Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Snells Law

Caricato da

satishchidrewarCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Snells Law

Caricato da

satishchidrewarCopyright:

Formati disponibili

ULTRASONIC TESTING - PRACTICAL LEVEL II A. KNOWLEDGE ABOUT TEST PARAMETERS 1. 2. 3. 4. 5.

Surface roughness effects on testing Couplant effects (at high temperature, at rough surface) Scanning speed Scanning directions Probe internal reflections and noise

B. EQUIPMENT PARAMETERS 1. 2. 3. 4. Horizontal linearity (Time base Linearity ) Vertical linearity (Amplitude linearity ) Warm-up and variation in response Dynamic range of equipment

C. NORMAL BEAM PROBE (SINGLE CRYSTAL) a. Probe characteristics 1. Resolution 2. Sensitivity 3. Dead zone 4. Penetration power (Probe and equipment combination) b. Probe calibration 1. Using IIW -VI calibration block 2. Using IIW-- V2 calibration block 3. Using Step wedge calibration block 4. DAC construction using "flat bottom hole (FBH) "block c. Testing 1. Plate lamination testing 2. Part penetration T - Joint, un-fused width (Land) measurement 3. Full penetration T- Joint, confirmation of full fusion d. Evaluation of findings i. True indication 1. Indication size, 2. depth, 3. length ( 6 dB /20 dB drop methods)and 4. type ii. False indication

Prepared by C.S.

Page 1 of 3

UT-PRACT-REV01 (06-01-2008)

D. NORMAL BEAM PROBE (TWIN CRYSTAL) a. Probe characteristics 1. Resolution 2. Sensitivity 3. Penetration power (Probe and equipment combination) b. Probe calibration 1. Using IIW -Vi calibration block 2. Using IIW- V2 calibration block 3. Using Step wedge calibration block c. Testing 1. Plate lamination testing 2. Partial penetration T - Joint, un-fused width (Land) measurement 3. Full penetration T- Joint, confirmation of full fusion d. Evaluation of findings i. True indication 1. Indication size, (6 dB /20 dB drop methods) 2. depth, 3. length and 4. type ii. False indication 5. Acceptance I rejection of indication as per given standard I acceptance norms 6. Report preparation E. ANGLE BEAM PROBE (SINGLE CRYSTAL) a. Probe characteristics 1. Resolution (Using resolution block or IOW block) 2. Sensitivity 3. Probe index (Beam exit point) 4. Probe angle 5. Beam plotting (Using IOW block) 6. Probe "squint" 7. Near field 8. Beam spread b. Probe calibration 1. Using IIW V1 (Type A) calibration block 2. Using IIW -Vi (Type B ) calibration block 3. Using IIW -V2 calibration block 4. DAC Construction I. using "Side drilled hole" (SDH) II. using "Flat bottom Hole" (FBH) III. using "Notch Block" Prepared by C.S. Page 2 of 3

UT-PRACT-REV01 (06-01-2008)

c. Testing 1. Raw material testing i. Rolled product - plate ii. Rolled product - shafts, bars iii. Forged Items iv. Casting items 2. Weld Testing 2.1 Pre requisite of weld testing i. Selection of probe angels ii. Skip distance calculation and marking in the specimen 2.2 Types of Welds Ultrasonic testing i. Butt welding ii. Fillet welding - partial penetration iii. Fillet welding - full penetration iv. T-K-Y Weld configuration d. Evaluation of findings i. True indication 1. Indication size, ( 6dB / 20dE drop methods) 2. depth, 3. length and 4. type ii. False indication e. Acceptance I rejection of indication as per given standard / acceptance norms f. Report preparation Prepared by C.S. Page 3 of 3 UT-PRACT-REV01 (06-01-2008)

A. KNOWLEDGE ABOUT TEST PARAMETERS 1. Surface roughness effects on testing Surface Finish. The finish on the scanning surfaces of the block shall be representative of the scanning surface finishes on the component to be examined. 2. Couplant effects (at high temperature, at rough surface) The coupling medium should be selected so that its viscosity is appropriate for the surface finish of the material to be examined. The following list is presented as a guide: Roughness Average (Ra in.) 5 to 100 50 to 200 80 to 600 100 to 400 Equivalent Couplant Viscosity SAE 10 wt. motor oil SAE 20 wt. motor oil glycerin SAE 30 wt. motor oil Equivalent Couplant Viscosity, Weight Motor Oil SAE 10 SAE 20 SAE 30 SAE 40 cup grease

Approximate Surface Roughness Average (Ra), in. [m] 5100 [0.12.5] 50200 [1.35.1] 100400 [2.510.2] 250700 [6.417.8] Over 700 [18]

At elevated temperatures as conditions warrant, heat-resistant coupling materials such as silicone oils, gels, or greases should be used. Further, intermittent contact of the search unit with the surface or auxiliary cooling of the search unit may be necessary to avoid temperature changes that affect the ultrasonic wave characteristics of the search unit. At higher temperatures, certain couplants based on inorganic salts or thermoplastic organic materials, high-temperature delay materials, and search units that are not damaged by high temperatures may be required.

3. Scanning speed Maximum speed 150 mm /second when doing manually 4. Scanning directions Normal probe Either full area scanning or grid scanning Angle probe Generally two opposite direction with swiveling at least 20 per side and as also per the requirement 5. Probe internal reflections and noise

Typical Display Response for Determination of Sensitivity and noise B. EQUIPMENT PARAMETERS 1. 2. 3. 4. Horizontal linearity (Time base Linearity ) Vertical linearity (Amplitude Linearity ) Warm-up and variation in response Dynamic range of equipment

Calibration of UT Equipment Equipment Probe Calibration block : NB, 10mm, 4MHz : IIW V1 Block

Horizontal Linearity A measure of proportionality of the signals appearing on the time or distance axis of the display and the input signals to the receiver from a calibrated time generator or from multiple echoes from a plate of material of known thickness 1. Set the equipment range to 125mm (or 250mm) only. (5 or 10 Back wall echoes only) 2. Place the Normal probe on 25mm thickness of V1 Block. 3. Adjust the 1st and 4th back wall echo only to set the required range and the BW echoes will fall on 2nd and 8th division. 4. Check the calibration with other known dimension. (Say 100mm width of the V1 Block should fall at 8th division 5. See that all other BW echoes 2nd, 3rd and 5th falling at exactly 4th, 6th and 10th division. (Place the probe on 25mm thickness of V1 Block) 6. Care should be taken while recording such that echoes should have same height (Amplitudes). Tolerance: 1% of Full screen distance or Less than half division.

Vertical Linearity

A measure of proportionality of the amplitude of the signal input to the receiver and the amplitude of the signal appearing on the display of the ultrasonic equipment or on an auxiliary display 1. Use the above calibration and place the probe on 25mm thickness of V1 Block 2. Set the 1st BW echo to 80 of the Full Screen Height (FSH) 3. Record equipment gain in dB 4. Take care the 1st BW echo should not fall within the Near Field. 5. Record all (5echoes) BW echoes amplitude. 6. Reduce 6dB and record the amplitudes. 7. It should be half of the initial amplitude. Tolerance: 5% of Full screen distance. A. NORMAL BEAM PROBE (SINGLE CRYSTAL) a. Probe characteristics 1. Resolution 2. Sensitivity 3. Dead zone 4. Penetration power (Probe and equipment combination)

Sensitivity A measure of the smallest ultrasonic signal which will produce a discernible indication on the display of an ultrasonic system. 1. Use the above calibration with a range of 125 mm and place the probe on 100mm width of V1 Block such that it pick up 1.5mm Side Drill Hole (SDH).

2. Move the probe back and forth to get the maximized amplitude from the SDH 3. Theoretically the least discontinuity size pick up by the probe is half wave length.

Resolution The ability of ultrasonic equipment to give simultaneous, separate indications from discontinuities having nearly the same range and lateral position with respect to the beam axis. 1. Use the above calibration and place the probe on 100mm width of V1 Block such that it picks up 85mm 91mm and 100mm distances.

2. Move the probe back and forth to get the maximized amplitude from the distances. 3. If all BW echoes distinguish and clearly visible the resolution said to be good otherwise its poor.

Dead zone The distance in the material from the surface of the test object to the depth at which a reflector can first be resolved under specified conditions. It is determined by the characteristics of the search unit, the ultrasonic test instrumentation, and the test object. 1. Use the above calibration and place the probe on the step wedge

2. Which least step gives clear BW echo is dead zone 3. Otherwise use 5mm and10 mm metal distances of V1 block and determine. 4. The width of the initial pulse within which discontinuity indications cannot be seen is the size of the dead zone.

Penetrating Power This term is used in BS 4331 To compare the energy output for a particular equipment and probe with the past performance or with similar equipments PLACE LONG ITUDINAL PROBE ON PERPEX INSERT OF IIW BLOCK GAIN OF THE INSTRUMENTS IS SET TO MAXIMUM NOTE THE NUMBER OF MULTIPLE ECHOES AND THE AMPLITUDE OF LAST ECHO WHICH EXPRESS THE MAXIMUM PENETRATION POWER OF THE EQUIPMENT AND PROBE

1. Use the above calibration and place the probe on Perspex thickness.

2. Set the gain to maximum. 3. Use delay and shift the BW echoes and find how many echoes in the screen preferably 5 BW echoes. 4. Record the amplitude of the last echo. 5. With the same setup we can check the UT equipment gain at the maximum at regular intervals.

b. Probe calibration 1. Using IIW -VI calibration block

2. Using IIW-- V2 calibration block 3. Using Step wedge calibration block Step wedge is used for calibration of TR Probe and it can be used to ascertain dead zone 4. DAC construction using "flat bottom hole (FBH) "block

c. Testing 1. Plate lamination testing Part penetration T - Joint, un-fused width (Land) measurement Full penetration T- Joint, confirmation of full fusion

d. Evaluation of findings i. True indication 1. Indication size, 2. depth, 3. length ( 6 dB /20 dB drop methods)and 4. type ii. False indication B. NORMAL BEAM PROBE (TWIN CRYSTAL) a. Probe characteristics 1. Resolution 2. Sensitivity 3. Penetration power (Probe and equipment combination) b. Probe calibration 1. Using IIW -Vi calibration block 2. Using IIW- V2 calibration block 3. Using Step wedge calibration block c. Testing 1. Plate lamination testing 2. Partial penetration T - Joint, un-fused width (Land) measurement 3. Full penetration T- Joint, confirmation of full fusion d. Evaluation of findings i. True indication 1. Indication size, (6 dB /20 dB drop methods) 2. depth, 3. length and 4. type

ii. False indication 5. Acceptance I rejection of indication as per given standard I acceptance norms 6. Report preparation E. ANGLE BEAM PROBE (SINGLE CRYSTAL) angle beam shear waves, where incident angles in wedges produce only refracted shear waves in the material under examination are generally termed angle beam examinations. a. Probe characteristics 1. Resolution (Using resolution block or IOW block) 2. Sensitivity 3. Probe index (Beam exit point) 4. Probe angle 5. Beam plotting (Using IOW block) 6. Probe "squint" 7. Near field 8. Beam spread

b. Probe calibration 1. Using IIW V1 (Type A) calibration block

Using IIW -Vi (Type B ) calibration block 3. Using IIW -V2 calibration block

4. DAC Construction I. using "Side drilled hole" (SDH)

II. using "Flat bottom Hole" (FBH) III. using "Notch Block" c. Testing 1. Raw material testing i. Rolled product plate Normal beam testing, Where ever necessary angle beam testing ii. Rolled product - shafts, bars Normal beam testing, iii. Forged Items Normal beam testing iv. Casting items Normal beam testing 2. Weld Testing 2.1 Pre requisite of weld testing

i. Selection of probe angels ii. Skip distance calculation and marking in the specimen 2.2 Types of Welds Ultrasonic testing i. Butt welding ii. Fillet welding - partial penetration iii. Fillet welding - full penetration d. Evaluation of findings i. True indication 1. Indication size, ( 6dB / 20dE drop methods) 2. depth, 3. length and 4. type ii. False indication Periodic Examination Checks. A calibration check on at least one of the basic reflectors in the basic calibration block or a check using a simulator shall be made at the finish of each examination or series of similar examinations, every 4 hr during the examination, and when examination personnel (except for automated equipment) are changed. The distance range points and sensitivity setting(s) recorded shall satisfy the requirements e. Acceptance I rejection of indication as per given standard / acceptance norms f. Report preparation

Where: VL1 is the longitudinal wave velocity in material 1. VL2 is the longitudinal wave velocity in material 2. VS1 is the shear wave velocity in material 1. VS2 is the shear wave velocity in material 2.

Mode conversion occurs every time a wave encounters an interface at an angle

FIG. 2 Technique 1, for Examining Butt Welds with Angle Beams

FIG. 3 Supplementary Technique 2, for Examining Butt Welds for Suspected Cross-Cracking when the Weld Bead is Ground Flush

FIG. 4 Supplementary Technique 3, for Examining Butt Welds for Suspected Cross-Cracking when the Weld Bead is not Ground Flush

FIG. 5 Two-Search-Unit Technique 4, for Use with Thick Weldments

FIG. 6 Technique 5, for Examining the Weld Volume of T-Welds

FIG. 7 Technique 6, for Examining the Fusion Zone of T-Welds

8(a) Technique 7, for Searching T-Welds for Discontinuities

FIG. 8 (b) Alternative Technique 7, for Searching T-Welds for Discontinuities

FIG. 9 Technique 8, for Examining the Weld Volume of DoubleVee Corner Welds

FIG. 10 Technique 9, for Examining the Fusion Zone of Double-

Vee Corner Welds FIG. 11 Techniques 10 and 11, for Examining Full-Penetration Double-Fillet Corner Welds

BASIC CALIBRATION BLOCK

Probe Movement Lateral movement To measure the length of the discontinuity Orbital movement To identify nature of the discontinuity Swivel movement To cover additional volume with angle probe Transverse movement To give information of size and location of the discontinuity Techniques Pulse echo technique Through Transmission technique Resonance technique

Normal Probe calibration Using IIW V1 calibration block Equipment detail Probe detail Normal Probe Range Calibration with V1 block 1. Select and set required Range. 2. Select appropriate mode (single crystal/Double crystal) 3. Select appropriate sound wave velocity in the Material (otherwise exact sound wave velocity in the Material will be established during calibration). 4. Set appropriate gain on the instrument. 5. Adjust the initial pulse to position zero with artificial zero control. 6. Place the probe on the Calibration block with adequate couplant 7. Maintain the distance between the back wall echoes with velocity control. 8. See that all back wall echoes falls with equal division (gap) and as per calculation if not fine tune velocity. 9. Adjust zero control to position the first BW echo appropriately. Calibration is completed. 10. Check the calibration with other known metal distance/dimension. No. Main scale division = Distance 10 ---------------------Range

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Fiber Optic Trainer/ Fiber & OSP TechnicianDocumento7 pagineFiber Optic Trainer/ Fiber & OSP Technicianapi-78570706Nessuna valutazione finora

- CLS 747 200Documento158 pagineCLS 747 200Rodrigo Adam100% (8)

- Deep Web Research and Discovery Resources 2019 by Marcus P. Zillman, M.S., A.M.H.A.Documento67 pagineDeep Web Research and Discovery Resources 2019 by Marcus P. Zillman, M.S., A.M.H.A.Tina CleoNessuna valutazione finora

- Production of Isopropyl Palmitate-Experimental StudiesDocumento12 pagineProduction of Isopropyl Palmitate-Experimental Studiesikaw_3Nessuna valutazione finora

- Rigaku Progeny Spec Sheet LTR 3.14Documento2 pagineRigaku Progeny Spec Sheet LTR 3.14DATA24Nessuna valutazione finora

- Distributed PowerDocumento3 pagineDistributed PowertibvalNessuna valutazione finora

- VXN150 Vixion Fuel Tank PDFDocumento3 pagineVXN150 Vixion Fuel Tank PDFHarris Jum'aniandaNessuna valutazione finora

- Oracle Jrockit Mission Control Lab GuideDocumento17 pagineOracle Jrockit Mission Control Lab GuideashuhegdeNessuna valutazione finora

- 03-1 Synchronous Machines 1 DNDocumento25 pagine03-1 Synchronous Machines 1 DNsaif thuraonNessuna valutazione finora

- Softening N Penetration Test BitumenDocumento11 pagineSoftening N Penetration Test BitumenEdwin LeonNessuna valutazione finora

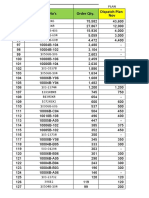

- Order Qty Vs Dispatch Plan - 04 11 20Documento13 pagineOrder Qty Vs Dispatch Plan - 04 11 20NPD1 JAKAPNessuna valutazione finora

- IEM PI A401 - ANNEXE - Design & Site ExperienceDocumento5 pagineIEM PI A401 - ANNEXE - Design & Site ExperienceapiplajengilaNessuna valutazione finora

- AI in RobotsDocumento75 pagineAI in RobotsIslam SehsahNessuna valutazione finora

- 4 Rec. ITU-R BS.775-3: Reference Loudspeaker Arrangement With Loudspeakers L/C/R and LS/RSDocumento3 pagine4 Rec. ITU-R BS.775-3: Reference Loudspeaker Arrangement With Loudspeakers L/C/R and LS/RSPaulo PiresNessuna valutazione finora

- Ecc Mech Sharq 22 016 Rev 01Documento6 pagineEcc Mech Sharq 22 016 Rev 01Muthu SaravananNessuna valutazione finora

- 1998-10 The Computer Paper - Ontario EditionDocumento156 pagine1998-10 The Computer Paper - Ontario Editionthecomputerpaper100% (1)

- Creating REST API Using NodeJS and Consuming in AngularJSDocumento8 pagineCreating REST API Using NodeJS and Consuming in AngularJSserignemodouNessuna valutazione finora

- Computer Networking: A Top-Down Approach Featuring The InternetDocumento27 pagineComputer Networking: A Top-Down Approach Featuring The InternetmssacNessuna valutazione finora

- EMOC 208 Installation of VITT For N2 Cylinder FillingDocumento12 pagineEMOC 208 Installation of VITT For N2 Cylinder Fillingtejcd1234Nessuna valutazione finora

- Air-Bag: (1) Connector InformationDocumento34 pagineAir-Bag: (1) Connector InformationbakriramziNessuna valutazione finora

- DT NotesDocumento117 pagineDT NotestessNessuna valutazione finora

- Session 5 PDFDocumento26 pagineSession 5 PDFToufic HageNessuna valutazione finora

- UMTS AircomDocumento20 pagineUMTS AircomDũng PhạmNessuna valutazione finora

- Justine J. Beroy: Career ObjectivesDocumento5 pagineJustine J. Beroy: Career ObjectivesJustine BeroyNessuna valutazione finora

- Measurement Advisory Committee Summary - Attachment 3Documento70 pagineMeasurement Advisory Committee Summary - Attachment 3MauricioICQNessuna valutazione finora

- 27C ChainDocumento19 pagine27C ChainyanaziNessuna valutazione finora

- The Difference Between The Internet and World Wide WebDocumento3 pagineThe Difference Between The Internet and World Wide WebSonal Jain100% (1)

- PACSystemsRX3i CS GFA559G (2010)Documento4 paginePACSystemsRX3i CS GFA559G (2010)Omar Alfredo Del CastilloNessuna valutazione finora

- PBLauncherDocumento50 paginePBLauncherborreveroNessuna valutazione finora

- Determination of The Solubility Product Constant of Silver AcetateDocumento8 pagineDetermination of The Solubility Product Constant of Silver AcetateSara Al AzemNessuna valutazione finora