Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

04 Buttweldfitt Tee Din2615

Caricato da

ivanmatijevicCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

04 Buttweldfitt Tee Din2615

Caricato da

ivanmatijevicCopyright:

Formati disponibili

S TA I N L E S S S T E E L

Butt-Weld Fittings

RO-FI Precision in Stainless Steel

Zuverlssigkeit

durch Qualittsmanagement

Reliability

by quality

management

Reliability by quality management - ISO 9001

Butt-Weld Fittings

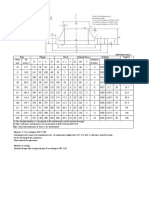

Tees DIN 2615

measures in mm

1 Coverage

This norm consider to seamless (S) and welded (W) tees

(reduced utilisation, see table 1 and chapter 5.) The tees

of steel whose wall thickness are resemble to this of wel-

will be used as fittings for welding.

ding tubes, but they allow just a lower inside pressure.

2 Type of design, description

The tees does not comply to the illustration. Just the

denoted dimensions must be strictly adhered. Accom-

Accomplishment A

Accomplishment B

remaining dimensions see

dimensions complyto

accomplishment B

accomplishment A

U22)

U12)

U22)

d2

s4

d2

s2

s2

s4

r 1)

s1

s1

r 1)

t12)

U12)

www.rofi.de

11.2007_1.000

plishment A or B in choice of the manufacturer.

t22)

s3

d1

s3

5

a

S3 S1

S4 S2

Appellation of a tee according to this norm part 1 (1) of

Tees DIN 2615 1 168,3 x 4,5 88,9 x 3,2 S F

the external diameter d1 = 168,3 mm, wall thickness s1 =

4,5 mm and external diameter d2 = 88,9 mm, wall thick-

1) See chapter 7.1

ness s2 = 3,2 mm, seamless S (S), of a material of the

2) See chapter 4

material group F (F) according to DIN 2609:

RO-FI Precision in Stainless Steel

4/17

Butt-Weld Fittings

Tees DIN 2615

3 dimensions

nomi- dianal

metr.

width

DN

d 1 1)

15

21,3

4/18

wall thickness s 1

line

1

2

1,6

3

2,0

4

3,2

5

4,0

20

26,9

1,6

2,3

3,2

4,0

25

33,7

2,0

2,6

3,2

4,0

32

42,7

2,0

2,6

3,6

4,0

40

48,3

2,0

2,6

4,0

5,0

50

60,3

2,0

2,9

4,5

5,6

65

76,1

2,3

2,9

5,0

7,1

80

88,9

2,3

3,2

5,6

8,0

100

114,3

2,6

3,6

6,3

8,8

125

139,7

2,6

4,0

6,3

10,0

150

168,3

2,6

4,0 4,5

7,1

11,0

200

219,1

2,9

4,5 6,3

8,0

12,5

nominal

width

DN2

15

10

20

15

10

25

20

15

32

25

20

15

40

32

25

20

50

40

32

25

20

65

50

40

32

25

80

65

50

40

32

100

80

65

50

40

125

100

80

65

50

150

125

100

80

65

200

150

125

100

80

RO-FI Precision in Stainless Steel

diametr.

d2

21,3

17,2

26,9

21,3

17,2

33,7

26,9

21,3

42,4

33,7

26,9

21,3

48,3

42,4

33,7

26,9

60,3

48,3

42,4

33,7

26,9

76,1

60,3

48,3

42,4

33,7

88,9

76,1

60,3

48,3

42,4

114,3

88,9

76,1

60,3

48,3

139,7

114,3

88,9

76,1

60,3

168,3

139,7

114,3

88,9

76,1

219,1

168,3

139,7

114,3

88,9

wall thickness s 2

line

1

1,6

1,6

1,6

1,6

1,6

2,0

1,6

1,6

2,0

2,0

1,6

1,6

2,0

2,0

2,0

1,6

2,0

2,0

2,0

2,0

1,6

2,3

2,0

2,0

2,0

2,0

2,3

2,3

2,0

2,0

2,0

2,6

2,3

2,3

2,0

2,0

2,6

2,6

2,3

2,3

2,0

2,6

2,6

2,6

2,3

2,3

2,9

2,6

2,6

2,6

2,3

4,0

4,5

4,0

3

2,0

1,8

2,3

2,0

1,8

2,6

2,3

2,0

2,6

2,6

2,3

2,0

2,6

2,6

2,6

2,3

2,9

2,6

2,6

2,6

2,3

2,9

2,9

2,6

2,6

2,6

3,2

2,9

2,9

2,6

2,6

3,6

3,2

2,9

2,9

2,6

4,0

3,6

3,2

2,9

2,9

4,5

4,0

3,6

3,2

2,9

6,3

4,5

4,0

3,6

3,2

4

3,2

2,9

3,2

3,2

2,9

3,2

3,2

3,2

3,6

3,2

3,2

3,2

4,0

3,2

3,2

3,2

4,5

4,0

3,6

3,2

3,2

5,0

4,5

4,0

3,8

3,2

5,6

5,0

4,5

4,0

3,6

6,3

5,6

5,0

4,5

4,0

6,3

6,3

5,6

5,0

4,5

7,1

6,3

6,3

5,6

5,0

8,0

7,1

6,3

6,3

5,6

5

4,0 25

4,0 29

4,0

4,0 38

4,0

4,0

4,0 48

4,0

4,0

4,0

5,0

4,0

4,0

4,0

5,6 64

5,0

4,0

4,0

4,0

7,1 76

5,6

5,0

4,0

4,0

8,0 86

7,9

5,6

5,0

4,0

8,8 105

8,0

7,1

5,6

5,0

10,0 124

8,8

8,0

7,1

5,6

11,0 143

10,0

8,8

8,0

7,1

12,5 178

11,0

10,0

8,8

8,0

25

25

29

29

29

38

38

38

48

48

48

48

57

57

57

57

64

60

57

51

44

76

70

67

64

57

86

83

76

73

70

105

98

95

89

86

124

117

111

108

105

143

137

130

124

121

178

168

162

156

152

acceptable

utilisation level in %

at wall thickness lines

1

2

3

4

5

52

55 62 66

60

59 73

49

54 59 62

57

57 69 73

65

61 73

49

52 55 59

57

59 74 79

57

59 74 79

46

49 54 55

53

57 58 65

53

61 66 74

60

63 76 84

44

47 53 57

48

52 54 59

55

60 58 62

55

60 58 62

41

46 52 55

48

49 55 59

52

54 56 56

59

61 60 64

58

64 68 72

40

43 50 55

42

50 54 55

49

53 58 59

53

57 59 57

60

65 63 65

38

42 50 55

42

44 51 56

45

51

55 56

51

54 59 60

55

58 60 59

37

40 48 52

40

44 52 58

44

46 53 59

48

53 58 60

53

56 61 64

34

39 45 51

39

42 52 54

42

46 56 59

46

47 57 61

49

54 61 61

32

37 38 44 50

36

40 46 53

41

43 52 56

44

47 57 61

49

49 58 62

30 35 39 42 48

34 39 41

46 53

38

40 48 56

43

43 55 58

46

48 59 63

11.2007_1.000

Table 1.

Butt-Weld Fittings

Tees DIN 2615

wall thickness s 1

wall thickness s 2

273,0

line

1

2

2,9 5,0

300

323,9

2,9

5,6

350

355,6

3,2

5,6

400

406,4

3,2

6,3

450

457,0

4,0

6,3

500

508,0

4,0

6,3

600

610

5,0

6,3

700

711,0

5,0

7,1

line

1

2,9

2,9

2,6

2,6

2,6

2,9

2,9

2,9

2,6

2,6

3,2

2,9

2,9

2,9

2,6

3,2

3,2

2,9

2,9

2,9

2,6

4,0

3,2

3,2

2,9

2,9

2,9

4,0

4,0

3,2

3,2

2,9

2,9

2,9

5,5

4,0

4,0

3,2

3,2

2,9

2,9

5,0

5,0

4,0

4,0

3,2

3,2

2,9

nominal

width

DN

250

diametr.

d 1 1)

nomi- dianal

metr.

width

3

4

5

DN2

d2

6,3 8,8 14,2 250

273,0

200

219,1

150

168,3

125

139,7

100

114,3

7,1 10,0 16,0 300

323,9

250

273,0

200

219,1

150

168,3

125

139,7

8,0 11,0 17,5 350

355,6

300

323,9

250

273,0

200

219,1

150

168,3

8,8 12,5 20,0 400

406,4

350

355,6

300

323,9

250

273,0

200

219,1

150

168,3

10,0 14,2 22,2 450

457,0

400

406,4

350

355,6

300

323,9

250

273,0

200

219,1

11,0 16,0 25

500

508,0

450

457,0

400

406,4

350

355,6

300

323,9

250

273,0

200

219,1

12,5 17,5

600

610,0

500

508,0

450

457,0

400

406,4

350

355,6

300

323,9

250

273,0

12,5

700

711,0

600

610,0

500

508,0

450

457,0

400

406,4

350

355,6

300

323,9

2

5,0

4,5

4,0

5,6

5,0

4,5

4,0

5,6

5,6

5,0

4,5

4,0

6,3

5,6

5,6

5,0

4,5

4,0

6,3

6,3

5,6

5,6

5,0

4,5

6,3

6,3

6,3

5,6

5,6

5,0

4,5

6,3

6,3

6,3

6,3

5,6

5,6

5,0

7,1

6,3

6,3

6,3

6,3

5,6

5,6

3

4

5

6,3 8,8 14,2

6,3 8,0 12,5

4,5

7,1 11,0

4,0 6,3 10,0

3,6 6,3 8,8

7,1 10,0 16,0

6,3 6,8 14,2

6,3 8,0 12,5

4,5

7,1 11,0

4,0 6,3 10,0

8,0 11,0 17,5

7,1 10,0 16,0

6,3 8,8 14,2

6,3 8,0 12,5

4,5

7,1 11,0

8,8 12,5 20,0

8,0 11,0 17,5

7,1 10,0 16,0

6,3 8,8 14,2

6,3 8,0 12,5

4,5

7,1 11,0

10,0 14,2 22,2

8,8 12,5 20,0

8,0 11,0 17,5

7,1 10,0 16,0

6,3 8,8 14,2

6,3 8,0 12,5

11,0 16,0 25,0

10,0 14,2 22,2

8,8 12,5 20,0

8,0 11,0 17,5

7,1 10,0 16,0

6,3 8,8 14,2

6,3 8,0 12,5

12,5 17,5

11,0 16,0

10,0 14,2

8,8 12,5

8,0 11,0

7,1 10,0

6,3 8,8

12,5

12,5

11,0

10,0

8,8

8,0

7,1

216

254

279

305

343

381

432

521

acceptable

utilisation level in %

at wall thickness lines

1

2

3

4

5

216 28 34 37 41 47

203 32

37 42 44 50

194 36 40 41

48 54

191 40

43 51 57

184 45

47 56 60

254 26 33 36 40 46

241 30 34 37 41 48

229 34 37 43 45 51

219 37

41 42 49 55

216 42

45 52 59

279 26 32 36 40 46

270 26 34 37 40 46

257 29 36 37 41 48

248 34 38 43 45 51

238 38 42 43 50 56

305 25

32 36 40 46

305 27

32 37 40 46

295 27

34 36 40 46

283 31

36 38 42 48

273 35

39 43 46 52

264 39 43 44 51 57

343 26 31 36 40 46

330 27

34 36 40 46

330 27

34 37 40 47

321 27

36 36 41 47

308 30 37 38 43 49

298 35

40 44 47 53

381 25

30 36 40 46

368 27

32 36 41 46

356 25

34 36 41 46

356 27

35 37 41 47

346 28 37 37 42 47

333 31

38 39 43 50

324 36 41 45 48 54

432 25

28 35 39

432 26 31 36 42

419 27

34 37 41

406 27

36 37 42

406 28 36 39 42

397 29 39 39 43

384 32

40 41

46

521 25

28 35

508 26 29 36

483 26 21 37

470 28 33 38

457 27

36 38

457 29 36 40

448 30 39 40

RO-FI Precision in Stainless Steel

www.rofi.de

11.2007_1.000

Table 1.

4/19

Butt-Weld Fittings

Tees DIN 2615

nomi- dianal

metr.

width

DN

d 1 1)

800

813,0

900

4/20

wall thickness s 1

line

1

2

3

4

5,6

8,0 12,5

914,0 6,3

10,0 12,5

1000

1016,0

6,3

10,0 12,5

1200

1220,6

6,3

12,5

nomi- dianal

metr.

width

DN2

d2

800

813,0

700

711,0

600

610,0

500

508,0

450

457,0

400

406,4

350

355,6

900

914,0

800

813,0

700

711,0

600

610,0

500

508,0

450

457,0

400

406,4

1000

1016,0

900

914,0

800

813,0

700

711,0

600

610,0

500

508,0

450

457,0

1200

1220,0

1000

1016,0

900

914,0

800

813,0

700

711,0

600

610,0

RO-FI Precision in Stainless Steel

wall thickness s 2

line

1

5,6

5,0

5,0

4,0

4,0

3,2

3,2

6,3

5,6

5,0

5,0

4,0

4,0

3,2

6,3

6,3

5,6

5,0

5,0

4,0

4,0

6,3

6,3

6,3

5,6

5,0

5,0

2

8,0

7,1

6,3

6,3

6,3

6,3

5,6

10,0

8,0

7,1

6,3

6,3

6,3

6,3

10,0

10,0

8,0

7,1

6,3

6,3

6,3

12,5

10,0

10,0

8,0

7,1

6,3

3

12,5

12,5

12,5

11,0

10,0

8,8

8,0

12,5

12,5

12,5

12,5

11,0

10,0

8,8

12,5

12,5

12,5

12,5

12,5

11,0

10,0

597 597

572

559

533

521

508

508

673 673

648

622

610

584

572

559

749 749

737

711

673

660

635

622

889 838

813

787

787

762

737

acceptable

utilisation level in %

at wall thickness lines

1

2

3

4

5

24

30 33

25

28 36

26 29 37

26 31 39

28 34 39

28 36 40

30 37 42

24

29 32

24

30 34

25

31 37

26 33 39

27

32 40

29 34 41

29 37 41

23

28 31

25

30

25

28 35

25

29 39

27

30 40

28 33 41

30 35 42

22

29

25

29

27

30

26 30

27

31

29 33

11.2007_1.000

Table 1.

Butt-Weld Fittings

Tees DIN 2615

4 Acceptable dimension variations

Modifications

Table 2. lower limiting-sizes of the wall thickness

(upper limiting-sizes see DIN 2609)

At DIN 2615/06.64 was made following changes:

nom. width

DN

600

> 600

nominal

wall thickness

all

10,0

> 10.0

lower

limiting-sizes

-12,5 %

-0,35 mm

-0,50 mm

The dimensions a and b can be through the use of auxiliary measurements u1, u2 and t 1, t 2 the following equations identified:

a = u1

2

+ u2

a) DIN 2515 separated in DIN 2615 and part 2.

b) Content of the norm complete over-worked.

c) ) Area adjusted till DN 1600.

International patent classification

F16L41/02 The calculation results with following exceptions:

lower limiting-size for tubes and tees according to

table 2

same material

b = t1 + t2

2

same longitudinal seam welding factor

Table 3. limiting-sizes of the dimensions a and b

without corrosion acceptance

nominal width

DN

15 to 200

250 to 700

800

The acceptable limiting-size can increase by the itemisatia

2,0

3,0

5,0

b

2,0

3,0

5,0

on. The carrying cross section surface was multiplied with

the factor 0,9 for to consider the radii between base body

and branch of the normal forming.

6 Differing wall thickness

5 Acceptable limiting-size and

base of the calculation

As acceptable limiting-size is in % the measure of the

acceptable (lower)internal pressure of the tee is acted up

to the acceptable internal pressure of the tube. As tube

internal pressure was adopted the smaller one which

offered of the affiliated tube at the pass. The acceptable

internal pressures were calculated according to TRD 301,

edition 04.79.

Cited norms and other basics

DIN 2609

DIN 2615 part 2

TRD leaflat

DIN 2615: 06.64

from the wall thickness of table 1, can be ordered according the agreement of this norm.

7.1 Change-over between base body and branch

The change-over has to built between base body and

branch with a radius r => s1. But the radius shall be provided just so big that the distance with minimal s1 or s2

before the weld stud spilt out. At forged and drilled tees

this condition does not need to abide.

7 Manufacturing

Fitting to weld in, technical conditi-

7.2 Tube dimension

ons of delivery

When indicated the tube dimensions may by chamfer of

Fitting to weld in, tees,

the inner bevel by a angle of 15 till 18 and/or the outer

full limiting-size

bevel by a angle of 28 till 30 manufactured, relating to

Cylinder jacket among the

the respective axis.

internal over pressure *)

Earlier editions

Tees with wall thickness for the order which differing

www.rofi.de

11.2007_1.000

same external diameter

8 Technical conditions of delivery

According to DIN 2609

RO-FI Precision in Stainless Steel

4/21

S TA I N L E S S S T E E L

www.rofi.de

South

Karl-Arnold-Strae 7

D-73230 Kirchheim/Teck

Tel. +49 (0) 70 21 94 35-0

Fax +49 (0) 70 21 5 60 31

kirchheim@rofi.de

North Export

Mittelgnrather Strae 15

D-42655 Solingen

Tel. +49 (0) 2 12 2 32 54-0

Fax +49 (0) 2 12 2 32 54-11

solingen@rofi.de

Middle

Ostendstrae 3

D-63110 Rodgau-Niederroden

Tel. +49 (0) 61 06 2 85 79-30

Fax +49 (0) 61 06 2 22 08

rodgau@rofi.de

East

Reuterstrae 2

D-99867 Gotha

Tel. +49 (0) 36 21 7 33 97-0

Fax +49 (0) 36 21 7 33 97-10

gotha@rofi.de

RO-FI Precision in Stainless Steel

Zuverlssigkeit

durch Qualittsmanagement

Reliability

by quality

management

Reliability by quality management - ISO 9001

Potrebbero piacerti anche

- Expansion Joint Manual 1501uk 5-12-12 20 DownloadDocumento323 pagineExpansion Joint Manual 1501uk 5-12-12 20 DownloadivanmatijevicNessuna valutazione finora

- 2022.02-Chemical Corrosion Guide-FinalDocumento52 pagine2022.02-Chemical Corrosion Guide-FinalEdward Alejandro Avendaño BeltranNessuna valutazione finora

- Expansion Calculations and Loop SizingDocumento2 pagineExpansion Calculations and Loop Sizingzshehadeh0% (1)

- McQuiston HVAC Analysis Design 6th SolutionsDocumento313 pagineMcQuiston HVAC Analysis Design 6th SolutionsProsperouscross77% (31)

- 03 Wire Rope Strand TerminationsDocumento20 pagine03 Wire Rope Strand Terminationsoluomo1Nessuna valutazione finora

- CadWorx Spec Editor Users GuideDocumento117 pagineCadWorx Spec Editor Users GuideDavid Smith100% (2)

- Impeller Design For Mixing of SuspensionsDocumento16 pagineImpeller Design For Mixing of SuspensionsFaycel OuerdienNessuna valutazione finora

- J.M. Hurst Cyclic AnalysisDocumento45 pagineJ.M. Hurst Cyclic AnalysisChristian Robinson80% (10)

- FlangesDocumento13 pagineFlangesThiruThirunavukkarasuNessuna valutazione finora

- Aluminium en AW 5754Documento4 pagineAluminium en AW 5754aldairlopesNessuna valutazione finora

- Iso 16028 1999Documento9 pagineIso 16028 1999MussardNessuna valutazione finora

- DIN Valve StandardsDocumento8 pagineDIN Valve StandardsdavNessuna valutazione finora

- Jis G3444Documento12 pagineJis G3444yapsguanNessuna valutazione finora

- Galvanised Malleable Iron Pipe FittingDocumento19 pagineGalvanised Malleable Iron Pipe FittingMichael SommerNessuna valutazione finora

- Filter Alternative - Cross ReferenceDocumento5 pagineFilter Alternative - Cross ReferenceKhun khai100% (1)

- Diet Coke & Mentos Geyser Lab 2011-2012Documento4 pagineDiet Coke & Mentos Geyser Lab 2011-2012Frederick LoganNessuna valutazione finora

- A Good Practice Guide For Flange Jointing of Polyethylene Pressure Pipes 1Documento5 pagineA Good Practice Guide For Flange Jointing of Polyethylene Pressure Pipes 1Bimal DeyNessuna valutazione finora

- Marco o Ring Size Chart Japanese PDFDocumento12 pagineMarco o Ring Size Chart Japanese PDFraymond ngoNessuna valutazione finora

- Tyco - Sintakote - Design - Manual - Nov2004editionDocumento140 pagineTyco - Sintakote - Design - Manual - Nov2004editionmottmac50% (2)

- Tyco Fig.110-190 Ball Valves DatasheetDocumento24 pagineTyco Fig.110-190 Ball Valves DatasheetMahdi Daly100% (1)

- Hydraulic Tubes and PipesDocumento18 pagineHydraulic Tubes and Pipeshp_vijaykNessuna valutazione finora

- Part List Rga-2315h1jt-11 2-La4-E1 (GB Cv05)Documento4 paginePart List Rga-2315h1jt-11 2-La4-E1 (GB Cv05)restu yanuar salamNessuna valutazione finora

- Purlin Girt ReinforcementDocumento16 paginePurlin Girt ReinforcementmaheshbandhamNessuna valutazione finora

- Problems PDFDocumento9 pagineProblems PDFEduarGelvezNessuna valutazione finora

- Rhein StromDocumento20 pagineRhein Stromalecugeorgescu100% (1)

- B635 Tank Mixing Eductors PDFDocumento12 pagineB635 Tank Mixing Eductors PDFivanmatijevicNessuna valutazione finora

- Flanged End Swing Check Valves DIN3202 F6Documento2 pagineFlanged End Swing Check Valves DIN3202 F6AndiniPermanaNessuna valutazione finora

- 8) Catalogue - GS Hightecher VALVESDocumento10 pagine8) Catalogue - GS Hightecher VALVESmarcusNessuna valutazione finora

- Elbows - DIN 2605: VL Code 711Documento3 pagineElbows - DIN 2605: VL Code 711ZAQWNessuna valutazione finora

- AMRI ISORIA 10 Type Series Booklet Data PDFDocumento20 pagineAMRI ISORIA 10 Type Series Booklet Data PDFMurrali Raj Jeyagapal50% (2)

- Adapters Instantaneous Male With BSP and NH ThreadsDocumento1 paginaAdapters Instantaneous Male With BSP and NH ThreadsRajadurai SinghNessuna valutazione finora

- Din 6914-10.9Documento2 pagineDin 6914-10.9vpjagannaathNessuna valutazione finora

- Fittings - DIN 2616: VL Code 731Documento2 pagineFittings - DIN 2616: VL Code 731RatheeshNessuna valutazione finora

- Siphon BreakerDocumento1 paginaSiphon BreakerpsychopassNessuna valutazione finora

- UNI EN 24014 DIN EN 24014 ISO 4014: Viti A Testa Esagonale Con Gambo Parzialmente FilettatoDocumento2 pagineUNI EN 24014 DIN EN 24014 ISO 4014: Viti A Testa Esagonale Con Gambo Parzialmente FilettatoEng. EmersonNessuna valutazione finora

- JC Catalogue Gate Valves BBDocumento24 pagineJC Catalogue Gate Valves BBMahdi DalyNessuna valutazione finora

- Castors and WheelsDocumento29 pagineCastors and WheelsJohan ConradieNessuna valutazione finora

- Pulley Groove Dimensions and SelectionDocumento1 paginaPulley Groove Dimensions and Selectionandysupa100% (1)

- E91 202006 20orifice 20plate 20 - 20doschDocumento6 pagineE91 202006 20orifice 20plate 20 - 20doschiaft100% (1)

- Carbon and Carbon-Manganese Steel Seamless Steel Tubes and Pipes For ShipDocumento10 pagineCarbon and Carbon-Manganese Steel Seamless Steel Tubes and Pipes For Shipvalli rajuNessuna valutazione finora

- Fittings Din11852 Din11850Documento14 pagineFittings Din11852 Din11850dingobk1Nessuna valutazione finora

- Bolt Shear Strength - MetricDocumento1 paginaBolt Shear Strength - MetricK.S.MAYILVAGHANANNessuna valutazione finora

- SLG-0001-1b Flange Designation Chart PDFDocumento2 pagineSLG-0001-1b Flange Designation Chart PDFMohd Shafuaaz KassimNessuna valutazione finora

- Narrow V Belt Pulleys Din 2211Documento1 paginaNarrow V Belt Pulleys Din 2211TudorNessuna valutazione finora

- Price List Orbitec Sales Rent English 1mbDocumento19 paginePrice List Orbitec Sales Rent English 1mbMarcos AndréNessuna valutazione finora

- Marine Side Scuttle: Code of MaterialDocumento11 pagineMarine Side Scuttle: Code of MaterialcnfguyNessuna valutazione finora

- Lap Joint Stub End PDFDocumento2 pagineLap Joint Stub End PDFBowo Edhi WibowoNessuna valutazione finora

- DN Pipe PDFDocumento6 pagineDN Pipe PDFnassimNessuna valutazione finora

- Mild Steel: Mushroom Head Square Neck Bolts (Cup Square) DIN 603Documento2 pagineMild Steel: Mushroom Head Square Neck Bolts (Cup Square) DIN 603MantasNessuna valutazione finora

- Nut Bolt HeightDocumento8 pagineNut Bolt HeightMian M KhurramNessuna valutazione finora

- ATC BrochureDocumento24 pagineATC BrochureCésar HermosoNessuna valutazione finora

- Jis g3456 Grade STPT 410 Pipes PDFDocumento1 paginaJis g3456 Grade STPT 410 Pipes PDFMitul MehtaNessuna valutazione finora

- Din Flange Din 2627: (Dimensions in MM.)Documento12 pagineDin Flange Din 2627: (Dimensions in MM.)Wisüttisäk PeäröönNessuna valutazione finora

- Jis Flanges PDFDocumento4 pagineJis Flanges PDFQuang ThanhNessuna valutazione finora

- WEP Standard For Reference OnlyDocumento37 pagineWEP Standard For Reference OnlyKiran NikateNessuna valutazione finora

- EN-GJL-200 - EN-JL1030 - Cast Iron Equivalent, Mechanical Properties, Chemical CompositionDocumento1 paginaEN-GJL-200 - EN-JL1030 - Cast Iron Equivalent, Mechanical Properties, Chemical CompositionBao Duy NguyenNessuna valutazione finora

- NPS - 'Nominal Pipe Size' and DN - 'Diametre Nominal'Documento3 pagineNPS - 'Nominal Pipe Size' and DN - 'Diametre Nominal'harisNessuna valutazione finora

- Catalogo GASKET General Measurement TablesDocumento20 pagineCatalogo GASKET General Measurement TablescastibraNessuna valutazione finora

- 08chapter6 ShaftfixingsDocumento12 pagine08chapter6 Shaftfixingsreinaldosidejunior100% (1)

- Thread Data ChartsDocumento4 pagineThread Data Chartsrasinv100% (1)

- Specification of Phosphor Bronze StripDocumento3 pagineSpecification of Phosphor Bronze Stripsaleemnel100% (1)

- Klinger Marine Valves & GasketsDocumento279 pagineKlinger Marine Valves & GasketsAndy Luthor100% (1)

- Carbon Hollow Bar ST 52Documento2 pagineCarbon Hollow Bar ST 52JeganeswaranNessuna valutazione finora

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDa EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNessuna valutazione finora

- Bondstrand 2400 SeriesDocumento20 pagineBondstrand 2400 SeriesTommytoo BernalNessuna valutazione finora

- SA RawlboltDocumento2 pagineSA Rawlboltpower_generator133850% (2)

- Catalog Profile Cu Pereti SubtiriDocumento52 pagineCatalog Profile Cu Pereti Subtirinelutu12345100% (1)

- En 10241 FittingsDocumento6 pagineEn 10241 FittingsDhavalNessuna valutazione finora

- Din 2440-78 Steel Tubes Medium Weight Suitable For Screwing: Global Marketing For Tube & PipeDocumento0 pagineDin 2440-78 Steel Tubes Medium Weight Suitable For Screwing: Global Marketing For Tube & PipeAdrian MarinNessuna valutazione finora

- Turbulent Modular Mixer-Template File: Created in COMSOL Multiphysics 5.3Documento12 pagineTurbulent Modular Mixer-Template File: Created in COMSOL Multiphysics 5.3ivanmatijevicNessuna valutazione finora

- Analysis of Solid-Liquid Interactions in A Model BioreactorDocumento15 pagineAnalysis of Solid-Liquid Interactions in A Model BioreactorivanmatijevicNessuna valutazione finora

- Creo On Apple MacsDocumento1 paginaCreo On Apple MacsivanmatijevicNessuna valutazione finora

- Turbulent Viscosity LimitedDocumento2 pagineTurbulent Viscosity LimitedivanmatijevicNessuna valutazione finora

- 28tamburini PDFDocumento6 pagine28tamburini PDFivanmatijevicNessuna valutazione finora

- Convergence and Mesh Independence StudyDocumento5 pagineConvergence and Mesh Independence StudyivanmatijevicNessuna valutazione finora

- Floefd Creo DemoguideDocumento332 pagineFloefd Creo DemoguideivanmatijevicNessuna valutazione finora

- Operation Guide 5142: Using The Crown About This ManualDocumento12 pagineOperation Guide 5142: Using The Crown About This ManualivanmatijevicNessuna valutazione finora

- Happy Foaming With Py FoamDocumento66 pagineHappy Foaming With Py FoamivanmatijevicNessuna valutazione finora

- CFD Simulation of Solid Liquid Suspensions in Baffled Stirred Vessels Below Complete Suspension SpeedDocumento6 pagineCFD Simulation of Solid Liquid Suspensions in Baffled Stirred Vessels Below Complete Suspension SpeedivanmatijevicNessuna valutazione finora

- 1539 RewfDocumento13 pagine1539 RewfivanmatijevicNessuna valutazione finora

- T3902-390-02 SG-Ins Exc EN PDFDocumento171 pagineT3902-390-02 SG-Ins Exc EN PDFBrunoPanutoNessuna valutazione finora

- CFD Simulation of Solids Suspension in Stirred Tanks: ReviewDocumento10 pagineCFD Simulation of Solids Suspension in Stirred Tanks: ReviewivanmatijevicNessuna valutazione finora

- A 672Documento73 pagineA 672Maulia SabrinaNessuna valutazione finora

- EMOC 208 Installation of VITT For N2 Cylinder FillingDocumento12 pagineEMOC 208 Installation of VITT For N2 Cylinder Fillingtejcd1234Nessuna valutazione finora

- Circuiting Explained-Water Coils PDFDocumento2 pagineCircuiting Explained-Water Coils PDFFrancisNessuna valutazione finora

- PIONEER AUTORADIO Deh-X4850bt Deh-X6850bt Operating Manual Ing - Esp - PorDocumento72 paginePIONEER AUTORADIO Deh-X4850bt Deh-X6850bt Operating Manual Ing - Esp - PorJesus NinalayaNessuna valutazione finora

- C12200Documento3 pagineC12200xgiorg100% (1)

- Service Manual: PhilipsDocumento39 pagineService Manual: PhilipsRogerio E. SantoNessuna valutazione finora

- 4 Rec. ITU-R BS.775-3: Reference Loudspeaker Arrangement With Loudspeakers L/C/R and LS/RSDocumento3 pagine4 Rec. ITU-R BS.775-3: Reference Loudspeaker Arrangement With Loudspeakers L/C/R and LS/RSPaulo PiresNessuna valutazione finora

- Efficia Infant WarmingDocumento8 pagineEfficia Infant WarmingNurhidayat MursalinNessuna valutazione finora

- Jacky Smith Resume Project ManagerDocumento1 paginaJacky Smith Resume Project ManagerGrey GrayNessuna valutazione finora

- Unit-II Some PPT NetDocumento2 pagineUnit-II Some PPT NetbandisaidaiahNessuna valutazione finora

- Ude My For Business Course ListDocumento51 pagineUde My For Business Course ListShehroz BhuttaNessuna valutazione finora

- 2019 All PDFDocumento27 pagine2019 All PDFvishesh bhatiaNessuna valutazione finora

- Receiving Material Procedure (Done) (Sudah Direvisi)Documento8 pagineReceiving Material Procedure (Done) (Sudah Direvisi)Hardika SambilangNessuna valutazione finora

- Meai Mar 2010Documento36 pagineMeai Mar 2010Daneshwer VermaNessuna valutazione finora

- VB Script ReferenceDocumento27 pagineVB Script ReferenceRajkumarNessuna valutazione finora

- Trade List 13 Mar 2019Documento74 pagineTrade List 13 Mar 2019Bharat JainNessuna valutazione finora

- Heat Transfer - A Basic Approach - OzisikDocumento760 pagineHeat Transfer - A Basic Approach - OzisikMaraParesque91% (33)

- JDE ApplicationDocumento642 pagineJDE ApplicationAnonymous cputyzNessuna valutazione finora

- Schematic Lenovo ThinkPad T410 NOZOMI-1Documento99 pagineSchematic Lenovo ThinkPad T410 NOZOMI-1borneocampNessuna valutazione finora

- Internship Report May 2016Documento11 pagineInternship Report May 2016Rupini RagaviahNessuna valutazione finora

- AquaCal Tropical Brochure PDFDocumento2 pagineAquaCal Tropical Brochure PDFJC ParedesNessuna valutazione finora

- Coal Combustion Monitoring Report Unwashed Semi Rev02 08.24.2021Documento17 pagineCoal Combustion Monitoring Report Unwashed Semi Rev02 08.24.2021Keith Danae SuquibNessuna valutazione finora

- Sewer Connection Application Guidance PDFDocumento7 pagineSewer Connection Application Guidance PDFSamuel FuentesNessuna valutazione finora

- Waqas Riaz: Total Years of Experience: 2 Years ObjectiveDocumento2 pagineWaqas Riaz: Total Years of Experience: 2 Years ObjectiveIrfanNessuna valutazione finora

- TDS Sadechaf UVACRYL 2151 - v9Documento5 pagineTDS Sadechaf UVACRYL 2151 - v9Alex MacabuNessuna valutazione finora

- Ultrasonic Mixer: Project 99.11Documento11 pagineUltrasonic Mixer: Project 99.11Febri SandiNessuna valutazione finora

- GIS Project Management GIS Project Management: Quality Issues Quality IssuesDocumento1 paginaGIS Project Management GIS Project Management: Quality Issues Quality IssuesLeo DobreciNessuna valutazione finora

- Sec VlanaclsDocumento10 pagineSec VlanaclsTry FajarmanNessuna valutazione finora