Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Alco Hi Tek Mono Flange

Caricato da

limresCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Alco Hi Tek Mono Flange

Caricato da

limresCopyright:

Formati disponibili

How to order mono-flange valves

Our part number system is made up of alphanumeric / generic code system as explained below. An example is :-

Mono Flange - needle, needle, needle. 1/4 vent & outlet ports with NPT threads. A350 LF2 carbon steel, 1/2 nominal bore, class 150, raised face pipe connections, fire-safe.

The part number shown below is made up using the system :-

Style

Valve configuration

Vent & outlet size (vent and / or outlet

Outlet Thread Type

Material of construction (body)

Nominal size

Pressure / class Rating

End type

Options

MF

NN

FS

ONN = OSY, Needle, Needle ONO = OSY, Needle, OSY NNN = Needle, Needle, Needle ON = OSY, Needle NN = Needle, Needle

R = S = J = F = BW SW N P T F = = = = NPT BSP BSPT FLG 4 = 1/2 6 = 3/4 8 = 1 12 = 1 1/2 16 = 2 24 = 3

Raised face Smooth raised face Ring type joint Flat Faced = Butt weld = Socket weld

SMF = OSY Primary Iso MF = NV Primary Iso DMF = Flange/Flange L = LF2 S = F316 U = F51/Duplex 6 = Inconel 625 8 = Inconel 825 D = Ali-Bronze SU = F55/Super Duplex T = Titanium 6MO = F44 I = Incoloy

FS = Fire-safe ATV = Anti-tamper vent IC = Injection quill S = Sample probe HLK = Handle locks A = 150 lbs B = 300 lbs C = 600 lbs D = 900 lbs E = 1,500 lbs F = 2,500 lbs 5K = 5,000 psi 10K = 10,000 psi

Blank = Flange x screwed D = Flange connection in & out

2 4 6 8

= = = =

1/4 1/2 3/4 1

Socket weld and butt weld end connectors may be extended for thermal protection of the valve internals

NOTE 1: The pressure ratings quoted within our literature are maximum hydrostatic pressure ratings for the valves always consult the factory for a GA drawing before you order. Certain options available are the products / designs of other manufacturers, Alco valves cannot accept any responsibility for these products unsuitability or failure in service. NOTE 2: The bore sizes shown above relate to the primary and or secondary valve only not necessarily to the vent valves. NOTE 3: It is always advisable to refer to specific product literature or contact our technical sales department when ordering valves as some of these options are available only on certain styles of valves. Any special end connections such as compression ends or butt / socket weld may limit the rated working pressure of the valve or component supplied in accordance with the relevant specification of design or use of that method of connection. The valve or component will still carry the maximum working pressure markings in accordance with the valve or component design not the connection method as they vary.

1999

REF: HTCAT2K069 REV: 00

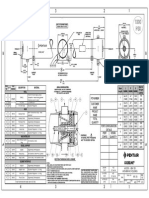

Mono Flange Type MF Pipeline to instrumentation solutions

General Information

The MF type DBB is a compact and lightweight double block and bleed valve system. All isolation valves are designed for high pressure instrument and process applications. Dual outlet connections are available to allow for the instrument to be mounted vertically or horizontally depending on the pipe orientation. The MF offers the lowest possible number of potential leakage points from a process connection, through 3 valves to a static instrument such as a pressure gauge. This involves only one joint - the pipeline flange to the valve body. It is easily understood that the benefits of this unit are many. Manometers, pressure gauges and temperature measurement devices can be easily installed reducing safety risks and cost. Using the MF style block & bleed or double block and bleed from Alco.

Part No. Shown: MF-NNN-4NS-8CR-FS

Design Features

Compact and lightweight. Leak paths reduced. Designed in accordance with ASME VIII, ANSI B16.34 / B16.5, ANSI B31.3, EEMUA 182 and API 6D. Fire-safe to BS6755 Part 2 as standard. High integrity multi-ring packings for long field life / service life. Bubble tight metal to metal seat for positive shut off. Back sealing stems to further extend packing life. Unique cam locking device at the body to bonnet connection for extra safety in service where vibration exists. Actuating threads are above the packings to prevent contamination by the process medium. Body to bonnet ingress seal fitted as standard to prevent crevice corrosion. 2 piece non-rotating hardened (17-4PH) tip for first time seal and long service life.

1999

REF: HTCAT2K070 REV: 00

Arrangement Details of type MF Pipeline to instrumentation solutions

Application

Mono-flange manifolds are suitable for gauge or instrument mounting direct to a system via a standard flange take off point. Various flange ratings available to suit almost any pressure rating and size within piping systems. Standard applications include static instrumentation, pressure gauges, manometers, temperature measurement devices and pressure switches. Due to the compact size of the MF weight savings are optimised, therefore offshore installations, F.P.S.Os can benefit greatly. Furthermore, this slimline format does not require supporting. All in all any installation requiring a safer, more compact, lightweight, cost saving pipeline instrument solution can take advantage of the Alco mono-flange manifold range.

General Arrangement

IS O LATE

IS O LATE

ISO L ATE

V EN T

For detailed dimensional information contact our sales offices

Technical Information

Available fire-safe to BS6755 Part 2. 1/2 to 6 nominal bore ANSI flange sizes. Pressure ANSI 150 - 2500. Isolation and vent 6mm as standard, available up to 25mm. Anti tamper locking vent option available. Simple quick and easy four bolt installation to pipelines. Available with stellite or ceramic tips where abrasive mediums are used. Also available in single isolation or single block & bleed formats. Additional porting to customer specification can be supplied i.e. for purging injection / sample purposes. Can be fitted with swivel gauge adapter for gauge rotation purposes. Flanged x flanged option available.

1999

REF: HTCAT2K071 REV: 00

Mono Flange Type SMF Pipeline to instrumentation solutions

General Information

The type SMF valve offers a compact lightweight instrument double block and bleed valve. Primary isolation is by a pipeline isolation outside screw and yoke bolted design with instrument needle design for secondary isolation and vent. Dual outlet connections are available to allow for the instrument to be mounted vertically or horizontally. The SMF offers the lowest possible number of potential leakage points from a process connection, through 3 valves to a static instrument such as a pressure gauge. This involves only one joint - the pipeline flange to the valve body. It is easily understood that the benefits of this unit are many. Manometers, pressure gauges and temperature measurement devices can be easily installed at a reduced safety risk and cost using the SMF.

Part No. Shown:

Piping class, fire-safe, primary isolation valve.

Design Features

Leak paths reduced. Massive space and weight savings. Fire-safe to BS6755 Part 2 as standard. Designed in accordance with ASME VIII, ANSI B16.34 / B16.5, ANSI B31.3, EEMUA 182 and API 6D. Flange x threaded and flange x flange options available. Unique cam locking device at the body to bonnet connection for extra safety in service where vibration exists. Bubble tight metal to metal seat for positive shut off. Compact and lightweight. Actuating threads are above the packings to prevent contamination by the process medium. Body to bonnet ingress seal fitted as standard to prevent crevice corrosion. 2 piece non-rotating hardened (17-4PH) tip for first time seal and long service life.

1999

REF: HTCAT2K072 REV: 00

Arrangement Details of Type SMF Pipeline to instrumentation solutions

Application

Mono-flange manifolds are suitable for gauge or instrument mounting direct to a system via a standard flange take off point. Various flange ratings available to suit almost any pressure rating and size within piping systems. Standard applications include static instrumentation, pressure gauges, manometers, temperature measurement devices and pressure switches. Due to the compact size of the MF weight savings are optimised, therefore offshore installations, F.P.S.Os can benefit greatly. Furthermore, this slimline format does not require supporting. All in all any installation requiring a safer, more compact, lightweight, cost saving pipeline instrument solution can take advantage of the Alco mono-flange manifold range.

General Arrangement

For detailed dimensional information contact our sales offices

Piping class, fire-safe primary isolation valve.

Technical Information

Available fire-safe to BS6755 Part 2. 1/2 to 6 ANSI flange sizes. Pressure ratings ANSI 150 - 2500. Isolation up to 19mm. 6mm needle valve bleed as standard, available up to 25mm. Anti tamper locking vent option available. Simple quick and easy four bolt installation to pipelines. Available with stellite or ceramic tips where abrasive mediums are used. Available in single isolation or single block and bleed. Flanged x flanged option available. Additional porting to customer specification can be supplied i.e. for purging injection / sample purposes. Can be fitted with swivel gauge adapter for gauge rotation purposes. Flanged x flanged option available.

1999

REF: HTCAT2K073 REV: 00

Mono Flange Type 10SMF Pipeline to instrumentation solutions

General Information

The type 10SMF valve offers a lightweight globe type double block and bleed. Primary and secondary isolation are by a pipeline isolation outside screw and yoke bolted design. The MF offers the lowest possible number of potential leakage points from a process connection, through 3 valves to a static instrument such as a pressure gauge. This involves only one joint - the pipeline flange to the valve body. It is easily understood that the benefits of this unit are many. Manometers, pressure gauges and temperature measurement devices can be easily installed at a reduced safety risk and cost using the MF style block & bleed or double block and bleed from Alco.

Shown with all stainless steel security locking feature

Design Features

Reduced leak points. Up to 19mm bore. Fire-safe to BS6755 Part 2. Designed in accordance with ASME VIII, ANSI B16.34 / B16.5, ANSI B31.3, EEMUA 182 and API 6D. Flange x threaded and flange x flange options available. Compact and lightweight. Bubble tight metal to metal seat for positive shut off. Back sealing stems to further extend packing life. Unique cam locking device at the body to bonnet connection for extra safety in service where vibration exists. Actuating threads are above the packings to prevent contamination by the process medium. Body to bonnet ingress seal fitted as standard to prevent crevice corrosion. 2 piece non-rotating hardened (17-4PH) tip for first time seal and long service life.

1999

REF: HTCAT2K074 REV: 00

Arrangement Details of Type 10SMF Pipeline to instrumentation solutions

Application

Mono-flange manifolds are suitable for gauge or instrument mounting direct to a system via a standard flange take off point. Various flange ratings available to suit almost any pressure rating and size within piping systems. Standard applications include static instrumentation, pressure gauges, manometers, temperature measurement devices and pressure switches. Due to the compact size of the MF weight savings are optimised, therefore offshore installations, F.P.S.Os can benefit greatly. Furthermore, this slimline format does not require supporting. All in all any installation requiring a safer, more compact, lightweight, cost saving pipeline instrument solution can take advantage of the Alco mono-flange manifold range. Widely used by TEXACO on the captain project 1999.

General Arrangement

For detailed dimensional information contact our sales offices

Technical Information

1/2 to 6 ANSI flange sizes. Pressure ratings ANSI 150 - API 10,000. Up to 19mm bore. ANSI 150 - 2500. Isolation and vent 6mm as standard, available up to 25mm. Anti tamper locking vent option available. Simple quick and easy four bolt installation to pipelines. Available with stellite or ceramic tips where abrasive mediums are used. Available in single isolation or single block and bleed. Security primary & secondary isolate valve feature. Additional porting to customer specification can be supplied i.e. for purging injection / sample purposes. Available fire-safe to BS6755 Part 2. Can be fitted with swivel gauge adapter for gauge rotation purposes. Flanged x flanged option available.

1999

REF: HTCAT2K075 REV: 00

Potrebbero piacerti anche

- How to prepare Welding Procedures for Oil & Gas PipelinesDa EverandHow to prepare Welding Procedures for Oil & Gas PipelinesValutazione: 5 su 5 stelle5/5 (1)

- Manual Ecoflux en - KrohneDocumento14 pagineManual Ecoflux en - Krohnemmihai_popa2006Nessuna valutazione finora

- Monoflanges VariAS BlocksDocumento20 pagineMonoflanges VariAS BlocksamuihNessuna valutazione finora

- 2011 07 Mar00080 en Katalog Typs WebDocumento28 pagine2011 07 Mar00080 en Katalog Typs WebzayerirezaNessuna valutazione finora

- Diapham Valve PDFDocumento8 pagineDiapham Valve PDFthouche007Nessuna valutazione finora

- Amisco Pilot ValveDocumento8 pagineAmisco Pilot ValveRaul CostiniucNessuna valutazione finora

- Instrument Manifold Valves 5000Documento16 pagineInstrument Manifold Valves 5000Maria MantillaNessuna valutazione finora

- Burmad 400 Series-Globe Type Deluge ValveDocumento8 pagineBurmad 400 Series-Globe Type Deluge Valvenastyn-1Nessuna valutazione finora

- Crane - Series.rs Center LineDocumento23 pagineCrane - Series.rs Center LinenedwestNessuna valutazione finora

- Three Way ValvesDocumento8 pagineThree Way ValvesWalter JosephNessuna valutazione finora

- DQ CatalogDocumento16 pagineDQ Catalogm_ramas2001Nessuna valutazione finora

- CO2 AnsulDocumento17 pagineCO2 AnsulJorge RVNessuna valutazione finora

- Neojv 0040 enDocumento0 pagineNeojv 0040 enLuis GuevaraNessuna valutazione finora

- Amarex N: Submersible Motor Pumps DN 50 To 100Documento44 pagineAmarex N: Submersible Motor Pumps DN 50 To 100Ben RahierNessuna valutazione finora

- Manifold Swagelok Ms 01 178Documento16 pagineManifold Swagelok Ms 01 178papashoNessuna valutazione finora

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Documento3 pagineDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)RamanNegiNessuna valutazione finora

- Differential Pressure DetectorsDocumento4 pagineDifferential Pressure Detectorskdp_806212786Nessuna valutazione finora

- HP Access Fitting Assemblies PDFDocumento4 pagineHP Access Fitting Assemblies PDFNicholas MaldonadoNessuna valutazione finora

- Knife Gate ValveDocumento7 pagineKnife Gate ValveAbdul RaheemNessuna valutazione finora

- Model 2100bDocumento4 pagineModel 2100bkeyur1109Nessuna valutazione finora

- Danfoss Non Return ValvesDocumento28 pagineDanfoss Non Return Valveskostaviga777Nessuna valutazione finora

- Mead Isonic V1 Series (WWW - Mead.co - Uk)Documento4 pagineMead Isonic V1 Series (WWW - Mead.co - Uk)Mead Engineering Services LtdNessuna valutazione finora

- Spirax Sarco BTM-7Documento3 pagineSpirax Sarco BTM-7Bambang Agung LaxmonoNessuna valutazione finora

- A1-Cam Groove CouplingsDocumento40 pagineA1-Cam Groove CouplingsedwinramonNessuna valutazione finora

- Product Range: Gate Valve / Sluice ValveDocumento6 pagineProduct Range: Gate Valve / Sluice ValveTanmoy DuttaNessuna valutazione finora

- Rotex Solenoid ValveDocumento16 pagineRotex Solenoid Valvemanmohansingh1999100% (1)

- Guntner MANDocumento28 pagineGuntner MANJosé Luis Boncún Carnero100% (2)

- Codeline, 150 PSI, Drawing - 80S15Documento3 pagineCodeline, 150 PSI, Drawing - 80S15RamanNegiNessuna valutazione finora

- ASCO Miniature Valve Products (AV017R5)Documento96 pagineASCO Miniature Valve Products (AV017R5)vasudeva yasasNessuna valutazione finora

- Flowserve Durco TX3 ValveDocumento20 pagineFlowserve Durco TX3 ValveDGWNessuna valutazione finora

- Integral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Documento12 pagineIntegral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Lê Duy MinhNessuna valutazione finora

- Saudi Aramco Piping QC Inspector Sample Interview QuestionsDocumento6 pagineSaudi Aramco Piping QC Inspector Sample Interview QuestionsRichard Periyanayagam100% (3)

- MCS Staubli Z515eDocumento16 pagineMCS Staubli Z515eleheteNessuna valutazione finora

- Index: Product List SR. NODocumento40 pagineIndex: Product List SR. NOch_yustinusNessuna valutazione finora

- Model"Dc": Dual Chamber Orifice FittingDocumento13 pagineModel"Dc": Dual Chamber Orifice FittingFrankNessuna valutazione finora

- Diaphragm-Type Diaphragm Seals: Block Flange Diaphragm SealDocumento2 pagineDiaphragm-Type Diaphragm Seals: Block Flange Diaphragm SealbehnamatgNessuna valutazione finora

- GF System Specification PVC-U BS InchDocumento14 pagineGF System Specification PVC-U BS InchDale CokleyNessuna valutazione finora

- Flanged X Flanged DBB Type X': General InformationDocumento2 pagineFlanged X Flanged DBB Type X': General InformationShahulNessuna valutazione finora

- InstrumentationDocumento15 pagineInstrumentationLenis Ceron0% (1)

- Air Handling Units Air Handling Units: Technical Catalogue Technical CatalogueDocumento34 pagineAir Handling Units Air Handling Units: Technical Catalogue Technical CatalogueSMBEAUTYNessuna valutazione finora

- DBB CatalogueDocumento20 pagineDBB Cataloguerawrr90Nessuna valutazione finora

- Ham-Let Astava Line of ManifoldsDocumento24 pagineHam-Let Astava Line of ManifoldsjcestupinanNessuna valutazione finora

- KLINGER Ballostar KHA 3 Pieces Ball Valve DN 10 - 150: Edition 2011Documento36 pagineKLINGER Ballostar KHA 3 Pieces Ball Valve DN 10 - 150: Edition 2011Andy LuthorNessuna valutazione finora

- SOR Pressure and Vacuum Detectors CatalogueDocumento32 pagineSOR Pressure and Vacuum Detectors CatalogueFerio ArsyadNessuna valutazione finora

- Perar Trunnion Ball ValvesDocumento54 paginePerar Trunnion Ball ValvesUday GokhaleNessuna valutazione finora

- (2012) Complete IELTS Bands 5-6.5 Student's BookDocumento3 pagine(2012) Complete IELTS Bands 5-6.5 Student's BookAhmed Hamdy0% (1)

- FlowMon Catalogue 2Documento12 pagineFlowMon Catalogue 2dhanu_aquaNessuna valutazione finora

- SPO Webversion HighDocumento6 pagineSPO Webversion HighchadNessuna valutazione finora

- Aramco Interview QuestionsDocumento38 pagineAramco Interview QuestionsMd Sharique83% (6)

- Cryo DiverterDocumento56 pagineCryo DiverterANILNessuna valutazione finora

- Mini Hermet Pressure SwitchesDocumento24 pagineMini Hermet Pressure SwitchesMilosglNessuna valutazione finora

- Pressure Relief Devices For Power Transformers (With Electric Contacts)Documento8 paginePressure Relief Devices For Power Transformers (With Electric Contacts)nagpurwale2011Nessuna valutazione finora

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDa Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsValutazione: 4 su 5 stelle4/5 (1)

- Pocket Guide to Flanges, Fittings, and Piping DataDa EverandPocket Guide to Flanges, Fittings, and Piping DataValutazione: 3.5 su 5 stelle3.5/5 (22)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerDa EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerValutazione: 5 su 5 stelle5/5 (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceDa EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceValutazione: 5 su 5 stelle5/5 (1)

- B Dep Piping and Instrument Diagram AppendixDocumento69 pagineB Dep Piping and Instrument Diagram AppendixAKSHEYMEHTA87% (15)

- Appendix C MTL Power Supplies For Non-Incendive Fieldbus ApplicationsDocumento10 pagineAppendix C MTL Power Supplies For Non-Incendive Fieldbus ApplicationslimresNessuna valutazione finora

- Handbook Safety Relays June-2006Documento13 pagineHandbook Safety Relays June-2006limres100% (1)

- MDRR-DT Features and Benefits: DIMENSIONS (In) MMDocumento1 paginaMDRR-DT Features and Benefits: DIMENSIONS (In) MMlimresNessuna valutazione finora

- 8px3 Install enDocumento36 pagine8px3 Install enlimresNessuna valutazione finora

- NETA Article - Low Voltage Breaker TestingDocumento5 pagineNETA Article - Low Voltage Breaker TestinglimresNessuna valutazione finora

- IEEE 117.d2Documento24 pagineIEEE 117.d2limresNessuna valutazione finora

- Work Activity Norms (Wan) : The Ec Harris Guide ToDocumento16 pagineWork Activity Norms (Wan) : The Ec Harris Guide Tolimres100% (1)

- Kongsberg Product Sheet A4 SSIV WebDocumento2 pagineKongsberg Product Sheet A4 SSIV WeblimresNessuna valutazione finora

- Electrical Equipment enDocumento8 pagineElectrical Equipment enlimresNessuna valutazione finora

- Alstomgui Training: Operating & Support BadenDocumento177 pagineAlstomgui Training: Operating & Support BadenlimresNessuna valutazione finora

- Refuse Chute PPT 01Documento11 pagineRefuse Chute PPT 01sanika shindeNessuna valutazione finora

- Osmotic Power Generation: Prepared byDocumento16 pagineOsmotic Power Generation: Prepared byPritam MishraNessuna valutazione finora

- Module 3 Passive Heating 8.3.18Documento63 pagineModule 3 Passive Heating 8.3.18Aman KashyapNessuna valutazione finora

- 55 Gentle Ways To Take Care of Yourself When You're Busy Busy BusyDocumento7 pagine55 Gentle Ways To Take Care of Yourself When You're Busy Busy Busyvanjami100% (1)

- Reading Comprehension MaterialsDocumento6 pagineReading Comprehension MaterialsDiana PundavelaNessuna valutazione finora

- Service Manual SM1-76-38.0: Collector Ring, ReconditionDocumento4 pagineService Manual SM1-76-38.0: Collector Ring, ReconditionJorge YuniorNessuna valutazione finora

- Yumiko@Documento2 pagineYumiko@api-25886263Nessuna valutazione finora

- Achai, Sydney Jill S. GE 15 - SIM - ULOcDocumento13 pagineAchai, Sydney Jill S. GE 15 - SIM - ULOcSydney AchaiNessuna valutazione finora

- Excavation PermitDocumento2 pagineExcavation PermitRajesh Kumar SinghNessuna valutazione finora

- Structural Tanks and ComponentsDocumento19 pagineStructural Tanks and ComponentsRodolfo Olate G.Nessuna valutazione finora

- Y. C. Fung - Biomechanics - Motion, Flow, Stress, and Growth-Springer-Verlag New York (1990)Documento582 pagineY. C. Fung - Biomechanics - Motion, Flow, Stress, and Growth-Springer-Verlag New York (1990)saurabh kumar gupta100% (2)

- Tutorial Slides - Internal Forced Convection & Natural ConvectionDocumento31 pagineTutorial Slides - Internal Forced Convection & Natural ConvectionVivaan Sharma75% (4)

- Tests Conducted On Under Water Battery - YaduDocumento15 pagineTests Conducted On Under Water Battery - YadushuklahouseNessuna valutazione finora

- Timbers Lesson 2Documento18 pagineTimbers Lesson 2bright possibleNessuna valutazione finora

- Chapter 2 - Alkanes PDFDocumento54 pagineChapter 2 - Alkanes PDFSITI NUR ALISSA BINTI AHMAD RASMANNessuna valutazione finora

- Contoh Permintaan Obat CitoDocumento2 pagineContoh Permintaan Obat CitoAriandy yanuarNessuna valutazione finora

- Chapter 1 Section 6 Spoon Feeding BasicsDocumento9 pagineChapter 1 Section 6 Spoon Feeding Basicskenneth mayaoNessuna valutazione finora

- 7 Solidification, Casting Defects.Documento5 pagine7 Solidification, Casting Defects.Ahmad AbdNessuna valutazione finora

- Life Everlasting 2021001Documento11 pagineLife Everlasting 2021001realangelinemylee2020721001Nessuna valutazione finora

- Define and State The Purpose of Therapeutic DietDocumento10 pagineDefine and State The Purpose of Therapeutic DietKen GarciaNessuna valutazione finora

- Assignment 1 Front SheetDocumento9 pagineAssignment 1 Front SheetBách PhạmNessuna valutazione finora

- Thai Cuisine: Reporters: Bantayan, Kenneth Samejon, Clarish Lovely Relevo, Mary GraceDocumento47 pagineThai Cuisine: Reporters: Bantayan, Kenneth Samejon, Clarish Lovely Relevo, Mary Gracemiralona relevoNessuna valutazione finora

- Textile Chemical Brochure 8.6.22 - 031Documento1 paginaTextile Chemical Brochure 8.6.22 - 031NIKESH PRAKASHNessuna valutazione finora

- RCSI Dentistry PG 118 125 A Manual For Space Analysis in The Mixed DentitionDocumento8 pagineRCSI Dentistry PG 118 125 A Manual For Space Analysis in The Mixed DentitionkarimelmestekawyNessuna valutazione finora

- TRAFFIC RULES PDF Project ReportDocumento18 pagineTRAFFIC RULES PDF Project ReportShweta SharmaNessuna valutazione finora

- DIABETES MELLITUS BensonDocumento14 pagineDIABETES MELLITUS BensonNixon KeyaNessuna valutazione finora

- Souvenir Mushrooms 1986Documento106 pagineSouvenir Mushrooms 1986Ankit MishraNessuna valutazione finora

- Anthropometric Article2Documento11 pagineAnthropometric Article2Lakshita SainiNessuna valutazione finora

- Switchyard Equipments, Switching Schmes & LayoutsDocumento66 pagineSwitchyard Equipments, Switching Schmes & LayoutsPraveen Kumar88% (17)

- TNEB Thermal Power PlantDocumento107 pagineTNEB Thermal Power Plantvicky_hyd_130% (1)