Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pukor 11-049e Priced Gsec Pdvsa Gas-Mega-Project 11058a-In-12 (P)

Caricato da

avaisharmaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pukor 11-049e Priced Gsec Pdvsa Gas-Mega-Project 11058a-In-12 (P)

Caricato da

avaisharmaCopyright:

Formati disponibili

ENSIVAL MORET ASIA

31 Mandai Estate, #07-07 Innovation Place, Tower 4, Immedia, Singapore 729933 Tel : (65)-6281 0667, (65)-6281 9180 Fax: (65)-6281 0908 E-mail : moret@pacific.net.sg Web Site Add. : www.em-pumps.com

Date: Our Ref:

June 7, 2011 Our Offer No. : PUKOR 11-049 E

BUDGET PRICED PROPOSAL

Address : GS E&C

Attn : Tel No. : Fax No. : E-MAIL:

Dear Sirs,

??? ysji@gsconst.co.kr ???

RE :

Project : PDVSA Gas Mega Project (Bidding) / V Fractionation Train At Jose RFQ. No. : 11058A-IN-12(P) Our Offer No. : PUKOR 11-049 E We thank you for your inquiry on the above subject reference and we are pleased to enclose herewith our Priced Proposal. Please find the following document in each set of proposal. - Priced Proposal - Pump Performance Curves Trust the above is in order and meet your requirement. Please feel free to contact us if you have any clarification and we hereby looking forward to your favorable reply, we remain. Yours faithfully,

ENSIVAL MORET ASIA

ENSIVAL MORET ASIA

31 Mandai Estate, #07-07 Innovation Place, Tower 4, Immedia, Singapore 729933 Tel : (65)-6281 0667, (65)-6281 9180 Fax: (65)-6281 0908 E-mail : moret@pacific.net.sg Web Site Add. : www.em-pumps.com

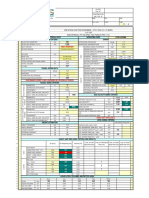

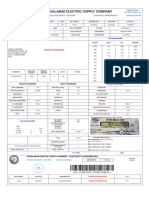

QUOTATION SUMMARY TABLE

To : Attn : Fax : GS E&C ??? ysji@gsconst.co.kr ??? Project : PDVSA Gas Mega Project (Bidding) / V Fractionation Train At Jose RFQ. No. : 11058A-IN-12(P) Our Offer No. : PUKOR 11-049 E Date : 07-Jun-2011 Material certificates 3.1 (Casing, Impeller and shaft) NDE (Liquid penetrant test for pressure parts) Witnessed Pump Perf. Test (Q,H,P & Eff) Unit Price (EURO) Bare Shaft Pump Item No. Model Qty Motor Base-Plate & Coupling Witnessed mechanical running test (4 hrs) Sub-total (Per Set) Total Price (with test and certificates)

Witnessed NPSH Test

Witnessed Hydro. Test

1 2 3 4 5 6 7 8 9 10 11 12 13

D3.22.0408/09 D3.23.1105/06 D3.23.1109 D3.23.1110/11 D3.23.1107/08 D3.23.3503/04/05 D3-23-5101/02 D3.22.3301/02 D3.23.3305/06 D3.22.0401/02 D3.22.0406/07 D3.22.0404/05 D3.22.0501/02

PRE 40-26 300 VEC 305-35-3 PRE 100-20 250 VEC 270-45-1 PRE 25-16 250 VE 270-31-2-IN MNVC 104 B -IN PRE 25-16 PRE 25-16A MNVC 120-IN PRE 40-32 PRE 40-32

NO QUOTE

2 2 1 2 2 3 2 2 2 2 2 2 0

54,595 170,031 26,135 128,695 37,430 127,028 85,319 52,744 52,744 202,930 30,184 30,184 7,022

5,388 227,778 11,747 26,961 2,564 153,175 6,296 1,888 1,666 20,440 6,083 6,083 0

Included Included Included Included Included Included Included Included Included Included Included Included Included

(EURO) 59,983 397,809 37,882 155,656 39,994 280,203 91,615 54,632 54,410 223,370 36,267 36,267 7,022

(EURO) 950 1,800 950 950 950 1,200 950 950 950 950 950 950 950

(EURO) 200 250 200 250 200 250 250 200 200 250 200 200 200

(EURO) NA NA NA NA NA 500 NA NA NA NA NA NA NA

(EURO) 1,350 6,250 2,200 4,150 1,350 4,150 1,350 1,350 1,350 2,200 1,350 1,350 0

(EURO) 360 360 360 360 360 360 360 360 360 360 360 360 360

(EURO) 900 900 900 900 900 900 900 900 900 900 900 900 900

(EURO) 500 500 500 500 500 500 500 500 500 500 500 500 500 EUR

PMI (Positive Material Identification)

(EURO) 128,486 815,738 42,992 325,532 88,508 864,189 191,850 117,784 117,340 457,060 81,054 81,054 0 15,246

Extra-Prices (on complete package) --->

Total Quantity of Pumps : 24

Commissioning spare parts (Detail refer to separate page enclosed in our quotation)

Grand Total (EUR) :

3,326,833

OPTION Prices --->

Thrid Party Inspection = "TPI" (LLOYD'S, SGS, Bureau Veritas, AIB Vincotte, ...) Thrid Party Inspection = "TPI" (LLOYD'S, SGS, Bureau Veritas, AIB Vincotte, ...)

per HALF DAY per COMPLETE DAY

EUR EUR

1,332 2,172

PUKOR 11-049E_GSEC_PDVSA_Gas-Mega-Project_11058A-IN-12(P)

6/7/2011

ENSIVAL MORET ASIA

31 Mandai Estate, #07-07 Innovation Place, Tower 4, Immedia, Singapore 729933 Tel : (65)-6281 0667, (65)-6281 9180 Fax: (65)-6281 0908 E-mail : moret@pacific.net.sg Web Site Add. : www.em-pumps.com

SPARE PARTS QUOTATION

To : GS E&C ysji@gsconst.co.kr Fax : ??? Project : PDVSA Gas Mega Project (Bidding) / V Fractionation Train At Jose RFQ. No. : 11058A-IN-12(P) Our Offer No. : PUKOR 11-049 E Date : 07-Jun-2011

Attn : ???

Erection, Pre-Commissioning, Commissioning & Start-Up Spare Parts (Unit prices in EUR) (Prices are only valid in case of global order with pumps)

Qty of pumps

S/No.

Pump

Set of Gasket & ORings for pump

Item

Qty 1 2 3 4 5 6 7 8 9 10 11 12 D3.22.0408/09 D3.23.1105/06 D3.23.1109 D3.23.1110/11 D3.23.1107/08 D3.23.3503/04/05 D3-23-5101/02 D3.22.3301/02 D3.23.3305/06 D3.22.0401/02 D3.22.0406/07 D3.22.0404/05 PRE 40-26 300 VEC 305-35-3 PRE 100-20 250 VEC 270-45-1 PRE 25-16 250 VE 270-31-2-IN MNVC 104 B -IN PRE 25-16 PRE 25-16A MNVC 120-IN PRE 40-32 PRE 40-32 2 2 1 2 2 3 2 2 2 2 2 2 2 2 1 2 2 3 2 2 2 2 2 2

Unit Total Price Price 290 580 1,222 2,444 270 270 618 1,236 230 460 804 2,412 902 1,804 230 460 230 460 1,880 3,760 340 680 340 680 15,246 Grand Total Price : 15,246

PUKOR 11-049E_GSEC_PDVSA_Gas-Mega-Project_11058A-IN-12(P)

6/7/2011

ENSIVAL MORET ASIA

31 Mandai Estate, #07-07 Innovation Place, Tower 4, Immedia, Singapore 729933 Tel : (65)-6281 0667, (65)-6281 9180 Fax: (65)-6281 0908 E-mail : moret@pacific.net.sg Web Site Add. : www.em-pumps.com

QUOTATION SUMMARY TABLE - NOISE of each MOTOR-PUMP UNIT

To : GS E&C ysji@gsconst.co.kr Fax : ???

// Customer request : MAX

85 dB(A)

Project : PDVSA Gas Mega Project (Bidding) / V Fractionation Train At Jose RFQ. No. : 11058A-IN-12(P) Our Offer No. : PUKOR 11-049 E Date : 07-Jun-2011 NOISE of each component Motor speed Pump rpm 3,600 1,800 3,600 1,200 3,600 1,800 3,600 3,600 3,600 3,600 3,600 3,600 dB(A) 75.6 82.0 81.5 78.7 71.7 82.0 75.8 69.1 67.1 82.0 73.0 73.3 Electric motor dB(A) 77.0 82.0 81.0 78.0 75.0 82.0 77.0 73.0 72.0 82.0 77.0 77.0 Steam turbine dB(A) NA NA NA NA NA NA NA NA NA NA NA NA Reducer dB(A) NA NA NA NA NA NA NA NA NA NA NA NA dB(A) 79.4 85.0 84.3 81.4 76.7 85.0 79.5 74.5 73.2 85.0 78.5 78.5 GLOBAL UNIT NOISE @ 1m (calculated)

Attn : ???

Item No.

Model

Qty

Motor Power kw

1 2 3 4 5 6 7 8 9 10 11 12

D3.22.0408/09 D3.23.1105/06 D3.23.1109 D3.23.1110/11 D3.23.1107/08 D3.23.3503/04/05 D3-23-5101/02 D3.22.3301/02 D3.23.3305/06 D3.22.0401/02 D3.22.0406/07 D3.22.0404/05

PRE 40-26 300 VEC 305-35-3 PRE 100-20 250 VEC 270-45-1 PRE 25-16 250 VE 270-31-2-IN MNVC 104 B -IN PRE 25-16 PRE 25-16A MNVC 120-IN PRE 40-32 PRE 40-32

2 2 1 2 2 3 2 2 2 2 2 2

21.0 700.0 63.0 125.0 8.6 260.0 25.0 4.6 3.5 125.0 25.0 25.0

Total Quantity of Pumps : 24

PUKOR 11-049E_GSEC_PDVSA_Gas-Mega-Project_11058A-IN-12(P)

6/7/2011

ENSIVAL MORET ASIA

31 Mandai Estate, #07-07 Innovation Place, Tower 4, Immedia, Singapore 729933 Tel : (65)-6281 0667, (65)-6281 9180 Fax: (65)-6281 0908 E-mail : moret@pacific.net.sg Web Site Add. : www.em-pumps.com

PERFORMANCE SUMMARY TABLE

To : GS E&C ysji@gsconst.co.kr Fax : ??? Project : PDVSA Gas Mega Project (Bidding) / V Fractionation Train At Jose RFQ. No. : 11058A-IN-12(P) Our Offer No. : PUKOR 11-049 E Date : 07-Jun-2011 Preferred Operating Region (m3/h) -------------------> MIN FLOW 110 % Rated Allowable Operating Region (m3/h) -------------------> MIN FLOW 120 % BEP of BEP flow Attn : ???

Rated Capacity / BEP Capacity = .. % < Rated Capa. < 40 % 110 %

< 12760

120 %

> 0.5

Shut Off Head Ratio (shut-off / Rated Head)

NPSHr @ 120 % of BEP flow (m3/h)

NPSHr @ impeller axis / rated flow

Flow at BEP at rated imp. (m3/h)

NPSHa @ impeller axis

Rated Capacity (m3/h)

@ rated

NPSHa - NPSHr @ 120.0 % of BEP flow

Shut Off Head (m)

Rated Head (m)

< Ratio <

in m3/hr.m.rpm

Item No.

Model

S/No.

Speed

Qty

120 %

> 0.0

Remarks

NPSHa - NPSHr = (m) flow 0.60 36.00 4.10 50.40 29.70 -1.50 1.23 2.20 2.60 2.60 1.60 1.60

1 2 3 4 5 6 7 8 9 10 11 12

D3.22.0408/09 D3.23.1105/06 D3.23.1109 D3.23.1110/11 D3.23.1107/08 D3.23.3503/04/05 D3-23-5101/02 D3.22.3301/02 D3.23.3305/06 D3.22.0401/02 D3.22.0406/07 D3.22.0404/05

PRE 40-26 300 VEC 305-35-3 PRE 100-20 250 VEC 270-45-1 PRE 25-16 250 VE 270-31-2-IN MNVC 104 B -IN PRE 25-16 PRE 25-16A MNVC 120-IN PRE 40-32 PRE 40-32

2 2 1 2 2 3 2 2 2 2 2 2

3580 1780 3580 1180 3580 1780 3580 3580 3580 3580 3580 3580

36.3 34.0 1613.0 1,900.0 204.4 220.0 806.5 780.0 17.9 19.0 1271.0 1,360.0 10.0 24.0 16.5 16.5 10.0 15.0 36.3 48.0 6.4 12.0 6.4 12.0

107% 85% 93% 103% 94% 93% 42% 100% 67% 76% 53% 53%

10 600 60 280 6 400 8 6 5 12 6 6

40 1,774 225 887 20 1,398 11 18 11 40 7 7

10 600 60 280 6 400 8 6 5 12 6 6

41 2,280 264 936 23 1,632 29 20 18 58 14 14

86.9 114.0 58.8 32.3 37.6 55.4 169.2 28.8 30.0 992.4 145.5 152.0

103.0 190.0 69.0 44.0 45.0 96.0 171.0 36.0 33.5 1,160.0 155.0 160.0

119%

167%

117%

136%

120%

173% 101% 125%

112% 117%

107% 105%

7182 12427 9462 12019 8186 10904 8716 8913 7416 8860 7956 7956

NSS

4.00 47.00 11.00 54.30 31.50 4.00 2.83 4.00 4.00 4.00 4.00 4.00

3.40 11.00 6.90 3.90 1.80 5.50 1.60 1.80 1.40 1.40 2.40 2.40

40.8 2280.0 264.0 936.0 22.8 1632.0 28.8 19.8 18.0 57.6 14.4 14.4

FLOW @

110 %

4.00 13.00 10.80 4.20 2.60 9.00 2.00 2.00 2.00 3.40 2.40 2.40

0.00 34.00 0.20 50.10 28.90 -5.00 0.83 2.00 2.00 0.60 1.60 1.60

With Inducer NPSH problem @ end of curve With Inducer

NPSH test to be performed - (*1)

With Inducer With Orifice With Orifice

(*1) NPSH test is not possible to be performed on pump type VS1, VS4 and VS5 NS = Not Specified / Not Stated

PUKOR 11-049E_GSEC_PDVSA_Gas-Mega-Project_11058A-IN-12(P)

Perf. Summary

6/7/2011

ENSIVAL MORET ASIA

31 Mandai Estate, #07-07 Innovation Place, Tower 4, Immedia, Singapore 729933 Tel : (65)-6281 0667, (65)-6281 9180 Fax: (65)-6281 0908 E-mail : moret@pacific.net.sg Web Site Add. : www.em-pumps.com

PRESSURE SUMMARY TABLE

To : GS E&C ysji@gsconst.co.kr Fax : ??? Project : PDVSA Gas Mega Project (Bidding) / V Fractionation Train At Jose RFQ. No. : 11058A-IN-12(P) Our Offer No. : PUKOR 11-049 E Date : 07-Jun-2011 Derating factor (for Max design temperature and quoted MOC) Derating factor (for ambient temperature and quoted MOC) Attn : ???

(Bar G)

Maximum Discharge Pressure @ (Bar G) rated impeller

(Bar G)

(Bar G)

Pump MAWP - Maximum Allowable Working pressure (for (Bar G) quoted MOC) at ambient temperature

(Bar G) Pump Hydrostatic test (= 1.5 X MAWP) at ambient temperature

Requested pump mechanical design pressure (MAX) (Bar G) --> stated on customer datasheet NS NS NS NS NS NS NS NS NS NS NS NS

6/7/2011

Material of construction quoted

Rated Capacity (m3/h)

Shut Off Head (m)

MAWP @ ambient temperature for Material of construction = STEEL (A216 WCB)

Rated Head (m)

Specific Gravity

Pump MAWP - Maximum Allowable Working pressure (for quoted MOC)

Pump MECHANICAL design temperature

Item No.

Max. Suction Pressure

Model

S/No.

Speed

Qty

( C)

Remarks

1 2 3 4 5 6 7 8 9 10 11 12

D3.22.0408/09 D3.23.1105/06 D3.23.1109 D3.23.1110/11 D3.23.1107/08 D3.23.3503/04/05 D3-23-5101/02 D3.22.3301/02 D3.23.3305/06 D3.22.0401/02 D3.22.0406/07 D3.22.0404/05

PRE 40-26 300 VEC 305-35-3 PRE 100-20 250 VEC 270-45-1 PRE 25-16 250 VE 270-31-2-IN MNVC 104 B -IN PRE 25-16 PRE 25-16A MNVC 120-IN PRE 40-32 PRE 40-32

2 2 1 2 2 3 2 2 2 2 2 2

3580 1780 3580 1180 3580 1780 3580 3580 3580 3580 3580 3580

36.3 1613.0 204.4 806.5 17.9 1271.0 10.0 16.5 10.0 36.3 6.4 6.4

86.9 114.0 58.8 32.3 37.6 55.4 169.2 28.8 30.0 992.4 145.5 152.0

103.0 190.0 69.0 44.0 45.0 96.0 171.0 36.0 33.5 1,160.0 155.0 160.0

0.59 0.80 0.85 0.70 0.85 1.00 1.00 0.75 0.64 0.61 0.70 0.70

1.00 (TBA) 7.12 1.81 15.93 6.18 1.00 (TBA) 6.77 1.00 (TBA) 1.00 (TBA) 1.00 (TBA) 1.00 (TBA) 1.00 (TBA)

7.6 23.5 8.1 19.2 10.3 11.4 25.2 3.9 3.3 77.3 12.7 13.1

40.0 BarG 25.0 BarG 40.0 BarG 25.0 BarG 40.0 BarG 16.0 BarG 40.0 BarG 40.0 BarG 40.0 BarG 80.0 BarG 40.0 BarG 40.0 BarG

1 0.96 1 0.99 0.93 1 0.98 1 1 1 1 1

A-8 S-6 S-1 S-6 S-1 A-8 S-1 A-8 A-8 A-8 A-8 A-8

40.0 BarG 24.0 BarG 40.0 BarG 24.8 BarG 37.2 BarG 16.0 BarG 39.2 BarG 40.0 BarG 40.0 BarG 80.0 BarG 40.0 BarG 40.0 BarG

@ @ @ @ @ @ @ @ @ @ @ @ @

40 C 261 C 40 C 216 C 293 C 40 C 232 C 40 C 40 C 40 C 40 C 40 C

40.0 BarG 25.0 BarG 40.0 BarG 25.0 BarG 40.0 BarG 16.0 BarG 40.0 BarG 40.0 BarG 40.0 BarG 80.0 BarG 40.0 BarG 40.0 BarG

1 1 1 1 1 1 1 1 1 1 1 1

60.0 37.5 60.0 37.5 60.0 24.0 60.0 60.0 60.0 120.0 60.0 60.0

NS = Not Specified / Not Stated

PUKOR 11-049E_GSEC_PDVSA_Gas-Mega-Project_11058A-IN-12(P)

Pressure

ENSIVAL MORET ASIA

31 Mandai Estate, #07-07 Innovation Place, Tower 4, Immedia, Singapore 729933 Tel : (65)-6281 0667, (65)-6281 9180 Fax: (65)-6281 0908 E-mail : moret@pacific.net.sg Web Site Add. : www.em-pumps.com

SUMMARY OF ENSIVAL-MORET GROUP STANDARD PAINT SYSTEMS

To : Attn : Fax : GS E&C ??? ysji@gsconst.co.kr ??? Project : PDVSA Gas Mega Project (Bidding) / V Fractionation Train At Jos RFQ. No. : 11058A-IN-12(P) Our Offer No. : PUKOR 11-049 E Date : 07-Jun-2011

Ensival-Moret Painting System N

Location

External External "Thick" Submerged External Guards

Temperature

Up to 120C Up to 120C Water up to 120C Between 120 and 600C Ambient

1st coat

Cryltane AC Cryltane AC Cryltane AC Vibol Aluminium Cryltane AC Oxypaint HS UNIVERSAL

Color and thickness

RAL 5015 60 m RAL 7035 50 to 55 m RAL 5015 40 45 m Aluminium Finish 25 to 30 m RAL 1021 60 m

2nd coat

--Mixtane Polyguard -----

Color and Total thickness thickness

--RAL 5015 40 m Black 701 60 to 70 m ----Any RAL 80 m 60 m 90 to 95 m 100 to 115 m 25 to 30 m (1) 60 m (1) (1)

Remarks

P1 P2 P3 P4 P5

P6.1 External for aggressive medium Lower than 120C P6.2

Primer High Build Cryltane HS finish White-Grey Polyurethane 130 m finish Primer High Build White-Grey 130 m Mixtane Polyurethane finish (Shining)

210 m

(1)

Oxypaint HS UNIVERSAL

Any RAL 40 m

170 m

(1)

(1): Tolerances on these painting systems is 15% on the total thickness

Proposed painting system for each item

Item All the coupling guard D3.22.0408/09 D3.23.1105/06 D3.23.1109 D3.23.1110/11 D3.23.1107/08 D3.23.3503/04/05 D3-23-5101/02 D3.22.3301/02 D3.23.3305/06 D3.22.0401/02 D3.22.0406/07 D3.22.0404/05 Pump MOC A-8 S-6 S-1 S-6 S-1 A-8 S-1 A-8 A-8 A-8 A-8 A-8 Max liquid temperature (C) 40 21 25 21 67 40 32.2 40 40 40 40 40 Painting system proposed on pump Final Colour Remarks -

P5 Not painted P1 P1 P1 P1 Not painted P1 Not painted Not painted Not painted Not painted Not painted

RAL 1021 NA RAL 5015 RAL 5015 RAL 5015 RAL 5015 NA RAL 5015 NA NA NA NA NA

ENSIVAL MORET ASIA

31 Mandai Estate, #07-07 Innovation Place, Tower 4, Immedia, Singapore 729933 Tel : (65)-6281 0667, (65)-6281 9180 Fax: (65)-6281 0908 E-mail : moret@pacific.net.sg Web Site Add. : www.em-pumps.com

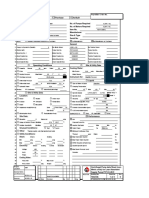

BURGMANN SEAL and SYSTEM SUMMARY TABLE

To : Attn : Fax : GS E&C ??? ysji@gsconst.co.kr ???

pump data quantity/supply systems pumpmanufacturer type

Project : PDVSA Gas Mega Project (Bidding) / V Fractionation Train At Jose RFQ. No. : 11058A-IN-12(P) Our Offer No. : PUKOR 11-049 E Date : 07-Jun-2011

service conditions BURGMANN Mechanical Seal and Supply System

Stuffing box pressure

viscosity @ pumping temperature

API 610 pump type

API 682 QUOTED Seal Configuration

DIN material code

pump shaft diam.

discharge press.

mechanical seal

specific gravity

min

norm

max

min

norm

max

min

norm

max

mm 1 2 3 4 5 6 7 8 9 10 11 12 13 D3.22.0408/09 D3.23.1105/06 D3.23.1109 D3.23.1110/11 D3.23.1107/08 D3.23.3503/04/05 D3-23-5101/02 D3.22.3301/02 D3.23.3305/06 D3.22.0401/02 D3.22.0406/07 D3.22.0404/05 D3.22.0501/02 2 2 1 2 2 3 2 2 2 2 2 2 0 2 2 0 2 2 0 0 2 2 2 0 0 0 PRE 40-26 300 VEC 305-35-3 PRE 100-20 250 VEC 270-45-1 PRE 25-16 250 VE 270-31-2-IN MNVC 104 B -IN PRE 25-16 PRE 25-16A MNVC 120-IN PRE 40-32 PRE 40-32 NO QUOTE OH2 VS6 OH2 VS6 OH2 VS1 VS6 OH2 OH2 VS6 OH2 OH2 OH2 40 85 40 65 40 85 45 40 40 45 50 50 0 0 0 0 0 0 0 0 0 0 0 0 0 0

rpm 3600 1800 3600 1200 3600 1800 3600 3600 3600 3600 3600 3600 720 HC (-) HOT OIL (-) HOT OIL (-) HOT OIL (-) HOT OIL (PUROLUB 32) WATER (-) CONDENSAT E (-) HC (-) HC (-) HC (-) HC (-) HC (-) HC (-) 0 0 0 0 0 0 0 0 0 0 0 0 0

C 40 21 25 21 67 40 32 40 40 40 40 40 0 40 145 40 145 293 40 167 40 40 40 40 40 0

bar a TBA 0.0 0.0 0.0 0.0 TBA 1.4 TBA TBA TBA TBA TBA 0.0

kg/m3 0.590 0.800 0.850 0.700 0.850 1.000 1.000 0.750 0.640 0.610 0.700 0.700 0.000

cP TBA 66.8 66.0 66.8 66.8 TBA 1.0 TBA TBA TBA TBA TBA 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0

bar g 1.0 3.7 0.9 3.7 2.5 1.0 1.6 1.0 1.0 1.0 1.0 1.0 0.0 1.0 7.1 1.8 15.9 6.2 1.0 6.8 1.0 1.0 1.0 1.0 1.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0

bar g 6.0 12.7 5.8 6.0 5.4 6.4 12.0 3.1 2.9 60.3 11.0 11.4 0.0 7.6 23.5 8.1 19.2 10.3 11.4 25.2 3.9 3.3 77.3 12.7 13.1 0.0

bar g 3.0 H75VK/..-PTA682X AQ2KMG-AQ2KMG AQ2KMG-AQ2KMG AQ2KMG AQ2KMG-AQ2KMG AQ2KMG-AQ2KMG AQ2VMG AQ2KMG AQ2KMG-AQ2KMG AQ2KMG-AQ2KMG AQ2KMG-AQ2KMG AQ2KMG AQ2KMG 0 BDPIN BDPIN BSTIN BDPIN BTAIN BSTFN BSTIN BDPIN BDPIN BDPIN BSTIN BSTIN 0 3CW-FB 3CW-FB 1CW-FX 3CW-FB 2CW-CS 1CW-FX 1CW-FX 3CW-FB 3CW-FB 3CW-FB 1CW-FX 1CW-FX 0 C2A3A C2A3A C2A1A C2A3A C2A2A C2A1A C2A1A C2A3A C2A3A C2A3A C2A1A C2A1A 0

Basic flush plan

Flush system Barrier system

23 11 23 23 11 13 11 11 0

53B 53A 61 53A

SPO9050/M250-D1 WE6045/A001-D0 15-TS6050/M53A-D0 0 WE6045/A001-D0 15-TS6050/M53A-D0 WE6045/A002-D1 0 0 SPO9050/M250-D1 SPO9050/M250-D1 SPO9050/M250-D1 0 0 0

12.7 H75VPK/...-PTA682X 2.9 6.0 4.5 6.4 H75VN/..-E682X H75VPK/...-PTA682X H75VK/..-CGSH682X H75VN/..-E682X

61 61 53B 53B 53B 61 61 0

12.0 H75VN/..-E682X 3.0 3.0 3.0 3.0 3.0 0.0 H75VK/..-PTA682X H75VK/..-PTA682X H75VK/..-PTA682X H75VN/..-E682X H75VN/..-E682X 0

supply system

suction press.

quantity/seals

vapour press.

Bearring size

temperature

API 610 QUOTED

API 682 QUOTED sealcode

medium

speed

Pos.

item

API-plan

ENSIVAL MORET ASIA

31 Mandai Estate, #07-07 Innovation Place, Tower 4, Immedia, Singapore 729933 Tel : (65)-6281 0667, (65)-6281 9180 Fax: (65)-6281 0908 E-mail : moret@pacific.net.sg Web Site Add. : www.em-pumps.com

QUOTATION

To : Attn : Fax : GS E&C ???

ysji@gsconst.co.kr

Project : PDVSA Gas Mega Project (Bidding) / V Fractionation Train At Jose RFQ. No. : 11058A-IN-12(P) Our Offer No. : PUKOR 11-049 E Date : 07-Jun-2011

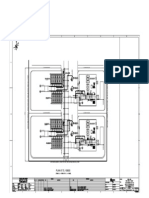

1 D3.22.0408/09 2 ENSIVAL MORET PRE 40-26 OH2 - Centerline-supported API 610 10th 3.00 '' 1.50 '' ANSI 300# RF -2 D3.23.1105/06 2 ENSIVAL MORET 300 VEC 305-35-3 VS6 - Vert., Double casing (CAN), Diffuser API 610 10th 20.00 '' 12.00 '' ANSI 300# RF 2000 3 D3.23.1109 1 ENSIVAL MORET PRE 100-20 OH2 - Centerline-supported API 610 10th 6.00 '' 4.00 '' ANSI 300# RF --

???

Description Position No. Quantity Required Make Pump Model Construction Design Code Suction Flange Size Discharge Flange Size Flanges Class (Suction / Discharge) Pump Length Criticality Rating Operating Data Product Other information on liquid (H2S, ) Temperature min Temperature MAX MAX Specific Gravity MAX Vapour Pressure MAX Vapour Pressure MAX Viscosity Rated Capacity Min. Flow Nom. Head @ Discharge flange Nom. Head @ Hydraulic Cell Nom. Speed Efficiency Impeller Size Duty (minimum) Impeller Size Duty (RATED) Impeller Size Duty (MAXIMUM) Impeller Type NPSH Available @ suction flange NPSH Available @ impeller axis NPSH Required @ impeller axis BHP at Duty BHP for SG = 1 (Water) Required Mechanical Design Pressure Required Mechanical Design temperature Material Code Casing Impeller Wear Ring(s) Shaft Shaft Sleeve Mechanical Seal/Packing Mech. Seal Material Code API Flushing Plan Coupling & Spacer End of curve power with d liquid Motor/Engine/Steam Turbine Type Model/Frame Size Rated Power @ 40C Speed Class/Protection Volt/Ph/Hz

" " mm

C o C kg/dm3 PSIA barA cP. m3/hr m3/hr m m rpm % mm mm mm m m m kw kw (Bar G) C

HC 40 40 0.59 TBA TBA

HOT OIL 21 145 0.8 0 0.00

HOT OIL 25 40 0.85 0 0.00

TBA

36.3 10 86.9 86.9 3580 45.53 200 220 260 CLOSED IMPELLER 4 4 3.4 11.1 18.9 NS 40 Degre C A-8 -

66.8

1613.0 600 114 114 1780 68.38 350 387 407 CLOSED IMPELLER 47 47 11 585.9 732.3 NS 261 Degre C S-6 -

66

204.4 60 58.8 58.8 3580 61.21 160 187 209 CLOSED IMPELLER 11 11 6.9 45.5 53.5 NS 40 Degre C S-1 -

Dual Cartridge Seal BDPIN / 3CW-FB / C2A3A-53B- / 53B / METASTREAM TSK-S 13.0 IEC TEFC 160 L 21 3600 Class 1, Group D, Div 2 --> ExnA IIT3 460 10% / 3 / 60 2%

Dual Cartridge Seal BDPIN / 3CW-FB / C2A3A2353A23 / 53A / METASTREAM TSK-S 605.0 IEC TEFC 500 L 700 1800 Class 1, Group D, Div 2 --> ExnA IIT3 4160 10% / 3 / 60 2%

Single Cartridge Seal BSTIN / 1CW-FX / C2A1A116111 / 61 / METASTREAM TSK-S 49.0 IEC TEFC 250 S 63 3600 Class 1, Group D, Div 2 --> ExnA IIT3 460 10% / 3 / 60 2%

kw rpm

Offer Price

Bareshaft pump Motor Baseplate & coupling Sub Total: Set(s)

EUR EUR EUR EUR EUR

Grand Total Testing Per Pump Unit

Witnessed Pump Perf. Test (Q,H,P & Eff) Witnessed Hydro. Test Witnessed NPSH Test Witnessed mechanical running test (4 hrs) Material certificates 3.1 (Casing, Impeller and shaft) NDE (Liquid penetrant test for pressure parts) PMI (Positive Material Identification)

54,595 5,388 Included 59,983 119,966 950 200 NA 1,350 360 900 500

170,031 227,778 Included 397,809 795,618 1,800 250 NA 6,250 360 900 500

26,135 11,747 Included 37,882 37,882 950 200 NA 2,200 360 900 500

6/7/2011

EUR EUR EUR EUR EUR EUR EUR

PUKOR 11-049E_GSEC_PDVSA_Gas-Mega-Project_11058A-IN-12(P)

ENSIVAL MORET ASIA

31 Mandai Estate, #07-07 Innovation Place, Tower 4, Immedia, Singapore 729933 Tel : (65)-6281 0667, (65)-6281 9180 Fax: (65)-6281 0908 E-mail : moret@pacific.net.sg Web Site Add. : www.em-pumps.com

QUOTATION

To : Attn : Fax : GS E&C ??? ysji@gsconst.co.kr ???

4 D3.23.1110/11 2 ENSIVAL MORET 250 VEC 270-45-1 VS6 - Vert., Double casing (CAN), Diffuser API 610 10th 20.00 '' 10.00 '' ANSI 300# RF 1000

Project : PDVSA Gas Mega Project (Bidding) / V Fractionation Train At Jose RFQ. No. : 11058A-IN-12(P) Our Offer No. : PUKOR 11-049 E Date : 07-Jun-2011

5 D3.23.1107/08 2 ENSIVAL MORET PRE 25-16 OH2 - Centerline-supported API 610 10th 2.00 '' 1.00 '' ANSI 300# RF -6 D3.23.3503/04/05 3 ENSIVAL MORET 250 VE 270-31-2-IN VS1 - Vertical, Single casing, diffuser API 610 10th 16.00 '' 10.00 '' ANSI 300# RF 3725 With Inducer HOT OIL 21 145 0.7 0 0.00 HOT OIL PUROLUB 32 67 293 0.85 0 0.00 WATER 40 40 1 TBA TBA

Description Position No. Quantity Required Make Pump Model Construction Design Code Suction Flange Size Discharge Flange Size Flanges Class (Suction / Discharge) Pump Length Criticality Rating Operating Data Product Other information on liquid (H2S, ) Temperature min Temperature MAX MAX Specific Gravity MAX Vapour Pressure MAX Vapour Pressure MAX Viscosity Rated Capacity Min. Flow Nom. Head @ Discharge flange Nom. Head @ Hydraulic Cell Nom. Speed Efficiency Impeller Size Duty (minimum) Impeller Size Duty (RATED) Impeller Size Duty (MAXIMUM) Impeller Type NPSH Available @ suction flange NPSH Available @ impeller axis NPSH Required @ impeller axis BHP at Duty BHP for SG = 1 (Water) Required Mechanical Design Pressure Required Mechanical Design temperature Material Code Casing Impeller Wear Ring(s) Shaft Shaft Sleeve Mechanical Seal/Packing Mech. Seal Material Code API Flushing Plan Coupling & Spacer End of curve power with d liquid Motor/Engine/Steam Turbine Type Model/Frame Size Rated Power @ 40C Speed Class/Protection Volt/Ph/Hz

" " mm

oC oC kg/dm3 PSIA barA cP. m3/hr m3/hr m m rpm % mm mm mm m m m kw kw (Bar G) C

66.8

806.5 280 32.3 32.3 1180 65.48 415 447 480 CLOSED IMPELLER 54.3 54.3 3.9 75.8 108.3 NS 216 Degre C S-6 -

66.8

17.9 6 37.6 37.6 3580 28.13 130 151 169 CLOSED IMPELLER 31.5 31.5 1.8 5.6 6.5 NS 293 Degre C S-1 -

TBA

1271.0 400 55.4 55.4 1780 81.34 310 338 360 CLOSED IMPELLER 4 4 5.5 235.7 235.7 NS 40 Degre C A-8 -

Dual Cartridge Seal BDPIN / 3CW-FB / C2A3A2353A23 / 53A / METASTREAM TSK-S 89.0 IEC TEFC 315 S 125 1200 Class 1, Group D, Div 2 --> ExnA IIT3 460 10% / 3 / 60 2%

Dual Cartridge Seal BTAIN / 2CW-CS / C2A2A2323 / / METASTREAM TSK-S 7.0 IEC TEFC 132 S 8.6 3600 Class 1, Group D, Div 2 --> ExnA IIT3 460 10% / 3 / 60 2%

Single Cartridge Seal BSTFN / 1CW-FX / C2A1A116111 / 61 / METASTREAM TSK-S 240.0 IEC TEFC 400 L 260 1800 Class 1, Group D, Div 2 --> ExnA IIT3 4160 10% / 3 / 60 2%

kw rpm

Offer Price

Bareshaft pump Motor Baseplate & coupling Sub Total: Set(s)

EUR EUR EUR EUR EUR

Grand Total Testing Per Pump Unit

Witnessed Pump Perf. Test (Q,H,P & Eff) Witnessed Hydro. Test Witnessed NPSH Test Witnessed mechanical running test (4 hrs) Material certificates 3.1 (Casing, Impeller and shaft) NDE (Liquid penetrant test for pressure parts) PMI (Positive Material Identification)

128,695 26,961 Included 155,656 311,312 950 250 NA 4,150 360 900 500

37,430 2,564 Included 39,994 79,988 950 200 NA 1,350 360 900 500

127,028 153,175 Included 280,203 840,609 1,200 250 500 4,150 360 900 500

6/7/2011

EUR EUR EUR EUR EUR EUR EUR

PUKOR 11-049E_GSEC_PDVSA_Gas-Mega-Project_11058A-IN-12(P)

ENSIVAL MORET ASIA

31 Mandai Estate, #07-07 Innovation Place, Tower 4, Immedia, Singapore 729933 Tel : (65)-6281 0667, (65)-6281 9180 Fax: (65)-6281 0908 E-mail : moret@pacific.net.sg Web Site Add. : www.em-pumps.com

QUOTATION

To : Attn : Fax : GS E&C ??? ysji@gsconst.co.kr ???

7 D3-23-5101/02 2 ENSIVAL MORET MNVC 104 B -IN VS6 - Vert., Double casing (CAN), Diffuser API 610 10th 4.00 '' 2.00 '' ANSI 300# RF 2000 With Inducer CONDENSATE 32.2 167 1 19.7 1.36 1 10.0 8 169.2 169.2 3580 36.75 147 148 164 CLOSED IMPELLER 1.83 2.83 1.6 12.5 12.5 NS 232 Degre C S-1 HC 40 40 0.75 TBA TBA HC 40 40 0.64 TBA TBA

Project : PDVSA Gas Mega Project (Bidding) / V Fractionation Train At Jose RFQ. No. : 11058A-IN-12(P) Our Offer No. : PUKOR 11-049 E Date : 07-Jun-2011

8 D3.22.3301/02 2 ENSIVAL MORET PRE 25-16 OH2 - Centerline-supported API 610 10th 2.00 '' 1.00 '' ANSI 300# RF -9 D3.23.3305/06 2 ENSIVAL MORET PRE 25-16A OH2 - Centerline-supported API 610 10th 2.00 '' 1.00 '' ANSI 300# RF --

Description Position No. Quantity Required Make Pump Model Construction Design Code Suction Flange Size Discharge Flange Size Flanges Class (Suction / Discharge) Pump Length Criticality Rating Operating Data Product Other information on liquid (H2S, ) Temperature min Temperature MAX MAX Specific Gravity MAX Vapour Pressure MAX Vapour Pressure MAX Viscosity Rated Capacity Min. Flow Nom. Head @ Discharge flange Nom. Head @ Hydraulic Cell Nom. Speed Efficiency Impeller Size Duty (minimum) Impeller Size Duty (RATED) Impeller Size Duty (MAXIMUM) Impeller Type NPSH Available @ suction flange NPSH Available @ impeller axis NPSH Required @ impeller axis BHP at Duty BHP for SG = 1 (Water) Required Mechanical Design Pressure Required Mechanical Design temperature Material Code Casing Impeller Wear Ring(s) Shaft Shaft Sleeve Mechanical Seal/Packing Mech. Seal Material Code API Flushing Plan Coupling & Spacer End of curve power with d liquid Motor/Engine/Steam Turbine Type Model/Frame Size Rated Power @ 40C Speed Class/Protection Volt/Ph/Hz

" " mm

oC oC kg/dm3 PSIA barA cP. m3/hr m3/hr m m rpm % mm mm mm m m m kw kw (Bar G) C

TBA

16.5 6 28.8 28.8 3580 35.61 130 134 169 CLOSED IMPELLER 4 4 1.8 2.7 3.6 NS 40 Degre C A-8 -

TBA

10.0 5 30 30 3580 24.66 130 134 169 CLOSED IMPELLER 4 4 1.4 2.1 3.3 NS 40 Degre C A-8 -

Single Cartridge Seal BSTIN / 1CW-FX / C2A1A136113 / 61 / METASTREAM TSK-S 21.0 IEC TEFC 180 M 25 3600 Class 1, Group D, Div 2 --> ExnA IIT3 460 10% / 3 / 60 2%

Dual Cartridge Seal BDPIN / 3CW-FB / C2A3A-53B- / 53B / METASTREAM TSK-S 3.6 IEC TEFC 112 M 4.6 3600 Class 1, Group D, Div 2 --> ExnA IIT3 460 10% / 3 / 60 2%

Dual Cartridge Seal BDPIN / 3CW-FB / C2A3A-53B- / 53B / METASTREAM TSK-S 3.0 IEC TEFC 100 L 3.5 3600 Class 1, Group D, Div 2 --> ExnA IIT3 460 10% / 3 / 60 2%

kw rpm

Offer Price

Bareshaft pump Motor Baseplate & coupling Sub Total: Set(s)

EUR EUR EUR EUR EUR

Grand Total Testing Per Pump Unit

Witnessed Pump Perf. Test (Q,H,P & Eff) Witnessed Hydro. Test Witnessed NPSH Test Witnessed mechanical running test (4 hrs) Material certificates 3.1 (Casing, Impeller and shaft) NDE (Liquid penetrant test for pressure parts) PMI (Positive Material Identification)

85,319 6,296 Included 91,615 183,230 950 250 NA 1,350 360 900 500

52,744 1,888 Included 54,632 109,264 950 200 NA 1,350 360 900 500

52,744 1,666 Included 54,410 108,820 950 200 NA 1,350 360 900 500

6/7/2011

EUR EUR EUR EUR EUR EUR EUR

PUKOR 11-049E_GSEC_PDVSA_Gas-Mega-Project_11058A-IN-12(P)

ENSIVAL MORET ASIA

31 Mandai Estate, #07-07 Innovation Place, Tower 4, Immedia, Singapore 729933 Tel : (65)-6281 0667, (65)-6281 9180 Fax: (65)-6281 0908 E-mail : moret@pacific.net.sg Web Site Add. : www.em-pumps.com

QUOTATION

To : Attn : Fax : GS E&C ??? ysji@gsconst.co.kr ???

10 D3.22.0401/02 2 ENSIVAL MORET MNVC 120-IN VS6 - Vert., Double casing (CAN), Diffuser API 610 10th 4.00 '' 2.00 '' ANSI 600# RF 2200 With Inducer HC 40 40 0.61 TBA TBA

Project : PDVSA Gas Mega Project (Bidding) / V Fractionation Train At Jose RFQ. No. : 11058A-IN-12(P) Our Offer No. : PUKOR 11-049 E Date : 07-Jun-2011

11 D3.22.0406/07 2 ENSIVAL MORET PRE 40-32 OH2 - Centerline-supported API 610 10th 3.00 '' 1.50 '' ANSI 300# RF -With Orifice HC 40 40 0.7 TBA TBA 12 D3.22.0404/05 2 ENSIVAL MORET PRE 40-32 OH2 - Centerline-supported API 610 10th 3.00 '' 1.50 '' ANSI 300# RF -With Orifice HC 40 40 0.7 TBA TBA

Description Position No. Quantity Required Make Pump Model Construction Design Code Suction Flange Size Discharge Flange Size Flanges Class (Suction / Discharge) Pump Length Criticality Rating Operating Data Product Other information on liquid (H2S, ) Temperature min Temperature MAX MAX Specific Gravity MAX Vapour Pressure MAX Vapour Pressure MAX Viscosity Rated Capacity Min. Flow Nom. Head @ Discharge flange Nom. Head @ Hydraulic Cell Nom. Speed Efficiency Impeller Size Duty (minimum) Impeller Size Duty (RATED) Impeller Size Duty (MAXIMUM) Impeller Type NPSH Available @ suction flange NPSH Available @ impeller axis NPSH Required @ impeller axis BHP at Duty BHP for SG = 1 (Water) Required Mechanical Design Pressure Required Mechanical Design temperature Material Code Casing Impeller Wear Ring(s) Shaft Shaft Sleeve Mechanical Seal/Packing Mech. Seal Material Code API Flushing Plan Coupling & Spacer End of curve power with d liquid Motor/Engine/Steam Turbine Type Model/Frame Size Rated Power @ 40C Speed Class/Protection Volt/Ph/Hz

" " mm

oC oC kg/dm3 PSIA barA cP. m3/hr m3/hr m m rpm % mm mm mm m m m kw kw (Bar G) C

TBA

36.3 12 992.4 992.4 3580 62.59 140

TBA

6.4 6 145.5 145.5 3580 13.26 260 265 320 CLOSED IMPELLER 4 4 2.4 13.4 19.1 NS 40 Degre C A-8 -

TBA

6.4 6 152 152 3580 12.65 260 270 320 CLOSED IMPELLER 4 4 2.4 14.7 20.9 NS 40 Degre C A-8 -

161

164 CLOSED IMPELLER 4 4 1.4 95.6 156.7 NS 40 Degre C A-8 -

Dual Cartridge Seal BDPIN / 3CW-FB / C2A3A-53B- / 53B / METASTREAM TSK-S 123.0 IEC TEFC 315 S 125 3600 Class 1, Group D, Div 2 --> ExnA IIT3 460 10% / 3 / 60 2%

Single Cartridge Seal BSTIN / 1CW-FX / C2A1A116111 / 61 / METASTREAM TSK-S 22.0 IEC TEFC 180 M 25 3600 Class 1, Group D, Div 2 --> ExnA IIT3 460 10% / 3 / 60 2%

Single Cartridge Seal BSTIN / 1CW-FX / C2A1A116111 / 61 / METASTREAM TSK-S 23.0 IEC TEFC 180 M 25 3600 Class 1, Group D, Div 2 --> ExnA IIT3 460 10% / 3 / 60 2%

kw rpm

Offer Price

Bareshaft pump Motor Baseplate & coupling Sub Total: Set(s)

EUR EUR EUR EUR EUR

Grand Total Testing Per Pump Unit

Witnessed Pump Perf. Test (Q,H,P & Eff) Witnessed Hydro. Test Witnessed NPSH Test Witnessed mechanical running test (4 hrs) Material certificates 3.1 (Casing, Impeller and shaft) NDE (Liquid penetrant test for pressure parts) PMI (Positive Material Identification)

202,930 20,440 Included 223,370 446,740 950 250 NA 2,200 360 900 500

30,184 6,083 Included 36,267 72,534 950 200 NA 1,350 360 900 500

30,184 6,083 Included 36,267 72,534 950 200 NA 1,350 360 900 500

6/7/2011

EUR EUR EUR EUR EUR EUR EUR

PUKOR 11-049E_GSEC_PDVSA_Gas-Mega-Project_11058A-IN-12(P)

ENSIVAL MORET ASIA

31 Mandai Estate, #07-07 Innovation Place, Tower 4, Immedia, Singapore 729933 Tel : (65)-6281 0667, (65)-6281 9180 Fax: (65)-6281 0908 E-mail : moret@pacific.net.sg Web Site Add. : www.em-pumps.com

QUOTATION

To : Attn : Fax : GS E&C ??? ysji@gsconst.co.kr ???

13 D3.22.0501/02 0 ENSIVAL MORET NO QUOTE OH2 - Centerline-supported API 610 10th " " mm ANSI 300# RF -ANSI 300# RF -ANSI 300# RF --

Project : PDVSA Gas Mega Project (Bidding) / V Fractionation Train At Jose RFQ. No. : 11058A-IN-12(P) Our Offer No. : PUKOR 11-049 E Date : 07-Jun-2011

14 15

Description Position No. Quantity Required Make Pump Model Construction Design Code Suction Flange Size Discharge Flange Size Flanges Class (Suction / Discharge) Pump Length Criticality Rating Operating Data Product Other information on liquid (H2S, ) Temperature min Temperature MAX MAX Specific Gravity MAX Vapour Pressure MAX Vapour Pressure MAX Viscosity Rated Capacity Min. Flow Nom. Head @ Discharge flange Nom. Head @ Hydraulic Cell Nom. Speed Efficiency Impeller Size Duty (minimum) Impeller Size Duty (RATED) Impeller Size Duty (MAXIMUM) Impeller Type NPSH Available @ suction flange NPSH Available @ impeller axis NPSH Required @ impeller axis BHP at Duty BHP for SG = 1 (Water) Required Mechanical Design Pressure Required Mechanical Design temperature Material Code Casing Impeller Wear Ring(s) Shaft Shaft Sleeve Mechanical Seal/Packing Mech. Seal Material Code API Flushing Plan Coupling & Spacer End of curve power with d liquid Motor/Engine/Steam Turbine Type Model/Frame Size Rated Power @ 40C Speed Class/Protection Volt/Ph/Hz

ENSIVAL MORET OH2 - Centerline-supported API 610 10th

ENSIVAL MORET OH2 - Centerline-supported API 610 10th

HC oC oC kg/dm3 PSIA barA cP. m3/hr m3/hr m m rpm % mm mm mm m m m kw kw (Bar G) C

0.45 0.00 428.0 877 877 0.00 0.00

OUT OF OUR MANUFACTURING RANGE

CLOSED IMPELLER 4 4 #DIV/0! #DIV/0! NS A-8 CLOSED IMPELLER 0 #DIV/0! #DIV/0! NS CLOSED IMPELLER 0 #DIV/0! #DIV/0! NS

???? 0 / 0 / 0000 0/0/0 METASTREAM TSK-S 0.5 IEC TEFC kw rpm

METASTREAM TSK-S 0.0 IEC TEFC

METASTREAM TSK-S 0.0 IEC TEFC

720 460 10% / 3 / 60 2%

720 460 10% / 3 / 60 2%

720 460 10% / 3 / 60 2%

Offer Price

Bareshaft pump Motor Baseplate & coupling Sub Total: Set(s)

EUR EUR EUR EUR EUR

Grand Total Testing Per Pump Unit

Witnessed Pump Perf. Test (Q,H,P & Eff) Witnessed Hydro. Test Witnessed NPSH Test Witnessed mechanical running test (4 hrs) Material certificates 3.1 (Casing, Impeller and shaft) NDE (Liquid penetrant test for pressure parts) PMI (Positive Material Identification)

7,022 0 Included 7,022 0 950 200 NA 0 360 900 500

7,022 0 Included 7,022 0 950 200 500 0 360 900 500

7,022 0 Included 7,022 0 950 200 500 0 360 900 500

6/7/2011

EUR EUR EUR EUR EUR EUR EUR

PUKOR 11-049E_GSEC_PDVSA_Gas-Mega-Project_11058A-IN-12(P)

ENSIVAL MORET ASIA

31 Mandai Estate, #07-07 Innovation Place, Tower 4, Immedia, Singapore 729933 Tel : (65)-6281 0667, (65)-6281 9180 Fax: (65)-6281 0908 E-mail : moret@pacific.net.sg Web Site Add. : www.em-pumps.com

TERMS AND CONDITIONS

To : GS E&C ysji@gsconst.co.kr Fax : ??? Project : PDVSA Gas Mega Project (Bidding) / V Fractionation Train At Jose RFQ. No. : 11058A-IN-12(P) Our Offer No. : PUKOR 11-049 E Date : 07-Jun-2011 Attn : ???

Delivery Time Price Packing Validity

Terms of Payment

Warranty

52-58 Weeks, Upon received of confirmed order, FOB Belgium. Excluded August Holiday (3 weeks). Price quoted in EURO, FOB Antwerp, Belgium. Freight and site delivery (with all possibles local taxes) are not in our quoted prices Seaworthy Packing incuded Up to October 5, 2011 - 15% at the order (against bank guarantee) by TT - 15% at the arrival of main foundries in our factory by TT - 70% at Ex-works (or FOB) delivery at sight against an irrevocable letter of credit opened at the effective date of the order and confirmed by a first class european Bank. At that time opening of a guarantee bond of 10% available up to the end of the guarantee period. 12 months after commissioning ; latest 18 months after FOB delivery date - (which ever comes first); normal wear excluded from warranty

This offer (contract, order confirmation) or fulfilment of contract is subject to the provison that required export licenses have been granted or that there are no other impediments arising from Belgian, European or other export regulations. Goods labeled with "AL not equal to N" are subject to European or Belgium export authorization when being exported out of the EU. Goods labeled with "ECCN not equal to N" are subject to US reexport authorization. Even without a label, or with label "AL:N" or "ECCN:N", authorization may be required due to the final whereabouts and purpose for which the goods are to be used

Supplier List

Mechanical seal Seal pot Electric motor LV Electric motor MV Coupling ARV Steam Turbine Burgmann / John Crane Burgmann / John Crane ABB / Siemens / HHI . ABB / Siemens / Schorch / HHI . Metastream (John-Crane) NA NA

PUKOR 11-049E_GSEC_PDVSA_Gas-Mega-Project_11058A-IN-12(P)

6/7/2011

ENSIVAL MORET ASIA

31 Mandai Estate, #07-07 Innovation Place, Tower 4, Immedia, Singapore 729933 Tel : (65)-6281 0667, (65)-6281 9180 Fax: (65)-6281 0908 E-mail : moret@pacific.net.sg Web Site Add. : www.em-pumps.com

REMARKS AND DEVIATIONS ABOUT OUR QUOTATION / YOUR SPECIFICATIONS / YOUR INQUIRY :

To : Attn : Fax : GS E&C ??? ysji@gsconst.co.kr ??? Project : PDVSA Gas Mega Project (Bidding) / V Fractionation Train At Jose RFQ. No. : 11058A-IN-12(P) Our Offer No. : PUKOR 11-049 E Date : 07-Jun-2011

GENERAL REMARKS :

- Thrid Party Inspection is not included in our prices ; the cost of TPI (LLOYD'S, SGS, Bureau Veritas, AIB Vincotte, ...) is given as optional price on the our price summary sheet (at the beginning of our proposal) - Special tools required for maintenance or erection are included in our scope of supply (where applicable) - Junction boxe and wires for instrumentation are not included in our scope of supply. - No Instrumentation / No local control panel in our scope - Performance test of pump are made as following: - At 50 Hz when contractual site frequency is 60 Hz - With Shop Motor when Job motor power do not cover the power required for test with water (due to SG of actual pumped liquid is << 1)

Remarks about each individual customer datasheets :

Item D3.22.0408/09 D3.23.1105/06 D3.23.1109 D3.23.1110/11 D3.23.1107/08 D3.23.3503/04/05 D3-23-5101/02 D3.22.3301/02 D3.23.3305/06 D3.22.0401/02 D3.22.0406/07 D3.22.0404/05 D3.22.0501/02 Request on datasheet Pump type requested VS6 Pump type requested VS6 NPSH available = 4 m on customer datasheet Remarks / Deviations We quoted as per your request and we also added in our documentation an alternative solution in OH2 pump type for your consideration We quoted as per your request and we also added in our documentation an alternative solution in OH2 pump type for your consideration NPSH a not suficient for VS1 pump selection with this big flow. Please increase your NPSHa -

PUKOR 11-049E_GSEC_PDVSA_Gas-Mega-Project_11058A-IN-12(P)

6/7/2011

ENSIVAL MORET ASIA

31 Mandai Estate, #07-07 Innovation Place, Tower 4, Immedia, Singapore 729933 Tel : (65)-6281 0667, (65)-6281 9180 Fax: (65)-6281 0908 E-mail : moret@pacific.net.sg Web Site Add. : www.em-pumps.com

LIST OF APPLICABLE SPECIFICATION

To : GS E&C Attn : ??? ysji@gsconst.co.kr Fax : ??? Project : PDVSA Gas Mega Project (Bidding) / V Fractionation Train At Jose RFQ. No. : 11058A-IN-12(P) Our Offer No. : PUKOR 11-049 E Date : 07-Jun-2011

Speficication Name / Number Specification for API Centrifugal Pumps DB1010701PW016MD08001 (Rev 0 Dated 11/01/2009)

Considered, Applicable or not to our scope ?, .. Considered; Remarks stated below Location "Egypt"? ; Utilization voltage 4000 V10% ? ; Frequency 60 Hz 2% OK ; Ambient temperature Max +33C? / 37.1C ? OK Motor quoted are as per IEC only (NEMA not considered!) Please note that your pump process datasheets specify a max ambient temperature of +42.2C (108F) Location "Egypt"? ; Voltage 460 V 10% OK ; Frequency 60 Hz 2% OK ; Ambient temperature Max +33C? / 37.1C ? OK Motor quoted are as per IEC only (NEMA not considered!) Please note that your pump process datasheets specify a max ambient temperature of +42.2C (108F) LV motor Voltage 480 V 10% ? --> we considered 460 V 10% as stated on each datasheet MV motor Voltage 4160 V 10% OK We considered MV motor is applicable for motor 150 kw (200 Hp) and above Frequency 60 Hz 5% ? --> we considered 60 Hz 2% as stated on typical motor datasheet Absolute Max ambient temperature = + 40C OK National standard / International stanrdards / PDVSA Standards referred in this specification are not in our hands and have not been considered Motor quoted are as per IEC only (NEMA not considered!) 11.4: junction box - Eexi - NEMA 4X - IP66 - 12" x 12" x 8" - 2x 24 terminals !! --> we will use reduced size box due to only 2 connections on the seal system 6.1.2.23: throttle prefered for dual=> if impossible please explain --> throttle bushing not always possible on OH2 - BD or BT seals due to axial place 6,1,6,4: sleeve 12Cr + colmonoy coating --> colmonoy old coating replaced by CrO2 coating (much better) 8.1.3: inspection by buyer before shipment - disassembly / removal of seal for safe shipment --> pump are shipped with the mechanical seal installed Noted ; No Comments

Typical Datasheet for MV motor

Typical Datasheet for LV motor

Electrical Specification for Induction motors DB1010701PWOI3ED10002 (rev 0 dated 08/FEB/2010)

Instrument with Equipment Packages Specifications DB1010701PWOI3ID07002 (rev 0 dated 22/NOV/2009)

Spec for shaft sealing for centrifugal pumps S030473102BM84302 (rev 0 dated 31/OCT/2006)

Surface preparation and Specifications for Painting DB1010701PWOI3MD08024 (rev 0 dated 16/DEC/2009)

Remarks about your Specification Specification for API Centrifugal Pumps DB1010701PW016MD08001 (Rev 0 Dated 11/01/2009) :

- Para 1.2.7: PDVSA-SN-252 "Equipement Noise Control": Specification not received --> Not considered - Para 1.3.2: cathodic Protection sacrificial anodes inside pump casing and other cathodic protection system IS NOT PART OF OUR SCOPE OF SUPPLY - Para 1.3.2: One set of pump/driver Mechanical Alignment kit IS NOT PART OF OUR SCOPE OF SUPPLY - Para 5.1.32: stuffing box is for cartridge mechanical seal OR for packing rings; Not possible to be suitable for both without modification. - Para 5.3.6: Suction pressure regions shall be designed for the same pressure as the discharge pressure;Vertical can pump shall have its can, bowls, columns and discharge head rated for the same value of MAWP; This requirement shall apply to multistage horizontal pumps too --> refer to our remark on pressure summary table in our quotation - Para 5.3.9: radially split case pumps are required for all services: OK, noted and confirmed - Para 5.12.4: All pump components shall be Charpy V-notch tested to qualify for minimum auto-refrigeration temperature of the pumpage at maximum allowable working pressure. Auto refrigeration is assumed to take place at full pump pressure due to leakage of pumpage through normal sealed or valved connection, or through unforseen cracks or openings; ASME VIII Division 1 requirement shall apply with regard to impact testing: we considered this requirement as applicable for all the items where the minimum liquid temperature on customer datasheet is < 0C. - Para 6.2.12: Shaft alignment kit (including mounting brackets) IS NOT PART OF OUR SCOPE - Para 2.7.5: Special tools such as Hydraulic kit for coupling removal, bearing puller, alignment bracket, laser type alignment kit, : all this not quoted and not included in our scope of supply.

ENSIVAL MORET ASIA

31 Mandai Estate, #07-07 Innovation Place, Tower 4, Immedia, Singapore 729933 Tel : (65)-6281 0667, (65)-6281 9180 Fax: (65)-6281 0908 E-mail : moret@pacific.net.sg Web Site Add. : www.em-pumps.com

To : Attn : Fax :

GS E&C ??? ysji@gsconst.co.kr ???

Project : PDVSA Gas Mega Project (Bidding) / V Fractionation Train At Jose RFQ. No. : 11058A-IN-12(P) Our Offer No. : PUKOR 11-049 E Date : 07-Jun-2011

COMMENTS / REMARKS / DEVIATION TO API610 10th EDITION

Horizontal Overhung pumps type PRE (Code OH2)

5.12.3.1 Non pressure parts (such as baseplates) are welded to our standard Sound level test will be performed during shop performance test. Only global noise level check can be done. Noise measurement in our test floor are made according to ISO 3746

Vertical pumps type VN / VE (Code VS1) ---------- VNC / VEC / MNVC (Code VS6)

5.8.2 5.8.10 5.12.3.1 7.3.3.3 8.3.6.2 8.3.6.3 8.3.8.2.3 8.3.10.2 Mechanical seal cannot be removed without disturbing the driver due to the fact that pumps is fitted with its own thrust bearing Pumps are shipped with seal installed because the pump has its own thrust bearing Non pressure parts (such as motor bracket) are welded to our standard The pump will be tested at 50 Hz. Not all intermediate section are installed (depending on pump length) Pump has its own thrust bearing. First impeller is overhung. Our pump has its own thrust bearing and is equiped with a FLEXIBLE coupling --> 8.3.8.2.3 not applicable Line shaft is OPEN We offer standard driver as the pump has its own thrust bearing. Sound level test will be performed during shop performance test. Only global noise level check can be done. Noise measurement in our test floor are made according to ISO 3746 Impellers are not axially individually secured

Page 17 of 19

General Conditions of Sales

For the companies in the ENSIVAL-MORET Group

1 General. The present general conditions apply to contractual relationships between the Supplier, every company in the ENSIVAL-MORET Group, and the client company hereinafter referred to as the Client. They form the legal basis of the contracts. 2 Formation of the contract. Unless otherwise specified, the offer is valid for one month. The contract is not considered complete until acceptance in writing (order confirmation) of the order by the Supplier. 3 Scope of the contract. The contract will be strictly limited to the goods and services expressly mentioned by the Parties using the data provided by the Client. The Supplier reserves the right to replace the goods being the object of the contract by goods of equivalent specification on condition that this does not result in either an increase in the price or a change in the quality for the Client. The Supplier reserves the right to contract out all or part of the work, goods and services, objects of the contract. 4 Documents. The information, photographs, weights, prices and drawings shown in the catalogues, brochures and price lists are given for reference only and are not contractual; the Supplier reserves the right to make any modifications. 5 Termination of the contract. The order expresses the consent of the Client in an irrevocable way; thus he cannot cancel it unless there is express and prior agreement by the Supplier. In this case, the Client indemnifies the Supplier for all the costs following this cancellation which cannot be less than 30% of the cancelled amount. The Supplier is not obliged to take back the new material which will be returned to him. 6 Modification of the contract. Any modification of the contract asked for by the Client is subject to the express acceptance by the Supplier and will be made in an amendment to the contract. In this case, the Client compensates the Supplier for all the costs incurred and for all the direct and indirect consequences following from this (such as costs of additional quantities asked for, stock replacement, logistics costs, and checks). 7 Ownership of the work, plans and documents. The Supplier retains the complete intellectual property rights for his work, plans and documents. Any reproduction requires the prior, written agreement of the Supplier. If the work done at the request of the Client or the documents provided to the Client is/are not followed by an order for the products, the costs incurred for these will be invoiced to the Client and the documents must be returned. All the intellectual property rights and the know-how incorporated in the documents handed over, the products delivered and the services rendered remain the exclusive property of the Supplier. Any cession of the rights for intellectual property or know-how must be the object of a contract with the Supplier. 8 Prices. The prices, fixed at the time of acceptance of the order, are understood as excluding taxes, excluding costs for customs, transport, insurance, standard packaging and ex-works. In the case of an event outside his control endangering the stability of the contract, the Supplier reserves the right to revise his prices according to the modalities predetermined by the parties (in particular in the case of variation in the cost of raw materials, modification of customs duties, changes in the exchange rates, evolution of legislation). 9. Payment conditions. 9.1 Payment terms and modalities. Unless expressly agreed otherwise, payments are due on the 30 th day following the date of supply. The contractually agreed payment dates cannot be changed unilaterally by the Client whatever the pretext including litigation. Unless specifically agreed, the advance payments are made without discount. 9.2 Payment arrears. In compliance with the European Directive 2000/35 EC of 29 June 2000, every late payment gives rise to the application of late payment interest at the rate of seven percent above the most recent European Central Bank lending rate. Any payment arrears or deterioration of the financial situation of the Client recorded by a financial institution results in forfeiture of the contractual terms and the total of all amounts becoming payable immediately. If the Supplier makes use of one and/or the other of these provisions, this does not affect implementation of the retention of title clause stipulated in Article 14. In the case of payment arrears, the Supplier has a right of lien on the manufactured products and connected supplies. 9.3 Offsets. The Client is forbidden to make any offset or retention and also generally prohibited to invoice the Supplier for any amount which has not expressly been recognized by the latter. 10. Delivery lead times. The lead time for making the material available, before receipt, runs from the time when the following conditions are satisfied: 1) Receipt of all the information necessary for proper performance of the contract. 2) Receipt of possible payments on account due with the order and/or the opening of the Letter of Credit. Unless otherwise stipulated, the delivery dates are for reference only. A delivery delay does not cause cancellation, even partial, of the contract.

Page 18 of 19

Gen. Cond. of Sales

11 Technical acceptance, trials, inspections, certificates. The Client is obliged to perform detailed verification of the product on receipt. If there are no complaints within a period of 4 days, the product is considered as in compliance with the contract. Costs for all acceptance operations, checks, trials and certificates requested by the Client are borne by the Client. These additional activities take place in the factory or onsite according to the discretion of the Supplier. If the Client, having been informed of the date of these activities, is not present, a report is communicated to him and its reception is considered to have taken place. 12 Packaging, delivery, transport, insurance, customs. The agreed terms of delivery are interpreted as compliant with INCOTERMS in force on the date of the conclusion of the contract. If no specific delivery condition has been agreed, the delivery is made ex-works. In the absence of any special request from the Client, the packaging requirement is at the complete discretion of the Supplier. The packaging is always at the cost of the Client and is not taken back by the Supplier. The Client is responsible for damage which may occur to or be caused by the products starting from their availability. In the case where the Client does not accept delivery and without needing to give notice, the Client bears all the costs and risks of storing the goods. 13 Installation, commissioning. Unless otherwise agreed, these are performed by the Client at his exclusive responsibility and according to the regulations. 14 Retention of title clause. The Supplier retains the complete title to the property comprising the object of the contract until complete and effective payment of the main and incidental prices. Failure to make payment on any of the due dates gives rise to a claim for the property. 15 Guarantee. Unless otherwise stipulated and without prejudice to guarantee legislation, the Supplier guarantees the products for 12 months starting from the availability of the products in the premises of the Supplier. It only covers repair of the materials recognized as defective which have been returned to the workshops of the Supplier. The guarantee does not apply: - to the elements which are subject to wear and tear by the nature of their materials or function, - in the case of deterioration or accidents arising from improper installation or use, non-observance of installation, usage and maintenance instructions, defective supervision, storage or maintenance, modification to or interference with the original product by the Client. It does not apply in the case of non-payment by the Client and he cannot benefit from this for suspending or deferring his payments. 16 Liability. The civil liability of the Supplier with the exception of personal injury and gross negligence is limited to the amount of the sums mentioned in the title of the contract. The Supplier expressly excludes any other liability with respect to indirect property damage and/or direct and indirect intangible damage and the compensation of any financial loss arising in particular from a loss of profit, deprivation of a right, interruption of a service rendered by a person or property insofar as such limitations or exclusions comply with and do not contradict the legal regulations in force. 17 Force majeure. None of the parties to the present contract can be held liable for his delay or default in performing his obligations under the contract if this delay or default is caused directly or indirectly by force majeure in a sense wider than the French jurisprudence such as: occurrence of a natural disaster, earthquake, storm, fire, flooding, conflicts, war, industrial dispute, complete or partial strike, injunction by the public authorities (import prohibition, embargo), industrial accidents, transport accidents, machine breakdowns, explosion, failures by suppliers. Each party immediately informs the other party of the incidence of a case of force majeure which it is aware of and which in his opinion can affect the performance of the contract. 18 Resolutory clause. If payment is not made within the 8 days following the date of sending notice of default by registered letter, the Supplier is entitled to terminate the contract. He is also entitled to obtain compensation for the complete loss incurred. If events of force majeure such as those described in Article 17 make performance of the contract impossible within a reasonable period, each of the parties is entitled to withdraw from the contract by simple, written notification to the other party without having to ask for the termination before a court of law. The termination of the contract for whatever reason does not affect the debts already incurred between the parties. 19 Disputes. In the case of any legal disputes relating to a supply or its settlement and irrespective of the accepted conditions of sale and payment, even in the case of a guarantee claim, or the plurality of defendants and except with amicable agreement, the bankruptcy court for the registered office of the Supplier will have exclusive jurisdiction for deciding the issue. The law in the country of the supplier is exclusively applicable.

Page 19 of 19

Gen. Cond. of Sales

ENSIVAL MORET BELGIUM S.A.

Bois-la-Dame 4, Z.I. des Plenesses, 4890 THIMISTER-CLERMONT BELGIUM

Tel 32 (0)87 46 81 11 Fax 32 (0)87 46 81 00 URL : http://www.ensival-moret.com / e-mail : info@em-pumps.com R.C. Verviers: 71510 T.V.A.: BE 467.613.838

GENERAL CONDITIONS FOR THE PROVISION OF TECHNICAL PERSONNEL ABROAD 1.-Scope of application 1.1. These conditions shall apply to the provision of technical personnel for carrying out work in the customer's country. 1.2. The customer's country shall be deemed to be the country where the work is to be carried out. 2.-Obligations of the customer 2.1 Notification The customer shall give adequate notice to the contractor of the date on which the contractor's personnel is expected on the site. 2.2 Preparations In order that the work may be started immediately on arrival of the personnel and may be prosecuted without unnecessary hindrance, all the equipment and tools required for the work and provided by the customer shall be available on the working site in advance and all other preparations shall be complete. Any foundations required for the works shall be perfectly dry and in accordance with the requirements specified by the contractor. 2.3 Lodging The customer shall provide the personnel with suitable furnished and air-conditioned single rooms with proper washing facilities in the vicinity of the working site. 2.4 Interpreters The customer shall ensure that competent interpreters are available free of charge to the contractor's personnel at the site during the work, unless the language used at site is the French language. 2.5 Accident prevention The customer shall take all necessary and all legally prescribed measures for accident prevention.

Page 1 of 7

THIMISTER-CLERMONT, the 10 Jan 2011.

th

ENSIVAL MORET BELGIUM S.A.

Bois-la-Dame 4, Z.I. des Plenesses, 4890 THIMISTER-CLERMONT BELGIUM

Tel 32 (0)87 46 81 11 Fax 32 (0)87 46 81 00 URL : http://www.ensival-moret.com / e-mail : info@em-pumps.com R.C. Verviers: 71510 T.V.A.: BE 467.613.838 3.-Prices and Charges 3.1 We make our qualified field servicemen available to the customer. Works, repairs and overhauls are carried out always without previous estimate to the best of our clients' interests and at the clients' own risk, and without any responsibility on our part as to duration of the work. 3.2 The services of our field servicemen are invoiced in Euros according to the basic rate of EUR. 135.00 per each normal working hour. Overtime hours are invoiced with a supplement of 50 %. In the event of work on a Sunday or a holiday, the working hours will be billed with a supplement of 100 %. By holidays shall be understood all days which are customarily free in the visited country. If they are workfree, they will be invoiced at the normal rate. This rate is to be increased by 25 % in case of work under dangerous, unhealthy conditions as also in case of work in the mine, alongside the pit or by night. The remuneration shall be due for 30 days in case of illness. 3.3 Invoicing method The normal week consists of 36 hours spread over the first five working days, provided the working hours occur between 6 a.m. and 6 p.m. and do not exceed 7.2 hours per day. Overtime hours are counted day by day. The hours are considered as overtime hours when they pass beyond either the daily limit of 7.2 hours or the conventional limit of 36 hours a week. The travelling hours will be invoiced at the normal rate of EUR. 135.00 per hour. If the daily journey between home base and working site or between working site and canteen requires more than 15 minutes in each direction, any time in excess of such 15 minutes shall be charged as working time. In case of work on a Sunday or a holiday a minimal rate of 5 effective working hours shall be charged. 3.4 Travelling expenses and holiday All travelling expenses incurred in connection with the contract shall be borne by the customer. By travelling expenses are to be understood: a.- fares for journeys by rail at the first class rate b.- fares for journeys by car at the rate of EUR. 0.65 per km c.- fares for journeys by air at the prevailing rate, either in first class or in tourist class depending on availability and on the nature of the journey. If our personnel should be obliged by local conditions to travel between their home base and the working site or between the working site and the canteen, and the customer does not provide free transport, the expenses for such local travel shall be borne by the customer. In addition to all charges for lodging, food and drinks, we require for our qualified servicemen a weekly premium for working abroad of EUR. 505.00 For all work performances lasting more than 3 consecutive months, each member of our personnel shall, at the end of each period of 3 months, be entitled to a journey to the country of the contractor and back at the client's costs. The daily allowance shall be payable during the period of travel but not during the period spent in the contractor's country. Page 2 of 7 THIMISTER-CLERMONT, the 10 Jan 2011.

th

ENSIVAL MORET BELGIUM S.A.

Bois-la-Dame 4, Z.I. des Plenesses, 4890 THIMISTER-CLERMONT BELGIUM

Tel 32 (0)87 46 81 11 Fax 32 (0)87 46 81 00 URL : http://www.ensival-moret.com / e-mail : info@em-pumps.com R.C. Verviers: 71510 T.V.A.: BE 467.613.838 3.5 Miscellaneous expenses All expenses such as telefax, telex, phone and the like required for the work shall be borne by the customer. 3.6 Waiting time Any waiting time for which the contractor or his personnel are not responsible shall be charged to the customer as normal working time. In the particular case of service assignments against a lump sum price, the wages, travelling expenses, accommmodation expenses etc. relating to any time wasted by our personnel under such circumstances shall be borne by the customer. 3.7 Carriage, freight and customs duties as well as insurance dues in connection with personnel effects, instruments and tools required for the contract shall be borne by the customer. 3.8 Checking Upon completion of the work or at the end of each week our field servicemen are required to submit to the client for signature a wage sheet on which are shown the hours they worked. These documents shall be used for the establishment of the invoices. 3.9 Charges for tools and contractor's equipment At the request of the contractor, the customer shall give all necessary assistance with the customs formalities required for the import and re-export of the contractor's tools and equipment free of all duties and taxes. 3.10 Taxes and dues The contractor shall be entitled to recover from the customer any taxes or dues levied in the customer's country on the contractor or his personnel in respect of obligations performed there by the contractor. In the event that any taxes or dues are claimed from the contractor on the price of supplies in respect of these obligations, such taxes and dues shall be borne by the customer. 4.- Accident, illness and death 4.1 Medical treatment In the event of accident or illness necessitating medical attention or hospital treatment, the customer shall, at his own expense, during the stay of the sick or injured person in the country where the work is to be done, provide the necessary medical attention and hospital treatment and procure the necessary medicaments, whether or not the accident or illness occurs in the course of work or during his off-time. Medical attention and hospital treatment shall be the best available. Page 3 of 7 THIMISTER-CLERMONT, the 10 Jan 2011.

th

ENSIVAL MORET BELGIUM S.A.

Bois-la-Dame 4, Z.I. des Plenesses, 4890 THIMISTER-CLERMONT BELGIUM

Tel 32 (0)87 46 81 11 Fax 32 (0)87 46 81 00 URL : http://www.ensival-moret.com / e-mail : info@em-pumps.com R.C. Verviers: 71510 T.V.A.: BE 467.613.838 4.2 Repatriation The customer shall, at his own expense in the most suitable and quickest way, send the said person home if this is advisable on medical grounds, or if the customer so decides and this is medically possible. If in any case the said person is sent home at his own request, the cost of sending him home shall not be borne by the customer. In the event of death of a member of the contractor's personnel the customer shall assume the same obligation in respect of the transportation of the deceased and the payment of the relevant costs. 4.3 Substitution In the event of death, or if by reason of illness or accident a member of the personnel is unavailable or unfit for work for more than 4 weeks, the contractor shall with all reasonable speed and at his own expense provide a substitute. 4.4 Reimbursement The expenses paid by the customer in pursuance of the present article and reimbursed either by the Belgian National Social Security Office ("Office National de Scurit Sociale O.N.S.S.") or by Compulsory Insurance ("Assurance Loi") shall be reimbursed to the customer. 5.-Interruption of work 5.1 If the work is interrupted for a cause for which the contractor is not responsible: a) The customer is entitled to require the contractor to withdraw his personnel, in which case the customer shall pay the expenses associated with their withdrawal and return to the site. b) The contractor is entitled to recall his personnel if the interruption exceeds a reasonable period, in which case also the customer shall pay the expenses under a). 5.2 If the contractor's personnel is withdrawn or recalled, the contract is not thereby terminated and its performance is merely suspended until the customer has required the return of the contractor's personnel to the site by giving a previous notice.

Page 4 of 7

THIMISTER-CLERMONT, the 10 Jan 2011.

th

ENSIVAL MORET BELGIUM S.A.

Bois-la-Dame 4, Z.I. des Plenesses, 4890 THIMISTER-CLERMONT BELGIUM

Tel 32 (0)87 46 81 11 Fax 32 (0)87 46 81 00 URL : http://www.ensival-moret.com / e-mail : info@em-pumps.com R.C. Verviers: 71510 T.V.A.: BE 467.613.838 6.-Accounting and Payment: 6.1 The contractor shall make out invoices relating to the preceding month or to such other period as may be agreed. Such invoices shall be sent to the customer not later than 30 days after the expiration of the month or other agreed period. 6.2 Unless otherwise agreed, payment shall be made in full within 30 days after the date of the invoice to the account of the contractor at the bank stated in the contract. Payment shall be made in Euro (Belgian currency). The rate of exchange shall be that prevailing on the date of payment. Nevertheless, in the case of late payment, the contractor shall be entitled to choose between the rate prevailing at the end of the above mentioned period of 30 days and the date of actual payment. He shall in any case be entitled to interest on the sum overdue, to which he shall become immediately entitled without further notice on expiry of the said period of 30 days. The rate of interest shall be 2 percent above the official discount rate of the contractor's country, without prejudice to the right of the contractor to claim additional compensation when this rate does not cover the loss actually suffered by him. The customer shall not be entitled to set off any sums due or alleged to be due to him from the contractor. 7.-Price revision clause: The hours rates and the premiums shall be adjusted according to the basic wage modifications of the class 4 issued by AGORIA. These modifications are combined with the social charges modifications also issued by the AGORIA OFFICE BELGIUM. 8.-Permits: The customer shall take any necessary steps to secure that the personnel, in good time, obtain visas and any official entry, exit or working permits required in the country where the work is to be carried out, as well as to ensure that the personnel have access to the working site. 9.-Local laws and regulations: Safety Regulations 9.1 The customer shall to the best of his ability assist the contractor to obtain the necessary information concerning the local laws and regulations applicable to the work. 9.2 1) The customer shall notify the contractor in full of safety regulations which the customer imposes on his own employees and the contractor shall secure the observance of such safety regulations by his own personnel. 2) If breaches of these regulations by the contractor's personnel come to the notice of the customer, he must inform the contractor in writing forthwith. The customer may take such measures as are necessary for the avoidance of danger resulting from such breaches, and may, in particular, forbid persons guilty thereof entry to the site. 3) The contractor shall inform the customer of any special dangers which the execution of the work may entail.

Page 5 of 7

THIMISTER-CLERMONT, the 10 Jan 2011.

th

ENSIVAL MORET BELGIUM S.A.

Bois-la-Dame 4, Z.I. des Plenesses, 4890 THIMISTER-CLERMONT BELGIUM

Tel 32 (0)87 46 81 11 Fax 32 (0)87 46 81 00 URL : http://www.ensival-moret.com / e-mail : info@em-pumps.com R.C. Verviers: 71510 T.V.A.: BE 467.613.838 10.- Working conditions 10.1 Unless otherwise agreed, the contract is made under the following conditions: 1) The work shall not be carried out in unhealthy or dangerous surroundings. 2) The customer shall make available to the contractor's personnel suitable board in the neighbourhood of the site and shall provide access to adequate medical services. 3) All necessary hoisting devices, scaffolding and other equipment, fuel power, lubricants, cleaning agents, consumable stores and water shall be provided, free of charge, by the customer in good time. 4) The customer shall provide the contractor (free of charge, unless otherwise agreed) with closed or guarded premises on or near the site as a protection against theft and deterioration of the contractor's tools and equipment and of the clothing of the contractor's personnel. Any departure from the conditions mentioned in this paragraph shall attract a reasonable extra charge. 10.2 If the circumstances resulting from such departure are such that it would be unreasonable to require the contractor to proceed with the work, the contractor may, without prejudice to his rights under the contract, refuse to do so. 11.-Additional Labour Upon the contractor's requirement in good time, the customer shall make available to the contractor, free of charge, such skilled and unskilled labour as may be found necessary even if not provided for in the contract. The persons made available by the customer under this clause shall provide their own tools. The contractor shall not be under any liability either towards such additional labour or for their acts and omissions. 12.-Work outside the contract. The customer shall not be entitled to use the contractor's personnel on any work unconnected with the subject matter of the contract without the previous consent of the contractor. Where the contractor so consents, he shall not be under any liability in respect of such work and the customer shall be responsible for the safety of the contractor's personnel while employed on such work.

Page 6 of 7

THIMISTER-CLERMONT, the 10 Jan 2011.

th

ENSIVAL MORET BELGIUM S.A.

Bois-la-Dame 4, Z.I. des Plenesses, 4890 THIMISTER-CLERMONT BELGIUM

Tel 32 (0)87 46 81 11 Fax 32 (0)87 46 81 00 URL : http://www.ensival-moret.com / e-mail : info@em-pumps.com R.C. Verviers: 71510 T.V.A.: BE 467.613.838 13.-Contractor's liability 13.1. The contractor shall be liable for loss and damage suffered by the customer by reason of the negligence or lack of diligence of the contractor or his personnel provided however that he has failed to choose suitable personnel for the work or to provide them in due time. 13.2 The contractor's liability shall not extend to loss or damage which the contractor could not reasonably have foreseen at the time of making the contract. 13.3 The contractor's liability shall not extend to losses due to service interruptions or loss of profit. 14.-Law applicable The contract shall be governed by the Belgian law. 15.-Arbitration Any dispute arising out of or in connection with this agreement shall be settled without recourse to the courts in accordance with the rules of conciliation and arbitration in the International chamber of Commerce by one or more arbitrators designated in conformity with those rules, the award being final and binding. The arbitrator or arbitrators shall have power to rule on their own competence and on the validity of the agreement to submit to arbitration. REMARK: This document draws largely from "THE CONDITIONS FOR THE PROVISION OF TECHNICAL PERSONNEL ABROAD" issued by "ORGALIME" (organisation for linking the European metallic industries). Brussels - January 1970.

NOTE: Services of our field servicemen including traveling hours are invoiced as follows: HOUR ORDINARY ...................................................................... EUR : 135.00 HOUR OVERTIME ....................................................................... EUR : 202.50 HOUR ON SUNDAYS AND HOLIDAYS ............................... EUR : 270.00 HOTEL & ACCOMODATIONS: by customer

Page 7 of 7

THIMISTER-CLERMONT, the 10 Jan 2011.

th

Potrebbero piacerti anche

- Fluidic Components and Equipment 1968–9: Pergamon Electronics Data SeriesDa EverandFluidic Components and Equipment 1968–9: Pergamon Electronics Data SeriesNessuna valutazione finora

- Pump SkillsDocumento1 paginaPump SkillsSaleem ChohanNessuna valutazione finora

- Columns Internals - PRICE-SHEET (U-114, 127, 214) - New FormatDocumento12 pagineColumns Internals - PRICE-SHEET (U-114, 127, 214) - New FormatErin JohnsonNessuna valutazione finora

- Ejector BasicsDocumento29 pagineEjector BasicsAnonymous pSozzNFcNessuna valutazione finora

- SPCL Offer 9 (New) - 03.12.09Documento55 pagineSPCL Offer 9 (New) - 03.12.09ptn999Nessuna valutazione finora

- SA - 980 - P - 11440 Fuel - Water Coalescer Separator Rev T02Documento2 pagineSA - 980 - P - 11440 Fuel - Water Coalescer Separator Rev T02altipatlarNessuna valutazione finora

- GA Drawing SO2 Scrubber - R1-To SadiartoDocumento1 paginaGA Drawing SO2 Scrubber - R1-To SadiartoAyahKenzieNessuna valutazione finora

- BP BPS 210aDocumento1 paginaBP BPS 210aVashish RamrechaNessuna valutazione finora

- 2022 Industrial Pump Price ListDocumento50 pagine2022 Industrial Pump Price ListpaachangaNessuna valutazione finora

- How To Prevent Caking in NPK Fertilizer Production ProcessDocumento2 pagineHow To Prevent Caking in NPK Fertilizer Production Processluna leNessuna valutazione finora

- Chapter 3 Warehouse LayoutsDocumento15 pagineChapter 3 Warehouse LayoutsSasank Sai100% (1)

- DcrerweDocumento1 paginaDcrerwesri9987Nessuna valutazione finora

- Instrument Hookup Drawing OF LEVEL SWITCHDocumento1 paginaInstrument Hookup Drawing OF LEVEL SWITCHEdafe DicksonNessuna valutazione finora

- Tornado Lobe Pump BrochureDocumento20 pagineTornado Lobe Pump BrochureAnonymous T7zEN6iLHNessuna valutazione finora

- Premium Pumping Technology For Desalination: PumpsDocumento16 paginePremium Pumping Technology For Desalination: PumpsShark1971Nessuna valutazione finora

- Sand Filter Design GuideDocumento2 pagineSand Filter Design Guideoanzar100% (1)

- 302 252 PDFDocumento257 pagine302 252 PDFabdelkader benabdallahNessuna valutazione finora

- 22146410-A02-DOC-LI-001-Master Document Register - V1.0 PDFDocumento5 pagine22146410-A02-DOC-LI-001-Master Document Register - V1.0 PDFBalasoobramaniam CarooppunnenNessuna valutazione finora

- Gautam Kar Resume.Documento3 pagineGautam Kar Resume.Ranish P. KurianNessuna valutazione finora

- 59-Qa60-R-201 - 0 - Equipment Numbering SystemDocumento59 pagine59-Qa60-R-201 - 0 - Equipment Numbering SystemNad EemNessuna valutazione finora

- Theory Hydrostatic Pressure PV Balance Secondary ContainmentDocumento42 pagineTheory Hydrostatic Pressure PV Balance Secondary ContainmentSofiane Halimi100% (1)

- KNT 001 GE ST3 SP 005 - 0 - Specification For Wood MaterialsDocumento14 pagineKNT 001 GE ST3 SP 005 - 0 - Specification For Wood MaterialsvamcodongNessuna valutazione finora

- V 020700506 F725 FCC P 106a 0011 DDocumento4 pagineV 020700506 F725 FCC P 106a 0011 DAlejandro Romero BallestasNessuna valutazione finora

- Proceeding of The Fertilizer Industry Round TableDocumento32 pagineProceeding of The Fertilizer Industry Round TableKhánh ĐỗNessuna valutazione finora

- Saudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsDocumento6 pagineSaudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsAnshu K MuhammedNessuna valutazione finora

- Detail A: Shuqaiq 3 Independent Water ProjectDocumento1 paginaDetail A: Shuqaiq 3 Independent Water ProjectABAID ULLAHNessuna valutazione finora