Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Anti-Vortex Structures at Hydropower Dams: Full Length Research Paper

Caricato da

Astri NgentTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Anti-Vortex Structures at Hydropower Dams: Full Length Research Paper

Caricato da

Astri NgentCopyright:

Formati disponibili

International Journal of the Physical Sciences Vol. 7(28), pp. 5069-5077, 19 July, 2012 Available online at http://www.academicjournals.

org/IJPS DOI: 10.5897/IJPS12.387 ISSN 1992 - 1950 2012 Academic Journals

Full Length Research Paper

Anti-vortex structures at hydropower dams

S. M. Taghvaei, R. Roshan, Kh. Safavi and H. Sarkardeh

Water Research Institute, Tehran, Iran.

Accepted 17 July, 2012

Vortex formation due to power generation at hydropower dams could cause serious problems, and eliminating or reduction in its strength is one of the dam designer and manager duties. Therefore, the design and use of anti-vortex structures is usual. Design of an anti-vortex structure for each project is unique and it is therefore necessary to have knowledge about the performance of each one. In the present study, to evaluate the performance of various anti-vortex structures, physical model of power intakes were constructed and used. Intakes were projected in the reservoir and are current in many dam projects. For each anti-vortex, a comprehensive study was performed to determine better Alternative in view of dissipating vortices. Experiments were conducted by recording class of vortices in different water elevations and with the current range of discharge for 13 anti-vortex Alternatives. Experiments showed that the horizontal plate had better performance in eliminating vortices. Key words: Anti-vortex structure, physical model, vortex, power generation, dam. INTRODUCTION Using hydropower dams is a way to generate green energy, which is presently commercially viable on a large scale. Formation of vortices at hydropower dams are undesirable phenomenon in lower water elevations which must be considered by dam designers and managers. Strong vortices can induce air and trash into the tunnel and reduce performance of turbine (Knauss, 1987). Based on Sarkardeh et al. (2010), vortices are classified into three general classes. Vortices of Class C are considered as the safe vortices and weak rotation of flow or a small drop maybe observed in water surface. Vortices Class B, the rotation of flow is extended down to the intake and may drag debris or trash into the intake. In vortices Class A, air bubbles or a stable air core are entrained from water surface and are transported down to the intake (Figure 1). To prevent formation of a strong vortex, a minimum operating level, called critical submerged depth Sc is recommended for the intake. Submerged depth is defined as the distance between water surface and the axis of the intake (Figure 2). Many researchers have been carried out to find a relationship for Sc based on prototype and physical model studies (Denny and Young, 1957; Berge, 1966; Gordon, 1970; Reddy and Pickford, 1972; Amphlett, 1976; Chang, 1977; Anwar et al., 1978; Jain et al., 1987; Odgaard, 1986; Sarkardeh et al., 2010). It should be noted that since the operating level of power intake be reduced below the critical submerged depth, the volume of water in this region cannot be used for power generation. Therefore increasing the submerged depth of the intake for prevention of vortex formation may not always be an economical solution. Moreover, construction of deeper intakes may be more expensive. Considering factors which has an effect on vortex strength (Sarkardeh et al., 2012), it can be concluded that vortex formation can also be prevented or its strength can be reduced if the distance between water surface and the intake is increased for example by installing a plate in the path of the vortex. Alternatively disturbing flow and increasing turbulence may have similar results. Knauss (1987) introduced various anti-vortex devices for intakes. These devices include: Vertical and half cylinder walls in front of the intakes, floating plates at reservoir water surface and horizontal plates installed on top of the intakes (Figure 3). By considering advantages of using anti-vortex devices in increasing the efficiency of hydropower plants, it seems design of them for hydropower dams is

*Corresponding author. E-mail: hamed_sarkardeh@yahoo.com.

5070

Int. J. Phys. Sci.

Vortex Class C

Vortex Class B

Vortex Class A

Figure 1. Vortex Classification (Sarkardeh et al., 2010).

Figure 2. Submerged depth at an intake (D is the tunnel diameter).

necessary. In the present work, by using physical model of Siahbisheh Pumped Storage Dam (scale 1:20), performance of four different types of anti-vortex structures with 13 variants was investigated. Also the performance of working two hydropower intakes together and its effect on strength of vortices was investigated.

EXPERIMENTAL SETUP All experiments were conducted on a Froude-based hydraulic model in the range of hydropower intake models (Figure 4). For this purpose, two parallel intakes with rectangular inlet by dimensions 70 cm 50 cm (height width) were made of Perspex. In each intake, a transition connected the rectangular inlet to circular tunnel with 28.5 cm diameter. Such configuration is usual in the design of hydropower conveyance members. For avoiding effects of boundary condition on vortex formation, a relatively large reservoir by dimensions 16 m 9.6 m (length width) was constructed. A centrifugal pump supplied water from a canal to the reservoir of the

model. A sharp crested rectangular weir was installed in the downstream of the model for discharge measurement. A precise limn meter was used to measure the water surface elevation (WRI, 2008). In order to avoid scale effects on the physical model studies of vortices and the effects of viscosity and surface tension, various minimum values were suggested for Re and We numbers as follows:

Re 5 10 4 (Daggett

and

Keulegan,

1974),

Re 7 .7 10 4 and We>600 (Padmanabhan and Hecker, 1984), Re 1 . 1 10 5 and We>720 (Odgaard, 1986) and We>120 (Jain

et al., 1987). Values of Re and We in the present work were more than the minimum values suggested by different researchers.

HYDRAULIC MODEL TESTS AND RESULTS Six different submerged depths (S/D = 2 to 4) were adjusted and regulated for tunnel Froude number of 0.7. To reach the stable condition, model was run for more

Taghvaei et al.

5071

(a)

(b)

(c)

(d)

Figure 3. Some anti-vortex devices at horizontal intakes. (a) Vertical wall (b) Half cylender wall(c) Floating perforated plate (d) Horizontal perforated plate.

Figure 4. Layout of the physical model used in the present work.

5072

Int. J. Phys. Sci.

Table 1. Class of vortices for various submerged depths.

S/D Left Intake Right Intake

2.10 Class B Class B

2.45 Class A Class B

2.80 Class B Class C

3.15 Class C Class C

3.50 Class B Class C

3.85 Class B ---

Figure 5. Different types of anti-vortex structures in Alternative 1.

than six hours. In each test, vortex class was recorded. Results are presented in Table 1. In prototype a trashrack structure is present at face of power intakes. Therefore a trashrack was installed at the intake entrance in the model. The net opening of trashrack was around 75% (USBR, 1987). In all tests, the trashrack was kept in the model to simulate the real condition. For investigating hydraulic performance of antivortex structures under critical operations, 13 Alternatives which were categorized in four general types (horizontal plates, vertical walls, wedge shape structures and combination of them) were installed and experiments were conducted on each separately (Figures 5, 6, 7 and 8). In Alternative 1, three types of thin wedge anti-vortex

plates were installed above the intake. Three variants of Alternative 1 with relative lengths, L/D=0.175, 0.35, 0.5 (where L is the length of anti-vortex plate expanded into the reservoir) and different shapes were investigated in the model (Figures 5 and 9). The distance between plates was supposed to be equal. Therefore the entrance of the left intake has been divided into three sections by about W/D=0.7 (where W is the distance between two plates). In Alternative 2, rectangular thin plates with L/D=0.175, 0.35, 0.5 were installed on the axis between two intakes (Figure 10). In Alternative 3, vertical plates with L/D=0.175, 0.35 and a combination with Alternative 2 were installed above the intakes (Figure 11).

Taghvaei et al.

5073

Figure 6. Different types of anti-vortex structures in Alternative 2.

Figure 7. Different types of anti-vortex structures in Alternative 3.

5074

Int. J. Phys. Sci.

Figure 8. Different types of anti-vortex structures in Alternative 4.

Alternative 1-1

Alternative 1-2

Alternative 1-3

Figure 9. Installed various types of Alternative 1 in the model.

Alternative 2-1

Alternative 2-2

Alternative 2-3

Figure 10. Installed various types of Alternative 2 in the model.

Taghvaei et al.

5075

Alternative 3-1

Alternative 3-2

Alternative 3-3

Figure 11. Installed various types of Alternative 3 in the model.

Alternative 3-4

Alternative 4-1

Alternative 4-2

Alternative 4-3

Figure 12. Installed various types of Alternative 4 in the model.

In Alternative 4, performance of horizontal anti-vortex plates with L/D=0.175, 0.35, 0.5 which were installed horizontally above both intakes were examined (Figure 12). Each described anti-vortex Alternatives were installed in the model and the relevant flow conditions over the intakes for different water elevations in the reservoir

were studied. These results are presented in Table 2. Installing anti-vortex structures over the intakes by introducing more friction to the flow or cutting the flow pass lines may cause elimination or reduction in vortex strength. Two general types of anti-vortex structures in the present paper were checked and results in detail are presented in Table 2. Results showed that in Alternative 1

5076

Int. J. Phys. Sci.

Table 2. Performance of different anti-vortex structures in the present model.

Alternative

Anti-vortex type 1-1

S/D 2.45

Intake Right Left Right Left Right Left Right Left Right Left Right Left Right Left Right Left Right Left Right Left Right Left Right Left Right Left

Vortex class C B C B --B C A C B --C --B --B --C --C C B C C --C

1-2

2.80

1-3

3.50

2-1

2.45

2-2

2.80

2-3

3.50

3-1

3.50

3-2 3 3-3

3.50

3.50

3-4

3.50

4-1

2.10

4-2

2.45

4-3

2.80

which is a set of vertical wedge shape thin walls (1-1, 1-2 and 1-3), increasing length of wedge shape walls has no significant effect on vortex class. However, installing a set of vertical wedge shape walls causes vortices to become unstable and by increase in the length of them, the instability was relatively increased. Installing Alternative 2 which was sloped vertical wall by different lengths had effect on the surface flow path lines by potential of circulation. This potential may be created by unsymmetrical reservoir geometry. This type of anti-vortex structures does not have any visible effect on degrading vortex classes as well as previous Alternative caused instability on formed vortices. Regarding to the effect of

sloped intake head walls on reduction of the strength of vortices (Sarkardeh et al., 2010), some test were performed by installing it on the model by using two lengths (3-1 and 3-2). Also, installing them does not add any meaningful effect on the vortex class. By combination of vertical sloped wall and sloped intake head wall, experiments were conducted to see the effect of working them together. In this condition, strength of vortices was reduced and all formed vortices became unstable. By considering the research of Amiri et al. (2011), installing solid anti-vortex plates at Alternative 4 had very good effect on vortex class degradation. This showed that cutting the vortex core pass caused decreasing the

Taghvaei et al.

5077

vortex class. By studying and comparing the flow conditions, the Alternative 4-2 had better performance. Conclusions In the present study different anti-vortex structures were tested on a physical model to eliminate or reduce the vortex strength. These structures could help designer and mangers to be allowed to use more water of the dam reservoir. 13 Alternatives and 3 different S/D between 2-4 and a current power intake discharge were selected. In each test effect of different Alternatives were visually studied. Finally, Alternative 4-2 which was solid plate had better performance to degrade vortex classes. ACKNOWLEDGEMENT The authors would like to thank Water Research Institute (WRI) for their kind cooperation in using data.

REFERENCES Amiri SM, Zarrati AR, Roshan R, Sarkardeh H (2011). Surface vortex prevention at power intakes by horizontal plates. J. Water Manag. (ICE) 164(4):193-200. Amphlett MB (1976). Air Entraining Vortices at Horizontal Intake. HRC Wallingford Rep. No.OD/7. Anwar HO, Weller JA, Amphlett MB (1978). Similarity of Free Vortex at Horizontal Intake. J. Hydraul. Res. 2:95-105.

Berge JP (1966). A Study of Vortex Formation and other Abnormal Flow in a Tank with and without a Free Surface. La Houille Blanche 1. Chang E (1977). Review of literature on drain vortices in cylindrical tanks. BHRA Rep. TN 1342. Daggett LL, Keulegan GH (1974). Similitude in free-surface vortex formation. ASCE J. Hydraul. Div. 100(11):1565-1580. Denny DF, Young GHJ (1957). The Prevention of Vortices and Swirl at Intakes. IAHR Cong. Lissabon paper C1. Gordon JL (1970). Vortices at Intakes. J. Water Power, 22(4):137-138. Jain AK, Raju KGR, Garde RJ (1987). Vortex Formation at Vertical Pipe Intake. J. Hydraul. Eng. 100(10):1427-1445. Knauss J (1987). Swirling flow problems at intakes. IAHR Hydraulic Structures Manual 1. Balkema, Rotterdam, The Netherlands pp.1338. Odgaard JA (1986). Free-surface air core vortex. J. Hydraul. Eng. 112(7):610-620. Padmanabhan M, Hecker GE (1984). Scale effects in pump sump models. J. Hydraulic Eng. 110(11):1540-1556. Reddy YR, Pickford JA (1972). Vortices at Intakes in Conventional Sumps. J. Water power 24(3):108-109. Sarkardeh H, Zarrati AR, Roshan R (2010). Effect of intake head wall and trash rack on vortices. J. Hydraul. Res. 48(1):108-112. Sarkardeh H, Zarrati AR, Jabbari E, Roshan R (2012). Discussion of Prediction of Intake Vortex Risk by Nearest Neighbors Modeling. J. Hydraul. Eng. ASCE 137(6):701-705. USBR (1987). Design of small dams. U.S. Department of the Interior, Bureau of Reclamation, Washington, DC. WRI Technical Report (2008). Hydraulic Model Studies of SiahBisheh Pump Storage Project. Hydraulic Structures Division. Water Research Institute (WRI) Tehran Iran.

Potrebbero piacerti anche

- Structural Design and Analysis: Composite Materials, Vol. 7Da EverandStructural Design and Analysis: Composite Materials, Vol. 7C. C. ChamisNessuna valutazione finora

- Cavitation Characteristics and Infinite Aspect Ration Characteristics of A Hydrofoil SectionDocumento31 pagineCavitation Characteristics and Infinite Aspect Ration Characteristics of A Hydrofoil SectionMuadz MuhammadNessuna valutazione finora

- Vortices PDFDocumento89 pagineVortices PDF10teste10100% (1)

- DP 07 Mechanical Bar Screen FDocumento2 pagineDP 07 Mechanical Bar Screen FEsteban N. Yucra LopezNessuna valutazione finora

- VFD Minimum Speed EquationDocumento4 pagineVFD Minimum Speed Equationforevertay2000Nessuna valutazione finora

- LdoDocumento12 pagineLdoAnonymous YcAZv5qF67Nessuna valutazione finora

- Mechanically Cleaned Bar Screens PDFDocumento4 pagineMechanically Cleaned Bar Screens PDFMarioNessuna valutazione finora

- Pipe Flow-Friction Factor Calculations With Excel Course Journal PDFDocumento30 paginePipe Flow-Friction Factor Calculations With Excel Course Journal PDFIzallmachineNessuna valutazione finora

- Iso5167 1 2003Documento38 pagineIso5167 1 2003OA Aoo100% (3)

- Air Vent in Penstock PDFDocumento14 pagineAir Vent in Penstock PDFGertjan DuniceriNessuna valutazione finora

- Surge Tank Thoma and Svee CriteriaDocumento79 pagineSurge Tank Thoma and Svee CriteriaManikandanNessuna valutazione finora

- Dorin Popescu FRP Allowable Stress - Intergraph CADWorx & AnalysisDocumento7 pagineDorin Popescu FRP Allowable Stress - Intergraph CADWorx & Analysisxaaabbb_550464353Nessuna valutazione finora

- Dynamic Testing of CheckvalveDocumento10 pagineDynamic Testing of Checkvalveamirthraj74Nessuna valutazione finora

- Pipe SupportDocumento6 paginePipe SupportEshant Rane RaneNessuna valutazione finora

- Residential Sprinkler System Design Handbook: A Step-By-Step Introduction To Design and InstallationDocumento20 pagineResidential Sprinkler System Design Handbook: A Step-By-Step Introduction To Design and Installationambition1340cnNessuna valutazione finora

- Air in Pipelines PDFDocumento92 pagineAir in Pipelines PDFJoelCristobalNessuna valutazione finora

- NotepadDocumento6 pagineNotepadAnkit KomarNessuna valutazione finora

- 14.surge Tanks Jan 2015 PDFDocumento10 pagine14.surge Tanks Jan 2015 PDFburhanuddin0% (1)

- TR-CON-Q0604-Foreman Electrical Works ConstructionDocumento162 pagineTR-CON-Q0604-Foreman Electrical Works ConstructionhkaruvathilNessuna valutazione finora

- Caihe ch1Documento30 pagineCaihe ch1dwaraganathan100% (1)

- Pump Calc ExampleDocumento21 paginePump Calc ExampleMohammad Usman HabibNessuna valutazione finora

- Design & Development of Air Release Valve/Anti Vacuum Valve For High PressureDocumento4 pagineDesign & Development of Air Release Valve/Anti Vacuum Valve For High PressureDheeraj ThakurNessuna valutazione finora

- Hydrodynamic Pressures On Sloping DamsDocumento7 pagineHydrodynamic Pressures On Sloping Damschutton681Nessuna valutazione finora

- Butterfly ValveDocumento8 pagineButterfly ValvebrunoNessuna valutazione finora

- ECF-SSF Actuator Catalogue DTD 08 11Documento20 pagineECF-SSF Actuator Catalogue DTD 08 11manmohansingh1999Nessuna valutazione finora

- USACE - Water Hammer and Mass Oscillation (WHAMO) Ver. 3.0 - UserDocumento256 pagineUSACE - Water Hammer and Mass Oscillation (WHAMO) Ver. 3.0 - UserAdrian FrantescuNessuna valutazione finora

- Pressure Loss in Schedule 40 Steel PipesDocumento11 paginePressure Loss in Schedule 40 Steel PipesAnonymous qrSsYuxyoYNessuna valutazione finora

- Ancient Roman Valves: Written by Wayne F. Lorenz, P.EDocumento7 pagineAncient Roman Valves: Written by Wayne F. Lorenz, P.Emaria romeroNessuna valutazione finora

- Silo Design Report-1Documento17 pagineSilo Design Report-1robertantoreniNessuna valutazione finora

- Labirinth Weirs Ijrewhs06Documento211 pagineLabirinth Weirs Ijrewhs06gertjaniNessuna valutazione finora

- Discharge Algorithms For Canal Radial GatesDocumento245 pagineDischarge Algorithms For Canal Radial Gatesbestbryant100% (1)

- 01 - AFT - Know Your Pump and System Curves - Part 1Documento7 pagine01 - AFT - Know Your Pump and System Curves - Part 1Alfonso José García LagunaNessuna valutazione finora

- OZKAN Butterfly ValvesDocumento11 pagineOZKAN Butterfly ValvesAhmed AbdelwaneesNessuna valutazione finora

- Pipe Flow CalculationDocumento5 paginePipe Flow CalculationEngr.Iqbal BaigNessuna valutazione finora

- AFT-Four Quadrant Pump Data - Theory Part 1 PDFDocumento15 pagineAFT-Four Quadrant Pump Data - Theory Part 1 PDFSCR_010101Nessuna valutazione finora

- On The Theoretical Link Between Design Parameters and Performance in Cross Flow Fans A Numerical and Experimental Study 2005 Computers and FluidsDocumento18 pagineOn The Theoretical Link Between Design Parameters and Performance in Cross Flow Fans A Numerical and Experimental Study 2005 Computers and Fluidsankushanks2591Nessuna valutazione finora

- TUTORIAL3 Series-Paralel-Branched Pipe SystemDocumento5 pagineTUTORIAL3 Series-Paralel-Branched Pipe SystemNurul QurratuNessuna valutazione finora

- Module 2 OM of Water PumpsDocumento101 pagineModule 2 OM of Water PumpsJeji Hirbora100% (1)

- Bell and Gossett Sump DesignDocumento8 pagineBell and Gossett Sump DesignVelpandian ManiNessuna valutazione finora

- Force Balance Design For Educational Wind TunnelsDocumento10 pagineForce Balance Design For Educational Wind Tunnelsnarien kondamNessuna valutazione finora

- Minor Loss Coefficients in Pipes and Tubes ComponentsDocumento1 paginaMinor Loss Coefficients in Pipes and Tubes ComponentsHimanshu1712Nessuna valutazione finora

- AFT Evaluating Pipe Dynamic Loads Caused by WaterhammerDocumento24 pagineAFT Evaluating Pipe Dynamic Loads Caused by WaterhammerroyalcomNessuna valutazione finora

- Elevated Water TankDocumento16 pagineElevated Water TankRANJITH PULIKESHINessuna valutazione finora

- UEME 3112 Flow VisualizationDocumento6 pagineUEME 3112 Flow Visualization嘉琪Nessuna valutazione finora

- Simplified Design of Flumes and WeirsDocumento17 pagineSimplified Design of Flumes and WeirsSalman LSBUNessuna valutazione finora

- Article1380536646 - Taghvaei Et AlDocumento9 pagineArticle1380536646 - Taghvaei Et AlAbdul wahid ButtNessuna valutazione finora

- Anti-Vortex Structures at Hydropower DamsDocumento10 pagineAnti-Vortex Structures at Hydropower DamsMohammad BayatlarNessuna valutazione finora

- Ijciet: International Journal of Civil Engineering and Technology (Ijciet)Documento18 pagineIjciet: International Journal of Civil Engineering and Technology (Ijciet)IAEME PublicationNessuna valutazione finora

- Numerical Investigation of Turbulent Flow Through Rectangular and Biconvex Shaped Trash RacksDocumento15 pagineNumerical Investigation of Turbulent Flow Through Rectangular and Biconvex Shaped Trash RacksEduardo Carrión C.Nessuna valutazione finora

- Comparative Analysis of Various Geometrical Shape Water Tanks Resting Over Ground For Same Capacity With Different Support ConditionsDocumento7 pagineComparative Analysis of Various Geometrical Shape Water Tanks Resting Over Ground For Same Capacity With Different Support ConditionsIJRASETPublicationsNessuna valutazione finora

- Continuous Assessment For Prof. Brendan O' Kelly - OdtDocumento18 pagineContinuous Assessment For Prof. Brendan O' Kelly - OdtteolearyNessuna valutazione finora

- Please Do Not Remove This Page: Thank You For Do Wnloading This Docum Ment From The Rmit R Research R RepositoryDocumento9 paginePlease Do Not Remove This Page: Thank You For Do Wnloading This Docum Ment From The Rmit R Research R RepositoryFreddie KooNessuna valutazione finora

- Ijaiem 2014 04 29 086Documento5 pagineIjaiem 2014 04 29 086International Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Anti-Clogging Drip Irrigation Emitter Design Innovation: Ali Abdulqader Mohammed AliDocumento11 pagineAnti-Clogging Drip Irrigation Emitter Design Innovation: Ali Abdulqader Mohammed AliVijay ChavanNessuna valutazione finora

- Development of Stilling Basin Models WitDocumento5 pagineDevelopment of Stilling Basin Models WitPinjis PliersNessuna valutazione finora

- 1 s2.0 S2214157X21005475 MainDocumento11 pagine1 s2.0 S2214157X21005475 Mainduraid ahmadNessuna valutazione finora

- Radial Consolidation TheoriesDocumento13 pagineRadial Consolidation TheoriesSidi Yéhia SounfountéraNessuna valutazione finora

- Determination of Submergence DepthDocumento8 pagineDetermination of Submergence DepthManikandan100% (1)

- Hydraulic Features of The Dissipation Chamber For Vortex Drop ShaftsDocumento8 pagineHydraulic Features of The Dissipation Chamber For Vortex Drop ShaftsMarco PazNessuna valutazione finora

- D Value CalcDocumento5 pagineD Value CalcAstri NgentNessuna valutazione finora

- Beam Desain1Documento2 pagineBeam Desain1Astri NgentNessuna valutazione finora

- Data Dial IndikatorDocumento2 pagineData Dial IndikatorAstri NgentNessuna valutazione finora

- ZX 100 K-Truss Support PadDocumento4 pagineZX 100 K-Truss Support PadAstri NgentNessuna valutazione finora

- Mud Barge Sea ChestDocumento1 paginaMud Barge Sea ChestAstri NgentNessuna valutazione finora

- Weld Analysis-IC Method v1.1Documento5 pagineWeld Analysis-IC Method v1.1jefersonpimentelNessuna valutazione finora

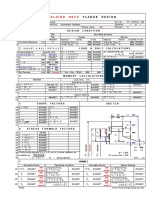

- Flange Example CalcDocumento14 pagineFlange Example CalcAstri NgentNessuna valutazione finora

- Spherical Roller Thrust Bearing PDFDocumento16 pagineSpherical Roller Thrust Bearing PDFAstri NgentNessuna valutazione finora

- Over Head Water Tank DesignDocumento5 pagineOver Head Water Tank DesignAstri Ngent100% (1)

- Bearing Layout PDFDocumento1 paginaBearing Layout PDFAstri NgentNessuna valutazione finora

- Gang SawDocumento55 pagineGang SawAstri NgentNessuna valutazione finora

- Brake and Shaft Seal UnitDocumento4 pagineBrake and Shaft Seal UnitAstri NgentNessuna valutazione finora

- College Physics Global 10th Edition Young Solutions ManualDocumento25 pagineCollege Physics Global 10th Edition Young Solutions ManualSaraSmithdgyj100% (57)

- En Jkm320pp (4bb)Documento2 pagineEn Jkm320pp (4bb)Ronal100% (1)

- Volumetric Efficiency: Object: To TheoryDocumento3 pagineVolumetric Efficiency: Object: To Theoryahmad shaheenNessuna valutazione finora

- Modeling and Simulation: Qiu-Zhou Runall - Tex - 12/25/2008 3:19am Page 13Documento51 pagineModeling and Simulation: Qiu-Zhou Runall - Tex - 12/25/2008 3:19am Page 13Samuel ChanNessuna valutazione finora

- CV 101Documento4 pagineCV 101frco1504Nessuna valutazione finora

- CHM 2045 Lab ReportDocumento11 pagineCHM 2045 Lab ReportlexilocoNessuna valutazione finora

- Earthquake AnalysisDocumento11 pagineEarthquake AnalysisSalauddinAnsariNessuna valutazione finora

- Boyles Law Lab AnswersDocumento5 pagineBoyles Law Lab AnswersShemelis AragawNessuna valutazione finora

- The Multiple Directions of Antiferromagnetic Spintronics Nature Physics PDFDocumento4 pagineThe Multiple Directions of Antiferromagnetic Spintronics Nature Physics PDFLog LouNessuna valutazione finora

- MATH22558 Final Project - Winter 2018Documento4 pagineMATH22558 Final Project - Winter 2018HardilazizNessuna valutazione finora

- Algebra2 Glenco EOCDocumento62 pagineAlgebra2 Glenco EOCDeborah LeeNessuna valutazione finora

- Vlsi DesignDocumento58 pagineVlsi Designy satishkumarNessuna valutazione finora

- Advanced Communication LaboratoryDocumento5 pagineAdvanced Communication LaboratoryJose DahlsonNessuna valutazione finora

- Questions and Solutions at End of Chapter 2: Measurement and Instrumentation. © 2016 Elsevier Inc. All Rights ReservedDocumento14 pagineQuestions and Solutions at End of Chapter 2: Measurement and Instrumentation. © 2016 Elsevier Inc. All Rights ReservedKevin AzizNessuna valutazione finora

- Signals & Systems (Solved Problems)Documento7 pagineSignals & Systems (Solved Problems)Lohith CoreelNessuna valutazione finora

- Condensate System ProtectionDocumento8 pagineCondensate System ProtectionmnasiroleslamiNessuna valutazione finora

- Electrical and Electronic Measurements and InstrumentationDocumento12 pagineElectrical and Electronic Measurements and InstrumentationKarthik VNessuna valutazione finora

- Simrit - Broșura Merkel PTFE U-RingsDocumento20 pagineSimrit - Broșura Merkel PTFE U-Ringsjo_rz_57Nessuna valutazione finora

- Calculus For Business and Social SciencesDocumento5 pagineCalculus For Business and Social SciencesMarchol PingkiNessuna valutazione finora

- Stiffness Analysis of FramesDocumento37 pagineStiffness Analysis of FramesCarolina VacaNessuna valutazione finora

- Higher School Physics Linear Motion Q&ADocumento9 pagineHigher School Physics Linear Motion Q&AGkid GkidNessuna valutazione finora

- International Conference: 26-27 (Saturday-Sunday)Documento5 pagineInternational Conference: 26-27 (Saturday-Sunday)suryamishraNessuna valutazione finora

- Lecture 24 - Strength Analysis of FuselagesDocumento6 pagineLecture 24 - Strength Analysis of FuselagesgavinNessuna valutazione finora

- Modified Moment Estimation For A Two Parameter Gamma DistributionDocumento9 pagineModified Moment Estimation For A Two Parameter Gamma DistributionInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Fundamentals of AC and All Air SystemDocumento36 pagineFundamentals of AC and All Air Systemnareshbv749Nessuna valutazione finora

- SkyscrapersDocumento31 pagineSkyscrapersAnas Shaikh100% (1)

- Formaldehyde Production 1Documento8 pagineFormaldehyde Production 1Raymond Feng100% (1)

- Division 2 - Site WorkDocumento14 pagineDivision 2 - Site WorkWincelet CelestinoNessuna valutazione finora

- Designing A MixerDocumento12 pagineDesigning A MixerPrasanna KumarNessuna valutazione finora

- Umass Lowell Computer Science 91.503: Graduate AlgorithmsDocumento46 pagineUmass Lowell Computer Science 91.503: Graduate AlgorithmsShivam AtriNessuna valutazione finora

- Well Control for Completions and InterventionsDa EverandWell Control for Completions and InterventionsValutazione: 4 su 5 stelle4/5 (10)

- Enhanced Oil Recovery Handout: A Focus on WaterfloodingDa EverandEnhanced Oil Recovery Handout: A Focus on WaterfloodingNessuna valutazione finora

- Well Integrity for Workovers and RecompletionsDa EverandWell Integrity for Workovers and RecompletionsValutazione: 5 su 5 stelle5/5 (3)

- A Practical Handbook for Drilling Fluids ProcessingDa EverandA Practical Handbook for Drilling Fluids ProcessingNessuna valutazione finora

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesDa EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesValutazione: 4 su 5 stelle4/5 (2)

- Advanced Production Decline Analysis and ApplicationDa EverandAdvanced Production Decline Analysis and ApplicationValutazione: 3.5 su 5 stelle3.5/5 (4)

- Casing and Liners for Drilling and Completion: Design and ApplicationDa EverandCasing and Liners for Drilling and Completion: Design and ApplicationValutazione: 5 su 5 stelle5/5 (3)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsDa EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNessuna valutazione finora

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideDa EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideValutazione: 2 su 5 stelle2/5 (1)

- Asset Integrity Management for Offshore and Onshore StructuresDa EverandAsset Integrity Management for Offshore and Onshore StructuresNessuna valutazione finora

- Flow Analysis for Hydrocarbon Pipeline EngineeringDa EverandFlow Analysis for Hydrocarbon Pipeline EngineeringNessuna valutazione finora

- Industrial Piping and Equipment Estimating ManualDa EverandIndustrial Piping and Equipment Estimating ManualValutazione: 5 su 5 stelle5/5 (7)

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsDa EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsNessuna valutazione finora

- Hybrid Enhanced Oil Recovery Using Smart WaterfloodingDa EverandHybrid Enhanced Oil Recovery Using Smart WaterfloodingNessuna valutazione finora

- An Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsDa EverandAn Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsNessuna valutazione finora

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryDa EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryValutazione: 5 su 5 stelle5/5 (3)

- The Petroleum Engineering Handbook: Sustainable OperationsDa EverandThe Petroleum Engineering Handbook: Sustainable OperationsValutazione: 3.5 su 5 stelle3.5/5 (5)

- Reservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesDa EverandReservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesValutazione: 5 su 5 stelle5/5 (7)

- Guide to the Practical Use of Chemicals in Refineries and PipelinesDa EverandGuide to the Practical Use of Chemicals in Refineries and PipelinesValutazione: 5 su 5 stelle5/5 (1)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDa EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesValutazione: 3.5 su 5 stelle3.5/5 (3)

- Essentials of Oil and Gas Utilities: Process Design, Equipment, and OperationsDa EverandEssentials of Oil and Gas Utilities: Process Design, Equipment, and OperationsValutazione: 4.5 su 5 stelle4.5/5 (4)

- 100 AI Use Cases in the Upstream Industry: A Comprehensive Guide for Professionals and Researchers to Overcome Industry Challenges Using AI and PythonDa Everand100 AI Use Cases in the Upstream Industry: A Comprehensive Guide for Professionals and Researchers to Overcome Industry Challenges Using AI and PythonNessuna valutazione finora