Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pipe Specification ASTM-A106

Caricato da

Ajay ChodankarDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pipe Specification ASTM-A106

Caricato da

Ajay ChodankarCopyright:

Formati disponibili

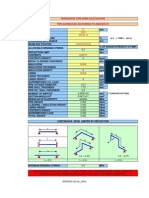

PIPE SPECIFICATIONS Scope A106 1/8" - 26" STD, XS AND XXS ANSI B36.

10 Covers SEAMLESS nominal size and wall pipe for hightemperature service, suitable for bending, flanging, and similar forming operations.

Heat treated cold drawn pipe may be furnished to this specification. Optional supplementary requirements may be specified when pipe 8 inch and larger is intended for use where a superior grade is required.

Other sizes and dimensions may be furnished Hydrostatic Testing Hydrostatic test pressures are calculated using the Barlow formula. Each pipe shall be tested to 60 percent of specified minimum yield strength, but not exceeding 2500 psi for3 inch nominal size or smaller, or 2800 psi for sizes over 3 inch. Permissible Variations in Weights Per Foot For schedule 120 and lighter Pipe shall not vary more than 6.5 percent over and 3.5 percent under weights shown in ANSI B36.10. For pipe heavier than schedule 120 Pipe shall not vary more than 10 percent over and 3.5 percent under weights shown in ANSI B36.10. Sizes 4 inch and smaller are weighed in convenient lots. Pipe in sizes larger than 4 inch is weighed separately.

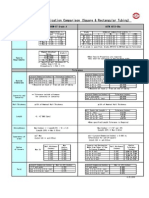

PIPE SPECIFICATIONS Permissible Variations in OD A106 1/8" - 26" STD, XS and XXS ANSI B36.10 Other sizes and dimensions may be furnished OUTSIDE DIAMETER shall not exceed variations as listed below: Nominal Pipe Size 1/8 to 1-1/2, incl Over 1-1/2 to 4, incl Over 4 to 8, incl Over 8 to 18, incl Over 18 to 26, incl Over, Inch 1/64 (0.015) 1/32 (0.031) 1/16 (0.062) 3/32 (0.093) 1/8 (0.125) Under, Inch 1/64 (0.015) 1/32 (0.031) 1/32 (0.031) 1/32 (0.031) 1/32 (0.031)

Permissible Variations in Wall Thickness Minimum wall thickness at any point shall not be more than 12.5 percent under nominal wall thickness specified. Specification contains a table of minimum wall thicknesses on inspection calculated as 0.875 x nominal wall. Chemical Requirements Composition, max. percent C Mn max. Grade A Grade B Grade C 0.25 0.30 0.35 0.27/0.93 0.29/1.06 0.29/1.06

P max. 0.035 0.035 0.035

S max. 0.035 0.035 0.035

Si min. 0.10 0.10 0.10

Tensile Requirements Tensile Strength min, psi Grade A Grade B Grade C Table lists minimum elongation values. 48,000 60,000 70,000 Yield Point min, psi 30,000 35,000 40,000

PIPE SPECIFICATIONS Mechanical Tests Specified A106 1/8" - 26" TENSILE TEST Required on all sizes.

STD, XS AND XXS ANSI B36.10

BEND TEST Required on sizes 2 inch and smaller. Pipe shall stand cold bending through 90 degrees around a mandrel with a diameter twelve times the nominal diameter of the pipe without cracking. If for close coiling bend shall be 180 degrees around diameter eight times the nominal diameter of pipe.

Other sizes and dimensions may be furnished FLATTENING TEST Required on sizes over 2 inch in nominal diameter.

Potrebbero piacerti anche

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsValutazione: 4.5 su 5 stelle4.5/5 (10)

- Din 17102Documento10 pagineDin 17102julio_rocha_1Nessuna valutazione finora

- All-in-One Manual of Industrial Piping Practice and MaintenanceDa EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceValutazione: 5 su 5 stelle5/5 (1)

- Weld Like a Pro: Beginning to Advanced TechniquesDa EverandWeld Like a Pro: Beginning to Advanced TechniquesValutazione: 4.5 su 5 stelle4.5/5 (6)

- Worldwide Flowmeter Calibration Facilities and Markets-Overview PDFDocumento18 pagineWorldwide Flowmeter Calibration Facilities and Markets-Overview PDFAjay ChodankarNessuna valutazione finora

- S/A 106 Spec Sheet A106 Pipe Specifications: ScopeDocumento7 pagineS/A 106 Spec Sheet A106 Pipe Specifications: ScopeyanurarzaqaNessuna valutazione finora

- A/SA 106 Spec Sheet A106 Pipe Specifications: American Piping Products Stocks A Full Range of A106 Pipe (SA106 Pipe) inDocumento8 pagineA/SA 106 Spec Sheet A106 Pipe Specifications: American Piping Products Stocks A Full Range of A106 Pipe (SA106 Pipe) inMostafizur RahmanNessuna valutazione finora

- A106 Pipe SpecificationsDocumento3 pagineA106 Pipe Specificationspundir_vineet100% (1)

- Astm A 500Documento3 pagineAstm A 500LuckySingh100% (2)

- Pipe Specification A106 Specification A106 NPS 1/8 - 48 ANSI Schedules To 160Documento1 paginaPipe Specification A106 Specification A106 NPS 1/8 - 48 ANSI Schedules To 160Denise Koh Chin HuiNessuna valutazione finora

- Fire Piping-Astm A106Documento4 pagineFire Piping-Astm A106sinahimsNessuna valutazione finora

- Hse Approved SpecificationDocumento16 pagineHse Approved SpecificationPrasit MeeboonNessuna valutazione finora

- Stainless Steel Tubing: Fractional SizesDocumento2 pagineStainless Steel Tubing: Fractional SizesmasimeriseNessuna valutazione finora

- A106 Seamless Carbon Steel Pipe: Hydrostatic TestingDocumento7 pagineA106 Seamless Carbon Steel Pipe: Hydrostatic TestingTan Chee MingNessuna valutazione finora

- Technical Data Chart G16667 (Pressure Rating For ASTM A53-40 ERW Type E)Documento2 pagineTechnical Data Chart G16667 (Pressure Rating For ASTM A53-40 ERW Type E)polysourceNessuna valutazione finora

- ASTM A312 2014 Specification For Seamless and Welded Austenitic Stainless Steel Pipe PDFDocumento4 pagineASTM A312 2014 Specification For Seamless and Welded Austenitic Stainless Steel Pipe PDFanon_295291420Nessuna valutazione finora

- Steel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsDocumento3 pagineSteel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationshamidharvardNessuna valutazione finora

- ASTM A106 Pipe Specifications - American Piping ProductsDocumento7 pagineASTM A106 Pipe Specifications - American Piping ProductsJonnah Faye MojaresNessuna valutazione finora

- A 822 - 90 r00 Qtgymi9bodiyts1sruqDocumento5 pagineA 822 - 90 r00 Qtgymi9bodiyts1sruqsachinguptachdNessuna valutazione finora

- Swagelok A2333 Data SheetDocumento1 paginaSwagelok A2333 Data SheetvanpupsNessuna valutazione finora

- Pipe Sizing and CalculationsDocumento17 paginePipe Sizing and CalculationsJaykumar100% (6)

- ASTM A572 Grade 50 Plate: AnalysisDocumento2 pagineASTM A572 Grade 50 Plate: Analysisdaniel moreno jassoNessuna valutazione finora

- Propiedades Grado 50 A572Documento2 paginePropiedades Grado 50 A572daniel moreno jassoNessuna valutazione finora

- A 632 - 02 Qtyzmi0wmkeDocumento4 pagineA 632 - 02 Qtyzmi0wmkeLUISALBERTO06011985Nessuna valutazione finora

- API 5L Line Pipes Wall Thickness Outside Diameter Tolerance - Stainless SteeDocumento2 pagineAPI 5L Line Pipes Wall Thickness Outside Diameter Tolerance - Stainless Steewilxj100% (1)

- 2 - 20 Spec - of Line PipesDocumento1 pagina2 - 20 Spec - of Line PipesCharu ChhabraNessuna valutazione finora

- Astm A500Documento1 paginaAstm A500chanchalmailNessuna valutazione finora

- Tube Pressure CalculatorDocumento4 pagineTube Pressure CalculatorRay FaiersNessuna valutazione finora

- Swagelok Tubing SpecificationsDocumento8 pagineSwagelok Tubing SpecificationsAugustine Owo UkpongNessuna valutazione finora

- PDF of Astm A53 Standard SpecificationDocumento4 paginePDF of Astm A53 Standard Specificationmarcelo10003Nessuna valutazione finora

- Pipeline DesignDocumento60 paginePipeline DesignEduardo Paulini Villanueva0% (1)

- Thickness CalculationDocumento6 pagineThickness CalculationBuddy EkoNessuna valutazione finora

- Astm A 178 A 178M 2002Documento4 pagineAstm A 178 A 178M 2002AnamulKabir0% (1)

- Steel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsDocumento4 pagineSteel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsSriniramu SriniramuNessuna valutazione finora

- A 789 - A 789M - 02 Qtc4os0wmkeDocumento4 pagineA 789 - A 789M - 02 Qtc4os0wmkeAhmad HajeerNessuna valutazione finora

- Spiralco - Specifications - ASTM A-139Documento4 pagineSpiralco - Specifications - ASTM A-139Özgür TuştaşNessuna valutazione finora

- Astm A572 - 04Documento1 paginaAstm A572 - 04Hai TranNessuna valutazione finora

- AST - Tank Shell DesignDocumento17 pagineAST - Tank Shell DesignAntony Bruno GenewinNessuna valutazione finora

- Pipeline DesignDocumento42 paginePipeline Designaydinjalali100% (4)

- Pipe Span Without Point LoadsDocumento36 paginePipe Span Without Point Loadsbakelly100% (4)

- Astm A 572Documento2 pagineAstm A 572Vijay KumarNessuna valutazione finora

- ASTM 213, t22Documento22 pagineASTM 213, t22amolgadgikar100% (1)

- Tube Trading CoDocumento3 pagineTube Trading CoChenthil KumarNessuna valutazione finora

- Astm A 106 Seamless Pressure PipeDocumento2 pagineAstm A 106 Seamless Pressure Pipegkdora574Nessuna valutazione finora

- Instrument Tubing Selection Guide: Contact InformationDocumento4 pagineInstrument Tubing Selection Guide: Contact InformationdagauthamNessuna valutazione finora

- API 570 Day 2 Book (1 To 51)Documento65 pagineAPI 570 Day 2 Book (1 To 51)AbdulQuddus100% (3)

- Pipe Inspection & TestingDocumento10 paginePipe Inspection & TestingRobert MichaelrajNessuna valutazione finora

- Astm A557 A557mDocumento3 pagineAstm A557 A557mارفع راسك فوق انت يمنيNessuna valutazione finora

- A500 Vs A513Documento2 pagineA500 Vs A513Angelo CubillosNessuna valutazione finora

- Data Sheet SS316L Seamless Tube Fluidline CustomerDocumento2 pagineData Sheet SS316L Seamless Tube Fluidline Customerinstrument.engineer.123Nessuna valutazione finora

- 2.6. Line and Nozzle Sizing Criteria A. General A.1 The Fluid Quantities To Be Used in Determining Line SizesDocumento7 pagine2.6. Line and Nozzle Sizing Criteria A. General A.1 The Fluid Quantities To Be Used in Determining Line SizesNastaran BagheriNessuna valutazione finora

- Thickness Tolerance of API 5L ASTM A53 EN10219 StandardDocumento2 pagineThickness Tolerance of API 5L ASTM A53 EN10219 StandardhungNessuna valutazione finora

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168Da EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168Nessuna valutazione finora

- Lecture Notes on Reinforced Concrete DesignDa EverandLecture Notes on Reinforced Concrete DesignNessuna valutazione finora

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopDa EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopValutazione: 4.5 su 5 stelle4.5/5 (2)

- How to prepare Welding Procedures for Oil & Gas PipelinesDa EverandHow to prepare Welding Procedures for Oil & Gas PipelinesValutazione: 5 su 5 stelle5/5 (1)

- Thermocouples CATALOGUEDocumento20 pagineThermocouples CATALOGUEAjay ChodankarNessuna valutazione finora

- 13) E-Waste Authorization FormDocumento3 pagine13) E-Waste Authorization FormAjay ChodankarNessuna valutazione finora

- Government of Goa: Published by AuthorityDocumento12 pagineGovernment of Goa: Published by AuthorityAjay ChodankarNessuna valutazione finora

- ISO 5167-5 Cone MetersDocumento2 pagineISO 5167-5 Cone MetersAjay Chodankar60% (5)

- FN400 H# Series Long Radius Flow Nozzles - Holding Ring TypeDocumento1 paginaFN400 H# Series Long Radius Flow Nozzles - Holding Ring TypeAjay ChodankarNessuna valutazione finora

- AB400# Model Coding Decoding SheetsDocumento7 pagineAB400# Model Coding Decoding SheetsAjay ChodankarNessuna valutazione finora

- MSRODocumento1 paginaMSROAjay ChodankarNessuna valutazione finora

- Suggested Wps Forms ASME - IX 2010Documento5 pagineSuggested Wps Forms ASME - IX 2010Ajay ChodankarNessuna valutazione finora

- Using Electronic Detonators To Improve All-Round Blasting PerformancesDocumento8 pagineUsing Electronic Detonators To Improve All-Round Blasting Performancesangel baez contrerasNessuna valutazione finora

- Catalogo Tecnico ENGDocumento52 pagineCatalogo Tecnico ENGAdvokat HadziTonicNessuna valutazione finora

- Bitustick - XL-Material Safety Data SheetDocumento2 pagineBitustick - XL-Material Safety Data Sheetaldred_chezka100% (1)

- CIVL311 - CIVL 911 - 2023 - Week 5 - Design of Columns and Walls - 4 Slides Per PageDocumento19 pagineCIVL311 - CIVL 911 - 2023 - Week 5 - Design of Columns and Walls - 4 Slides Per PageAsfin HaqueNessuna valutazione finora

- Ha Coating On Ti 3.1Documento9 pagineHa Coating On Ti 3.1Truong DucQuangNessuna valutazione finora

- Timer PaperDocumento5 pagineTimer Paperhajjiyare2016Nessuna valutazione finora

- Astm B 265-2010Documento9 pagineAstm B 265-2010bryan wengNessuna valutazione finora

- Weld Design SpreadsheetDocumento4 pagineWeld Design SpreadsheetAli AkbarNessuna valutazione finora

- PSD Important QuestionDocumento1 paginaPSD Important Questionsushant sahooNessuna valutazione finora

- Welding Visual ReportDocumento6 pagineWelding Visual ReportFerdie OSNessuna valutazione finora

- PSA Valves CriticalDesignFeatures MARKEDDocumento41 paginePSA Valves CriticalDesignFeatures MARKEDdj22500Nessuna valutazione finora

- For Bolstering Concrete: Panicum Maximum Jacq. Ash and Pulverized Corbicula Fluminea As An AdmixtureDocumento4 pagineFor Bolstering Concrete: Panicum Maximum Jacq. Ash and Pulverized Corbicula Fluminea As An AdmixtureKristianKurtRicaroNessuna valutazione finora

- Nanotechnology and New Engineering MaterialsDocumento36 pagineNanotechnology and New Engineering MaterialsJosh NobinsNessuna valutazione finora

- Modified Phosphate and Silica Waste in Pigment PaintDocumento12 pagineModified Phosphate and Silica Waste in Pigment PaintDani M RamdhaniNessuna valutazione finora

- EN1992 2 ManciniDocumento138 pagineEN1992 2 Mancinidragos_bogdan1974Nessuna valutazione finora

- Astm C1567 - 13 PDFDocumento6 pagineAstm C1567 - 13 PDFAnonymous SBjNS7Gw0qNessuna valutazione finora

- Non-Catalytic and Heterogeneous Acid/base-Catalyzed Biodiesel Production: Recent and Future DevelopmentsDocumento34 pagineNon-Catalytic and Heterogeneous Acid/base-Catalyzed Biodiesel Production: Recent and Future DevelopmentsJelian GraceNessuna valutazione finora

- PVC Butterfly Valve (Lever)Documento4 paginePVC Butterfly Valve (Lever)Elias SusantoNessuna valutazione finora

- Deflection in BimetalDocumento4 pagineDeflection in BimetalRoisin ClearNessuna valutazione finora

- 21-137 Masonry Restoration NotesDocumento3 pagine21-137 Masonry Restoration Notescap zagNessuna valutazione finora

- Manufacturing Technology II - Notes PDFDocumento17 pagineManufacturing Technology II - Notes PDFSenthil Kumar Subramanian100% (1)

- Topic 7Documento39 pagineTopic 7deema dmdNessuna valutazione finora

- CM 425 CM 425: Properties of Fresh ConcreteDocumento9 pagineCM 425 CM 425: Properties of Fresh ConcretesamNessuna valutazione finora

- Joseph Abrusci - Professional Homemade Cherry BombsDocumento26 pagineJoseph Abrusci - Professional Homemade Cherry BombsLê Nguyên ĐứcNessuna valutazione finora

- NBR Catalogue Eng KKPCDocumento2 pagineNBR Catalogue Eng KKPCChandrasekar KrishnamurthyNessuna valutazione finora

- Lecture LinimentsDocumento22 pagineLecture LinimentsAlena Golod33% (3)

- FOUNDATION RCD of Footings 1 Square FTGDocumento5 pagineFOUNDATION RCD of Footings 1 Square FTGChris Michelle JapinNessuna valutazione finora

- Pinnacle Flo, InC.Documento16 paginePinnacle Flo, InC.r_chulinNessuna valutazione finora

- Seismic Code Evaluation Trinidad and TobagoDocumento7 pagineSeismic Code Evaluation Trinidad and TobagodeniscoteingNessuna valutazione finora