of Indian RailwaysDocumento11 pagineIntroduction To Railway Engineering and An Overview of Indian RailwaysNiranjanAryanNessuna valutazione finora

- Soudal R83a Repair All Epoxy StickDocumento2 pagineSoudal R83a Repair All Epoxy StickCarlos ChoqueNessuna valutazione finora

- Brunei Darussalam: Institutional Framework Safer Road UsersDocumento1 paginaBrunei Darussalam: Institutional Framework Safer Road UsersBarbi PoppéNessuna valutazione finora

- Vulcan Thread BecoDocumento12 pagineVulcan Thread Becos_barrios100% (1)

- Welding of Reinforcing SteelsDocumento6 pagineWelding of Reinforcing SteelsruwanpuraNessuna valutazione finora

- Shipping Law and BusinessDocumento3 pagineShipping Law and Businessdarrelsilva100% (1)

- Section XXXXX - Stone ColumnsDocumento6 pagineSection XXXXX - Stone ColumnsRitunjay JhaNessuna valutazione finora

- Project On JK TyresDocumento61 pagineProject On JK TyresPraveen NairNessuna valutazione finora

- Coal Handling PLantDocumento8 pagineCoal Handling PLantPrasanna kumar subudhiNessuna valutazione finora

- NSW and Sydney Trains MAPDocumento1 paginaNSW and Sydney Trains MAPMauricio Senior RamírezNessuna valutazione finora

- API 660 Vs TEMA RequirementsDocumento3 pagineAPI 660 Vs TEMA Requirementstndeshmukh88% (8)

- Pad EyesDocumento60 paginePad Eyesjuyta100% (1)

- BL (La Mejor)Documento1 paginaBL (La Mejor)Niquilinsebas100% (1)

- Spare Parts ManagementDocumento11 pagineSpare Parts Managementritendert100% (3)

- A Review of Trip and Parking Generation Rates in The PhilippinesDocumento10 pagineA Review of Trip and Parking Generation Rates in The PhilippinesRobert Oconer AguilarNessuna valutazione finora

- Consolidation WarehousingDocumento22 pagineConsolidation WarehousingJoshua AbrahamNessuna valutazione finora

- Douglas C-47Documento5 pagineDouglas C-47Emerson URNessuna valutazione finora

- 1971 FAA Private Pilot SyllabusDocumento17 pagine1971 FAA Private Pilot SyllabusJason SchroederNessuna valutazione finora

- DecathlonDocumento14 pagineDecathlonDivyanshu Shahi100% (2)