Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Technical Submittal

Caricato da

Haythem AhmedDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Technical Submittal

Caricato da

Haythem AhmedCopyright:

Formati disponibili

SAMCRETE CO.

TORMA SILO ENGINEERING

Ministry of Trade and Industry

Egyptian Holding Company for Silos and Storage

Grain Silo Complexes Tender

No. 6/2013

TECHNICAL DOCUMENTATION O ELE!T"O#MECHANICAL E$UI%MENT O" THE SILO %LANTS IN

SAN EL HAGGA" &El S'ar(ia Go)ernorate*+ EL MENIA&El Menia Go)ernorate* !!A T EL DA,A" &-e'eire Go)ernorate* EL !HAL!A &El !alou.ia Go)ernorate*

June 18 2013

SAMCRETE CO. TORMA SILO ENGINEERING

Contents/ 1. !e"#ni"al des"ription of t#e plants page $ 2. !e"#ni"al spe"ifi"ation for 2.1 San El Haggar flat %ottom solution page 11 2.11 San El Haggar #opper %ottom solution 2.2 El &enia flat %ottom solution page 21 2.21 El &enia #opper %ottom solution 2.3 'afr El (a)ar flat %ottom solution 2.31 'afr El (a)ar #opper %ottom solution 2.$ El '#al*a flat %ottom solution 2.$1 El '#al*a #opper %ottom solution 3. !e"#ni"al des"ription of t#e e,uipment $. Statements En.ironmental impa"t (e"laration of t#e design of dri.ing Cal"ulation of "apa"ity /. &anufa"turer and supplier of t#e e,uipment page 30 page 3+ page $page --

page 83

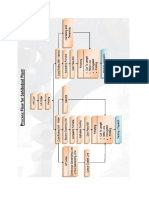

0nne1es2 References 3eferen"es of !43&0 5td. Drawings 6lo) diagrams for San El Haggar flat %ottom 6lo) diagram for San El Haggar #opper %ottom 6lo) diagram for 'afr El (a)ar and El '#al*a flat %ottom 6lo) diagram for El &enia flat %ottom 6lo) diagram for El &enia #opper %ottom 6lo) diagram for 'afr El (a)ar #opper %ottom 6lo) diagram for El '#al*a #opper %ottom 5ay out for San El Haggar flat %ottom and #opper %ottom

2

SAMCRETE CO. TORMA SILO ENGINEERING

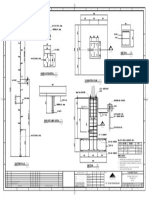

5ay out for 'afr El (a)ar and El '#al*a flat %ottom 5ay out for El &enia flat %ottom 5ay out for El &enia #opper %ottom 5ay out for 'afr El (a)ar #opper %ottom 5ay out for El '#al*a #opper %ottom 7or*ing to)er arrangement of 2/m #eig#t restri"tion 7or*ing to)er and side .ie) for flat %ottom of El &enia 'afr El (a)ar and El '#al*a Side .ie) for San El Haggar #opper %ottom !ru"* pit

Leaflets 5eaflet of %ins from S8&090 5eaflet for "#ain "on.eyor of :ntersystem 5eaflet of %u"*et ele.ator of :ntersystem 5eaflet of filters of &09 &illing C#ara"teristi" "ur.es for fans 5eaflet of ;i%rating pre"leaner of 7estrup 5eaflet of (esinse"tion e,uipment from (etia<(eges"# 5eaflet of &ulti)ay distri%utor of :ntersytem =>endulair?

SAMCRETE CO. TORMA SILO ENGINEERING

TECHNOLOGICAL DESC"I%TION O THE %LANTS

SAMCRETE CO. TORMA SILO ENGINEERING

!#e silo plants #a.e a "apa"ity as follo)s2 San El Haggar 60.000tons El &enia 60.000tons 'afr El (a)ar +0.000tons El '#al*a +0.000tons 0""ording to t#e !ender @oo* all of t#e silo<plants s#ould %e t)o different solution )#i"# are2 flat %ottom solution "on"rete #opper %ottom solution.

!#e operation of t#e silo plant )ill done %y a "ontrolling "omputer system )#ere t#e different operations are preliminary inAe"ted to t#e "omputer system =>5C? %ut t#ere is room for t#e operator to "ontrol t#e plant manually %y t#e *ey %oard. !o %e on t#e safe side t#ere is a possi%ility to operate all silo plants )it# pus# %uttons too. !o ma*e easier t#e operation t#e &asters Control >anel lo"ated in t#e "ontrol room )ill #a.e a surfa"e )it# t#e flo) diagram )#i"# is signalling t#e e,uipment in operation )it# lamps. !#e "ontrolling >C "an a%sor% all data from t#e 3oad )eig#%ridge t#e Continuous )eig#er and t#e !emperature monitoring. !#e "ontrolling >C "an %e "onne"ted to t#e %oo**eeping of t#e plant to *no) a"tually t#e sto"* t#e inflo) and outflo) "ontinuously.

SAMCRETE CO. TORMA SILO ENGINEERING

!#e follo)ing operations are possi%le2 3e"ei.ing operation !#e in"oming tru"* )ill %e measured at gate %y t#e )eig#%ridge. !#e dri.er )ill get a ti"*et )#i"# "ontains t#e total )eig#t of t#e tru"* t#e date )it# #our and minutes t#e plate num%er. 0fter t#e )eig#ing t#e dri.er )ill %e too* pla"e %y t#e re"ei.ing #opper. He open t#e tru"* and t#e load of t#e tru"* )ill %e poured to t#e re"ei.ing pit. !#e grain )ill fill t#e re"ei.ing pit. !#e "#ain "on.eyor pla"ed in t#e %ottom of t#e re"ei.ing #opper "olle"t t#e grain and t#roug# a rotary permanent magnet and a "ross "on.eyor it )ill %e "on.eyed to one of t#e %u"*et ele.ators. !#e %u"*et ele.ators )ill lift t#e grain and t#roug# a pendulair distri%utor t#e grain )ill %e "#uted to t#e "#arging "#ain "on.eyors pla"ed on t#e top of t#e silo %ins and it )ill %e "on.eyed to t#e "#osen silo %in. :f needed )eig#t measuring for t#e in"oming grain from t#e %u"*et ele.ator t#e grain )ill %e "#uted to t#e "ontinuous )eig#er. 6rom #ere t#e grain )ill go %y gra.ity to an ot#er %u"*et ele.ator )#i"# ele.ated t#e grain and t#e pro"ess "an start again to t#e filling t#e silo or using t#e "leaner. :n "ase of needed "leaning for t#e in"oming grain from t#e %u"*et ele.ator t#e grain )ill %e "#uted t#roug# a "as"ade magnet to t#e Cleaners. 6rom t#e Cleaners t#e grain )ill go %y gra.ity to an ot#er @u"*et ele.ator )#i"# lift t#e grain again and repeating t#e pro"ess )#at )e #a.e mentioned.

SAMCRETE CO. TORMA SILO ENGINEERING

6or t#e operator it is needed to gi.e t#e starting point =re"ei.ing pit? t#e pro"esses ="leaning and/or )eig#ing? and t#e finis#ing point =num%er of t#e storing %in?. 7#en #e #as gi.en t#is data and gi.e t#e order for t#e start t#e "omputer ma*e e.eryt#ing starting t#e ma"#ines in se,uen"es opening t#e .al.es et". and t#e operation )ill go smoot#ly. !#e tru"* )#en lea.e t#e site )ill %e measured again in t#e )eig#%ridge and get a ti"*et )it# t#e tara )eig#t t#e %rut )eig#t t#e date and t#e plate num%er. Normally t#is ti"*et )ill %e t#e main do"ument for t#e in.oi"ing and t#e sto"* management.

>reser.ing t#e grain !o preser.e t#e grain in t#e plant t#ere are t)o possi%ilities. 1. 0eration t#e %in 2. !urn around t#e grain 7#en t#e temperature in t#e %in =t#ere are 63 sensing points inside of t#e storing %in? rea"# a preliminary adAusted temperature t#e temperature monitoring system )ill gi.e a signal =a"ousti" and lig#t? a%out t#e #a.arie. !#e operator "an "#oose )#i"# system #e )ants to use. He "an start t#e fan of t#e %in )it# t#e #a.arie and t#e fan )ill pus# fres# ="ooler? air to t#e %in and t#e grain )ill %e "ooled. :f t#e outside temperature too #ig# or t#e aeration pro"ess is not #a.e an a""epta%le result t#e operator "an start turning t#e grain.

SAMCRETE CO. TORMA SILO ENGINEERING

:n t#is "ase t#e operator gi.e t#e "omputer t#e starting point =%in )it# #ig# temperature? and t#e finis#ing point =ot#er silo %in? and t#e "omputer )ill do e.eryt#ing to "on.ey t#e grain. !#e >C. )ill start t#e dis"#arging "#ain "on.eyor under t#e #ig# temperature %in start one of t#e @u"*et ele.ators start t#e "#arging "on.eyor open t#e .al.es and t#e pro"ess are running.

(eli.ering t#e grain !#e operator )ill appoint t#e starting point =t#e %in )#i"# )ill %e t#e sour"e for t#e deli.ering? t#e pro"ess =)eig#ing? and t#e finis#ing point =one of t#e transit %ins?< !#e "omputer )ill start t#e ma"#ines t#e dis"#arging "on.eyor t#e %u"*et ele.ator t#e "ontinuous )eig#er t#e "#arging "on.eyor for transit %in. 4pen t#e .al.es and t#e pro"ess )ill start immediately. :n "ase of t#e le.el indi"ators s#o) empty %in %y t#e flat %ottom solution t#e s)eeper s#ould start =it )ill go only rmanual "ontrolling? and t#e grain s#ould start to flo) again. !#e pro"ess )ill stop again if t#e le.el indi"ator )ill s#o) again empty status. !#e )eig#er "an %e adAusted t#at gi.e a signal and stop t#e pro"ess )#en t#e )eig#ted grain rea"# t#e gi.en le.el. =one tru"* load of grain? !#e empty tru"* at t#e gate )ill %e measured and )eig#t t#e tara and after t#at t#e tru"* )ill pla"e under t#e "#osen transit %ins. !#e operator )ill open t#e .al.e under t#e transit %in and t#e grain )ill %e poured to t#e tru"*. !#e lengt# of t#e fle1i%le teles"opi" dis"#arge tu%e )ill %e operated %y t#e dri.er to ma*e minimum t#e dust of t#e pouring grains. 7#en t#e tru"* is full t#e operator )ill stop t#e grain flo) t#e dri.er lift up t#e teles"opi" tu%e and lea.e t#e site. 9oing out t#e tru"* )ill %e measured and t#e dri.er get t#e ti"*et )it# t#e tara )eig#t t#e full )eig#t of tru"* t#e date t#e plate num%er. Normally t#is ti"*et is t#e do"ument fro t#e grain deli.ery.

8

SAMCRETE CO. TORMA SILO ENGINEERING

:mpurities and (ust "ontrolling system !#e in"oming grain "ontains impurities and dust. 4ur system "ontains t#e follo)ing se"tions for "ontrolling t#ese dust and impurities in t#e plant2 < 3oad #opper. !#e in"oming grain "ontains some per"entage of dust. 7#en t#e re"ei.ing pit #as "#arged %y t#e grain from tru"* some part of t#ese dust going into t#e air. !#e surfa"e of t#e #opper is open only t#e area )#ere grain is flo)ing do)n. 0 self "losing system pre.ent t#e dust "oming out from t#e pit. 7e use a su"tion system under t#is self "losing system. !#e dust )ill %e "olle"ted %y a filter system of #oses. 6rom t#e #oses t#e dust %y a "ounter<"urrent air %lo) fallen and a s"re) under t#e #oses out "#arging. !#e dust from #ere go %a"* to t#e "ross "on.eyor. < Cleaning system !#e grain arri.ing to t#e "leaner going t#roug# an Bair "urtainB )#i"# "olle"t out t#e dusted air. !#e dusted air "leaned %y a filter on t#e same )ay as )e e1plained %y t#e road #opper system. 6rom t#e filter t#e dust )ill %e "#uted to t#e dust %in. :n t#e "leaner t#e o.er and under siCed impurities )ill %e ta*e out. !#ese impurities )ill %e "#uted %y gra.ity to t#e impurities %in. < Central dust system 0ll e,uipment )#i"# pouring t#e grain =it means dust is a.aila%le? is "onne"ted to t#e "entral dedusting system. !#e ele.ators "#ain "on.eyors )eig#er are "onne"ted to t#e "entral dedu"ting system. !#e dusted air )ill %e su"*ing to t#e "entral dedusting system )#i"# )or*ing prin"iple is t#e same as t#e road #opper dedusting filter. !#e "#ain "on.eyors )ill %e "onne"ted to ea"# ot#er )#i"# means t#ey are t#e same airspa"e and enoug# to "onne"t t#e first one.

SAMCRETE CO. TORMA SILO ENGINEERING

Controlling system !#e "ontrol "omputer "an a%sor% t#e data of t#e in and outflo) of t#e )eig#%ridge and "an "on.ey t#e data for in.oi"ing if t#e Client )ants to get t#is *ind of a"ti.ities from our side. 0ll starting pro"ess is starting )it# an a"ousti" signal to gi.e )arning e.ery%ody a%out t#e starting of t#e pro"ess. !#e flo) diagram of t#e silo<plant "an %e seen at t#e monitor %uilt< in t#e "ontrol %oard. !#e %uttons indi"ated at t#e monitor %y t#e *ey%oard mouse "ontrols t#e pro"esses. !#e "oloring of t#e diagram indi"ates t#e )or*ing pro"ess. !#e )or*ing ma"#ine or tu%e )#ere t#e grain is flo) %e"omes green. !#e le.els are yello) et". 0ll of t#e %rea* do)n or #a.arie )ill gi.e a pulsing red lig#t. 0ll pro"ess "an %e starting or stopping )it# t#e *ey%oard and t#e mouse. :n "ase of needed all e,uipment and motors "an %e "ontrolled manually from t#e Control %oard. 7e put #ere a p#oto from a )or*ing plant )#i"# is similar as te"#nologi"al pro"ess %ut "ontains less %in and "on.eying ma"#ine. 7e put it #ere to see t#e "#ara"teristi"s of t#e solution )#at )e are offering. 0""ording to t#e tender pres"riptions )e )ill pla"e a flo) diagram of a %uilt in monitor and lig#t and start<stop %uttons on t#e front panel of t#e Control %oard. 7e #a.e systems )#i"# are )or*ing more t#an t)enty years )it#out any failure.

10

SAMCRETE CO. TORMA SILO ENGINEERING

TECHNICAL SPECIFICATION FOR THE SILO PLANT OF SAN EL HAGGAR

12

Specification for Egypt / Silos complex/2013.06

Specification for flat bottom of San El Haggar 60000MTs SILOPROJEKT Seizmic load UBC 2 12.06.2013 (1. Solution) Item Description Mechanical machinery 1* Silo bins for grain storage S1-S12 1*1 Roof aeration system 1*2 Ladder+3 platform 1*3 Ladder+1 platform 2* Aeration system flat bottom 2*1 Aeration fan 2*2 Distribution system for aeration +tubes 3* Transit bins T1, T2. T3 4* Bucket elevator E1, E2, E3, E4 5* Hopper chain conveyor ,special TR1 6* Cross /hopper/chain conveyor TR2 6*1 Cross chain conveyor TR2a 7* Charging chain conveyor to S1, S7 /TR 3, TR4/ 7*1 Charging chain conveyor to S4, S10 /TR5, TR6/ 8* Charging chain conveyor toS2,S3 /TR7/ 8*1 Charging chain conveyor toS5,S6 /TR8/ 8*2 Charging chain conveyor toS8,S9 /TR9/ 8*3 Charging chain conveyor toSS11,S12 /TR9/ 10* Charging chain conveyor to T1,T2,T3 / TR 11/ 11* Discharging chain conveyor S1,S2,S3 /TR12/ 11*1 Discharging chain conveyor S4, S5, S6 /TR13/ 11*2 Discharging chain conveyor /TR13a-cross/ 12* Discharging chain conveyor S7, S8, S9 /TR15/ 12*1 Discharging chain conveyor S10, S 11, S12 /TR16/ Pcs 12 12 4 8 12 24 12 3 4 1 1 1 2 2 1 1 1 1 1 1 1 1 1 1 Capacity 6850m3 6 vents 16 meters 3meters H type 11000m3/h 155m3 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h Page 13 Size Dia 22.15 0.29m2/pc platform 1x0.5m platform 1x0.5m 0.5x 60m 140mmWC Dia. 4,60m 36meters 22,0meters 22,0 meters 20,0meters 20,0meters 31meters 54meters 54meters 54meters 54meters 32,0 meters 70meters 52meters 28meters 70meters 52meters H=22,44m Power/ item kW Weight /item MT 720 1,44 1,3 1,2 1,2 7,68 1,4 15 22,4 3,3 3,2 2,2 5,6 5,6 4,5 4,5 4,5 4,5 3,2 8,5 4 2,3 8,5 4 Details see 3.1 3.2

3.2 3.2 3.53 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4

8 45 degree 18m pit length inclined 7 inclined 7 inclined 16 inclined 13 25+4 15 11 11 15 15 15 15 15 15 15 22,5 15 11 22,5 15

Item 12*2 12*3 13* 14* 15* 15*1 15*2 16 17* 17*1 18* 19* 20* 21* 22* 23* 26* 27*1 27*2

Description Discharging chain conveyor /TR16a-cross/ Discharging chain conveyor /TR20a, TR21a-cross/ Sweeper Dust collecting system for receiving hopper+fan Pre-cleaning machine Filter for precleaning machine with fan Collecting chain conveyor Central dust separation unit Dust and broken grain bin Dust discharging screw conveyor Two way direction boxes Pneumatic valves under silo bins Manual valves under bins Pneumatic valves under conveyor Telescopic discharge tube Desinsection equipment Screw compressor unit Air tank for compressor Tubes for compressed air (set) Temperature measuring system with computer and screen + UPS main. 28* connecting possibilities to the Controlling PC 28*1 Multiway distributor vertical (Pendulum) 29* Level indicators 30* Continuous weigher+standing 30*1 Prebin for weigher 30*2 After bin for weigher 31* Hoist crane 32* Road weighbridge 33* Catwalks for silos set 34* Catwalk for transit silos

Pcs 1 1 12 1 1 1 2 1 2 2 16 15 15 15 5 4 2 1 1

Capacity 200t/h 200t/h 60m2 200t/h 60m2 10t/h 60m2 60m3 15t/h 200t/h 200t/h 200t/h 200t/h 12tab/t/h 50m3/h 1m3 1,5"/1"/1/2"

Size 26meters 28meters 11 meters 20.000m3 SP-2000 20.000m3 38meters 20.000m3/h Dia 200mm 300x300mm 300x300mm 300x300mm 400x784mm 2.5meters 9 bars 445meters 6/5 sensors /cable 8 out capacitive 10m3 3m3 36 meters 21x3meters 2MT 1,2MT

Power/ item kW 11 11 30 18,5+0,75 3 18,5+0,75 4,4 18,5+0,75 2,2 pneumatic

cooler/dryer 300kgs with valves

0,75 7,5

Weight /item MT 2,7 2,8 9,6 3,2 3 3,2 0,9 3,2 3,2 0,8 1,4 0,9 0,45 1,1 0,6 0,08 1,4 0,3 13,2

Details see 3.4 3.4 3.54 3.7 3.9 3.7 3.10 3.7 3.12 3.11 3.13 3.5 3.6 3.5 3.16 3.15 3.17 3.18 3.19

1 4 29 2 2 2 1 1 1 1

7xcable/bin 1 in 200t/h

0,75 0,5

2 tons 100t Width 1400mm Width 1400mm Page 14

2,2 electronic 185m 38m

2,2 2,4 0,02 2,6 4 2,4 1,4 4,2 18,2 3,8

3.20 3.14 3.21 3.22 3.23 3.24 3.26 3.25 3.27 3.27

Item 34*1 35* 36* 36*1 36*2 37* 38* 39* 40* 41* 42* 43* 45* E4 E5 E6 E7 E7a E7b E8 E9 E10 E11 E12 E13 E14

Description Supporting structure for transit silos Chutes for grain (set) Grid for receiving hopper Buffling system under grid of hopper Steel hopper with AR surface Cascade magnet separator Rotary magnet separator Tubes for central dust deducting system (set) Duct system for road hopper (set) Technological tower Supporting elements and steel structure set Laboratory equipment Workshop Electrical machinery Main distribution board Power Factor Correction System Master Control Panel Motor control boxes Slide control boxes Two-way valve boxes Emergency stops Lighting system Lightning system Earthing system Aircraft approach light Fire fighting system Silo inspection light

Pcs 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 84 30 20 15 1 1 1 3 1 4

Capacity Dia 312mm

Size with elbows 18x3m 18x3m 2x18x2 meters

Power/ item kW

14MT 2.7MT 100m3 0,25 3,3MT

600Gauss 600Gauss

8x8.0m

app36m

Weight /item MT 9,6 5,4 14 2,7 13 0,12 0,2 2,8 2,5 23 7,9

Details see 3.28 3.29

3.31 3.31 3.32 3.33 3.34

1200kVA 60 Farad keyboard 19"monitor

5 sections UPS

1,2 2,2 0,8

3.39 3.40 3.41 3.42 3.42 3.42 3.43 3.45 3.44 3.46 3.47 3.48

with cables

200W

Page 15

Item Description Cables NYY 4 G 1,5 1500m NYY 4 G 2,5 1500m NYY 4 G 4 1400m NYY 4 G 6 250m NYY 4 G 16 450m NYY 4 G 50 100m YSLY 2x0,5 2500m YSLY 3x0,5 1500m YSLY 7x0,5 3500m YSLY 15x0,5 1200m E15 LiYLY 4x0,5 100m E16 Communication system E17 Air Conditioner Total Spare parts 44* Spare parts for the imported machines E18 Spare part for imported electrical items

Pcs

Capacity

Size

Power/ item kW

Weight /item MT

Details see

split type 1030,4 1018,69

3.49 3.50 3.51

1 1

for two years for two years

3.35 3.52

Page 16

Specification for Egypt / Silos complex/2013.06

Specification for concrete hopper bottom of San El Haggar 60000MTs SILOPROJEKT Seizmic load UBC 2 12.06.2013 (1. Solution) Item Description Mechanical machinery 1* Silo bins for grain storage S1-S12 1*1 Roof aeration system 1*2 Ladder+3 platform 1*3 Ladder+1 platform 2* Aeration system hopper bottom 2*1 Aeration fan 2*2 Distribution system for aeration +tubes 3* Transit bins T1, T2. T3 4* Bucket elevator E1, E2, E3, E4, 5* Hopper chain conveyor ,special TR1 6* Cross /hopper/chain conveyor TR2 6*1 Cross chain conveyor TR2a 7* Charging chain conveyor to S1, S7 /TR 3, TR4/ 7*1 Charging chain conveyor to S4, S10 /TR5, TR6/ 8* Charging chain conveyor toS2,S3 /TR7/ 8*1 Charging chain conveyor toS5,S6 /TR8/ 8*2 Charging chain conveyor toS8,S9 /TR9/ 8*3 Charging chain conveyor toSS11,S12 /TR9/ 10* Charging chain conveyor to T1,T2,T3 / TR 11/ 11* Discharging chain conveyor S1,S2,S3 /TR12/ 11*1 Discharging chain conveyor S4, S5, S6 /TR13/ 11*2 Discharging chain conveyor /TR13a-cross/ 12* Discharging chain conveyor S7, S8, S9 /TR15/ 12*1 Discharging chain conveyor S10, S 11, S12 /TR16/ Pcs 12 12 4 8 12 12 12 3 4 1 1 1 2 2 1 1 1 1 1 1 1 1 1 1 Capacity 5548m3 6 vents 16 meters 3meters 6pcs/bin 20000m3/h 155m3 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h Page 17 Size Dia 22.15 0.29m2/pc platform 1x0.5m platform 1x0.5m 8 meters long H=19,02m Power/ item kW Weight /item MT 555 1,44 1,3 1,2 9 7,68 14,4 15 22,4 3,3 3,2 2,2 5,6 5,6 4,5 4,5 4,5 4,5 3,2 8,5 4 2,3 8,5 4 Details see 3.1 3.2

3.2

15 Dia. 4,60m 36meters 22,0meters 22,0 meters 20,0meters 20,0meters 31meters 54meters 54meters 54meters 54meters 32,0 meters 70meters 52meters 28meters 70meters 52meters 45 degree 18m pit length inclined 7 inclined 7 inclined 16 inclined 13 25+4 15 11 11 15 15 15 15 15 15 15 22,5 15 11 22,5 15

3.53 3.3 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4

Item 12*3 14* 15* 15*1 15*2 16 17* 17*1 18* 19* 20* 21* 22* 23* 26* 27*1 27*2

Description Discharging chain conveyor /TR16a-cross/ Dust collecting system for receiving hopper+fan Pre-cleaning machine Filter for precleaning machine with fan Collecting chain conveyor Central dust separation unit Dust and broken grain bin Dust discharging screw conveyor Two way direction boxes Pneumatic valves under silo bins Manual valves under bins Pneumatic valves under conveyor Telescopic discharge tube Desinsection equipment Screw compressor unit Air tank for compressor Tubes for compressed air (set) Temperature measuring system with computer and screen + UPS main. connecting possibilities to the Controlling PC Multiway distributor vertical (Pendulum) Level indicators Continuous weigher+standing Prebin for weigher After bin for weigher Hoist crane Road weighbridge Catwalks for silos set Catwalk for transit silos Supporting structure for transit silos Chutes for grain (set)

Pcs 1 1 1 1 2 1 2 2 16 15 15 15 5 4 2 1 1

Capacity 200t/h 60m2 200t/h 60m2 10t/h 60m2 60m3 15t/h 200t/h 200t/h 200t/h 200t/h 12tab/t/h 50m3/h 1m3 1,5"/1"/1/2"

Size 28meters 20.000m3 SP-2000 20.000m3 38meters 20.000m3/h Dia 200mm 300x300mm 300x300mm 300x300mm 400x784mm 2.5meters 9 bars 445meters 6/5 sensors /cable 8 out capacitive 10m3 3m3 36 meters 21x3meters 2MT 1,2MT

Power/ item kW 11 18,5+0,75 3 18,5+0,75 4,4 18,5+0,75 2,2 pneumatic

cooler/dryer 300kgs with valves

0,75 7,5

Weight /item MT 2,8 3,2 3 3,2 0,9 3,2 3,2 0,8 1,4 0,9 0,45 1,1 0,6 0,08 1,4 0,3 13,2

Details see 3.4 3.7 3.9 3.7 3.10 3.7 3.12 3.11 3.13 3.5 3.6 3.5 3.16 3.15 3.17 3.18 3.19

28* 28*1 29* 30* 30*1 30*2 31* 32* 33* 34* 34*1 35*

1 4 29 2 2 2 1 1 1 1 1 1

7xcable/bin 1 in 200t/h

0,75 0,5

2 tons 100t Width 1400mm Width 1400mm Dia 312mm Page 18

2,2 electronic 185m 22m

with elbows

2,2 2,4 0,02 2,6 4 2,4 1,4 4,2 18,2 3,8 9,6 5,4

3.20 3.14 3.21 3.22 3.23 3.24 3.26 3.25 3.27 3.27 3.28 3.29

Item 36* 36*1 36*2 37* 38* 39* 40* 41* 42* 43* 45* E4 E5 E6 E7 E7a E7b E8 E9 E10 E11 E12 E13 E14

Description Grid for receiving hopper Buffling system under grid of hopper Steel hopper with AR surface Cascade magnet separator Rotary magnet separator Tubes for central dust deducting system (set) Duct system for road hopper (set) Technological tower Supporting elements and steel structure set Laboratory equipment Workshop Electrical machinery Main distribution board Power Factor Correction System Master Control Panel Motor control boxes Slide control boxes Two-way valve boxes Emergency stops Lighting system Lightning system Earthing system Aircraft approach light Fire fighting system Silo inspection light

Pcs 1 1 1 1 1 1 1 1 1 1 1 1 1 1 44 30 16 15 1 1 1 3 1 4

Capacity

Size 18x3m 18x3m 2x18x2 meters

Power/ item kW 14MT 2.7MT 100m3 0,25 3,3MT

600Gauss 600Gauss

8x8.0m

app36m

Weight /item MT 14 2,7 13 0,12 0,2 2,8 2,5 23 7,9

Details see

3.31 3.31 3.32 3.33 3.34

900kVA 60 Farad keyboard 19"monitor

5 sections UPS

1,2 2,2 0,8

3.39 3.40 3.41 3.42 3.42 3.42 3.43 3.45 3.44 3.46 3.47 3.48

with cables

200W

Page 19

Item Description Cables NYY 4 G 1,5 1500m NYY 4 G 2,5 1500m NYY 4 G 4 1400m NYY 4 G 6 250m NYY 4 G 16 450m NYY 4 G 50 100m YSLY 2x0,5 2500m YSLY 3x0,5 1500m YSLY 7x0,5 3500m YSLY 15x0,5 1200m LiYLY 4x0,5 100m Communication system Air Conditioner Total Spare parts Spare parts for the imported machines Spare part for imported electrical items

Pcs

Capacity

Size

Power/ item kW

Weight /item MT

Details see

E15 E16 E17

split type 643,9 862,19

3.49 3.50 3.51

44* E18

1 1

for two years for two years

3.35 3.52

Page 20

SAMCRETE CO. TORMA SILO ENGINEERING

TECHNICAL SPECIFICATION FOR THE SILO PLANT OF EL MENIA

21

Specification for Egypt / Silos complex/2013.06

Specification for flat bottom of El Menia 60000MTs SILOPROJEKT Seizmic load UBC 2 12.06.2013 (1. Solution) Item Description Mechanical machinery 1* Silo bins for grain storage S1-S12 1*1 Roof aeration system 1*2 Ladder+3 platform 1*3 Ladder+1 platform 2* Aeration system flat bottom 2*1 Aeration fan 2*2 Distribution system for aeration +tubes 3* Transit bins T1, T2. T3 4* Bucket elevator E1, E2, E3, E4, 5* Hopper chain conveyor ,special TR1 6* Cross /hopper/chain conveyor TR2 6*1 Cross chain conveyor TR2a 7* Charging chain conveyor to S1, S7 /TR 3, TR4/ 7*1 Charging chain conveyor to S3, S9 /TR5, TR6/ 7*2 Charging chain conveyor to S2, S8 /TR7, TR8/ 8* Charging chain conveyor toS4,S5,S6 /TR9-TR11/ 8*1 10* 11* 11*1 11*2 11*3 12* Charging chain conveyor to S10,S11,S12 /TR12-TR14/ Charging chain conveyor to T1,T2,T3 /TR 15/ Discharging chain conveyor S2,S5 /TR16 Discharging chain conveyor S1-S4, /TR17/ Discharging chain conveyor S3,S6 /TR18/ Discharging chain conveyor TR17a-TR18a-cross Discharging chain conveyor S8, S11 /TR19/ Pcs 12 12 6 6 12 24 12 3 4 1 1 1 2 2 2 3 3 2 1 1 1 2 1 Capacity 6850m3 6 vents 16 meters 3meters H type 11000m3/h 155m3 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h Page 22 Size Dia 22.15 0.29m2/pc platform 1x0.5m platform 1x0.5m 0.5x 60m H=22,44m Power/ item kW Weight /item MT 720 1,44 1,3 1,2 1,2 7,68 1,4 15 20,4 3,3 3,2 2,2 5,6 5,6 3 2,3 2,3 3,2 3,9 2,3 2,3 6 3,8 Details see 3.1 3.2

3.2

8 Dia. 4,60m 31meters 22,0meters 22,0 meters 20,0meters 30meters 30meters 17meters 25meters 25meters 32,0 meters 40meters 26meters 26meters 31meters 40meters 45 degree 18m pit length inclined 7 inclined 7 inclined 10 inclined 10 inclined 10 21+4 15 11 11 15 15 11 11 11 15 15 11 11 15 15

3.53 3.3 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4

Item 12*1 12*2 12*3 13* 14* 15* 15*1 15*2 16 17* 17*1 18* 19* 20* 21* 22* 23* 26* 27*1 27*2

Description Discharging chain conveyor S7, S 10 /TR20/ Discharging chain conveyor S9, S 12 /TR21/ Discharging chain conveyor /TR20a, TR21a-cross/ Sweeper Dust collecting system for receiving hopper+fan Pre-cleaning machine Filter for precleaning machine with fan Collecting chain conveyor Central dust separation unit Dust and broken grain bin Dust discharging screw conveyor Two way direction boxes Pneumatic valves under silo bins Manual valves under bins Pneumatic valves under conveyor Telescopic discharge tube Desinsection equipment Screw compressor unit Air tank for compressor Tubes for compressed air (set)

Pcs 1 1 2 12 1 1 1 2 1 2 2 20 15 15 15 5 4 2 1 1

Capacity 200t/h 200t/h 200t/h 200t/h 60m2 200t/h 60m2 30t/h 60m2 60m3 15t/h 200t/h 200t/h 200t/h 200t/h 12tab/t/h 50m3/h 1m3 1,5"/1"/1/2"

Size 26 meters 26meters 31meters 11 meters 20.000m3 SP-2000 20.000m3 38meters 20.000m3/h Dia 200mm 300x300mm 300x300mm 300x300mm 400x784mm 2.5meters 9 bars 545meters 6/5 sensors /cable 8 out capacitive 10m3 3m3 25 meters 21x3meters 2MT 1,2MT

Power/ item kW 11 11 15 30 22+0,75 3 22+0,75 4,4

2,2 pneumatic

cooler/dryer 300kgs with valves

0,75 7,5

Weight /item MT 2,3 2,3 6 9,6 3,2 3 3,2 0,9 3,2 3,2 0,8 1,4 0,9 0,45 1,1 0,6 0,08 1,4 0,3 13,2

Details see 3.4 3.4 3.4 3.54 3.7 3.9 3.7 3.10 3.7 3.12 3.11 3.13 3.5 3.6 3.5 3.16 3.15 3.17 3.18 3.19

Temperature measuring system with computer and screen + UPS main. 28* connecting possibilities to the Controlling PC 28*1 Multiway distributor vertical (Pendulum) 29* Level indicators 30* Continuous weigher+standing 30*1 Prebin for weigher 30*2 After bin for weigher 31* Hoist crane 32* Road weighbridge 33* Catwalks for silos set

1 4 27 2 2 2 1 1 1

7xcable/bin 1 in 200t/h

0,75 0,5

2 tons 100t Width 1400mm Page 23

1,5 electronic total 366m

2,2 2,4 0,02 2,6 4 2,4 1,1 4,2 31,2

3.20 3.14 3.21 3.22 3.23 3.24 3.26 3.25 3.27

Item 34* 34*1 35* 36* 36*1 36*2 37* 38* 39* 40* 41* 42* 43* 45* E4 E5 E6 E7 E7a E7b E8 E9 E10 E11 E12 E13 E14

Description Catwalk for transit silos Supporting structure for transit silos Chutes for grain (set) Grid for receiving hopper Buffling system under grid of hopper Steel hopper with AR surface Cascade magnet separator Rotary magnet separator Tubes for central dust deducting system (set) Duct system for road hopper (set) Technological tower Supporting elements and steel structure set Laboratory equipment Workshop Electrical machinery Main distribution board Power Factor Correction System Master Control Panel Motor control boxes Slide control boxes Two-way valve boxes Emergency stops Lighting system Lightning system Earthing system Aircraft approach light Fire fighting system Silo inspection light

Pcs 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 71 30 20 15 1 1 1 3 1 4

Capacity Width 1400mm Dia 312mm

Size 38m with elbows 18x3m 18x3m 2x18x2 meters

Power/ item kW

14MT 2.7MT 100m3 0,25 3,3MT

600Gauss 600Gauss

8x8.0m

app25,0m

Weight /item MT 3,8 9,6 5,4 14 2,7 13 0,12 0,2 2,8 2,5 23 7,9

Details see 3.27 3.28 3.29

3.31 3.31 3.32 3.33 3.34

1200kVA 60 Farad keyboard 19"monitor

5 sections UPS

1,2 2,2 0,8

3.39 3.40 3.41 3.42 3.42 3.42 3.43 3.45 3.44 3.46 3.47 3.48

200W

Page 24

Item Description Cables NYY 4 G 1,5 1500m NYY 4 G 2,5 2500m NYY 4 G 4 1900m NYY 4 G 6 450m NYY 4 G 16 550m NYY 4 G 50 100m YSLY 2x0,5 2900m YSLY 3x0,5 1500m YSLY 7x0,5 4500m YSLY 15x0,5 1400m LiYLY 4x0,5 100m Communication system Air Conditioner Total Spare parts Spare parts for the imported machines Spare part for imported electrical items

Pcs

Capacity

Size

Power/ item kW

Weight /item MT

Details see

E15 E16 E17

split type 1086,45 1015,09

3.49 3.50 3.51

44* E18

1 1

for two years for two years

3.35 3.52

Page 25

Specification for Egypt / Silos complex/2013.06

Specification for concrete hopper bottom of El Menia 60000MTs SILOPROJEKT Seizmic load UBC 2 12.06.2013 (1. Solution) Item Description Mechanical machinery 1* Silo bins for grain storage S1-S12 1*1 Roof aeration system 1*2 Ladder+3 platform 1*3 Ladder+1 platform 2* Aeration system hopper bottom 2*1 Aeration fan 2*2 Distribution system for aeration +tubes 3* Transit bins T1, T2. T3 4* Bucket elevator E1, E2, E3, E4, 5* Hopper chain conveyor ,special TR1 6* Cross /hopper/chain conveyor TR2 6*1 Cross chain conveyor TR2a 7* Charging chain conveyor to S1, S7 /TR 3, TR4/ 7*1 Charging chain conveyor S3, S9 /TR5, TR6/ 7*2 Charging chain conveyor S2, S8 /TR7, TR8/ 8* Charging chain conveyor toS4,S5,S6 /TR9-TR11/ 8*1 10* 11* 11*1 11*2 11*3 12* Charging chain conveyor to S10,S11,S12 /TR12-TR14/ Charging chain conveyor to T1,T2,T3 /TR 15/ Discharging chain conveyor S2,S5 /TR16 Discharging chain conveyor S1-S4, /TR17/ Discharging chain conveyor S3,S6 /TR18/ Discharging chain conveyor TR17a-TR18a-cross Discharging chain conveyor S8, S11 /TR19/ Pcs 12 12 6 6 12 12 12 3 4 1 1 1 2 2 2 3 3 2 1 1 1 2 1 Capacity 4474m3 6 vents 16 meters 3meters 6 pcs/bin 20000m3/h 155m3 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h Page 26 Size Dia 27,5m 0.29m2/pc platform 1x0.5m platform 1x0.5m 8 meters long H=13,4m Power/ item kW Weight /item MT 740 1,44 1,3 1,2 9 4,8 14,4 15 20,4 3,3 3,2 2,2 5,6 5,6 3 9,3 9,3 6,4 5 3,1 3,1 7 5 Details see 3.1 3.2

3.2

15 Dia. 4,60m 31meters 22,0meters 22,0 meters 20,0meters 34meters 34meters 20meters 30meters 30meters 32,0 meters 54meters 32,0 meters 32,0 meters 36meters 54meters 45 degree 18m pit length inclined 7 inclined 7 inclined 10 inclined 10 inclined 10 21+4 15 11 11 15 15 11 15 15 15 18,75 15 15 15 18,75

3.53 3.3 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4

Item 12*1 12*2 12*3 14* 15* 15*1 15*2 16 17* 17*1 18* 19* 20* 21* 22* 23* 26* 27*1 27*2

Description Discharging chain conveyor S7, S 10 /TR20/ Discharging chain conveyor S9, S 12 /TR21/ Discharging chain conveyor /TR20a, TR21a-cross/ Dust collecting system for receiving hopper+fan Pre-cleaning machine Filter for precleaning machine with fan Collecting chain conveyor Central dust separation unit Dust and broken grain bin Dust discharging screw conveyor Two way direction boxes Pneumatic valves under silo bins Manual valves under bins Pneumatic valves under conveyor Telescopic discharge tube Desinsection equipment Screw compressor unit Air tank for compressor Tubes for compressed air (set) Temperature measuring system with computer and screen + UPS main. 28* connecting possibilities to the Controlling PC 28*1 Multiway distributor vertical (Pendulum) 29* Level indicators 30* Continuous weigher+standing 30*1 Prebin for weigher 30*2 After bin for weigher 31* Hoist crane 32* Road weighbridge 33* Catwalks for silos set 34* Catwalk for transit silos

Pcs 1 1 2 1 1 1 2 1 2 2 20 15 15 15 5 4 2 1 1

Capacity 200t/h 200t/h 200t/h 60m2 200t/h 60m2 30t/h 60m2 60m3 15t/h 200t/h 200t/h 200t/h 200t/h 12tab/t/h 50m3/h 1m3 1,5"/1"/1/2"

Size 32,0 meters 32,0 meters 36meters 20.000m3 SP-2000 20.000m3 38meters 20.000m3/h Dia 200mm 300x300mm 300x300mm 300x300mm 400x784mm 2.5meters 9 bars 995meters 6/5 sensors /cable 8 out capacitive 10m3 3m3 25 meters 21x3meters 2MT 1,2MT

Power/ item kW 15 15 15 22+0,75 3 22+0,75 4,4 22+0,75 2,2 pneumatic

cooler/dryer 300kgs with valves

0,75 7,5

Weight /item MT 3,1 3,1 7 3,2 3 3,2 0,9 3,2 3,2 0,8 1,4 0,9 0,45 1,1 0,6 0,08 1,4 0,3 13,2

Details see 3.4 3.4 3.4 3.7 3.9 3.7 3.10 3.7 3.12 3.11 3.13 3.5 3.6 3.5 3.16 3.15 3.17 3.18 3.19

1 4 29 2 2 2 1 1 1 1

7xcable/bin 1 in 200t/h

0,75 0,5

2 tons 100t Width 1400mm Width 1400mm Page 27

1,5 electronic total 474m 38m

2,2 2,4 0,02 2,6 4 2,4 1,1 4,2 43,5 3,8

3.20 3.14 3.21 3.22 3.23 3.24 3.26 3.25 3.27 3.27

Item 34*1 35* 36* 36*1 36*2 37* 38* 39* 40* 41* 42* 43* 45* E4 E5 E6 E7 E7a E7b E8 E9 E10 E11 E12 E13 E14

Description Supporting structure for transit silos Chutes for grain (set) Grid for receiving hopper Buffling system under grid of hopper Steel hopper with AR surface Cascade magnet separator Rotary magnet separator Tubes for central dust deducting system (set) Duct system for road hopper (set) Technological tower Supporting elements and steel structure set Laboratory equipment Workshop Electrical machinery Main distribution board Power Factor Correction System Master Control Panel Motor control boxes Slide control boxes Two-way valve boxes Emergency stops Lighting system Lightning system Earthing system Aircraft approach light Fire fighting system Silo inspection light

Pcs 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 71 30 20 15 1 1 1 3 1 4

Capacity Dia 312mm

Size with elbows 18x3m 18x3m 2x18x2 meters

Power/ item kW

14MT 2.7MT 100m3 0,25 3,3MT

600Gauss 600Gauss

8x8.0m

app25,0m

Weight /item MT 9,6 5,4 14 2,7 13 0,12 0,2 2,8 2,5 23 7,9

Details see 3.28 3.29

3.31 3.31 3.32 3.33 3.34

900kVA 60 Farad keyboard 19"monitor

5 sections UPS

1,2 2,2 0,8

3.39 3.40 3.41 3.42 3.42 3.42 3.43 3.45 3.44 3.46 3.47 3.48

200W

Page 28

Item Description Cables NYY 4 G 1,5 1800m NYY 4 G 2,5 100m NYY 4 G 4 1900m NYY 4 G 6 350m NYY 4 G 16 750m NYY 4 G 50 100m YSLY 2x0,5 2900m YSLY 3x0,5 2500m YSLY 7x0,5 4200m YSLY 15x0,5 1800m E15 LiYLY 4x0,5 100m E16 Communication system E17 Air Conditioner Total Spare parts 44* Spare parts for the imported machines E18 Spare part for imported electrical items

Pcs

Capacity

Size

Power/ item kW

Weight /item MT

Details see

split type 784,7 1080,41

3.49 3.50 3.51

1 1

for two years for two years

3.35 3.52

Page 29

SAMCRETE CO. TORMA SILO ENGINEERING

TECHNICAL SPECIFICATION FOR THE SILO PLANT OF KAFR EL DAWAR

30

Specification for Egypt / Silos complex/2013.06

Specification for flat bottom of Kafr El Dawar 90000MTs SILOPROJEKT Seizmic load UBC 3 12.06.2013 (1. Solution) Item Description Mechanical machinery 1* Silo bins for grain storage S1-S18 1*1 Roof aeration system 1*2 Ladder+3 platform 1*3 Ladder+1 platform 2* Aeration system flat bottom 2*1 Aeration fan 2*2 Distribution system for aeration +tubes 3* Transit bins T1, T2. T3 4* Bucket elevator E1, E2, E3, E4, 5* Hopper chain conveyor ,special TR1 6* Cross /hopper/chain conveyor TR2 6*1 Cross chain conveyor TR2a 7* Charging chain conveyor to S1, S7 /TR 3, TR4/ 7*1 Charging chain conveyor to S3, S9 /TR5, TR6/ 7*2 Charging chain conveyor to S2, S8 /TR7, TR8/ Charging chain conveyor to S4-S13,S5-S14,SS15 /TR9-TR11/ 8* Charging chain conveyor to S10-S16,S11-S17,S12-S18/TR12-TR14/ 8*1 10* Charging chain conveyor to T1,T2,T3 / TR 15/ 11* Discharging chain conveyor S2,S5,S14 /TR16 11*1 Discharging chain conveyor S1-S4,S13 /TR17/ 11*2 Discharging chain conveyor S3,S6,S15 /TR18/ 11*3 Discharging chain conveyor TR17a-TR18a-cross 12* Discharging chain conveyor S8, S11,S17 /TR19/ Pcs 18 18 6 12 18 36 18 3 4 1 1 1 2 2 2 3 3 2 1 1 1 2 1 Capacity 6850m3 6 vents 16 meters 3meters H type 11000m3/h 155m3 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h Page 31 Size Dia 22.15 0.29m2/pc platform 1x0.5m platform 1x0.5m 0.5x 60m H=22,44m Power/ item kW Weight /item MT 1080 2,04 1,3 1,4 2 11,52 1,8 15 20,4 3,3 3,2 2,2 5,6 5,6 3 8,9 8,9 3,2 5,2 4,5 4,5 6 5,2 Details see 3.1 3.2

3.2

8 Dia. 4,60m 31meters 22,0meters 22,0 meters 20,0meters 30meters 30meters 17meters 52meters 52meters 32,0 meters 66meters 52meters 52meters 31meters 66meters 45 degree 18m pit length inclined 7 inclined 7 inclined 10 inclined 10 inclined 10 21+4 15 11 11 15 15 11 18,75 18,75 15 22,5 18,75 18,75 15 22,5

3.53 3.3 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4

Item 12*1 12*2 12*3 13* 14* 15* 15*1 15*2 16 17* 17*1 18* 19* 20* 21* 22* 23* 26* 27*1 27*2

Description Discharging chain conveyor S7, S 10, S16 /TR20/ Discharging chain conveyor S9, S 12, S 18 /TR21/ Discharging chain conveyor /TR20a, TR21a-cross/ Sweeper Dust collecting system for receiving hopper+fan Pre-cleaning machine Filter for precleaning machine with fan Collecting chain conveyor Central dust separation unit Dust and broken grain bin Dust discharging screw conveyor Two way direction boxes Pneumatic valves under silo bins Manual valves under bins Pneumatic valves under conveyor Telescopic discharge tube Desinsection equipment Screw compressor unit Air tank for compressor Tubes for compressed air (set) Temperature measuring system with computer and screen + UPS main. 28* connecting possibilities to the Controlling PC 28*1 Multiway distributor vertical (Pendulum) 29* Level indicators 30* Continuous weigher+standing 30*1 Prebin for weigher 30*2 After bin for weigher 31* Hoist crane 32* Road weighbridge 33* Catwalks for silos set

Pcs 1 1 2 18 1 1 1 2 1 2 2 20 21 21 27 5 4 2 1 1

Capacity 200t/h 200t/h 200t/h 200t/h 60m2 200t/h 60m2 30t/h 60m2 60m3 15t/h 200t/h 200t/h 200t/h 200t/h 12tab/t/h 50m3/h 1m3 1,5"/1"/1/2"

Size 52meters 52meters 31meters 11 meters 20.000m3 SP-2000 20.000m3 38meters 20.000m3/h Dia 200mm 300x300mm 300x300mm 300x300mm 400x784mm 2.5meters 9 bars 755meters 6/5 sensors /cable 8 out capacitive 10m3 3m3 25 meters 21x3meters 2MT 1,2MT

Power/ item kW 18,75 18,75 15 30 22+0,75 3 22+0,75 4,4

2,2 pneumatic

0,75 cooler/dryer 300kgs with valves

Weight /item MT 4,5 4,5 6 9,6 3,2 3 3,2 0,9 3,2 3,2 0,8 1,4 0,9 0,45 1,1 0,6 0,08 1,4 0,3 13,2

Details see 3.4 3.4 3.4 3.54 3.7 3.9 3.7 3.10 3.7 3.12 3.11 3.13 3.5 3.6 3.5 3.16 3.15 3.17 3.18 3.19

1 4 36 2 2 2 1 1 1

7xcable/bin 1 in 200t/h

0,75 0,5

2 tons 100t Width 1400mm Page 32

1,5 electronic total 590m

2,2 2,4 0,02 2,6 4 2,4 1,1 4,2 49,2

3.20 3.14 3.21 3.22 3.23 3.24 3.26 3.25 3.27

Item 34* 34*1 35* 36* 36*1 36*2 37* 38* 39* 40* 41* 42* 43* 45* E4 E5 E6 E7 E7a E7b E8 E9 E10 E11 E12 E13 E14

Description Catwalk for transit silos Supporting structure for transit silos Chutes for grain (set) Grid for receiving hopper Buffling system under grid of hopper Steel hopper with AR surface Cascade magnet separator Rotary magnet separator Tubes for central dust deducting system (set) Duct system for road hopper (set) Technological tower Supporting elements and steel structure set Laboratory equipment Workshop Electrical machinery Main distribution board Power Factor Correction System Master Control Panel Motor control boxes Slide control boxes Two-way valve boxes Emergency stops Lighting system Lightning system Earthing system Aircraft approach light Fire fighting system Silo inspection light

Pcs 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 101 42 20 15 1 1 1 3 1 4

Capacity Width 1400mm Dia 312mm

Size 38m with elbows 18x3m 18x3m 2x18x2 meters

Power/ item kW

14MT 2.7MT 100m3 0,25 3,3MT

600Gauss 600Gauss

8x8.0m

app25,0m

Weight /item MT 3,8 9,6 7,3 14 2,7 13 0,12 0,2 2,8 2,5 23 7,9

Details see 3.27 3.28 3.29

3.31 3.31 3.32 3.33 3.34

1600kVA 60 Farad keyboard 19"monitor

5 sections UPS

1,2 2,2 0,8

3.39 3.40 3.41 3.42 3.42 3.42 3.43 3.45 3.44 3.46 3.47 3.48

200W

Page 33

Item Description Cables NYY 4 G 1,5 1600m NYY 4 G 2,5 1600m NYY 4 G 4 2200m NYY 4 G 6 450m NYY 4 G 16 850m NYY 4 G 50 100m YSLY 2x0,5 3100m YSLY 3x0,5 1800m YSLY 7x0,5 3900m YSLY 15x0,5 1500m LiYLY 4x0,5 100m Communication system Air Conditioner Total Spare parts Spare parts for the imported machines Spare part for imported electrical items

Pcs

Capacity

Size

Power/ item kW

Weight /item MT

Details see

E15 E16 E17

split type 1439,95 1425,53

3.49 3.50 3.51

44* E18

1 1

for two years for two years

3.35 3.52

Page 34

Specification for Egypt / Silos complex/2013.06

Specification for concrete hopper bottom of Kafr El Dawar 90000MTs SILOPROJEKT Seizmic load UBC 3 12.06.2013 (1. Solution) Item Description Mechanical machinery 1* Silo bins for grain storage S1-S18 1*1 Roof aeration system 1*2 Ladder+3 platform 1*3 Ladder+1 platform 2* Aeration system hopper bottom 2*1 Aeration fan 2*2 Distribution system for aeration +tubes 3* Transit bins T1, T2. T3 4* Bucket elevator E1, E2, E3, E4, 5* Hopper chain conveyor ,special TR1 6* Cross /hopper/chain conveyor TR2 6*1 Cross chain conveyor TR2a 7* Charging chain conveyor to S1, S11 /TR 3, TR4/ 7*1 Charging chain conveyor to S4, S13 /TR5, TR6/ 7*2 Charging chain conveyor to S2, S3 /TR7, TR8/ 7*8 7*9 10* 11* Charging chain conveyor S16, S 18 /TR17/ Charging chain conveyor S14 /TR18/ Charging chain conveyor to T1,T2,T3 Discharging chain conveyor/TR21/ / TR20/ Pcs 18 18 6 12 18 18 18 3 4 1 1 1 2 2 2 1 1 1 1 1 1 1 1 1 Capacity 4474m3 6 vents 16 meters 3meters 6 pcs/bin 20000m3/h 155m3 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h Page 35 Size Dia 27,5m 0.29m2/pc platform 1x0.5m platform 1x0.5m 8 meters long H=13,4m Power/ item kW Weight /item MT 742 2,04 1,3 1,4 9 7,2 14,4 15 20,4 3,3 3,2 2,2 5,6 5,6 3 4,3 3,6 2,2 3,2 4,1 3,2 3,2 4,1 2,2 Details see 3.1 3.2

3.2

15 Dia. 4,60m 31meters 22,0meters 22,0 meters 20,0meters 40meters 40meters 26meters 45meters 32 meters 26 meters 32,0 meters 54meters 32meters 32meters 54meters 26 meters 45 degree 18m pit length inclined 7 inclined 7 inclined 10 inclined 10 inclined 10 21+4 15 11 11 15 15 11 18,75 15 11 15 18,75 15 15 18,75 11

3.53 3.3 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4

7*10 Charging chain conveyor S17 /TR19/

11*1 Discharging chain conveyor S7-S10 /TR22/ 11*2 Discharging chain conveyor S9 /TR23/ 11*3 Discharging chain conveyor S8 /TR24/ 11*4 Discharging chain conveyor S6 /TR25/

Item Description 11*5 Discharging chain conveyor S3,S4 /TR26/ 11*6 Discharging chain conveyor S5 /TR27/ 11*7 Discharging chain conveyor S1, S 2 /TR28/ 12* Discharging chain conveyorTR 29 12*1 Discharging chain conveyor S12, S13 /TR 30/ 12*2 Discharging chain conveyor S16, S18 /TR 31/ 12*3 Discharging chain conveyor S17 /TR 32/ 12*4 Discharging chain conveyor S15 /TR 33/ 12*5 Discharging chain conveyor S13 /TR 34/ 12*6 Discharging chain conveyor S11 /TR 35/ 12*2 Discharging chain conveyor S9, S 12 /TR21/ 12*3 Discharging chain conveyor /TR20a, TR21a-cross/ 14* 15* Dust collecting system for receiving hopper+fan Pre-cleaning machine

Pcs 1 1 2 1 1 1 1 1 1 1 1 2 1 1 1 2 1 2 2 20 21 21 27 5 4 2 1 1

Capacity 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 60m2 200t/h 60m2 30t/h 60m2 60m3 15t/h 200t/h 200t/h 200t/h 200t/h 12tab/t/h 50m3/h 1m3 1,5"/1"/1/2" Page 36

Size 40meters 16meters 26 meters 54meters 54meters 40meters 16meters 40meters 20meters 36meters 32meters 36meters 20.000m3 SP-2000 20.000m3 38meters 20.000m3/h Dia 200mm 300x300mm 300x300mm 300x300mm 400x784mm 2.5meters pneumatic

Power/ item kW 15 11 11 18,75 18,75 15 11 15 11 15 15 15 22+0,75 3 22+0,75 4,4

Weight /item MT 4 1,9 2,2 4,1 4,1 4 1,9 4 2 4 3,2 6,4 3,2 3 3,2 0,9 3,2 3,2

Details see 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.7 3.9 3.7 3.10 3.7 3.12 3.11 3.13 3.5 3.6 3.5 3.16 3.15 3.17 3.18 3.19

15*1 Filter for precleaning machine with fan 15*2 Collecting chain conveyor 16 17* 18* 19* 20* 21* 22* 23* 26* Central dust separation unit Dust and broken grain bin Two way direction boxes Pneumatic valves under silo bins Manual valves under bins Pneumatic valves under conveyor Telescopic discharge tube Desinsection equipment Screw compressor unit

17*1 Dust discharging screw conveyor

2,2

0,8 1,4 0,9 0,45 1,1 0,6

0,75 9 bars 1185meters cooler/dryer 300kgs with valves 7,5

0,08 1,4 0,3 13,2

27*1 Air tank for compressor 27*2 Tubes for compressed air (set)

Item Description Temperature measuring system with computer and screen + UPS main. connecting possibilities to the Controlling PC Level indicators Continuous weigher+standing

Pcs

Capacity

Size 6/5 sensors /cable 8 out capacitive

Power/ item kW

Weight /item MT

Details see

28* 29* 30*

1 4 41 2 2 2 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

7xcable/bin 1 in 200t/h

2,2 0,75 0,5 2,4 0,02 2,6 4 2,4 1,5 electronic total 590m 38m 1,1 4,2 53 3,8 9,6 5,4 14MT 2.7MT 100m3 0,25 3,3MT 14 2,7 13 0,12 0,2 2,8 2,5 23 7,9 2MT 1,2MT

3.20 3.14 3.21 3.22 3.23 3.24 3.26 3.25 3.27 3.27 3.28 3.29

28*1 Multiway distributor vertical (Pendulum)

30*1 Prebin for weigher 30*2 After bin for weigher 31* 32* 33* 34* 35* 36* Hoist crane Road weighbridge Catwalks for silos set Catwalk for transit silos Chutes for grain (set) Grid for receiving hopper

10m3 3m3 2 tons 100t Width 1400mm Width 1400mm Dia 312mm with elbows 18x3m 18x3m 2x18x2 meters 600Gauss 600Gauss 25 meters 21x3meters

34*1 Supporting structure for transit silos

36*1 Buffling system under grid of hopper 36*2 Steel hopper with AR surface 37* 38* 39* 40* 41* 42* 43* 45* E4 E5 Cascade magnet separator Rotary magnet separator Tubes for central dust deducting system (set) Duct system for road hopper (set) Technological tower Supporting elements and steel structure set Laboratory equipment Workshop Electrical machinery Main distribution board Power Factor Correction System

3.31 3.31 3.32 3.33 3.34

8x8.0m

app25,0m

1200kVA 60 Farad Page 37

5 sections

1,2 2,2

3.39 3.40

Item Description E6 E7 Master Control Panel Motor control boxes

Pcs 1 75 48 20 15 1 1 1 3 1 4

Capacity keyboard

Size 19"monitor UPS

Power/ item kW

Weight /item MT 0,8

Details see 3.41 3.42 3.42 3.42 3.43 3.45 3.44 3.46 3.47

E7a Slide control boxes E7b Two-way valve boxes E8 E9 Emergency stops Lighting system

E10 Lightning system E11 Earthing system E12 Aircraft approach light E13 Fire fighting system E14 Silo inspection light Cables NYY 4 G 1,5 1700m NYY 4 G 2,5 1800m NYY 4 G 4 2400m NYY 4 G 6 450m NYY 4 G 16 850m NYY 4 G 50 100m YSLY 2x0,5 3500m YSLY 3x0,5 2100m YSLY 7x0,5 4300m YSLY 15x0,5 1800m E15 LiYLY 4x0,5 100m E16 Communication system E17 Air Conditioner Total Spare parts 44* Spare parts for the imported machines

200W

3.48

3.49 3.50 2 split type 991,95 1 1 for two years for two years 1125,51 3.35 3.52 3.51

E18 Spare part for imported electrical items

Page 38

SAMCRETE CO. TORMA SILO ENGINEERING

TECHNICAL SPECIFICATION FOR THE SILO PLANT OF EL KHALKA

39

Specification for Egypt / Silos complex/2013.06

Specification for flat bottom of El Khalka 90000MTs SILOPROJEKT Seizmic load UBC 3 12.06.2013 (1. Solution) Item Description Mechanical machinery 1* Silo bins for grain storage S1-S18 1*1 Roof aeration system 1*2 Ladder+3 platform 1*3 Ladder+1 platform 2* Aeration system flat bottom 2*1 Aeration fan 2*2 Distribution system for aeration +tubes 3* Transit bins T1, T2. T3 4* Bucket elevator E1, E2, E3, E4, 5* Hopper chain conveyor ,special TR1 6* Cross /hopper/chain conveyor TR2 6*1 Cross chain conveyor TR2a 7* Charging chain conveyor to S1, S7 /TR 3, TR4/ 7*1 Charging chain conveyor to S3, S9 /TR5, TR6/ 7*2 Charging chain conveyor to S2, S8 /TR7, TR8/ Charging chain conveyor to S4-S13,S5-S14,SS15 /TR9-TR11/ 8* Charging chain conveyor to S10-S16,S11-S17,S12-S18/TR12-TR14/ 8*1 10* Charging chain conveyor to T1,T2,T3 / TR 15/ 11* Discharging chain conveyor S2,S5,S14 /TR16 11*1 Discharging chain conveyor S1-S4,S13 /TR17/ 11*2 Discharging chain conveyor S3,S6,S15 /TR18/ 11*3 Discharging chain conveyor TR17a-TR18a-cross 12* Discharging chain conveyor S8, S11,S17 /TR19/ Pcs 18 18 6 12 18 36 18 3 4 1 1 1 2 2 2 3 3 2 1 1 1 2 1 Capacity 6850m3 6 vents 16 meters 3meters H type 11000m3/h 155m3 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h Page 40 Size Dia 22.15 0.29m2/pc platform 1x0.5m platform 1x0.5m 0.5x 60m H=22,44m Power/ item kW Weight /item MT 1080 2,04 1,3 1,4 2 11,52 1,8 15 20,4 3,3 3,2 2,2 5,6 5,6 3 8,9 8,9 3,2 5,2 4,5 4,5 6 5,2 Details see 3.1 3.2

3.2

8 Dia. 4,60m 31meters 22,0meters 22,0 meters 20,0meters 30meters 30meters 17meters 52meters 52meters 32,0 meters 66meters 52meters 52meters 31meters 66meters 45 degree 18m pit length inclined 7 inclined 7 inclined 10 inclined 10 inclined 10 21+4 15 11 11 15 15 11 18,75 18,75 15 22,5 18,75 18,75 15 22,5

3.53 3.3 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4

Item 12*1 12*2 12*3 13* 14* 15* 15*1 15*2 16 17* 17*1 18* 19* 20* 21* 22* 23* 26* 27*1 27*2

Description Discharging chain conveyor S7, S 10, S16 /TR20/ Discharging chain conveyor S9, S 12, S 18 /TR21/ Discharging chain conveyor /TR20a, TR21a-cross/ Sweeper Dust collecting system for receiving hopper+fan Pre-cleaning machine Filter for precleaning machine with fan Collecting chain conveyor Central dust separation unit Dust and broken grain bin Dust discharging screw conveyor Two way direction boxes Pneumatic valves under silo bins Manual valves under bins Pneumatic valves under conveyor Telescopic discharge tube Desinsection equipment Screw compressor unit Air tank for compressor Tubes for compressed air (set)

Pcs 1 1 2 18 1 1 1 2 1 2 2 20 21 21 27 5 4 2 1 1

Capacity 200t/h 200t/h 200t/h 200t/h 60m2 200t/h 60m2 30t/h 60m2 60m3 15t/h 200t/h 200t/h 200t/h 200t/h 12tab/t/h 50m3/h 1m3 1,5"/1"/1/2"

Size 52meters 52meters 31meters 11 meters 20.000m3 SP-2000 20.000m3 38meters 20.000m3/h Dia 200mm 300x300mm 300x300mm 300x300mm 400x784mm 2.5meters 9 bars 755meters 6/5 sensors /cable 8 out capacitive 10m3 3m3 25 meters 21x3meters 2MT 1,2MT

Power/ item kW 18,75 18,75 15 30 22+0,75 3 22+0,75 4,4

2,2 pneumatic

0,75 cooler/dryer 300kgs with valves

Weight /item MT 4,5 4,5 6 9,6 3,2 3 3,2 0,9 3,2 3,2 0,8 1,4 0,9 0,45 1,1 0,6 0,08 1,4 0,3 13,2

Details see 3.4 3.4 3.4 3.54 3.7 3.9 3.7 3.10 3.7 3.12 3.11 3.13 3.5 3.6 3.5 3.16 3.15 3.17 3.18 3.19

Temperature measuring system with computer and screen + UPS main. 28* connecting possibilities to the Controlling PC 28*1 Multiway distributor vertical (Pendulum) 29* Level indicators 30* Continuous weigher+standing 30*1 Prebin for weigher 30*2 After bin for weigher 31* Hoist crane 32* Road weighbridge 33* Catwalks for silos set

1 4 36 2 2 2 1 1 1

7xcable/bin 1 in 200t/h

0,75 0,5

2 tons 100t Width 1400mm Page 41

1,5 electronic total 590m

2,2 2,4 0,02 2,6 4 2,4 1,1 4,2 49,2

3.20 3.14 3.21 3.22 3.23 3.24 3.26 3.25 3.27

Item 34* 34*1 35* 36* 36*1 36*2 37* 38* 39* 40* 41* 42* 43* 45* E4 E5 E6 E7 E7a E7b E8 E9 E10 E11 E12 E13 E14

Description Catwalk for transit silos Supporting structure for transit silos Chutes for grain (set) Grid for receiving hopper Buffling system under grid of hopper Steel hopper with AR surface Cascade magnet separator Rotary magnet separator Tubes for central dust deducting system (set) Duct system for road hopper (set) Technological tower Supporting elements and steel structure set Laboratory equipment Workshop Electrical machinery Main distribution board Power Factor Correction System Master Control Panel Motor control boxes Slide control boxes Two-way valve boxes Emergency stops Lighting system Lightning system Earthing system Aircraft approach light Fire fighting system Silo inspection light

Pcs 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 101 42 20 15 1 1 1 3 1 4

Capacity Width 1400mm Dia 312mm

Size 38m with elbows 18x3m 18x3m 2x18x2 meters

Power/ item kW

14MT 2.7MT 100m3 0,25 3,3MT

600Gauss 600Gauss

8x8.0m

app25,0m

Weight /item MT 3,8 9,6 7,3 14 2,7 13 0,12 0,2 2,8 2,5 23 7,9

Details see 3.27 3.28 3.29

3.31 3.31 3.32 3.33 3.34

1600kVA 60 Farad keyboard 19"monitor

5 sections UPS

1,2 2,2 0,8

3.39 3.40 3.41 3.42 3.42 3.42 3.43 3.45 3.44 3.46 3.47 3.48

200W

Page 42

Item Description Cables NYY 4 G 1,5 1600m NYY 4 G 2,5 1600m NYY 4 G 4 2200m NYY 4 G 6 450m NYY 4 G 16 850m NYY 4 G 50 100m YSLY 2x0,5 3100m YSLY 3x0,5 1800m YSLY 7x0,5 3900m YSLY 15x0,5 1500m LiYLY 4x0,5 100m Communication system Air Conditioner Total Spare parts Spare parts for the imported machines Spare part for imported electrical items

Pcs

Capacity

Size

Power/ item kW

Weight /item MT

Details see

E15 E16 E17

split type 1439,95 1425,53

3.49 3.50 3.51

44* E18

1 1

for two years for two years

3.35 3.52

Page 43

Specification for Egypt / Silos complex/2013.06

Specification for concrete hopper bottom of Kafr El Dawar 90000MTs SILOPROJEKT Seizmic load UBC 3 12.06.2013 (1. Solution) Item Description Mechanical machinery 1* Silo bins for grain storage S1-S18 1*1 Roof aeration system 1*2 Ladder+3 platform 1*3 Ladder+1 platform 2* Aeration system hopper bottom 2*1 Aeration fan 2*2 Distribution system for aeration +tubes 3* Transit bins T1, T2. T3 4* Bucket elevator E1, E2, E3, E4, 5* Hopper chain conveyor ,special TR1 6* Cross /hopper/chain conveyor TR2 6*1 Cross chain conveyor TR2a 7* Charging chain conveyor to S1 /TR 3/ 7*1 Charging chain conveyor to S2 /TR5/ 7*2 Charging chain conveyor to S3, S4 /TR6/ 7*3 Charging chain conveyor S6,S7 /TR7, TR 8/ 7*4 Charging chain conveyor S5 /TR9/ 7*5 Charging chain conveyor S8, S9 /TR10/ 8* Charging chain conveyor S10 /TR11/ 8*1 Charging chain conveyor S11 /TR12/ 8*2 Charging chain conveyor S12, S13 /TR13/ 8*3 Charging chain conveyor S14, S 16 /TR14, TR15/ 8*4 Charging chain conveyor S15 /TR16/ 8*5 Charging chain conveyor S17, S18 /TR17/ Pcs 18 18 6 12 18 18 18 3 4 1 1 1 1 1 1 2 1 1 1 1 1 2 1 1 Capacity 4474m3 6 vents 16 meters 3meters 6 pcs/bin 20000m3/h 155m3 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h Page 44 Size Dia 27,5m 0.29m2/pc platform 1x0.5m platform 1x0.5m 8 meters long H=13,4m Power/ item kW Weight /item MT 742 2,04 1,3 1,4 9 7,2 14,4 15 20,4 3,3 3,9 3,9 3,8 5,6 3,9 6,2 3,3 6,2 3,6 5,6 3,9 6,2 3,3 6,2 Details see 3.1 3.2

3.2

15 Dia. 4,60m 31meters 22,0meters 42meters 40meters 38meters 52meters 40meters 30meters 32 meters 60meters 36meters 52meters 40meters 30meters 32 meters 60meters 45 degree 18m pit length inclined 4 inclined 4 inclined 13 21+4 15 15 15 15 18,75 18,75 11 15 18,75 15 18,75 18,75 15 15 18,75

inclined 13

3.53 3.3 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4

Item 10* 11* 11*1 11*2 11*3 11*4 11*5 12* 12*1 12*2 12*3 12*4 14* 15* 15*1 15*2 16 17* 17*1 18* 19* 20* 21* 22* 23* 26* 27*1 27*2

Description Charging chain conveyor to T1,T2,T3 / TR18/ Discharging chain conveyor S1, S2 /TR21/ Discharging chain conveyor S3, S4 /TR22/ Discharging chain conveyor/TR21a-, TR22a/ Discharging chain conveyor S5,S6 /TR23/ Discharging chain conveyor S7, S8, S9 /TR24/ Discharging chain conveyor /TR24a/ Discharging chain conveyor S 15 /TR 25/ Discharging chain conveyor S10 /TR 26/ Discharging chain conveyor S11, S12, S13 /TR 27/ Discharging chain conveyor S14 /TR 28/ Discharging chain conveyor S16,S17,S18/TR28-30/ Dust collecting system for receiving hopper+fan Pre-cleaning machine Filter for precleaning machine with fan Collecting chain conveyor Central dust separation unit Dust and broken grain bin Dust discharging screw conveyor Two way direction boxes Pneumatic valves under silo bins Manual valves under bins Pneumatic valves under conveyor Telescopic discharge tube Desinsection equipment Screw compressor unit Air tank for compressor Tubes for compressed air (set) Temperature measuring system with computer and screen + UPS main. connecting possibilities to the Controlling PC

Pcs 1 1 1 2 1 1 1 1 1 1 1 3 1 1 1 2 1 2 2 20 21 21 27 5 4 2 1 1

Capacity 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 200t/h 60m2 200t/h 60m2 30t/h 60m2 60m3 15t/h 200t/h 200t/h 200t/h 200t/h 12tab/t/h 50m3/h 1m3 1,5"/1"/1/2"

Size 38meters 32 meters 36meters 43meters 30meters 60meters 30meters 54meters 16meters 70meters 32 meters 30meters 20.000m3 SP-2000 20.000m3 12meters 20.000m3/h Dia 200mm 300x300mm 300x300mm 300x300mm 400x784mm 2.5meters 9 bars 1185meters 6/5 sensors /cable

Power/ item kW 15 18,75 15 15 15 18,75 15 18,75 11 22,5 15 15 18,5+0,75 3 18,5+0,75 3 18,5+0,75 2,2 pneumatic

cooler/dryer 300kgs with valves

0,75 7,5

Weight /item MT 3,8 3,4 3,7 8,2 3,1 6,2 3,1 5,8 2,8 7,6 3,3 9,3 3,2 3 3,2 1,9 3,2 3,2 0,8 1,4 0,9 0,45 1,1 0,6 0,08 1,4 0,3 13,2

Details see 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.7 3.9 3.7 3.10 3.7 3.12 3.11 3.13 3.5 3.6 3.5 3.16 3.15 3.17 3.18 3.19

28*

7xcable/bin Page 45

2,2

3.20

Item 28*1 29* 30* 30*1 30*2 31* 32* 33* 34* 34*1 35* 36* 36*1 36*2 37* 38* 39* 40* 41* 42* 43* 45*

Description Multiway distributor vertical (Pendulum) Level indicators Continuous weigher+standing Prebin for weigher After bin for weigher Hoist crane Road weighbridge Catwalks for silos set Catwalk for transit silos Supporting structure for transit silos Chutes for grain (set) Grid for receiving hopper Buffling system under grid of hopper Steel hopper with AR surface Cascade magnet separator Rotary magnet separator Tubes for central dust deducting system (set) Duct system for road hopper (set) Technological tower Supporting elements and steel structure set Laboratory equipment Workshop Electrical machinery E4 Main distribution board E5 Power Factor Correction System E6 Master Control Panel E7 Motor control boxes E7a Slide control boxes E7b Two-way valve boxes E8 Emergency stops

Pcs 4 41 2 2 2 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 75 48 20 15

Capacity 1 in 200t/h

Size 8 out capacitive 10m3 3m3 25 meters 21x3meters 2MT 1,2MT

Power/ item kW 0,75 0,5

2 tons 100t Width 1400mm Width 1400mm Dia 312mm

1,5 electronic total 590m 38m

with elbows 18x3m 18x3m 2x18x2 meters

14MT 2.7MT 100m3 0,25 3,3MT

600Gauss 600Gauss

8x8.0m

app25,0m

Weight /item MT 2,4 0,02 2,6 4 2,4 1,1 4,2 53 3,8 9,6 5,4 14 2,7 13 0,12 0,2 2,8 2,5 23 7,9

Details see 3.14 3.21 3.22 3.23 3.24 3.26 3.25 3.27 3.27 3.28 3.29

3.31 3.31 3.32 3.33 3.34

1200kVA 60 Farad keyboard 19"monitor

5 sections UPS

1,2 2,2 0,8

3.39 3.40 3.41 3.42 3.42 3.42

Page 46

Item E9 E10 E11 E12 E13 E14

Description Lighting system Lightning system Earthing system Aircraft approach light Fire fighting system Silo inspection light Cables NYY 4 G 1,5 1700m NYY 4 G 2,5 1800m NYY 4 G 4 2400m NYY 4 G 6 450m NYY 4 G 16 850m NYY 4 G 50 100m YSLY 2x0,5 3500m YSLY 3x0,5 2100m YSLY 7x0,5 4300m YSLY 15x0,5 1800m LiYLY 4x0,5 100m Communication system Air Conditioner Total Spare parts Spare parts for the imported machines Spare part for imported electrical items

Pcs 1 1 1 3 1 4

Capacity

Size

Power/ item kW

Weight /item MT

200W

Details see 3.43 3.45 3.44 3.46 3.47 3.48

E15 E16 E17

split type 974,15 1141,01

3.49 3.50 3.51

44* E18

1 1

for two years for two years

3.35 3.52

Page 47

SAMCRETE CO. TORMA SILO ENGINEERING

3. TECHNICAL DESCRIPTION OF THE DIFFERENT KIND OF EQUIPMENT

48

SAMCRETE CO. TORMA SILO ENGINEERING

1. Silobin for grain storage, Diameter: San El Haggar flat bottom hopper bottom El Menia, Kafr El Dawar, El Khalka flat bottom hopper bottom Eave height San El Haggar flat bottom hopper bottom El Menia, Kafr El Dawar, El Khalka flat bottom hopper bottom Overall height San El Haggar flat bottom hopper bottom with hopper bottom El Menia, Kafr El Dawar, El Khalka flat bottom hopper bottom with hopper bottom Total volume: San El Haggar flat bottom hopper bottom with hopper bottom El Menia, Kafr El Dawar, El Khalka flat bottom hopper bottom with hopper bottom Capacity with flat bottom San El Haggar El Menia, Kafr El Dawar, El Khalka Capacity with hopper bottom San El Haggar El Menia, Kafr El Dawar, El Khalka

22,15m 22,15m 22,15m 27,5m 16,01m 12,59m 16,01m 5,75m 22,44m 19,02m 22,44m 13,4m 24,2m 6865m3 5548m3 6754m3 6865m3 4774m3 6670m3 5148MT 5148MT 5065MT 5003MT

49

SAMCRETE CO. TORMA SILO ENGINEERING

Capacity with compacting / flat bottom San El Haggar El Menia, Kafr El Dawar, El Khalka Capacity with compacting / hopper bottom San El Haggar El Menia, Kafr El Dawar, El Khalka Acceleration Zone 3 / 0,26G Kafr El Dawar, El Khalka Acceleration Zone 2 / 0,20G San El Haggar, El Menia

5450MT 5450MT 5360MT 5253MT

Galvanization 600 gr/m2 two sides 145 kph wind design Silos design for free flowing wheat according to DIN 1055-6 Specific weight for design 918 kgs/m3 Load carrying capacity of roof peak is 4500kgs uniformly applied to rafter ring Large 1,6 meters roof deck Pitch size 86,5mm Complete Ring of Heavy roof compression beams High Roof Ribs Rigidized Roof Panels Double roof sheets Continuous eave angle for roof panel attachment Corrugated wall panels Number of stiffener (column Omega Shaped) 22,15meter diameter 84pcs 27,5meter diameter 108 pcs Wide overlap at vertical seams Roof access doors Sidewall door 685x685mm in the second tier Base sealer Roof stair unit Includes single steps, attachment brackets and handrails

50

SAMCRETE CO. TORMA SILO ENGINEERING

Thicknesses of wall elements: 22,15m-diameter Sheets Stiffeners 1 row uppermost 1,5 1,5 2 row 1,5 2,0 3 row 1,5 2,0 4 row 1,5 2,5 5 row 1,5 4,0 6 row 1,8 4,0 7 row 1,8 4,0+2,0 8 row 2,0 4,0+2,0 9 row 2,2 4,0+4,0 10 row 2,8 4,0+4,0 11 row 3,2 4,0+4,0 12 row 3,2 4,0+4,0+2,5 13 row 4,0 4,0+4,0+2,5 14 row 4,0 4,0+4,0+2,5 Manufacturer: SYMAGA / Spain 2. Aeration system f the silobin of hopper bottom consisting of: 14 pcs of elbow vent to free air area above grain in the silobin, fixed on the roof Air inlet regulation no Supplier: / Egypt the silobin of flat bottom 47m2 surface of aeration with dia 1,5mm perforation coeefficient 23% Supplier: TORMA Ltd. / Hungary

27,5m-diameter Sheets Stiffeners 1,5 1,5 1,5 2,0 1,5 2,0 1,5 2,5 2,0 2,5

51

SAMCRETE CO. TORMA SILO ENGINEERING

3. Bucket elevator Type: Capacity: Height overall Main motor Motor speed RELIANCE Soft Starting Protection

GE3620 200t/h in the specification San El Haggar 25kW 1500 rpm constructor of motor electronic galvanised head and bottom hot galvanised leg hot galvanised 3.2m/sec Belt material Rubber (SOF) (SOR) oil resistant, flame retardant antistatic 381mm 80kg/cm Mechanical with screw SKF and double rim with TG seal self aligning spherical outside yes Lubricator DODGE TA 7315 Class 2 100mm 55mm

Belt speed Elevator belt

Width Tension in belt (max) Tensioning system Bearing and driving Bearing Placing Bearing temperature protection Oiling system Type of reductor Size of head shaft Size of leg shaft

52

SAMCRETE CO. TORMA SILO ENGINEERING

Securities rotation sensor anti runback anti deflagration misalignment switch over charge sensor speed limit switch Blow out panel in head Blow out panel in leg Inspection door at the head Buckets Dimensions Spacing: Material Brand Elevator body Thickness of head Thickness of boot Thickness of legs Material of wearing plates Thickness Control doors Blow-out doors with chain Cleaning doors Inlet Location Slope Wearing material Dust aspiration Location Itching motor Manufacturer: Intersystem Inc. / USA

yes yes yes yes yes yes yes yes 3 pieces yes 355mm wide 222.3mm steel Grain belt 4 mm 4.6 mm 2.5mm Anti abrasion steel lining / UHMW in boot 3.4mm in head 3.4mm in leg by chuting 3.4mm 2 service doors in leg 3 pcs on leg 1 in Head cover 2 in the boot under the hopper both end of boot 45 degree AR Steel 3.4 mm head dia 150mm boot dia 150mm yes for maintenance 4 kW

53

SAMCRETE CO. TORMA SILO ENGINEERING

4. Chain conveyors Type: San El Haggar item 7, 7*1 Capacity: Length Motor power Speed of chain Housing Dimensions San El Haggar item 7, 7*1 Material Material protection Closing Thicknesses: Antiwear lining Bottom Side Material Chain Quality of chain Dimensions pitch 101.6mm Breaking load Chain guide Chain material Sprockets Material No. of Teeth

EMC 1717 GV EMC 2126 GV 200t/h see in the specification see in the specification 0.62 m/sec Transport section 292x431.8mm Transport section 286x533mm Steel bottom Anti abrasion steel Galvanized dust and watertight bottom 6.4mm side 4 mm cover 2.5mm 10mm 6mm Nylon/Teflon or equivalent 212l on/teflon over 22kW 22.000kgs under 22 kW 16.000kgs no chain guide Steel C4S 10

54

SAMCRETE CO. TORMA SILO ENGINEERING

Flights Material Operation temperature: Sparkle risk Antistatic power: Hardness: Spacing Bearing Location Type Driving Speed reduction Motor speed Motor type: Driving type: Type of variator Lubrication material Inspection doors Location Type Securities Choke detector Pressure relief door moving detector glass indicator starting Manufacturer: Intersystem Inc. / USA

mounted UHMW thickness 10mm -20 / +85 Nil negative min 105 Rockwell 304.8mm outside the box. Pillow block shaft mounted 1500 rpm RELIANCE TEFC DODGE Ta 5215 Class 2 ungraduated only for hopper conveyor electronic, oil 1 pc on both end hinged and dust proof closing yes yes with over flow detector yes yes over 7.5kW is soft starter

55

SAMCRETE CO. TORMA SILO ENGINEERING

5. Pneumatic valves Capacity: Size: under silo bins under chain conveyors Driving Limit definitions No. of limit switch Manual operation possibility Slide material Protection Supplier: Torma Ltd. Hungary 6. Manual valves Capacity: Size: Driving Limit definions No. of limit switch Slide material Protection Supplier: Torma Ltd. Hungary 7. Filters Capacity: receiving hopper central dedusting system for cleaners Type: Material housing filter

200t/h 300x300mm 431x914mm pneumatic piston magnetic detectors 2 yes steel bolted and sealed steel sheets

200t/h under silo bins300x300mm rack bar and pinion mikroswitch 1, closed status steel bolted and sealed steel sheets

20.000m3/h 20.000m3/h 20.000m3/h super jet modulated steel antistatic wool-nylon cloth

56

SAMCRETE CO. TORMA SILO ENGINEERING

Filtering surface Receiving hopper system Central dedusting system Cleaners Cleaning system

60m2 60m2 60m2 counter current modulated air hammer

Air flow of fan Receiving hopper system 330m3/min Central deducting system 330m3/min Cleaners 330m3/min Pressure of air-flow by fan 190mm w.c. Air pressure on filters max. 120mm Air ratio to surface of filters less than 6 Motor power of fan Receiving hopper system 11 kW Central dedusting system 11 kW Cleaners 2x5.5 kW Air lock Capacity: 15 t/h Power 0.75kW Explosion doors surface 200x600mm Manufacturer: MAG Milling Ltd. / Hungary

8. Dust transport screw conveyor Capacity: 15 t/h dust Diameter of screw 150mm Type of screw double casing Length of screw: 4 meters Casing directly bolted on the bottom of the dust/broken grain bin. Bearing: SKF or FAG Driving: Motorreductor with chain Manufacturer: MAG Milling Ltd. / Hungary

57

SAMCRETE CO. TORMA SILO ENGINEERING

9. Precleaner Capacity: 200t/h Type: SP 2000 Receiving part with dust separator part for air cleaning, and distribution shaft Vibrating table with screens. The thickness of the grain-flow can be adjusted by weighed flap. The in and outgoing grain has sucked. . The channel for air-cleaning can be regulated. Screens frames 4 pcs moved by an excenter drive Each screen frames has: Oversize screen 1.5 x 2meters undersized screen 1.5 x 2meters Screen inclination Oversize screen 8 Undersized screen 11 Effective ratio of screens 0.83 Cleaning of the screens gum balls Driving excenter drive Extra set of sieves for maize Manufacturer: Westrup SA / Denmark 10. Collecting screw conveyor Under the precleaner collecting the impurities Capacity: 10tons/hour Diameters 100mm Length: 4,5 meters Bearing: SKF or FAG Driving: Motorreductor with chain Manufacturer: MAG Milling Ltd. / Hungary

58

SAMCRETE CO. TORMA SILO ENGINEERING

11. Charging screw conveyor Under the dust bins Capacity: 15tons/hour Diameters 150mm Length: 2 meters Bearing: SKF or FAG Driving: Motorreductor with chain Manufacturer: MAG Milling Ltd. / Hungary

12. Dust and broken grain bin Holding capacity: Size: Hopper bottom Roof Wall Bottom hole Free space under Total height: Manhole level indicator Discharge Manufacturer: / Egypt

60m3 3x3 in two direction 49 degree other direction strait 30 degree strait and smooth 3000x400mm 3500mm 11.000mm yes 2 pcs (full and empty) by double screw Item 17*1

13. Two way direction box Capacity: Size: Driving: Manual control Motion limit Protection Supplier: Torma Ltd.

200t/h 300x300mm pneumatic cylinder available magnetic sensor Galvanization

59

SAMCRETE CO. TORMA SILO ENGINEERING

14. Multiway distributor vertical/pendular type Capacity: 200t/h Model 108 Size: 324x324mm Inlets 1 pcs Outlets 8 pcs Driving: 0.75 kW motor Dust suction hole yes, dia 100mm Inspection holes yes Motion control magnetic detectors Case: steel Case width 710mm Case height 2900mm Manufacturer: Intersystem Inc. / USA

15. Desinsection equipment Capacity: 12 tablet / t /h Max. capacity: 200 t/h Hopper capacity: 6000 tablets Cover of hopper transparent Driving: 0.75 kW motor Manufacturer: Detia - Degesch / Germany

16. Telescopic discharge tube Capacity: Min. length Max. length: Driving Supplier: Torma Ltd. / Hungary

200 t/h 0.75m 2.5 m manual

60

SAMCRETE CO. TORMA SILO ENGINEERING

17. Compressor screw type Capacity: Working method Cooler Cleaner, dryer Max. pressure Working pressure Motor power Regulation of capacity Manufacturer: Atlas Copco / Sweden

50m3/h screw pressuring in built in built 9 bar 7 bar 7.5kW continuous and automatic

18. Air tank for compressed air Holding capacity: holding pressure with the necessary security devices. Manufacturer: / Egypt

1 m3 9 bar

19. Tubes for compressed air Tube type Sizes: valves dewatering and oiling equipment Supply: / Egypt

steel, seamless, galvanized 1/2" see specification length 1" see specification length 1.5" see specification length 1/2" 24 pcs 1" 30 pcs 1.5" 6 pcs 1" 4 pcs 1/2" 8 pcs

61

SAMCRETE CO. TORMA SILO ENGINEERING

20. Temperature measuring system Cable type heavy duty cable number/bin 7 sensing points / cable 5/6 connection boxes yes special wiring yes connection to the PC data line Measuring elements are set into a stainless steel rope of 8 mm in diameter. This rope creates only a low friction force with the cereal. As ropes are hanging on the roof of the silo, it is very important to reduce the friction force. During discharging of silo about 2000 N/rope force is pulling the roof, and no more. Measuring limit: -20C +100C. Lower end of ropes are attached to the bottom of silo in the interest of keeping the optimal measuring position. (by hopper bottom) Process and storing by own computer With UBS Power pack Interface for the central controlling computer Supplier: GESCASER / Spain and TORMA Ltd. / Hungary

21. Level indicators Type: Working method Housing Fixing method Length in bin Supplier: TORMA Silo Engineering.

IT 5065 capacitive completely closed plastic M24x1 fixing 50mm

22. Continuous weigher Type: MP-AFG-200 Capacity: 200 t/h Weighing batch max. 1100kg Accuracy: 1 kg/batch Size: 2.0x2.0x2.1m Manufacturer: Metripond Plus / Hungary

62

SAMCRETE CO. TORMA SILO ENGINEERING

23. Pre bin for continuous weigher Volume: Size: Hopper bottom: Material: Protection: Weight: with level indicator on the bottom Manufacturer: / Egypt

10m3 2,5x2,5x3,2m 45 degree St 52 painted 2 tons

24. After bin for continuous weigher Volume: Size: Hopper bottom: Material: Protection: Weight: with level indicator on the upper level Manufacturer: / Egypt

3m3 1,5x1,5x3m 45 degree St 52 painted 1.2 tons

25. Road weighbridge Type: Capacity: Divisions Dimensions. Number of load cell Capacity of load cell Model of load cell Height of the weighing platform Surface of platform Protection of platform Manufacturer: Egypt

100tons 50 kgs 21.11x3m 8 pcs 35 tons 400mm chequered plates anti-sliding paint

63

SAMCRETE CO. TORMA SILO ENGINEERING

26. Hoist crane Type: Capacity: Lifting height Lifting means Lifting speed Length of the control with free running trolley Manufacturer: TRAKTEL / France

TK 2000 2000kgs see specification steel rope and hook 2 meters/min 5 meters

27. Catwalk Width: 1.400mm Width of the walking surface 700mm Surface of walking path chequered plate Height of handrails 1.000mm Weight: 125 kg/meter Protection: Galvanised Material: L, U beams, closed sections with the necessary supports for silo top and silo walls Manufacturer: / Egypt

28. Supporting structures for transit silos Dimensions: Material Protection Weight: Manufacturer: / Egypt

17.7x5.5x7.4m St 52, I and U beams galvanized 16 tons

29. Chutes for grain Size: diameter 312mm Thickness: 3 mm Protection: painted with elbows, segments, bends, union rings, tied sleeves, hoppers, Manufacturer: / Egypt

64

SAMCRETE CO. TORMA SILO ENGINEERING

30. Receiving hopper -Truck pit Length 18 meters Width 3 meters Height of pit 2800mm Inclination of the bottom 45 Weight 8 tons -Grid size: 18 x 3 meters Weight: 14 tons Max. axle load 16 tons Size of holes 50x30mm Moveable sections - Under the grid mounted baffling system as a dust guarding with moving and fixed part The system is a self-alignment system Weight: 2.7 tons - Surface of hopper The surface of hopper will be covered by steel sheets Supported by the concrete foundation Thickness: 6mm Weight: 3.5 tons Manufacturer: / Egypt 31. Magnet separators Magnet type: Permanent 1. Solution: ROM400-600 1. Placing: in between the two part of cross conveyor 1. Number of magnets 1 pcs 1. Size diameter 400mm 1. Magnetic power 600 Gauss 2. Solution GMM 350 2. Number of magnet cascade 1 pc 2. Placing in front of the cleaners 2. Magnetic power 600 Gauss Manufacturer: MAGNES Ltd. / Hungary

65

SAMCRETE CO. TORMA SILO ENGINEERING

32. Tubes, ducts for dust deduction Size: diameter 50 - 300mm Thickness of sheets 2 mm Protection: painted with the necessary connection, sleeves, elbow, etc. Manufacturer: / Egypt 33.Technological tower Size: Height: San El haggar El Menia, Kafr El Dawar. El Khalka Level number San El Haggar El Menia, Kafr El Dawar. El Khalka Used material Max grade for stairs Handrail Protection: Cover Manufacturer,: / Egypt

8 x 8 meter 36 meters 25 meters 5 levels 4 levels I, U beams 45 degree yes painted no cover

34. Laboratory equipment Sample picking pen NILEMA Hectolitre weigher Precision weigher Oven for moisture measuring Digital moisture measuring Sample divider set manual Dock-age carter Sieves set for wheat and corn CO2 measure kit Supplyer: Torma Ltd. / Hungary

5 pcs 2 pcs 2 pcs 2 pcs 2 pcs 2 sets 1 pc 1 set 1 set

66

SAMCRETE CO. TORMA SILO ENGINEERING

35. Spare parts for imported machines Bucket elevators Bearing at tension end Head of Bearing Shaft of drive Transmission chain of drive Belt 380mm wide Griff for connection of belt Buckets with bolts Detector for central running Sensor for overflow Chain conveyor Bearing in drive end Bearing in tail end Flight Chain Sprocket Filters Filter bags Asco's valve Reducer for the air lock Set of pats for cabinet control Valves, Pendular, Two way boxes, Contactor for valve under conveyor Microswitch Pneumatic piston Magnetic control for piston Cleaner Gumball Set of sieves Compressor Set of gaskets set of filters

2 pcs 2 pcs 2pcs 2 pcs 20mt 3 sets 50 pcs 1 pc 1 pc 4pcs 4pcs 40pcs 20meters 2 pcs 50 pcs 2 pcs 2 pcs 1 set 4 pcs 10 pcs 3 pcs 2 pcs 15 pcs 2 sets 1 set 1 set

67

SAMCRETE CO. TORMA SILO ENGINEERING

Continuous weigher Load cell Pneumatic piston Supplier: Torma Ltd / Hungary

1 pc 1 pc

39. Low voltage distribution board with capacitor bank Main switch Sections No. 5 from - 1 section for the main switch and lamps and measuring equipment - 1 section for the capacitor bank - 1 section for the lighting distributor boards - 1 section for Motor Control Centre 1 and 2. - 1 section for the buildings Supplier: Egypt

40. Masters control centre To control the machines and distribute the power for them it consists of: The MCC panel is located in two places. The first and main panel is located in the adjacent of control room. The second panel is located on the highest level of the working tower. The panels are a free standing construction, all sections are 800mm wide and 600mm deep and 2100mm high. The width of the complete MCC: 3200mm + 3200mm The main cables connected via manual fuse holders, capacity 630 A, for disconnect any cable for safety and service. The main circuit breaker has an electronic protection unit, with short circuit and overload protection. The door of input section locked to the handle of the main circuit breaker open only the breaker is off position.

68

SAMCRETE CO. TORMA SILO ENGINEERING