Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ALG AAndingsluft System

Caricato da

Denim BeširovićCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ALG AAndingsluft System

Caricato da

Denim BeširovićCopyright:

Formati disponibili

ultra.

pure ALG Breathing Air Systems

ultra.pure ALG Breathing Air Systems

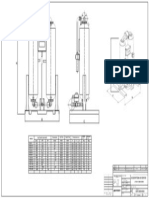

n The ultra.pure breathing air systems ALG 50 S

375 S are desiccant type purification systems to supply breathing air in excess of all relevant international standards and medical prescriptions.

adsorber (SP-stage), before the air is led through a deep bed filling of activated carbon (AK) to adsorb still present oil vapours and hydrocarbons to a level below 0,003 mg/m3.

n The following deep bed filling of a catalyst

(OX-stage) converts CO into CO2 and thereby reduces the carbon monoxide level down below 1 ppm.

n The purification consists of seven stages:

A two-stage prefiltration with a microfilter MF and a submicrofilter SMF removes water, oil (liquid stage) and solid particles larger than 0.01 m. The remaining oil content after the prefiltration is less than 0.01 mg/m3.

n The final particle filter PE removes all particles

which might be carried over from the adsorption and/or catalyst stages.

n The following desiccant dryer reduces the water vapour content of the compressed air down to a pressure dew point of 40 C (equivalent to a remaining water content of 0,11 g/m3).

Applications:

n Hospitals n Cleaning Works n Paint Industry

n The CO2-content is adsorbed to a level far below 300 ppm by a special grade molecular sieve

ALG Breathing Air Systems

Features: Complete purication package with CO and CO2 removal Guaranteed and validated separation efficiency Benets: turnkey-product, no additional installation required, all components are designed to t to each other Breathing air quality in excess of all relevant international standards, as e.g.: DIN EN 12021 (DIN 3188); BS 4275; ANSI/CGA G.7.1; Z 180, 1 M85; AS 2299-1979; NZL 5813 Low pressure drops and low running costs Simple access to all components. Easy to maintain and to service. Taylor-made system solutions Operating pressure: max. 16 bar g / min 4 bar g max. oil content 3 ppm Initial p 350 mbar Approval Declaration of conformity Inlet tempreature: min. 4 oC / max. 50 oC Regeneration air requirement: approx. 15 % at an average max. design temperature 60 oC Power supply 230 v / 50 Hz Ave. power consumption 0.03 kW

Optimal adaption and generous dimensioning of components User and service friendly housings Close range of sytems. Media: Compressed air Pressure dewpoint: -40 C at 100 % nominal load

o

Ambient temperature: min 2 C, max. 50 C

o o

Vessel design: EN 286-1

Air quality (related to standard inlet conditions) Particles Residual oil content Oil vapour & hydrocarbons CO2 CO Water vapour Taste & odours < 0.01 ppm < 0.01 ppm < 0.003 ppm < 300 ppm < 1 ppm 0.11 ppm free of taste and odour

Correction factors

pressure bar g

4 0.63

5 0.75

6 0.88 25 1

7 1

8 1.12 30 1

9 1.25 35 1

10 1.38 40 0.8

11 1.5 45 0.7

12 1.62 50 0.5

13 1.75

14 1.88

15 2

16 2.13

pp

ultralter DB-ALG GB 11/08 Rev.0

Inlet temperature oC

20

ALG Breathing Air Systems

Type volume flow (max) m3/h 35 80 100 150 225 300 375 Connect. G

1 3

Height A mm 1060 1610 1610 1980 1980 2140 2310

Width B mm 650 940 940 1140 1140 1580 1600

Depth C mm 340 430 430 580 580 670 800

Weight kg 70 199 240 288 420 530 795

ALG 35 S ALG 80 S ALG 100 S ALG 150 S ALG 225 S ALG 300 S ALG 375 S

/2 /4

1 1 1 /2

1 1 1

1 /2 1 /2

Technical alterations reserved.

ultralter gmbh

Otto-Hahn-Str. 1 40721 Hilden Germany Tel: +49 (0) 21 03.33 36-0 Fax +49 (0) 21 03.33 36-36 e-Mail: info@ultra-lter.de www.ultra-lter.de

ultralter DB-ALG GB 11/08 Rev.0

Potrebbero piacerti anche

- BOP Shear Pressure Calculations Rev 1Documento3 pagineBOP Shear Pressure Calculations Rev 1unduh100% (1)

- Simpson Anchors Anchoring and Fastening Systems 1461056Documento236 pagineSimpson Anchors Anchoring and Fastening Systems 1461056Foisul AlamNessuna valutazione finora

- Presentation CompressorDocumento15 paginePresentation Compressorarslan_ahmed_198744100% (1)

- API 510 Questions Amp Answers Closed Book 1 PDF FreeDocumento12 pagineAPI 510 Questions Amp Answers Closed Book 1 PDF Freejakariya100% (2)

- ASM ChartDocumento38 pagineASM ChartIan Steven Tolentino Bautista100% (2)

- Gas Sweetening and Processing Field ManualDa EverandGas Sweetening and Processing Field ManualValutazione: 4 su 5 stelle4/5 (7)

- HOVAL BrochureDocumento28 pagineHOVAL Brochurenisuss100% (1)

- Softening N Penetration Test (Bitumen)Documento11 pagineSoftening N Penetration Test (Bitumen)Thamilaarasan SonOf Nathan29% (7)

- Project EngineerDocumento3 pagineProject EngineerMuhammad NadeemNessuna valutazione finora

- CEA GuidelinessDocumento132 pagineCEA Guidelinesschellaae274850% (2)

- DENAIR 30KW Air Compressor Technical Proposal and QuotationDocumento17 pagineDENAIR 30KW Air Compressor Technical Proposal and QuotationOleg Semonenko100% (1)

- Adsorption Dryer CatalogueDocumento8 pagineAdsorption Dryer CatalogueAmirArmanNessuna valutazione finora

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsDa EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNessuna valutazione finora

- Cat 3616 (50-60hz) - JulDocumento7 pagineCat 3616 (50-60hz) - JulLei YinNessuna valutazione finora

- ScrollDocumento8 pagineScrolltrung2iNessuna valutazione finora

- CJC Off-Line FilterDocumento1 paginaCJC Off-Line FilterDenim BeširovićNessuna valutazione finora

- ABAC Smart Screw CompressorDocumento6 pagineABAC Smart Screw CompressorDaniel Arbeláez0% (1)

- Compressed Air Treatment, Drier and StorageDocumento24 pagineCompressed Air Treatment, Drier and StorageAna PrisacariuNessuna valutazione finora

- Wtm-058 Ut Procedure Aws d1.5 (2010)Documento9 pagineWtm-058 Ut Procedure Aws d1.5 (2010)Wisüttisäk Peäröön0% (1)

- MWM TCG 2020Documento4 pagineMWM TCG 2020MohammadFaisalAmjadNessuna valutazione finora

- ZR - ZT 110-900 BrochureDocumento24 pagineZR - ZT 110-900 BrochureSreenivasNessuna valutazione finora

- Methodology Well Foundation (R3)Documento14 pagineMethodology Well Foundation (R3)jitendra100% (2)

- Fd60hz Secador Atlas Copco - ManualDocumento8 pagineFd60hz Secador Atlas Copco - ManualEdvaldo França100% (1)

- Pollution Control Handbook for Oil and Gas EngineeringDa EverandPollution Control Handbook for Oil and Gas EngineeringNessuna valutazione finora

- Ingersoll Rand Compressed Air FilterDocumento4 pagineIngersoll Rand Compressed Air FilterSergiSerranoNessuna valutazione finora

- Compressed Air-Quality Optimisation For Pneumatic Control SystemDocumento19 pagineCompressed Air-Quality Optimisation For Pneumatic Control Systemupendra35Nessuna valutazione finora

- AirPreparationSystem Leaflet by SMCDocumento8 pagineAirPreparationSystem Leaflet by SMCAhmed AliNessuna valutazione finora

- Total Quality Air Package: Atlas CopcoDocumento8 pagineTotal Quality Air Package: Atlas CopcoCastillo PercyNessuna valutazione finora

- TCG2032Documento4 pagineTCG2032sdiamanNessuna valutazione finora

- Comp AirDocumento6 pagineComp AirOliver CambelNessuna valutazione finora

- ML17Documento2 pagineML17Stevan BoljevicNessuna valutazione finora

- Membranli Hava Fi̇li̇treDocumento44 pagineMembranli Hava Fi̇li̇trebulentbulutNessuna valutazione finora

- AMH - High Inlet Temperature Dryer - EnglishDocumento2 pagineAMH - High Inlet Temperature Dryer - EnglishOMEGA AIR d.o.o. LjubljanaNessuna valutazione finora

- Refrigerant Dryer CatalogDocumento4 pagineRefrigerant Dryer CatalogManny MendozaNessuna valutazione finora

- Energy-Saving and Easy Maintenance: Printed in Japan (H)Documento6 pagineEnergy-Saving and Easy Maintenance: Printed in Japan (H)Bánh Cuốn Tôm ThịtNessuna valutazione finora

- Air DryerDocumento4 pagineAir Dryerrashm006ranjanNessuna valutazione finora

- Diesel Particulate Matter (Louisville)Documento29 pagineDiesel Particulate Matter (Louisville)Dharmesh patelNessuna valutazione finora

- FR 91674Documento3 pagineFR 91674Juan Diego SarangoNessuna valutazione finora

- KG 600Documento15 pagineKG 600kedarkanase1Nessuna valutazione finora

- J208V06 enDocumento4 pagineJ208V06 enMartin KratkyNessuna valutazione finora

- OX100 Oxygen CompressorDocumento3 pagineOX100 Oxygen CompressorErnesto Valto0% (1)

- 2012 LHVAC CatalogueDocumento16 pagine2012 LHVAC CatalogueSehrish KhanNessuna valutazione finora

- Standard Dryer PDFDocumento4 pagineStandard Dryer PDFAveenNessuna valutazione finora

- J208V25 enDocumento4 pagineJ208V25 enMartin KratkyNessuna valutazione finora

- Screw Compressors: Eko 75 S Technical SpecificationsDocumento1 paginaScrew Compressors: Eko 75 S Technical Specificationssanta3Nessuna valutazione finora

- Atlus Copco Compressor PDFDocumento24 pagineAtlus Copco Compressor PDFashish_pradhan75Nessuna valutazione finora

- 6000 NDocumento6 pagine6000 NAlie Bhin Abhu Dhabi100% (2)

- JMS 312 GS-B.L: Technical SpecificationDocumento4 pagineJMS 312 GS-B.L: Technical SpecificationMartin KratkyNessuna valutazione finora

- Bebicon Air Compressors BrochureDocumento2 pagineBebicon Air Compressors BrochureRktBatam100% (1)

- Doosan Xhp1170fcat t3 Bid SpecDocumento7 pagineDoosan Xhp1170fcat t3 Bid Specmuhammad afiqNessuna valutazione finora

- JMS 208 GS-N.L: Technical SpecificationDocumento4 pagineJMS 208 GS-N.L: Technical SpecificationMartin KratkyNessuna valutazione finora

- Air Preparation Equimaents FilDocumento80 pagineAir Preparation Equimaents Filloveselvan43Nessuna valutazione finora

- CompressorDocumento7 pagineCompressorelrajilNessuna valutazione finora

- Compact Heatless Air DryersDocumento1 paginaCompact Heatless Air DryersBossman Instruments TechnologyNessuna valutazione finora

- CompAir L23 - L29 - RS Compressor Brochure PDFDocumento8 pagineCompAir L23 - L29 - RS Compressor Brochure PDFbulentbulutNessuna valutazione finora

- GDS134Documento4 pagineGDS134Saurabh VermaNessuna valutazione finora

- J316V21 enDocumento4 pagineJ316V21 enMartin KratkyNessuna valutazione finora

- TCG 2020 OlsDocumento4 pagineTCG 2020 Olssdiaman100% (1)

- J312V202 enDocumento4 pagineJ312V202 enMartin KratkyNessuna valutazione finora

- CRX-D Series 2010 Catalogue 1Documento8 pagineCRX-D Series 2010 Catalogue 1Do Ngoc HuuNessuna valutazione finora

- GasEngines&Gensets PDFDocumento4 pagineGasEngines&Gensets PDFShakhowath Chowdhury100% (1)

- ABAC Formula 5.5 22kWDocumento6 pagineABAC Formula 5.5 22kW1976gt500Nessuna valutazione finora

- KDON-350Y - 1200 Technical Solution of Air Separation EquipmentDocumento18 pagineKDON-350Y - 1200 Technical Solution of Air Separation EquipmentYJoe18Nessuna valutazione finora

- Tbg620k 50hz enDocumento4 pagineTbg620k 50hz enEhsanur RahmanNessuna valutazione finora

- Typical Fan CurveDocumento1 paginaTypical Fan CurveBalanSelvamNessuna valutazione finora

- Catalogo Generador Cat 3512Documento6 pagineCatalogo Generador Cat 3512pamg50% (1)

- Dogalgaz MotorlariDocumento4 pagineDogalgaz MotorlarinotmybbqNessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Zubadan Outdoor UnitDocumento9 pagineZubadan Outdoor UnitAlex HerzogNessuna valutazione finora

- Geodezija - Vježbe : GrađevinciDocumento15 pagineGeodezija - Vježbe : GrađevinciDenim BeširovićNessuna valutazione finora

- Service Manual Ehse-Ym9Ec - Uk Ehse-Ym9Ecr1.Uk Ehse-Mec - Uk Ehse-Mecr1.Uk Erse-Ym9Ec - Uk Erse-Ym9Ecr1.Uk Erse-Mec - Uk Erse-Mecr1.UkDocumento76 pagineService Manual Ehse-Ym9Ec - Uk Ehse-Ym9Ecr1.Uk Ehse-Mec - Uk Ehse-Mecr1.Uk Erse-Ym9Ec - Uk Erse-Ym9Ecr1.Uk Erse-Mec - Uk Erse-Mecr1.UkDenim BeširovićNessuna valutazione finora

- Service Manual: PUHZ-SHW230YKA2 PUHZ-SHW230YKA2R1 PUHZ-SHW230YKA2R2Documento64 pagineService Manual: PUHZ-SHW230YKA2 PUHZ-SHW230YKA2R1 PUHZ-SHW230YKA2R2Denim BeširovićNessuna valutazione finora

- Mathematical Modeling of Wind ForcesDocumento20 pagineMathematical Modeling of Wind ForcesDenim BeširovićNessuna valutazione finora

- Service Manual Ehse-Ym9Ec - Uk Ehse-Ym9Ecr1.Uk Ehse-Mec - Uk Ehse-Mecr1.Uk Erse-Ym9Ec - Uk Erse-Ym9Ecr1.Uk Erse-Mec - Uk Erse-Mecr1.UkDocumento76 pagineService Manual Ehse-Ym9Ec - Uk Ehse-Ym9Ecr1.Uk Ehse-Mec - Uk Ehse-Mecr1.Uk Erse-Ym9Ec - Uk Erse-Ym9Ecr1.Uk Erse-Mec - Uk Erse-Mecr1.UkDenim BeširovićNessuna valutazione finora

- 0001 001 PDFDocumento68 pagine0001 001 PDFDenim BeširovićNessuna valutazione finora

- CertificateDocumento1 paginaCertificateDenim BeširovićNessuna valutazione finora

- Modeling Physiological Resistance in Bacterial Biofilms: N.G. Cogan, Ricardo Cortez, Lisa FauciDocumento23 pagineModeling Physiological Resistance in Bacterial Biofilms: N.G. Cogan, Ricardo Cortez, Lisa FauciDenim BeširovićNessuna valutazione finora

- Examples of Mathematical Modeling: Tales From The CryptDocumento7 pagineExamples of Mathematical Modeling: Tales From The CryptDenim BeširovićNessuna valutazione finora

- A019-0018 v15 To v20 AirendDocumento1 paginaA019-0018 v15 To v20 AirendDenim BeširovićNessuna valutazione finora

- Examples of Mathematical Modeling: Tales From The CryptDocumento7 pagineExamples of Mathematical Modeling: Tales From The CryptDenim BeširovićNessuna valutazione finora

- DDD DrawingDocumento1 paginaDDD DrawingDenim BeširovićNessuna valutazione finora

- Linear Bushing Inch-3Documento3 pagineLinear Bushing Inch-3Denim BeširovićNessuna valutazione finora

- 1999 02 28 ThalmannDocumento4 pagine1999 02 28 ThalmannDenim BeširovićNessuna valutazione finora

- KF Check ValvesDocumento32 pagineKF Check ValvesDenim BeširovićNessuna valutazione finora

- EagleBurgmann EA560 enDocumento3 pagineEagleBurgmann EA560 enDenim BeširovićNessuna valutazione finora

- Linear Bushing Inch1Documento1 paginaLinear Bushing Inch1Denim BeširovićNessuna valutazione finora

- KF Check ValvesDocumento32 pagineKF Check ValvesDenim BeširovićNessuna valutazione finora

- 12048en LGFP2Documento2 pagine12048en LGFP2Denim BeširovićNessuna valutazione finora

- Thern DavitCrane Selection SheetDocumento1 paginaThern DavitCrane Selection SheetShubhamkumarsharmaNessuna valutazione finora

- Nte 123 ADocumento4 pagineNte 123 AAndres Mauricio Quiceno BetancourtNessuna valutazione finora

- Rigging Guide 2008Documento222 pagineRigging Guide 2008Alex1Nessuna valutazione finora

- Thermo Sample ProblemsDocumento5 pagineThermo Sample ProblemsDeniel AndalNessuna valutazione finora

- GA-I (H) D 1000 Series ROBOTDocumento1 paginaGA-I (H) D 1000 Series ROBOTmfarrukhkNessuna valutazione finora

- Constantinos Apostolou DoxiadisDocumento6 pagineConstantinos Apostolou DoxiadisEdith Nerissa SantiagoNessuna valutazione finora

- Creating A Use Case Diagram in Rational RoseDocumento2 pagineCreating A Use Case Diagram in Rational RoseRaguramrecNessuna valutazione finora

- Goals of True Broad Band's Wireless Next Wave (4G-5G)Documento5 pagineGoals of True Broad Band's Wireless Next Wave (4G-5G)alokcena007Nessuna valutazione finora

- M4700Documento4 pagineM4700kylegazeNessuna valutazione finora

- Mini-Excavators: Breaking New GroundDocumento7 pagineMini-Excavators: Breaking New GrounddongNessuna valutazione finora

- AAFDS Service SpecificationDocumento20 pagineAAFDS Service SpecificationLUIS GIRALDONessuna valutazione finora

- PeopleSoft 9.1 PeopleBook Approval FrameworkDocumento166 paginePeopleSoft 9.1 PeopleBook Approval Frameworkkhaleel_blrNessuna valutazione finora

- NTN FR PDFDocumento292 pagineNTN FR PDFAnonymous 37PvyXCNessuna valutazione finora

- Lalmonirhat Social Services Office - 26 - 09 - 19 - LegendDocumento1 paginaLalmonirhat Social Services Office - 26 - 09 - 19 - LegendTauhid RahmanNessuna valutazione finora

- Clase N 5Documento4 pagineClase N 5Xthian Vidal CortezNessuna valutazione finora

- N Queen ProblemDocumento2 pagineN Queen ProblemManikandanNessuna valutazione finora

- Automotive (2) Lab: EXP3: Drive Axles and DifferentialDocumento7 pagineAutomotive (2) Lab: EXP3: Drive Axles and DifferentialMohammad YahyaNessuna valutazione finora

- Process Costing PDFDocumento52 pagineProcess Costing PDFsachinNessuna valutazione finora

- Downtown Crossing Signage GuidelinesDocumento35 pagineDowntown Crossing Signage GuidelinesMai Tran Thi ChucNessuna valutazione finora

- MEMB453 - Eddy Current (ET) Home Quiz 2018S1Documento4 pagineMEMB453 - Eddy Current (ET) Home Quiz 2018S1Menny RossNessuna valutazione finora

- National Apprenticeship Training Scheme (NATS) EstablishmentDocumento2 pagineNational Apprenticeship Training Scheme (NATS) EstablishmentKumarNessuna valutazione finora