Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

F1+ Accesorios

Caricato da

Rodrigo Andrade ScarpaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

F1+ Accesorios

Caricato da

Rodrigo Andrade ScarpaCopyright:

Formati disponibili

Publ.

1711/LPubl.

1711/Leif

A./00-12-07

Truck Accessories

Adaptor kits and accessories for F1, F1plus, F2, T1plus and VP1 pumps

Catalogue HY17-8242/UK May 2001

1 2 3

NO

LR RMA UNNI

ANGE FILTE CH R

R

R O TA TI O N

Catalogue HY17-8242/UK

Technical Information

Truck Accessories

Contents

Fitting kits for F1, F2 and VP1 pumps Suction fittings for F1plus and T1plus pumps PTO Air valve kits: - Universal - Volvo PTOs - Scania PTOs PTO adapter kits: - for Scania ED 90 engines - for Scania ED 120 engines - for Scania ED 140 engines - for Scania ED 160 engines - for Mercedes engines MB-F2-H1 torque limiting valve Check valves Bypass valves: - BPV-F1/-T1 - BPV-F1-25 and -81 - BPV-F2 - BPV-VP1 - BPV-L, line mounted FDV-VP1 unloading valve Electrical connector assembly ES line mounted unloading valves Cardan shafts, pump couplings and mounting brackets Return filter and filter indicator Air breather filter SB splitter boxes F1, F1plus, F2 and VP1 ordering numbers

Page

3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 18 19 19 20 21 23 24 25 26

Parker Hannifin reserves the right to modify products without prior notice. Even though the brochure is revised and updated continuously, there is always a possibility of errors. For more detailed information about the products, please contact Parker Hannifin (Mobile Controls Div.).

Hydraulics

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Catalogue HY17-8242/UK

Technical Information

Truck Accessories

Fitting kits

for series F1, F2 and VP1 pumps Kits with straight suction fitting

Pump size F1-20/-30 F1-40/-60 F1-80/-110; VP1 F1-80/-110; VP1*

* Above 100 l/min

Ordering no. 370 4934 370 4935 370 4936 370 7220

C1 BSP 1/2" BSP 3/4" BSP 3/4" BSP 1"

C2 dia. 11/2" 2" 2" 2"

Pressure fitting

C1

Straight suction fitting

C2

Kits with 45 suction fitting

Pump size F1-20/-30 F1-40/-60 F1-80/-110; VP1 F1-80/-110; VP1* F2 F2 Pump size F1-20/-30 F1-40/-60 F1-80/-110; VP1 F1-80/-110; VP1* F2

* Above 100 l/min

Ordering no. 370 9017 379 9564 379 9563 379 9562 379 9914 379 9561 A 71 " " 64 " B 154 " " 147 "

C1 BSP 1/2" BSP 3/4" BSP 3/4" BSP 1" BSP 3/4" BSP 3/4"

C2 dia. 2" 2" 2" 1 2 /2" 2" 1 2 /2"

Pressure fitting

C2

C1

45 adjustable suction fitting

B

Kits with 90 suction fitting

Pump size F1-20/-30 F1-40/-60 F1-80/-110; VP1 F2 Pump size F1-20/-30 F1-40/-60 F1-80/-110; VP1 F2 Ordering no. 379 9915 379 9916 379 9918 379 9917 A 144 " " " B 128 " " " C1 BSP 1/2" BSP 3/4" BSP 1" BSP 3/4" C2 dia. 2" 2" 2" 2"

Pressure fitting

C2

C1

90 adjustable suction fitting

NOTE: Each kit consists of a pressure fitting (two pressure fittings for F2), a suction fitting, and corresponding seal washers.

Hydraulics

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Catalogue HY17-8242/UK

Technical Information

Truck Accessories

Suction fitting Cap screw Hold-down clamp

Suction fittings

for series F1plus and T1plus pumps

NOTE: The F1plus and T1plus pumps do not include a suction fitting; it must be ordered separately.

A suction fitting consists of a straight, 45, 90 or 125 suction fitting, 2 clamps, 2 cap screws and an O-ring.

C A

O-ring

Straight suction fittings

Ordering no. 378 0635 378 0636 378 0637 378 0973 378 0974 A mm 0 17 25 17 17 B mm 85 136 145 136 136 C dia. mm (in.) 38 (11/2 ") 50 (2 ") 63 (21/2 ") 45 48

A 'Straight' fitting C B 20

45 suction fittings

Ordering no. 378 1234 1) 378 0633 1) 378 0364 2) 378 0634 378 1062 378 0975 378 0965 A mm 60 60 67 75 67 67 67 B mm 104 104 110 117 110 110 110 C dia. mm (in.) 32 (11/4") 38 (11/2 ") 50 (2 ") 63 (21/2 ") 40 45 48

45 fitting C

20

1) Suitable for frame size F1-25. 2) Suitable for pump sizes F1-41,-51,-61,-81 and -110.

90 suction fittings

Ordering no. 378 0978 378 0979 378 0976 378 0977 378 1980 A mm 126 135 135 135 147 B mm 83 83 83 83 103 C dia. mm (in.) 38 (11/2 ") 50 (2 ") 45 48 63 (21/2 ")

90 fitting B 20

125 suction fitting

Ordering no. 378 1867 A mm 166 B mm 73 C dia. mm (in.) 50 (2 ")

A

NOTE: Suction fittings fit all frame sizes (F1-25, -41, -51, -61, -81 and -101). A suction fitting must be ordered separately (not included with the pump).

125 fitting

20

Hydraulics

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Catalogue HY17-8242/UK

Technical Information

Truck Accessories

Universal PTO air valve kit

The kit includes all parts required for maneouvering the PTO as illustrated below. The air valve kit is suitable for most PTO's with a metric M12x1.5 air connection. The air valve can be installed with other air valves on the chassis which means simple installation with common air supply and a minimum of hoses. The air valve can be connected to electrical wires usually pre-installed on the chassis.

Universal air valve kit

PTO air valve kit Air valve nominal voltage [VDC] Nominal current [A] Required power [W] Max air pressure [bar] Air hose size Operating mode

Universal 24 0.4 9.6 10 1/ " 4 Activated solenoid: Air valve open and PTO engaged. 370 8779

Ordering number

Hydraulics

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Catalogue HY17-8242/UK

Technical Information

Truck Accessories

Air valve kit for Volvo PTO's

The air valve kit is suitable for operating a Volvo PTO on Series FM and FH truck chassis (FH introduced Nov. -98). All parts required to operate the PTO are included in the kit (as shown below). The air valve can be combined with other air valves on the chassis; this means a simple installation with a common air supply and a minimum of hoses. All electrical wires are pre-installed on the chassis. The relay should be installed in socket K1-14 behind the dashboard cover. Function: The relay makes sure the PTO is being disengaged as soon as the 'ignition key' is turned off. To re-engage the PTO, the operator has to put the switch back to neutral, and then move it to the 'ON' position.

Air valve kit for Volvo PTO's.

PTO air valve kit Air valve nominal voltage [VDC] Nominal current [A] Required power [W] Max air pressure [bar] Air hose size Operating mode

Volvo 24 0.4 9.6 10 1/ " 4 Activated solenoid: Air valve open and PTO engaged. 378 1010

Ordering number, series FM and FH 1)

1) Series FH(c) introduced Nov. -98.

Hydraulics

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Catalogue HY17-8242/UK

Technical Information

Truck Accessories

Air valve kit for Scania PTO's

All parts required for operating a Scania PTO are included in the kit (shown below). The air valve kit is suitable for all Scania chassis, Scania Original PTO's, and PTO's from Parker Hannifin (Mobile Controls Div.) for Scania chassis. The air valve can be combined with other air valves on the chassis; this means a simple installation with a common air supply and a minimum of hoses. All electrical wires are pre-installed on the chassis.

Air valve kit for Scania PTO's.

PTO air valve kit Air valve nominal voltage [VDC] Nominal current [A] Required power [W] Max air pressure [bar] Air hose size Operating mode

Scania 24 0.4 9.6 10 1/ " 4 Activated solenoid: Air valve open and PTO engaged. 370 5215

Ordering number

Hydraulics

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Catalogue HY17-8242/UK

Technical Information

Truck Accessories

PTO adapter kit for Scania ED 90 engines

With the adapter kit, an hydraulic pump that meets the ISO standard can be installed on PTO of the Scania 9 liter engine DS/DSC 9. The PTO must be ordered with the chassis from Scania. For additional information please refer to Scania Service Information 19-86 03 30 GT SV.

Pump size Max. operating pressure [bar] Bypass valve

NOTE:

F1-25 F1-41 F1-51 F1-61 F1-81 F1-101 350 350 350 350 223 235 Required

F2-53/53 220

F2-70/35 220

Max operating pressures shown for the F2 frame sizes are valid when both ports are pressurized to the same level simultaneously.

Max. torque [Nm] Gear ratio (engine:pump) Pump rotation PTO adapter kit Scania ED-90

360 1 : 0.975 Right hand (clockwise) Ordering number 379 1729

Hydraulics

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Catalogue HY17-8242/UK

Technical Information

Truck Accessories

PTO adapter kit for Scania ED 120 engines

With the adapter kit, an hydraulic pump (e.g. F1 or VP1) that meets the ISO standard can be installed on the PTO of the Scania 12 liter engine. The PTO gear is supplied with the chassis. Please note: The engine must be ordered with a PTO.

Pump size Max. operating pressure [bar] Bypass valve

NOTE:

F1-25 F1-41 F1-51 F1-61 F1-81 F1-101 350 Required

Max operating pressures shown for the F2 frame sizes are valid when both ports are pressurized to the same level simultaneously.

F2-53/53 350

F2-70/35 350

350

Max. torque [Nm] Gear ratio (engine : pump) Pump rotation PTO adapter kit ED-120-F1 ED-120-VP1

600 1 : 1.19 Right hand (clockwise) Ordering number * 378 2021 378 2022

* Part numbers valid from 00-10-23 (W0043);

replacing 379 9888 and 379 9889 respectively.

Hydraulics

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Catalogue HY17-8242/UK

Technical Information

Truck Accessories

PTO adapter kit for Scania ED 140 engines

With the adapter kit, an hydraulic pump that meets the ISO standard can be installed on PTO of the Scania 14 liter engine DS 14. The PTO gear is not supplied with the kit; it must be ordered separately. For model 144 and later it can be ordered either from Parker Hannifin (Mobile Controls Division), ordering number 379 9413, or from Scania Spare Parts.

A PTO gear is required from model 143.

Pump Max. operating pressure [bar] Bypass valve

F1-25 F1-41 F1-51 F1-61 350 350 285 200 Required

F1-811) 150 1)

1) The engine transmission permits only 150 bar on the F1-81.

Max. torque [Nm] Gear ratio (engine-to-pump) Pump rotation Designation ED-140 adapter kit PTO gear (from model 144)

186 1:1 Right hand (clockwise) Ordering number 370 8445 379 9413

NOTE: Model 143 also requires a PTO gear: Scania part no. 259 206.

10

Hydraulics

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Catalogue HY17-8242/UK

Technical Information

Truck Accessories

PTO adapter kit for Scania ED 160 engines

With the adapter kit, an hydraulic pump (e.g. F1 or VP1) that meets the ISO standard can be installed on the PTO of the Scania 16 liter engine. The PTO gear is supplied with the chassis. Please note: The engine must be ordered with a PTO.

Pump size Max. operating pressure [bar] Bypass valve

NOTE:

F1-25 F1-41 F1-51 F1-61 F1-81 F1-101 350 Required 350

F2-53/53 F2-70/35 350 350

Max operating pressures shown for the F2 frame sizes are valid when both ports are pressurized to the same level simultaneously.

Max. torque [Nm] Gear ratio (engine : pump) Pump rotation PTO adapter kit ED-160-F1

600 1 : 1.19 Left hand (counter clockwise) Ordering number 378 2001

11

Hydraulics

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Catalogue HY17-8242/UK

Technical Information

Truck Accessories

PTO adapter kit for Mercedes engines (Actros)

With the adapter kit, an hydraulic pump that meets the ISO standard can be installed on the PTO of the Mercedes V6 and V8 engines. The PTO must be ordered with the chassis from the manufacturer or through the distributor; when ordering, state 'N53 without pump'.

TOP

Pump Max. operating pressure [bar] for short duration, non-frequent work cycles (e.g. tippers and skip loaders) Max. operating pressure [bar] for continuous work cycles (e.g. cranes and winches) Bypass valve Pump Max. operating pressure [bar] for short duration, non-frequent work cycles (e.g. tippers and skip loaders) Max. operating pressure [bar] for continuous work cycles (e.g. cranes and winches) Bypass valve

NOTE:

F1-25 350

F1-41 350

F1-51 350

F1-61 350

F1-81 350

F1-101 270

350

350

350

350

310

225

Required F2-53/53 F2-70/35 270 270 VP1-045 VP1-075 350 350

230

230

300

300

Required

Max operating pressures shown for the F2 frame sizes are valid when both ports are pressurized to the same level simultaneously.

Max. non-frequent/continuous torque [Nm] Gear ratio (engine-to-pump) Pump rotation Adapter kit VH-PTO-DB

470/390 1 : 1.075 Right hand (clockwise) Ordering number 379 2568

12

Hydraulics

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Catalogue HY17-8242/UK

Technical Information

Truck Accessories

MB-F2-H1 torque limiting valve

The torque limiting valve protects the PTO output shaft (which drives the hydraulic pump) from being overloaded. When the set pressure in the system is reached, the flow from the pump circuit connected to the valve is being unloaded; refer to the schematic.

177 (max)

Pressure drop The diagram below shows pressure drop (P-to-T) vs. flow when the set pressure is reached and the valve unloads one of the pump flows to tank.

p [bar] 20 10 0 0 40 80 120 160 200 [l/min]

MB-F2-H1

Port T (BSP 1") 70

Port S (BSP 1/4")

20 10 65 10

10.5 (x2)

Port P (BSP 1")

Application examples The following schematics show how the MB valve can be connected to the F2.

Torque limiting valve Max pressure [bar] Adjustment range [bar] Ordering number

MB-F2-H1 350 150 350 378 0202

T MB-F2-H1 P Alt. 70 35 53 53 S P

T MB-F2-H1 S Alt.

MB-F2-H1 valve for system pressures to 350 bar (application examples).

13

Hydraulics

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Catalogue HY17-8242/UK

Technical Information

Truck Accessories

Check valves

Check valve

1/ " 2 3/ " 4

Ordering Max flow Max press. Opening number [l/min] [bar] press. [bar] 379 1963 379 1964 379 1965 75 130 200 350 350 350 0,5 0,5 0,5

A B

C D

1"

E G 1/2" check valve.

Check valve

1/ " 2 3/ " 4

Dimensions in mm; B and C threads are BSP. A B C D E F G 32 36 40

1/ " 2 3/ " 4 1/ " 2 3/ " 4

1"

1"

1"

30 34 43

19 20 20

35 13 15

69 65 70

A B

C D

NOTE: Free flow is indicated by the arrow.

E G 3/4" check valve. F

A B

C D

E G

1" check valve.

14

Hydraulics

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Catalogue HY17-8242/UK

Technical Information

Truck Accessories

BPV-F1/-T1 bypass valves

An F1 or T1 pump supplied with a bypass valve can be utilized in applications where the pump is operating constantly i.e. when the pump is driven from the crankshaft through a propshaft or belt, or when it is installed on a PTO. In most cases, the bypass valve allows the pump to be driven at max engine rpm during transportation at no load. This prevents pump cavitation and high heat generation which may otherwise be encountered at large flows. The BPV valve connects the outlet and inlet ports of the pump, and only a small oil flow goes through the system to tank. The valve is installed directly on top of the pump port surface with banjo fittings. As the BPV valve is symmetrical it can be turned 180 to suit either left hand or right hand pump rotation, or to prevent interference with chassis components. The valve can only be engaged or disengaged (through the 12 or 24 VDC solenoid) at no-load system pressure. Bypass valve, type Max operating pressure [bar] Solenoid voltage [VDC] standard (optional) Power requirement [W] Operating mode BPV-F1/-T1 350 24 (12) 17 Activated solenoid: Check valve closed

Check valve (pilot operated)

Solenoid valve (24 or 12 VDC)

Directional valve block (open center) 'S'

'T' F1 or T1 pump BPV-F1/-T1 bypass valve block 1

1. To limit system pressure, a 1/4" relief valve (not included) can be installed between pilot gauge port 'S' and inlet gauge port 'T'.

Banjo fitting P (from pump outlet) Banjo fitting T (to pump inlet)

O-ring (P)

DIN 43650 connector

Outlet gaug port 'P' (BSP 3/8") A

O-ring (T)

Pilot gauge port 'S' (BSP 1/4")

Inlet gauge port 'T' (BSP 3/8")

Bypass valve designation BPV-F1-20/30 BPV-F1-40/60 BPV-F1-80 BPV-F1-110 BPV-T1-50 O-ring kit

Ordering number 24 VDC 12 VDC 379 2123 370 8086 379 7508 379 1962 379 7509 370 8088 379 8775 379 4472 379 9883

Dimensions [mm] B C D E 100 100 100 100 74 74 74 74 26 26 26 26 26 40 40 40 40 40

BSP thread T P

3/ " 4 1/ 3/ 2"

Torque [Nm] T P 50 50 100 100 50 50 50 100 100 50

105 115 130 140

1" 1 1 /4" 11/4" 1"

4" 1" 1" 4"

115 100 74

3/

Contains banjo fitting O-rings for the above valves.

15

Hydraulics

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Catalogue HY17-8242/UK

Technical Information

Truck Accessories

BSP 1" (BSP 3/4") Pressure connector Valve body

BPV-F1-25 and -81 bypass valves

The bypass valve is mainly utilized in applications where the F1plus pump is driven from the crankshaft through a cardan shaft, or when it is installed on an engine PTO. The BPV bypass valve should be engaged during transportation when the pump is operating constantly and the engine is running at max rpm; the hydraulic system is not sized for the large flow that would otherwise go through it. The BPV valve substantially reduces the energy loss during transportation. The valve installs directly on top of the pump end cap with a pressure port banjo fitting and an inlet port spacer bushing with two cap screws; refer to the illustration to the right. As the BPV valve is symmetrical, it can be turned 180 to prevent interference with chassis components; it can be utilized for either left hand or right hand pumps. The valve function must only be activated or released (by means of the 24 VDC solenoid) at no-load (below 20 bar) system pressure. IMPORTANT INFORMATION - In order to prevent heat build-up in the pump during transportation, it is important that at least 5 l/min comes out of the filter at q (refer to the schematic below right). This applies to an open center system when the valve is in the bypass mode (non-activated solenoid).

- Please note: a) If the flow at q is less than 5 l/min (caused e.g. by a high pressure drop in the main system) when the valve is in the bypass mode, or b) if the hydraulic system is of the closed center type, then an external drain line must be installed from the bypass valve drain port directly to tank as shown in the schematic; a drain kit is available (see below). Bypass valve, type Max pressure, continuous [bar] intermittent [bar] Solenoid voltage [VDC] Power requirement [W] Operating mode BPV-F1-25/-81 350 400 24 17 Activated solenoid: Check valve closed For F1 size -25/-41/ -51/-61 -81/-101 Torque press. connector to: 50 Nm

F1 pump Valve block Drain port

Suction adapter Holddown clamp (x2) O-ring (x3) Spacer bushing

39 (39)

O-ring (x2) (F1plus end cap) Pump pressure port Female connector

Pump suction port

Solenoid valve

Cable length Male connector 0,55 m

Valve housing Drain port (plugged; BSP 1/4") Holddown clamp (x2) Cap screw (x2) 110 (105) NOTE: Dimensions are shown for BPV-F1-81 (those for BPV-F1-25 are in parenthesis). 110 (110) IMPORTANT: Always tighten the pressure connector before tightening the cap screws.

Bypass valve installation and cross section.

Pilot operated check valve Solenoid valve Directional control valve ('open center')

Bypass valve kits BPV-F1 -25, 24 VDC 12 VDC BPV-F1-81, 24 VDC 12 VDC O-ring kit

Ordering number 378 1401 378 1318 378 1402 378 1319 378 0641

'q' (External line)

100 Nm

Bypass valve schematic.

Drain fitting kit

Contains all five O-rings (as illustrated to the right); included in all valve kits 378 1640 Contains a drain line fitting and a bonded seal. 16

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Hydraulics

Catalogue HY17-8242/UK

Technical Information

Truck Accessories

BPV-F2 bypass valves

An F2 twin pump fitted with a bypass valve can be utilized in applications where the pump is operating constantly i.e. when the pump is driven from the crankshaft through a propshaft, or when it is installed on a PTO. In addition, it can be used when, temporarily, one of the two circuits is not required; the power loss is thus reduced as the non-required flow is not forced through lines and open center valves. In most cases, the bypass valve allows the pump to be driven at max engine rpm during transportation at a minimum load. This prevents pump cavitation and high heat generation which may otherwise be encountered at large flows. The BPV valve connects the outlet and inlet ports of the pump, and only a small oil flow goes through the system and to the reservoir. The valve is installed directly on top of the pump port surface with banjo fittings and two cap screws (refer to the split view to the right). As the BPV valve is symmetrical it can be turned 180 so as not to interfere with chassis components.The valve can accommodate left hand as well as right hand rotating pumps. The valve can only be engaged or disengaged (through the 24 or 12 VDC solenoid) at low system pressures (below 20 bar).

F2 twin-flow pump Pilot operated Solenoid valve Directional check valve (24 or 12 VDC) control valves

A B

Separate drain line

BPV-F2

Bypass valve circuit schematic (example).

1- BPV-F2 valve kit

Cap screw 2) Pressure connector (x2) 1 )

2 - Suction fitting kit

Suction fitting 2) Hold-down clamp (x2) 2) Drain line (not included) to be connected directly to tank O-ring 2) Drain line fitting 1 ) (BSP 1/4") Bonded seal 1 ) Valve block sub-ass'y 1 ) O-ring (x2) 1 )

Parker

IMPORTANT INFORMATION

- In order to secure a cooling flow through the system, a separate drain line must be connected from the BPV-F2 drain line fitting (shown in the split view) directly to tank; refer also to the schematic. - The pressure connectors must be tightened (to 100 Nm) before the suction fitting clamp screws are tightened. Bypass valve, type Max operating pressure [bar] Solenoid voltage [VDC] standard (optional) Power requirement [W] Operating mode Ordering number 1), standard optional O-ring kit 2) BPV-F2 350 24 (12) 17 (each solenoid) Activated solenoid: Check valve closed 378 1459 (24 VDC) 378 1567 (12 VDC) 378 0641

O-ring (x4) 1 )

Solenoid valve (x2) 1) (with cable and male connector; female connector included) Plug with O-ring 1) Spacer bushing 1) O-ring (x2) 1)

1) The BPV-F2 valve kit contains parts designated 1 in the split view to the right. 2) Contains all O-rings shown in the split view .

Bypass valve split view (with F2plus end cap). NOTE: A suction fitting kit (parts designated 2 in the split view) is not included with the F2 plus pump; it must be ordered separately (refer to page 4).

17

Hydraulics

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Catalogue HY17-8242/UK

Technical Information

Truck Accessories

BPV-VP1 bypass valve

The BPV-VP1 bypass valve is utilized in hydraulic systems where the pump is operating constantly. The valve, which requires no additional control valve, allows the pump to operate on- or off-load up to its max selfpriming speed. The valve protects the pump from overheating in the off-load mode by allowing a small flow through the pump (refer to the schematic to the right). When a load sensing valve function is engaged, the bypass flow is cut off (as port 'X' is being pressurized). Valve type BPV-VP1 Ordering number 379 8799 Rated flow Max press. [l/min] [bar] 20 350

Outlet (pressure) port (BSP 1") Inlet (suction) port (BSP 11/4") Pressure gauge port (BSP 1/4"); connect to port S of the bypass valve.

VP1 pump

Bypass valve (5 bar)

Load sensing valve

S X P T

Load sensing (LS) signal

BPV-VP1 bypass valve

4 mm hex key

53

BSP 1/4" 6.5 (x3) (x2)

D

51.5

S X T P

8.5 9 92 32

30

40

41

VP1 end view

BPV-L line mounted bypass valve

The unloading valve is utilized in hydraulic systems where the fixed displacement pump is engaged constantly and no flow is required, i.e. during transportation. The flow is directed through the unloading valve which has a low pressure loss and less heat is being generated in the system. When the solenoid is activated the unloading valve closes and the pump flow is directed to the directional control valve or other user. The opening time of the valve can be increased or decreased by adjusting the needle valve (which is fully open when delivered).

Unloading valve

Needle valve

Gauge port G

Directional control valve

Inlet (IN) Outlet (UT)

Solenoid valve (24 VDC)

Female connector Male connector Cable length 0.55 m

Unloading valve, type Max operating pressure [bar] Max flow [l/min] Solenoid voltage [VDC] Required power [W] Operating mode Ordering number

BPV-L 350 250 24 17 Activated solenoid: Check valve closed 378 1487

50

9 (x2) 100 62 45 IN UT Solenoid valve (24 VDC) Gauge port (BSP 1/4")

10 10 45 100

BSP 1"(x2) 58

18

Hydraulics

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Catalogue HY17-8242/UK

Technical Information

Truck Accessories

FDV-VP1 unloading valve

The FDV-VP1 unloading valve is used in hydraulic systems where two directional control valves are utilized: 1. An open center valve for e.g. tipper and/or support legs that dont benefit from a load sensing function. 2. A load sensing valve for the remaining work functions. When a section of the open center control valve is engaged and the FDV solenoid is energized, the VP1 pump load sensing line is connected to the pump outlet. The pump then goes to max displacement and full flow is delivered to the open center valve. Valve type FDV-VP1 Ordering number 379 8937 Rated flow Max press. [l/min] [bar] 150 350

Unloading valve Open center control valve Load sensing control valve

'1'

'2' Load sensing (LS) signal '3'

Solenoid (24 VDC/19 W)

DIN 43650 connector

136

BSP 1/4" (x3)

1

63.5 52.5 34.5

2 3

7 (x2) 14.5

49

32

4.8

54 63.5

Electrical connector assembly

The assembly consists of a DIN 43650 (Hirschmann) connector and a protective, flexible cable tubing that is securely installed in the connector; two insulated wires are hooked up to terminals 1 and 2. The inside of the connector is filled with silicon grease to prevent water penetration. The cable length is approximately 5.5 m. The connector assembly fits the following accessory valves: BPV-F1/-T1 bypass valves page 15 BPV-F2 bypass valve " 17 BPV-L line mounted bypass valve " 18 FDV-VP1 unloading valve " 19 ES line mounted unloading valves " 20 Designation Ordering number Connector ass'y 378 0147

'1'

'2'

5.5 m

19

Hydraulics

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Catalogue HY17-8242/UK

Technical Information

Truck Accessories

ES line mounted unloading valves

The ES unloading valve is intended for hyadraulic circuits with a fixed or variable displacement pump. The valve is available in two versions: - ES-CFO (for a system with a fixed displacement pump and a directional valve type CFO) - ES-LS (for a load sensing system with a variable displacement pump and a dir. control valve type LS). The valve block installs with M10 screws (alt. with M8 screws and nuts); main ports are BSP 1". The ES valve has a built-in, adjustable pressure relief valve (3). ES-CFO system function: When the solenoid is nonactive (refer to the schematic below left) the entire pump flow goes through port T to tank and port P2 is blocked. An activated solenoid allows flow through the valve from P1 to P2. ES-LS system function: When the solenoid is being de-activated, the pump goes to min displacement and the reduced flow is directed through port T to tank; port P2 is blocked (refer to the schematic below right). When the solenoid is activated, the required pump flow goes through the valve from P1 to P2. Unloading valve design. Max operating press. [bar] Max flow [l/min] Solenoid voltage [VDC] Required power [W] Non-activated solenoid: Activated solenoid: Ordering number ES-CFO ES-LS

350 200 24* 12 P1toT1 P1toP2 376 6684 376 7031

* A 12 VDC solenoid is optional; contact Parker Hannifin, Mobile Controls Div.

P1M (BSP1/4") P1 (BSP1")

LS (BSP1/4")

1

Dir. control valve (CFO)

P1M (BSP1/4") P1 (BSP1")

LS (BSP1/4")

1

Dir. control valve (LS)

P2 (BSP 1") Manual override

P2 (BSP 1") Manual override

T (BSP1")

Valve block ES-CFD

24 VDC solen. valve (12 VDC optional)

T (BSP1")

Valve block ES-CFD

24 VDC solen. valve (12 VDC optional)

Hydraulic schematic - CFO system (example).

Hydraulic schematic - LS system (example).

55

LS

84 CFO: Nozzle 1,0 mm (std.) LS: Plugged 28 12

P2

2 5

1

VOAC

Electrical connector DIN 43650 (female connector included) Drilled through 8,5 mm (thread M10x15, opposite side)

P1M P1

4

P2

85

P1

135

Manual override

Parker

T

3

LS

39 15 28 115 58 78

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Installation information.

Pressure setting (standard: 280 bar)

20

Hydraulics

Catalogue HY17-8242/UK

Technical Information

Truck Accessories

Cardan shafts, pump couplings and mounting brackets

F1plus shown

Pump or splitter box type F1 1) F1plus F1 F1plus F2 T1-50 VP1 SB154, SB118

Cardan shaft kit Type Ordering no. SAE 88 1) " SAE 97 " " " " SAE 97 073 001 " 370 0315 " " " " 370 0315

Pump coupling Type Ordering no. SAE 88 1) " SAE 97 " " " " 370 4628 378 0644 370 4631 378 0645 " " "

Bracket ordering no. 379 7831 " 379 7831 " " " " 370 5221

Bracket kit ordering no. 379 7832 " 379 7832 " " " " 370 5220

SAE 97/ Included with DIN 90 splitter box

1) The SAE 88 cardan shaft and pump coupling can also be used to drive a series F2, T1-50 or VP1 pump providing max allowed shaft torque (below) is not exceeded.

Cardan shaft specifications

Cardan shaft type SAE 88 SAE 97 Spicer designation K1140 K1310 Max length [mm] 1220 2) 1220 2) Diameter [mm] 45 50 Max torque peak/contin. [Nm] 600/300 1000/500 Ordering number 073 001 370 0315

2) One end not welded

PTO flange adapters

Cardan shaft type SAE 88 SAE 97 SAE 116 DIN 90 DIN 100 PTO flange type SAE 116 SAE 116 SAE 97 DIN 100 DIN 90 Flange adapter ordering no. 370 5895 370 5896 370 5897 3) 370 5898 370 5899 3)

PTO flange Flange adapter Cardan shaft

3) WARNING! The utilized cardan shaft torque limits (above) must not be exceeded.

21

Hydraulics

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Catalogue HY17-8242/UK

Technical Information Pump couplings

Designation A B C D E1 E2 (F1plus) Ordering no. F1plus DIN 90 (fig. 1) 90 74.5 47 h7 M8 61.5 57.2 370 4634 378 0642

E1 A B C

Truck Accessories

NOTE: Max torque is limited by the cardan shaft.

E2 (F1plus)

D (thread; x4)

Fig. 1. DIN 90 (370 4634)

R1 (max) 0.4 A B C

(378 0642)

Designation A B C D E Ordering no.

DIN 90 (fig. 2) 90 74.5 47 h7 8.2 61.5 370 7423

55 h9

NOTE: Max torque is limited by the cardan shaft.

32 E1

D (x4)

Fig. 2. DIN 90

Designation SAE88 (fig. 3) A B C D E Max torque [Nm] interm./contin. Ordering no. F1plus 88 69.9 57.15 H8 5/ " UNC 16 65 600/ 300 370 4628 378 0644

(370 7423)

A B C 10

E1

E2 (F1plus)

D (thread; x4)

Fig. 3. SAE 88 (370 4628)

(378 0644)

DesignationSAE97 (fig. 4) A B C D E Max torque [Nm] interm./contin. Ordering no. F1plus 97 79.4 60.33 H8 3/ " UNC 8 65 1000/ 500 370 4631 378 0645

E1 E2 (F1plus) D (thread; x4) A B C 10

Fig. 4. SAE 97 (370 4631)

(378 0645)

22

Hydraulics

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Catalogue HY17-8242/UK

Technical Information

Truck Accessories

Return filter and filter indicator

Return flow filter

The low pressure, full flow return filter contains a replaceable fiber glass cartridge with a large flow area. The filter is designed for vertical installation on top of the hydraulic reservoir. The built-in bypass function opens at 1.6 bar; the overflow is above the cartridge, preventing accumulated dirt inside the filter to enter the flow. The aluminum housing contains three BSP 1/8" ports which can be utilized for the installation of a filter indicator (see below). Designation Rated flow (at 30 cSt) [l/min] Cartridge pressure drop at rated flow and 30 cSt [bar] Degree of filtration (25 75, ISO 4572) [m] Cartridge collapse rating (ISO 2941) ]bar] Inlet port size Weight incl. cartridge [kg] Ordering code, filter ass'y filter cartridge only Return filter 230 < 0.1 25 (abs.) 8 BSP 11/4" 6 946 395 946 396

87 96 BSP 1/8" (x2) 40 102

132 dia.

Gasket (included)

294

154 BSP 1/8" BSP 11/4"

NOTE: The flow capacity of the filter should be at least twice the pump flow under normal operating conditions.

123.5 square

11 dia. (x4)

Filter indicator

The visual filter indicator installs in one of the filter housing ports (BSP 1/8"; see above). When the hydraulic system has reached normal operating temperature, the position of the indicator needle shows the condition of the filter cartridge: 'Green' - The cartridge is OK. 'Red' - Replace the cartridge. NOTE: A needle in the red area indicates that only part of the oil flow is being filtered which, in turn, means that system components such as the pump will suffer from increased wear. Designation 'Green' pressure range [bar] 'Red' pressure range [bar] Max pressure (peak) [bar] Installation thread Ordering number Filter indicator 1.0 1.0 1.6 2.5 BSP 1/8" 378 0191

40 dia.

31

BSP 1/8" 10 'Red' 'Green'

L RUN RMA NI N NO

ANGE FILTE R CH

23

Hydraulics

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Catalogue HY17-8242/UK

Technical Information

Truck Accessories

Air breather filter

The oil level in the reservoir can sink drastically when max pump capacity is utilized e.g. to fill the piston end of a cylinder with a large 'piston/piston rod' ratio and the return flow back to tank is comparatively small. A corresponding volume of air must then enter the tank through the breather. The air breather shown to the right, which mounts on top of the reservoir, is adequately dimensioned for most applications. It has sufficient filtering properties to prevent external dirt from entering the hydraulic system. The breather has a built-in function which limits the tank pressure to 0.5 bar. Designation Nominal air flow [l/min] Nominal degree of filtration [m] Exhaust opening pressure [bar] Installation thread Ordering number Air filter 300 6 0.5 BSP 3/4" 378 0190

82 dia.

45

O-ring (incl.) BSP 3/4" 15

NOTE: Preferably, the air flow capacity should be at least twice the pump flow under normal operating conditions.

24

Hydraulics

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Catalogue HY17-8242/UK

Technical Information

Truck Accessories

Installation information

1. Series F1, T1 and F1plus (fig. 2) Valid: At continuous operation less than 30 min. and/or less than 80 kW continuous power output. - Remove the uppermost drain plug and add 0.5 liter Shell Spirax AX (or similar fluid). - Install the breather (and the 90 adapter, part no. 378 1069, if required). NOTE: The F1 or T1 shaft seal must not be removed. 2. Series F1 and T1 (left illustration, fig. 3) Valid: At continuous operation more than 30 min. and/or more than 80 kW continuous power output. - Remove the shaft seals. - Install a drain hose between the drain port on the side of the splitter box (see the illustr.) and the reservoir; it must end below the lowest oil level in the reservoir. Utilize one of the 'banjo' couplings included in hose kit 378 1085. 3. Series F1plus (right illustration, fig. 3) Valid: At continuous operation more than 30 min. and/or more than 80 kW continuous power output. - Install hose kit 378 1085 between the lowest drain port on one of the pumps (see fig. 3) and the lowest drain port of the splitter box. - Install a drain hose between the drain port on the side of the splitter box and the reservoir; it must end below the lowest oil level in the reservoir. Utilize one of the banjo couplings included in hose kit 378 1085.

SB splitter boxes

The splitter box is utilized to drive two pumps, providing two separate, independent flows. The high permissible input shaft torque allows two large pumps to be operated simultaneously; make sure, however, that the PTO and the cardan shaft will stand the intended load. Pump mounting flange and shaft end must meet the ISO standard. The splitter box is available with either of two gear ratios (input shaft-to-pump): SB 118 - 1:1.18 SB 154 - 1:1.54 The shipping carton contains all parts required for the installation of the two pumps.

Recommendations

Use the following tables to verify that max pump rpm and max splitter box input torque are not exceeded. Pump size F1-20 F1-30 F1-40 F1-60 F1-80 F1-110 T1-50 Max input speed [rpm] SB 118 SB 154 1950 1700 1525 1300 1100 1100 1350 1500 1300 1200 975 850 850 1000

Example: An SB 118 with an F1-20 and an F1-80 can be operated at max 1100 rpm (splitter box input speed), and an SB 154 with the same pumps at max 850 rpm. Pump size F1-20 F1-30 F1-40 F1-60 F1-80 F1-110 T1-50 F2-53/53 F2-70/40 Pump input torque [Nm] at 250 bar 300 bar 350 bar 80 120 160 240 315 435 200 420 435 95 140 190 285 380 525 240 505 525 110 165 225 335 445 610 275 590 610

Example: An F1-40 at 350 bar requires 225 Nm and an F1-60 at 300 bar 285 Nm. Total required splitter box input torque: SB 118: (225 + 285) x 1.18 610 Nm. SB 154: (225 + 285) x 1.54 785 Nm Compare with max permissible torque (interm. 1000 Nm; continuous 700 Nm). NOTE: If the splitter box should be utilized at close to the max permissible torque and/or max the permissible speed, please contact Parker Hannifin (Mobile Controls Div.)

NOTE: The inlet (suction) ports of the pumps should always face the splitter box center, as shown, in order to counteract internal gear forces. Fig. 1. F1-pumps installed on a splitter box. Designation Gear ratio (inp. shaft-to-pump) Max input torque intermittent/continuous [Nm] Max power SB 118 1:1.18 SB 154 1:1.54

Weight [kg] Ordering number

1000 / 700 Housing oil temperature must not exceed 75 C. 11.5 379 4981 370 5100

25

Hydraulics

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Catalogue HY17-8242/UK

Technical Information

Breather Breather with 90, adjustable adapter

Truck Accessories

'Banjo' coupling (without hose)) Hose assembly (incl. 'banjo' couplings)

F1, T1

Breather kit (incl. 90, adjustable adapter and seals): Part no. 378 1069. Fig. 2. Breather installation on the splitter box.

F1plus

Hose kit (hose sub-ass'y and separate 'banjo' coupling): Part no. 378 1085. Fig. 3. Forced cooling of the splitter box.

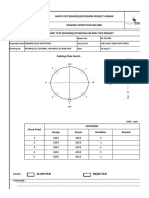

Splitter box installation

12 Splitter box mounting studs (M12; x4) on 140 mm P/D. Pump mounting centerline

Spacer ring for DIN 90 (GWB 287,00); fits inside the input flange

100 dia. 310

186

M8 screws (DIN 90; x4)

3/8" UNC screws (SAE 97; x4)

160 Input flange fits cardan shaft according to DIN 90 and SAE 97 (equals Spicer K1310)

100 M12 pump mounting studs (4 + 4)

25

F1, F1plus, F2 and VP1 pump ordering numbers

Pump order. code F1-20-R F1-30-R F1-40-R F1-60-R F1-80-R F1-110-R T1-50 Ordering number 370 4520 370 4530 370 3940 370 3960 379 6380 370 9110 379 2050 Pump Ordering order. code * number F1-25-R -L F1-41-R -L F1-51-R -L F1-61-R -L F1-81-R -L F1-101-R -L

refer to page 4.

Pump order. code F2-53/53-R F2-53/53-L F2-70/35-R F2-70/35-L

Ordering number 378 1453 378 1454 378 1470 378 1471

Pump order. code VP1-045-R VP1-045-L VP1-075-R VP1-075-L

Ordering number 378 0334 378 0335 378 0336 378 0337

378 1024 378 1025 378 1040 378 1041 378 1050 378 1051 378 1060 378 1061 378 1080 378 1081 378 1100 378 1101

* NOTE: No suction fitting included;

26

Hydraulics

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Catalogue HY17-8242/UK

Technical Information

Truck Accessories

Notes

27

Hydraulics

Parker Hannifin Mobile Controls Division Trollhttan, Sweden

Please contact our sales representative:

Parker Hannifin Mobile Controls Division SE-461 82 Trollhttan Sweden Tel. +46 520 986 00 Fax +46 520 371 05 www.parker.com

Catalogue HY17-8242/UK Ed. 1711-0121

Potrebbero piacerti anche

- Manual Hyundai 2.7Documento101 pagineManual Hyundai 2.7juanmanuel_4615958100% (1)

- 4045 6068+Electronicos,+Manual+ServicioDocumento678 pagine4045 6068+Electronicos,+Manual+ServicioNarciso Alberto Hernandez Tovar91% (33)

- Thom-Katt TK 25: Trailer-Mounted Hydraulic Concrete PumpDocumento2 pagineThom-Katt TK 25: Trailer-Mounted Hydraulic Concrete PumpAlexander LabautNessuna valutazione finora

- Aw50 40.aw50 42Documento8 pagineAw50 40.aw50 42eedee392% (13)

- TRITORC New 2017 Hydraulic and Bolting Catalogue PDFDocumento45 pagineTRITORC New 2017 Hydraulic and Bolting Catalogue PDFSun ChenNessuna valutazione finora

- Moog G122-829A DS A4 v2Documento4 pagineMoog G122-829A DS A4 v2Hammad AshrafNessuna valutazione finora

- FOS Bearings and SealsDocumento88 pagineFOS Bearings and SealsRodrigo Andrade Scarpa100% (1)

- HR28000 3 Velocidades Short DropDocumento64 pagineHR28000 3 Velocidades Short DropRodrigo Andrade ScarpaNessuna valutazione finora

- MCQs Chemistry Class 6 To 10Documento10 pagineMCQs Chemistry Class 6 To 10Anonymous CVKDY65OGNessuna valutazione finora

- Air Condition 1,9l TDI (AHF)Documento5 pagineAir Condition 1,9l TDI (AHF)ghitacrainicNessuna valutazione finora

- Pest AnalysisDocumento3 paginePest AnalysisNeeraj Naman100% (2)

- Renewable EnergyDocumento15 pagineRenewable Energyveguruprasad100% (1)

- SD 6 eDocumento16 pagineSD 6 eseaqu3stNessuna valutazione finora

- 4wre 6-10 Sew1xDocumento12 pagine4wre 6-10 Sew1x2267airportNessuna valutazione finora

- So, You Think You Know Shuttle Valves?Documento6 pagineSo, You Think You Know Shuttle Valves?AkileshNessuna valutazione finora

- ALISON HIDRAULIC - Catalogue PDFDocumento250 pagineALISON HIDRAULIC - Catalogue PDFbaba0% (1)

- Catálogo de Peças Plataforma 1200SJP e 1350SJP (Ing)Documento400 pagineCatálogo de Peças Plataforma 1200SJP e 1350SJP (Ing)LuizNessuna valutazione finora

- Proportional Valve GroupDocumento36 pagineProportional Valve GroupjulianoNessuna valutazione finora

- Z-100 Installation Manual: 2200 Lb. LiftgatesDocumento45 pagineZ-100 Installation Manual: 2200 Lb. LiftgatesPatricia Lizeth Cossio ZuritaNessuna valutazione finora

- Hy17 8523 UkDocumento6 pagineHy17 8523 Ukexay40Nessuna valutazione finora

- Duplo MaticDocumento8 pagineDuplo MaticHENRYGALLEGOSNessuna valutazione finora

- Ssdx12-25 Handbook Dse702 & Esr3.1 Issue 3Documento29 pagineSsdx12-25 Handbook Dse702 & Esr3.1 Issue 3azry_alqadryNessuna valutazione finora

- Valvulas Moog Hoja de DatosDocumento24 pagineValvulas Moog Hoja de DatosLuis Alberto RamosNessuna valutazione finora

- Variable Displacement Pump A11VO: For Open CircuitsDocumento48 pagineVariable Displacement Pump A11VO: For Open Circuitsjose salvadorNessuna valutazione finora

- Saufer Danfoss Load Sensing Steering UnitsDocumento92 pagineSaufer Danfoss Load Sensing Steering UnitsaapereirazNessuna valutazione finora

- Re77502 2004-05Documento20 pagineRe77502 2004-05pamururamuNessuna valutazione finora

- Catalogo Hiab 122Documento4 pagineCatalogo Hiab 122Daniel Gonzalez MuñozNessuna valutazione finora

- Introduction To Hydraulics For Industry Professionals: Hydraulic Systems Volume 1Documento20 pagineIntroduction To Hydraulics For Industry Professionals: Hydraulic Systems Volume 1Narasimha DNessuna valutazione finora

- Service Bulletin Trucks: Clutch Bearing Lubrication TubesDocumento2 pagineService Bulletin Trucks: Clutch Bearing Lubrication TubesNavarro NayraNessuna valutazione finora

- Moog G122-829-001 - Catalog1Documento2 pagineMoog G122-829-001 - Catalog1Jean-Roch JacquesNessuna valutazione finora

- AirValves 2013 PDFDocumento268 pagineAirValves 2013 PDFSergio Sebastian Ramirez GamiñoNessuna valutazione finora

- Maflosh 02 IngDocumento44 pagineMaflosh 02 IngNicoleta CosteaNessuna valutazione finora

- Hydraulic System and Power Take-OffDocumento42 pagineHydraulic System and Power Take-OffЕвгений Аксёнов100% (1)

- Sun Hydraulics FDBA-LANDocumento2 pagineSun Hydraulics FDBA-LANJustinNessuna valutazione finora

- Liebherr Short Description DPVD FR PDFDocumento4 pagineLiebherr Short Description DPVD FR PDFMohamed SalamNessuna valutazione finora

- Mine TruckDocumento2 pagineMine TruckyesNessuna valutazione finora

- Solenoid Control Hk66o102Documento40 pagineSolenoid Control Hk66o102seaqu3stNessuna valutazione finora

- Steering Diagnostics Service Manual: TRW AutomotiveDocumento52 pagineSteering Diagnostics Service Manual: TRW Automotivecristian picadoNessuna valutazione finora

- METRUS Test Bench Overview 2017Documento8 pagineMETRUS Test Bench Overview 2017Ozawa MagooNessuna valutazione finora

- K58L XRZ: Truck-Mounted Concrete Boom PumpDocumento2 pagineK58L XRZ: Truck-Mounted Concrete Boom PumpAhmed RashadNessuna valutazione finora

- Especalogo Actros 4144K 45 8x4Documento3 pagineEspecalogo Actros 4144K 45 8x4Manuel PomahualiNessuna valutazione finora

- Uph Concentric He1000-2000-2200 GB - CDocumento28 pagineUph Concentric He1000-2000-2200 GB - CRubenNessuna valutazione finora

- A600-1106 Rev0 PDFDocumento2 pagineA600-1106 Rev0 PDFLuis Alejandro Piñeros PardoNessuna valutazione finora

- Hydraulic Cartridge SystemsDocumento14 pagineHydraulic Cartridge SystemsJas SumNessuna valutazione finora

- RadiatorsDocumento12 pagineRadiatorsMiljkovic NesaNessuna valutazione finora

- Overview Eng CD PDFDocumento20 pagineOverview Eng CD PDFRafael Cortes100% (1)

- Unit 4: Hydraulic Fundamentals - Pilot Operated Hydraulic SystemDocumento28 pagineUnit 4: Hydraulic Fundamentals - Pilot Operated Hydraulic Systemoscar el carevergaNessuna valutazione finora

- Flow Control ManifoldsDocumento4 pagineFlow Control ManifoldsBrayan AguileraNessuna valutazione finora

- Hydraulics Part 2Documento28 pagineHydraulics Part 2MACHINERY101GEAR100% (1)

- A17FODocumento16 pagineA17FOJose SalvadorNessuna valutazione finora

- Cooling System Troubleshooting D13FDocumento3 pagineCooling System Troubleshooting D13FHamilton MirandaNessuna valutazione finora

- Re91401 A2foDocumento20 pagineRe91401 A2foTaz Juan GNessuna valutazione finora

- TDV 100Documento6 pagineTDV 100林育豪Nessuna valutazione finora

- Automatic Greasing SystemDocumento70 pagineAutomatic Greasing SystemDatNessuna valutazione finora

- Basic Hydraulics NWTDocumento22 pagineBasic Hydraulics NWTsengottaiyanNessuna valutazione finora

- Pumpstar Pump Cell 2003Documento50 paginePumpstar Pump Cell 2003Dave StutzmanNessuna valutazione finora

- Steering Gear PDFDocumento5 pagineSteering Gear PDFChristopher JonatanNessuna valutazione finora

- VSD Pump Solution Catalog E-PUIO-CC002-E LRDocumento63 pagineVSD Pump Solution Catalog E-PUIO-CC002-E LRharisNessuna valutazione finora

- PVG Proportional Valve Rev.a 05.2006Documento1 paginaPVG Proportional Valve Rev.a 05.2006Sasko DimitrovNessuna valutazione finora

- 2009 3560ton Lowboys Web PDFDocumento55 pagine2009 3560ton Lowboys Web PDFFelipe Pan Iturra Ramirez100% (2)

- OLS-OLSA-OLSB Parts Manual-HN29DD52 PDFDocumento12 pagineOLS-OLSA-OLSB Parts Manual-HN29DD52 PDFliu zhao liu zhaoNessuna valutazione finora

- DF1v ParkerDocumento8 pagineDF1v ParkerHector Carrera MoralesNessuna valutazione finora

- Manual SerDia2010 EN PDFDocumento217 pagineManual SerDia2010 EN PDFAttila EngiNessuna valutazione finora

- Liebherr Hs DimensionsDocumento12 pagineLiebherr Hs DimensionsLiebherrNessuna valutazione finora

- User Manual 3002549Documento8 pagineUser Manual 3002549Carlos MioNessuna valutazione finora

- Accessories: PTO Air Valve KitsDocumento13 pagineAccessories: PTO Air Valve KitsCarpatica LogisticNessuna valutazione finora

- 1776279Documento82 pagine1776279Tengku Nizarul AslamiNessuna valutazione finora

- Catalog Bomba de Paletas General Eaton PDFDocumento200 pagineCatalog Bomba de Paletas General Eaton PDFJunior Enrique Yataco ArizaNessuna valutazione finora

- FOS Air ConditioningDocumento102 pagineFOS Air ConditioningRodrigo Andrade Scarpa100% (2)

- Piston Pumps: VickersDocumento9 paginePiston Pumps: VickersRodrigo Andrade ScarpaNessuna valutazione finora

- Bombas Denison SDV10!20!2010-2020Documento14 pagineBombas Denison SDV10!20!2010-2020Rodrigo Andrade ScarpaNessuna valutazione finora

- Bombas Denison T6Documento35 pagineBombas Denison T6Rodrigo Andrade ScarpaNessuna valutazione finora

- Hilo BSPDocumento1 paginaHilo BSPRodrigo Andrade ScarpaNessuna valutazione finora

- F 1 F 2Documento66 pagineF 1 F 2Rodrigo Andrade ScarpaNessuna valutazione finora

- FC Revision DDocumento4 pagineFC Revision DRodrigo Andrade ScarpaNessuna valutazione finora

- Bombas Parker Móvil F11Documento126 pagineBombas Parker Móvil F11Rodrigo Andrade ScarpaNessuna valutazione finora

- F11 Service InformationDocumento8 pagineF11 Service InformationRodrigo Andrade ScarpaNessuna valutazione finora

- Tillegg X30 Homologering 2020 1Documento6 pagineTillegg X30 Homologering 2020 1Alejandro Martínez PonsNessuna valutazione finora

- Doosan g420fDocumento284 pagineDoosan g420fWalter100% (1)

- Frank Pedersen - Diesel Engine Combus - jun.2005.SECPDocumento53 pagineFrank Pedersen - Diesel Engine Combus - jun.2005.SECPAhmed Samir We ShreenNessuna valutazione finora

- S. No. Name of The Company Address Contact Person: Pradeep KauraDocumento23 pagineS. No. Name of The Company Address Contact Person: Pradeep KauraPankaj YadavNessuna valutazione finora

- Checklist PMS TBDocumento3 pagineChecklist PMS TBalsitorNessuna valutazione finora

- Strainers In-Line and Angle: Descripɵ OnDocumento4 pagineStrainers In-Line and Angle: Descripɵ OnLê Tuấn AnhNessuna valutazione finora

- Omt 1908981Documento15 pagineOmt 1908981SERNessuna valutazione finora

- Completamiento AngsiDocumento8 pagineCompletamiento Angsimafe_0830Nessuna valutazione finora

- Compressed Air SystemDocumento372 pagineCompressed Air SystemMauricioNessuna valutazione finora

- Additions, Revisions, or Updates: Subject DateDocumento10 pagineAdditions, Revisions, or Updates: Subject DateEduardo TorresNessuna valutazione finora

- ATA ChaptersDocumento1 paginaATA Chaptersrandz8Nessuna valutazione finora

- 35d PDFDocumento8 pagine35d PDFhuskerchampsNessuna valutazione finora

- TM 5-3222 Tractor T-9Documento298 pagineTM 5-3222 Tractor T-9AdvocateNessuna valutazione finora

- Understand Real World Problems in EjectorDocumento8 pagineUnderstand Real World Problems in EjectorEdgar Enrique Diaz Marquina100% (1)

- Crusher: C38R High Performance Cone CrusherDocumento1 paginaCrusher: C38R High Performance Cone CrusherFrancisco Javier López BarrancoNessuna valutazione finora

- SPERRE Compressor-Oils PDFDocumento8 pagineSPERRE Compressor-Oils PDFRafael ZuritaNessuna valutazione finora

- Jinjiang Junri Machinery Co - LTD Develop and Design Marine NozzleDocumento17 pagineJinjiang Junri Machinery Co - LTD Develop and Design Marine Nozzle1070242585100% (3)

- Service Training Manual: Engine Axle Transfer CaseDocumento13 pagineService Training Manual: Engine Axle Transfer Casefrancisca19100% (1)

- LIQUIDATION #1 MAY15-JUNE19 (00000002)Documento6 pagineLIQUIDATION #1 MAY15-JUNE19 (00000002)Hanabishi RekkaNessuna valutazione finora

- PT 6Documento235 paginePT 6Joel AlbuquerqueNessuna valutazione finora

- M-12C-003 Padding Plate Fuel Gas Cold Vent StackDocumento4 pagineM-12C-003 Padding Plate Fuel Gas Cold Vent StackYurizal FirmansyahNessuna valutazione finora

- Diesel Fuel Diesel Fuel Systems LEBW4976-04Documento64 pagineDiesel Fuel Diesel Fuel Systems LEBW4976-04MuhammadRidwan100% (7)

- Evinrude 115 Direct Injection ManualDocumento62 pagineEvinrude 115 Direct Injection ManualKonstantinos Karakoulas67% (3)

- Multiphase - Pumps - Axel CalgaryDocumento45 pagineMultiphase - Pumps - Axel CalgaryAlberto Enrique De Santa Anna CampderáNessuna valutazione finora

- Deck Machineries For Cargo ShipsDocumento5 pagineDeck Machineries For Cargo ShipsRachitNessuna valutazione finora

- 89E303 Touareg - ManualDocumento67 pagine89E303 Touareg - Manualeduardorojas00767% (3)