Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Development of Embedded Software and Verification For Peripherals of Arm7Tdmi-S

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Development of Embedded Software and Verification For Peripherals of Arm7Tdmi-S

Copyright:

Formati disponibili

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 3, Issue 3, March 2014 ISSN 2319 - 4847

Development of Embedded Software and Verification for Peripherals of ARM7TDMI-S

Santhosh T.P1 , Prof T.S. Bharath Kumar2 and Dr M.Z.Kurian3

1

4th sem, M.Tech (VLSI and Embedded systems), SSIT, Tumkur 2 Professor, Dept of ECE, SSIT, Tumkur 3 Dean & HOD, Dept of ECE, SSIT, Tumkur, Karnataka

Abstract

Embedded systems are revolving around us into various products. Every 18 months the transistor density increases as per moors law and we able to have a better features of the peripherals within the microcontroller. But the manufacturing company had hardly verified all the functionalities of the peripherals due to time to market. Embedded engineers face challenges when programming these peripherals when there is no proper support provided by the chip manufacturing company. In this paper there will be detailed study of the features of the peripherals provided by the LPC2148 microcontroller. Necessary embedded software will be developed to test the peripherals features provided by the manufactures. The developed embedded software will be verified for its functionalities. The documentation of this development and verification of the embedded software will be carried out the meet the knowledge standards.

Keywords: ARM7TDMI-S, Keil compiler, LPC 2148, embedded software

1. INTRODUCTION

When designing an embedded system application, other than execution speed, Total cost is the most important factor need to be considered. Most of the application that run on embedded platform faces a common problem with the availability of restricted or very small memory area available for storing the program for application.. Minimizing the code size is a straight forward solution to minimize the memory used by the application program. The C programming language is a general-purpose programming language that provides efficiency in codes, Keil compiler is a software which introduces embedded C programming for various embedded applications In this paper an attempt has been made for implementation of a compiler using Keil tool for an ARM7TDMI-S microprocessor for an embedded application which will reduce the code size to approximately 5% of a code which has already passed through all the levels of optimization embedded in the Keil compiler. The market of embedded systems is spreading faster than that of information technology. Mostly, the segments of embedded systems are consumer markets, with very short product lifetimes and short market windows. Hence, time-to-market is an important factor. Cutting down the time to market for products that became more and more complex is possible through re-use. Another important characteristics of the embedded system market is the ease of incorporating late design changes, i.e. flexibility of the target technology, this led to the use of processors in embedded systems. This in turn led to the use of embedded software. Keil compiler is an 8051 and ARM compiler which support the various applications. A programmer when programming always try to follow the conventional constructs of the higher level language which certain cases doesnt digested by the compiler due its own methods of syntax and constructs. If the embedded programmer uses the extensive syntax and constructs of the compiler then the application code can perform better and add code optimality. Keil compiler supports embedded C programming for better optimization.

2. RELATED WORK

The ARM7TDMI-S processor uses a pipeline to increase the speed of the flow of instructions to the processor. This enables several instructions to run continuously, and the processing, and memory systems to operate continuously. [1] The Systems Architecture Laboratory designed and implemented the first phase C programming language compiler for the ARM7TDMI architecture. It consists of two parts viz analysis and synthesis [2] The optimized code produced by the compiler after passing through nine levels of optimization could be reduced further. Simulation has shown that a further reduction of approximately 5% could be achieved by using this algorithm. The proposed algorithm will be tested for Thumb instructions also which already reduces 30% of the code when compared to ARM.[3] A retargetable compiler in Visual Basic is capable of generating MIPS and ARM code. This compiler is a user retargetable compiler. The retargetable efforts are intermediate. Some of the information is entered as parameters through the graphical user interface and rest is used at the time of coding. The following can be provided to the CPU: size of the

Volume 3, Issue 3, March 2014

Page 266

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 3, Issue 3, March 2014 ISSN 2319 - 4847

register file, name of registers and details of functional units. It is observed that the code is good in terms of code size, cycle count and compilation times.[4]

3. SYSTEM DESIGN

Figure 1. System block diagram The system block diagram is shown in fig 1.This block diagram shows the proposed implementation of keil compiler constructs for an embedded application. In this paper an example of Beverage vending machine(BVM) is considered as an Embedded application. The main function of Beverage vending machine is to deliver beverage products. Like coffee, tea etc after undergoing different processes likes accepting the cash, selecting the beverage, dispensing the change and several other optimizations. For this vending machine several code optimizations required,. Here an attempt is made to develop embedded c code using keil compiler constructs. Processor is the main part of any embedded system, here in BVM it uses LPC 2148 (ARM7TDMI), the ARM7TDMI core is a member of the ARM family of 32 bit Microprocessor. It is widely used across a range of applications. The ARM7 family is a range of low-power 32-bit RISC microprocessor cores optimized for cost and power-sensitive consumer applications. The ARM7 incorporates the Thumb 16-bit instruction set - enabling 32-bit performance at 8/16-bit system cost. The ARM architecture is based on Reduced Instruction Set Computer (RISC) architecture. The RISC instruction set and related decode mechanism are much simpler than those of Complex instruction set computer (CISC) designs. Implementation of the vending machine using ARM based processor along with its peripherals is done by developing the embedded C code. Most of the operational models are stochastic and dynamic, which invariably need a computing facility to see the result within a given time. The software is programmed through Keil compiler. The extensive utilization of the embedded Kiel compiler for the embedded application using the microcontroller will be made to meet the performance and optimality using Keil compiler and analyze the performance of the developed application code.

Figure 2 : Interface block diagram The interface block diagram is as shown in figure 2.The interfacing is done by UART and it displays the message in UART window when the program is executed. Initially it displays the welcome message followed by the beverages that are available with its prices. These messages will be displayed on LCD display and below that there will be buttons to select the beverage of the customers choice after displaying the messages, it then asks for entering the amount. Then if we enter the amount, processing is done and remaining amount is given back to the customer. After the remaining amount is given back, it displays which button should be pressed for respective beverages of tea, coffee, black tea. It indicates the button t is pressed for tea. As soon as this button is pressed, the signal is given to the motors. In this project stepper motor has been used. Initially the milk motor runs for 10 rotations to drive 200 milligrams of milk powder to the container. It shows after the milk motor has run for 10 rotations, the tea motor starts rotating and runs until 6 rotations as it requires to drive 160 milligrams of tea powder into the container in which milk powder is already present

4. PERIPHERALS ASSOCIATED WITH LPC2148.

4.1 Different peripheral components associated with LPC2148 GPIO-The General Purpose Input/Output (GPIO ) Dialog controls the direction of the general purpose port pins UART-To review the communication baud rate and other parameters of the system I2C Interface-To review the ITC bus activities and data communication SPI Interface-This interface allows to view and edit the serial peripheral Interface Simulator configuration

Volume 3, Issue 3, March 2014

Page 267

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 3, Issue 3, March 2014 ISSN 2319 - 4847

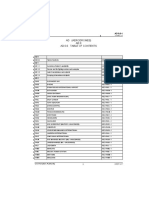

Pulse width modulator-The Three-Phase PWM dialog configures Three-Phase PWM simulation for the ADuC7000 series devices. The PWM generator contains its own timing unit and is not dependent on any of the CPU Timers A/DConverter-It provides 16 channels of 10-bit analog to digital conversion. Voltages presented to the input pins on Port 5 are converted to digital values and may be read from the result register. D/A Converter-It provides 16 channels of 10-bit digital to analog conversion 4.2 Peripheral verification for Beverage Vending machine (BVM) In this paper an attempt is made to develop embedded software for Beverage vending machine. Here utilizing embedded c programming using keil compiler a code has been developed .when this code is compiled and run, Different peripherals like GPIO and A/D Converter shows different attributes and functions of LPC2148.It as shown in fig 3

FIGURE 3. Different peripherals associated when tea is selected and milk motor is running Initially it shows a welcome message. Later it asks to enter the amount if the entered amount is more than the required it process to give remaining change and then it asks to select between different beverages. In this example beverage Tea has been selected .In figure 3 It indicates the button t is pressed for tea. As soon as this button is pressed, the signal is given to the motors. Initially the milk motor runs for 10 rotations to drive 200 milligrams of milk powder to the container. The milk motor which runs is shown in the GPIO port0. The General Purpose Input/Output 0 (GPIO 0) Dialog controls the direction of the general purpose port 0 pins. IODIR0 (Input Output Direction Register) contains the direction assignments for each I/O port bit. The check boxes are checked for output and unchecked for input. IOSET0 (Input Output Set Register) bits are checked to force a high level for a that port bit during output. IOCLR0 (Input Output Clear Register) bits are checked to force a low level for a that port bit during output. IOPIN0 (Input Output Pin Value Register) contains the current condition of the GPIO 0 pins. Pins are used to manually control a pin value. The dialog displays the status registers for all of the converters supported by this device. : CLKS (Conversion Clocks) selects the number of clocks used for each conversion in Burst mode and the bit accuracy. START controls when and if the conversion is started. SEL selects which pins of the analog input (AINn) are to be sampled and converted CLKDIV (Clock Divisor) is the value (minus 1) divided into the VPB clock to produce the A/DRate. PDN (Power Down) is set id th A/D will be operational. If reset, the A/D is in power down mode. (BURST) is set to use the number of clocks which are specified in BURST. If reset, conversions are software controlled and requires 11 clocks. (EDGE) is set to start the conversion on rising edge. If reset, conversion starts on falling edge.

Volume 3, Issue 3, March 2014

Page 268

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 3, Issue 3, March 2014

Data

ISSN 2319 - 4847

ADDR (A/D Data Register) contains the following bits for controllong A/D data conversion: CHN (Channel) is the channel containing the converted bits. DONE is set when the A/D conversion completes. OVERRUN is set if one or more conversions were overwritten before the current conversion completed.

Analog Inputs (AINn) (Analog Input Channels n) are used for setting voltage input . These inputs are alternate functions for Port pins. The text box displays the analog voltage value for each input channel. These are some of specifications of different peripheral verifications associated with GPIO and A/D convertor ports. Figure 3 shows the snapshot when beverage tea is selected and milk motor starts rotating. After 10 rotations, the tea motor starts rotating and runs until 6 rotations as it requires to drive 160 milligrams of tea powder into the container in which milk powder is already present. The tea motor which runs is shown in the GPIO port1.This is shown in figure 4.

Figure 4 Different peripherals associated when tea motor is running and to determine the initial temperature

Figure 5 Different peripherals associated when showing the final temperature and to deliver Tea

Volume 3, Issue 3, March 2014

Page 269

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 3, Issue 3, March 2014 ISSN 2319 - 4847

The final temperature during the beverage is done during the beverage mixing is done with hot water. Then it shows that the beverage is ready .and later it concludes saying your tea is ready. This is as shown in figure 5

5. CONCLUSION

The optimized code produced by the compiler after passing through nine levels of optimization could be reduced further of approximately 5% could be achieved by using Keil compiler algorithm. This provides a backbone for the implementation of this paper. The compiler if provided additional optimizations improves the performance of embedded system. Thumb instructions are useful in embedded systems and one of the goals is to be able to support these. This compiler is able to produce thumb instructions for single core and dual core processor by adding a new code generator. These thumb instructions also benefit from the additional optimizations implemented. This paper enhances the extreme usage of ARM7 and Keil compiler constructs and also for verification of different peripherals associated with it. An embedded software has been developed to run a Beverage vending machine taking tea,coffee,black coffee as example .This paper enhances more of functions of different peripherals when the keil compiler code has been developed for Vending machines using ARM7 processor.

REFERENCES

[1] Sherry Joy Alvionne V. Sebastian, Implementation of the Phase II Compiler for the ARM7TDMI-S Dual-Core Microprocessor on 2011 Second International Conference on Intelligent Systems, Modelling and Simulation 2011 IEEE DOI 10.1109/ISMS.2011.46 [2] Sendhilraj Thangaraj, Sudhakar Gummadi, Shanmugasundaram Radhakrishnan, Enhancement in ARM Code Optimization for Memory Constrained Embedded Systems 1-4244-0716-8/06/$20.00 2006 IEEE. [3] Dr. Manoj Kumar Jain, Veena Ramnani, Developing a Retargetable Compiler For Mips32k and ARM7TDMI-S ,ISSN-2229-371X, Volume 3, No. 2, February 2012 Journal of Global Research in Computer Science [4] Dimanarig, Mendoza, Moscoso, Recla, Power Optimization of the ARM7TDMI-S Microprocessor in 90nm CMOS Process. Undergraduate Student Project, Electrical and Electronics Engineering Institute, University of the Philippines, Diliman, October 2009 [5] Delas Alas, Santos, Torralba, Umbal, Compiler Implementation for the Dual-Core ARM7 Microprocessors. Undergraduate Student Project, Electrical and Electronics Engineering Institute, University of the Philippines, Diliman [6] Rainer Leupers and Peter Marwedel, Function inlining under code size constraints for embedded processors, in Proceedings of the 1999 IEEE/ACM International Conference on Computer-Aided Design, pp. 253-256.

Volume 3, Issue 3, March 2014

Page 270

Potrebbero piacerti anche

- Intermediate C Programming for the PIC Microcontroller: Simplifying Embedded ProgrammingDa EverandIntermediate C Programming for the PIC Microcontroller: Simplifying Embedded ProgrammingNessuna valutazione finora

- Gui Based Liquid Indicator Using Cortex M3 For Industry Monitoring SystemDocumento9 pagineGui Based Liquid Indicator Using Cortex M3 For Industry Monitoring SystemeditorijaiemNessuna valutazione finora

- Wireless Automobile Monitoring SystemDocumento48 pagineWireless Automobile Monitoring SystemVaibhav TiwariNessuna valutazione finora

- Workshop ManualDocumento19 pagineWorkshop ManualHassan Ali Khan100% (1)

- CLASS 1-Complex Systems and Micro ProcessorsDocumento21 pagineCLASS 1-Complex Systems and Micro ProcessorsSivakumar KNessuna valutazione finora

- Automatic Generation A Way of Ensuring PLC and HMI StandardsDocumento4 pagineAutomatic Generation A Way of Ensuring PLC and HMI Standardsrcfrcf279Nessuna valutazione finora

- "LCD Device Driver" For Reconfigurable Instrument ClusterDocumento6 pagine"LCD Device Driver" For Reconfigurable Instrument ClustersrikanthshenoyNessuna valutazione finora

- C Programming of Microcontroller For Hobby RoboticsDocumento14 pagineC Programming of Microcontroller For Hobby RoboticsCMPENessuna valutazione finora

- Unit Iii The Microchip Pic Micro (R) Microcontroller 1.types of Microcontroller PIC MicrocontrollerDocumento7 pagineUnit Iii The Microchip Pic Micro (R) Microcontroller 1.types of Microcontroller PIC MicrocontrollerAshwin Prabhu .M VISTASNessuna valutazione finora

- ES Lab Manual 1Documento95 pagineES Lab Manual 1Rufus DavidNessuna valutazione finora

- Ramgopal Embedded ResumeDocumento5 pagineRamgopal Embedded ResumeVinod KumarNessuna valutazione finora

- 3 RD ChapterDocumento6 pagine3 RD ChaptergouttNessuna valutazione finora

- A PROJECT REPORT ON Electronic Voting MachineDocumento97 pagineA PROJECT REPORT ON Electronic Voting Machinereddu143Nessuna valutazione finora

- 07 - Chapter 3Documento58 pagine07 - Chapter 3Chibueze EzeokaforNessuna valutazione finora

- Design and Implementation of Electronic Control Trainer With PIC MicrocontrollerDocumento7 pagineDesign and Implementation of Electronic Control Trainer With PIC Microcontrolleryousif al mashhadanyNessuna valutazione finora

- IRJET Design of Low Power 32 Bit RISC PRDocumento8 pagineIRJET Design of Low Power 32 Bit RISC PRpawan vermaNessuna valutazione finora

- Configurable Multiprocessor Platform Without RTOS For Distributed Interfacing and ControllingDocumento4 pagineConfigurable Multiprocessor Platform Without RTOS For Distributed Interfacing and ControllingnileshchaurasiaNessuna valutazione finora

- Internal Combustion Engine Control 1. Engine Control Unit SoftwareDocumento10 pagineInternal Combustion Engine Control 1. Engine Control Unit SoftwareLahcen KhalifNessuna valutazione finora

- Files 1510298855 27889 PDFDocumento151 pagineFiles 1510298855 27889 PDFDãyäñidhï ÑæïkNessuna valutazione finora

- Dma& Usb Interfacing For Keyboard Using Cypress Psoc-5Documento12 pagineDma& Usb Interfacing For Keyboard Using Cypress Psoc-5International Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Simulation and Implementation of PLC Based For Detecting Burned Potato Chips and Remove Using PLCSIM and HMIDocumento6 pagineSimulation and Implementation of PLC Based For Detecting Burned Potato Chips and Remove Using PLCSIM and HMIEditor IJTSRDNessuna valutazione finora

- Using The AT89C2051 MCU As Virtual MachineDocumento11 pagineUsing The AT89C2051 MCU As Virtual MachineplcmanaNessuna valutazione finora

- Chapter 6 - Introduction To An Embedded System and ITs Design - Microcontrollers & Embedded SystemsDocumento16 pagineChapter 6 - Introduction To An Embedded System and ITs Design - Microcontrollers & Embedded SystemsAmish VermaNessuna valutazione finora

- MC & ESY NotesDocumento144 pagineMC & ESY NotesgodaserbNessuna valutazione finora

- Tarmac ReportDocumento102 pagineTarmac Reportshubham.neNessuna valutazione finora

- Embedded System Lect1Documento47 pagineEmbedded System Lect1VivekanandanvrNessuna valutazione finora

- CCCCCC CDocumento60 pagineCCCCCC CSanthan ManneNessuna valutazione finora

- Final Project1Documento23 pagineFinal Project1Vinod Pathak100% (1)

- Vehicle Collision Avoidance With Dynamic Speed Governor: Kashyap A RDocumento9 pagineVehicle Collision Avoidance With Dynamic Speed Governor: Kashyap A RHoney SinghNessuna valutazione finora

- Vehicle Collision Avoidance With Dynamic Speed Governor: Kashyap A RDocumento9 pagineVehicle Collision Avoidance With Dynamic Speed Governor: Kashyap A RChiluka ShyluNessuna valutazione finora

- Metro Train Prototype: A Summer Training Report OnDocumento34 pagineMetro Train Prototype: A Summer Training Report OnPooja SharmaNessuna valutazione finora

- Web Controlled Industrial Actuators: Vrushab Bagul. Sudarshan NikaljeDocumento22 pagineWeb Controlled Industrial Actuators: Vrushab Bagul. Sudarshan NikaljeMayur RaneNessuna valutazione finora

- 39 1490338118 - 24-03-2017 PDFDocumento3 pagine39 1490338118 - 24-03-2017 PDFEditor IJRITCCNessuna valutazione finora

- 3.7.7 The PC As A Controller: 3.8 Programmable Logic ControllersDocumento23 pagine3.7.7 The PC As A Controller: 3.8 Programmable Logic ControllersMohamed HamdallahNessuna valutazione finora

- Mbed BK Ed2 CH 1Documento12 pagineMbed BK Ed2 CH 1Pedro Augusto PeresNessuna valutazione finora

- Sms Based Notice BoardDocumento39 pagineSms Based Notice Boardreddu143Nessuna valutazione finora

- Programming Attiny85 Programmer A Complete GuideDocumento11 pagineProgramming Attiny85 Programmer A Complete GuidejackNessuna valutazione finora

- UVM Based Verification of CAN Protocol Controller Using System VerilogDocumento5 pagineUVM Based Verification of CAN Protocol Controller Using System VerilogEditor IJRITCCNessuna valutazione finora

- Minor Project: DTMF Controlled Robot "Mobot"Documento65 pagineMinor Project: DTMF Controlled Robot "Mobot"Shyami GovindNessuna valutazione finora

- Microprocessors-Quick Notes (For Exam Preparation) - ClassleDocumento4 pagineMicroprocessors-Quick Notes (For Exam Preparation) - ClassleTapasRoutNessuna valutazione finora

- Embedded Trainer BoardDocumento5 pagineEmbedded Trainer BoardSolomon AkpanNessuna valutazione finora

- Automatic Code Generation, A.K.A. "Auto-Code": Rapid Controls Prototyping (RCP)Documento4 pagineAutomatic Code Generation, A.K.A. "Auto-Code": Rapid Controls Prototyping (RCP)Ashwin PintoNessuna valutazione finora

- Embedded Steer-by-Wire System DevelopmentDocumento7 pagineEmbedded Steer-by-Wire System DevelopmentkeshNessuna valutazione finora

- Color Making and Mixing Process Using PLCDocumento5 pagineColor Making and Mixing Process Using PLCInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- ReportDocumento5 pagineReportNitin RajNessuna valutazione finora

- WP Software Design Dec08 en 2 Lektorat (2) - CorrectedDocumento9 pagineWP Software Design Dec08 en 2 Lektorat (2) - CorrectedbattikaNessuna valutazione finora

- LED DisplayDocumento25 pagineLED DisplayCreative StudioNessuna valutazione finora

- Introduction To Embedded SystemsDocumento14 pagineIntroduction To Embedded SystemsSreekesh ManipuzhaNessuna valutazione finora

- The Various Ways of Programming and Embedding Firmware Into An ARM Cortex-M3 Microcontroller Based HardwareDocumento6 pagineThe Various Ways of Programming and Embedding Firmware Into An ARM Cortex-M3 Microcontroller Based HardwareIJAFRCNessuna valutazione finora

- Example ReportDocumento26 pagineExample ReportSofi FaizalNessuna valutazione finora

- Online Course On Embedded SystemsDocumento75 pagineOnline Course On Embedded SystemspandiNessuna valutazione finora

- An Introduction To Embedded Systems: Abs TractDocumento6 pagineAn Introduction To Embedded Systems: Abs TractSailu KatragaddaNessuna valutazione finora

- Research Paper Pic MicrocontrollerDocumento6 pagineResearch Paper Pic Microcontrollerupvipbqlg100% (1)

- Balancing PAC IPC PLC PDFDocumento5 pagineBalancing PAC IPC PLC PDFlucasgianini100% (1)

- Embedded PLC Implementation Using ARMDocumento5 pagineEmbedded PLC Implementation Using ARMsnehagoyankaNessuna valutazione finora

- Teaching Human Computer Interaction Methods in Embedded System DesignDocumento6 pagineTeaching Human Computer Interaction Methods in Embedded System DesignHasan AlkhedrNessuna valutazione finora

- Internship Report Body PDFDocumento28 pagineInternship Report Body PDFSanjayNessuna valutazione finora

- Application Examples Overview enDocumento26 pagineApplication Examples Overview enArunagiriNessuna valutazione finora

- Computer Aided Assessment For Engine Room SimulatorDocumento13 pagineComputer Aided Assessment For Engine Room SimulatorPavithra PNessuna valutazione finora

- Chapter 3Documento11 pagineChapter 3nikhilNessuna valutazione finora

- An Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewDocumento9 pagineAn Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- THE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSDocumento7 pagineTHE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Customer Satisfaction A Pillar of Total Quality ManagementDocumento9 pagineCustomer Satisfaction A Pillar of Total Quality ManagementInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Experimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterDocumento7 pagineExperimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Study of Customer Experience and Uses of Uber Cab Services in MumbaiDocumento12 pagineStudy of Customer Experience and Uses of Uber Cab Services in MumbaiInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Detection of Malicious Web Contents Using Machine and Deep Learning ApproachesDocumento6 pagineDetection of Malicious Web Contents Using Machine and Deep Learning ApproachesInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Soil Stabilization of Road by Using Spent WashDocumento7 pagineSoil Stabilization of Road by Using Spent WashInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- THE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSDocumento7 pagineTHE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Analysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyDocumento6 pagineAnalysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Study of Customer Experience and Uses of Uber Cab Services in MumbaiDocumento12 pagineStudy of Customer Experience and Uses of Uber Cab Services in MumbaiInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Customer Satisfaction A Pillar of Total Quality ManagementDocumento9 pagineCustomer Satisfaction A Pillar of Total Quality ManagementInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Synthetic Datasets For Myocardial Infarction Based On Actual DatasetsDocumento9 pagineSynthetic Datasets For Myocardial Infarction Based On Actual DatasetsInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Detection of Malicious Web Contents Using Machine and Deep Learning ApproachesDocumento6 pagineDetection of Malicious Web Contents Using Machine and Deep Learning ApproachesInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Experimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterDocumento7 pagineExperimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Staycation As A Marketing Tool For Survival Post Covid-19 in Five Star Hotels in Pune CityDocumento10 pagineStaycation As A Marketing Tool For Survival Post Covid-19 in Five Star Hotels in Pune CityInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- The Mexican Innovation System: A System's Dynamics PerspectiveDocumento12 pagineThe Mexican Innovation System: A System's Dynamics PerspectiveInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Analysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyDocumento6 pagineAnalysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- The Impact of Effective Communication To Enhance Management SkillsDocumento6 pagineThe Impact of Effective Communication To Enhance Management SkillsInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- A Digital Record For Privacy and Security in Internet of ThingsDocumento10 pagineA Digital Record For Privacy and Security in Internet of ThingsInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Design and Detection of Fruits and Vegetable Spoiled Detetction SystemDocumento8 pagineDesign and Detection of Fruits and Vegetable Spoiled Detetction SystemInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Performance of Short Transmission Line Using Mathematical MethodDocumento8 paginePerformance of Short Transmission Line Using Mathematical MethodInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Challenges Faced by Speciality Restaurants in Pune City To Retain Employees During and Post COVID-19Documento10 pagineChallenges Faced by Speciality Restaurants in Pune City To Retain Employees During and Post COVID-19International Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- A Deep Learning Based Assistant For The Visually ImpairedDocumento11 pagineA Deep Learning Based Assistant For The Visually ImpairedInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- An Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewDocumento9 pagineAn Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- A Comparative Analysis of Two Biggest Upi Paymentapps: Bhim and Google Pay (Tez)Documento10 pagineA Comparative Analysis of Two Biggest Upi Paymentapps: Bhim and Google Pay (Tez)International Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Secured Contactless Atm Transaction During Pandemics With Feasible Time Constraint and Pattern For OtpDocumento12 pagineSecured Contactless Atm Transaction During Pandemics With Feasible Time Constraint and Pattern For OtpInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Advanced Load Flow Study and Stability Analysis of A Real Time SystemDocumento8 pagineAdvanced Load Flow Study and Stability Analysis of A Real Time SystemInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Predicting The Effect of Fineparticulate Matter (PM2.5) On Anecosystemincludingclimate, Plants and Human Health Using MachinelearningmethodsDocumento10 paginePredicting The Effect of Fineparticulate Matter (PM2.5) On Anecosystemincludingclimate, Plants and Human Health Using MachinelearningmethodsInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Impact of Covid-19 On Employment Opportunities For Fresh Graduates in Hospitality &tourism IndustryDocumento8 pagineImpact of Covid-19 On Employment Opportunities For Fresh Graduates in Hospitality &tourism IndustryInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Anchoring of Inflation Expectations and Monetary Policy Transparency in IndiaDocumento9 pagineAnchoring of Inflation Expectations and Monetary Policy Transparency in IndiaInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Functional Buttons and Auto Power Off: International Electrical SymbolsDocumento2 pagineFunctional Buttons and Auto Power Off: International Electrical SymbolsVentas SA TabNessuna valutazione finora

- Hoja Tecnica Val Vu La 8044Documento5 pagineHoja Tecnica Val Vu La 8044train_ponce1080Nessuna valutazione finora

- Rattan Pole BendingDocumento21 pagineRattan Pole Bendingcintamore_jos355Nessuna valutazione finora

- RC4 Vector Key Based Conditional Access System in Pay-TV Broadcasting SystemDocumento5 pagineRC4 Vector Key Based Conditional Access System in Pay-TV Broadcasting SystemAlad Manoj PeterNessuna valutazione finora

- H07RN-F - (LTC) - 4Documento6 pagineH07RN-F - (LTC) - 4Faizal AzwaryNessuna valutazione finora

- Aerodromes PDFDocumento522 pagineAerodromes PDFaditya100% (1)

- Adly 50 RS Parts ListDocumento50 pagineAdly 50 RS Parts ListZsibrita GyörgyNessuna valutazione finora

- Work and Power Worksheet: Text Text Text Text Text TextDocumento2 pagineWork and Power Worksheet: Text Text Text Text Text TextJvonta DixonNessuna valutazione finora

- Self Priming Water Lifting Booster PumpDocumento2 pagineSelf Priming Water Lifting Booster PumpzhelipumpNessuna valutazione finora

- English Today Vol 2Documento10 pagineEnglish Today Vol 2StancuLucianNessuna valutazione finora

- Grill Size CalculationDocumento2 pagineGrill Size CalculationSiva SankarNessuna valutazione finora

- Automation Anywhere Enterprise (Excel Commands)Documento37 pagineAutomation Anywhere Enterprise (Excel Commands)Surbhi SharmaNessuna valutazione finora

- 080Documento10 pagine080Luis Adrián ElguézabalNessuna valutazione finora

- Unit: Pltu Bolok Area: UNIT #1 Equipment Standard Measurement Point Unit Minggu 1 Minggu 2 Minggu 3 Minggu 4 StatusDocumento18 pagineUnit: Pltu Bolok Area: UNIT #1 Equipment Standard Measurement Point Unit Minggu 1 Minggu 2 Minggu 3 Minggu 4 StatusAchmad Zaki MubarokNessuna valutazione finora

- ITC Classmate-Market Research in MaduraiDocumento26 pagineITC Classmate-Market Research in Maduraipriyatrs06Nessuna valutazione finora

- A.J Mcdougall: VP Director / Principal ConsultantDocumento27 pagineA.J Mcdougall: VP Director / Principal ConsultantDe SambasNessuna valutazione finora

- BulldogDocumento20 pagineBulldogFlorinNessuna valutazione finora

- ASOC Exam Study Based On Latest Syllabus IndiaDocumento238 pagineASOC Exam Study Based On Latest Syllabus IndiaBiju Gopi ThilakaNessuna valutazione finora

- 5 Star SynopsisDocumento22 pagine5 Star Synopsisabdul wahidNessuna valutazione finora

- Project 5 - Magic 8 Ball Fortune Telling ProjectDocumento23 pagineProject 5 - Magic 8 Ball Fortune Telling ProjectHidden Gem50% (2)

- Installation Removal Maintaining Shrink Discs 3 Part enDocumento8 pagineInstallation Removal Maintaining Shrink Discs 3 Part enhadimarviNessuna valutazione finora

- Snort ProjectDocumento12 pagineSnort Projectsubhendu0% (1)

- Spray Nozzle Flow Rate CalculatorDocumento10 pagineSpray Nozzle Flow Rate CalculatorRavindra VasudevaNessuna valutazione finora

- Zeroing RobotDocumento44 pagineZeroing RobotArno BothaNessuna valutazione finora

- Hydro Generator CoolingDocumento4 pagineHydro Generator CoolingHamedJamshidiNessuna valutazione finora

- 6 Data Storage and QueryingDocumento58 pagine6 Data Storage and Queryingfdghj100% (1)

- Unit Plan: Economics Educated: Submitted By: Nancy Vargas-CisnerosDocumento4 pagineUnit Plan: Economics Educated: Submitted By: Nancy Vargas-CisnerosNancy VargasNessuna valutazione finora

- Oops-Program 10-MduDocumento6 pagineOops-Program 10-MduAtul MalhotraNessuna valutazione finora

- SEO For Growth: The Ultimate Guide For Marketers, Web Designers & EntrepreneursDocumento7 pagineSEO For Growth: The Ultimate Guide For Marketers, Web Designers & EntrepreneursJoyce M LaurenNessuna valutazione finora