Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pilot Operated Main Valves For Regulating Pressure and Temperature

Caricato da

Pavel FlorinDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pilot Operated Main Valves For Regulating Pressure and Temperature

Caricato da

Pavel FlorinCopyright:

Formati disponibili

Pilot operated main valves for regulating pressure and temperature, type PM

Introduction

PM valves are pilot operated main valves for regulating pressure and temperature in refrigeration systems. PM main valves can be used on the high and lowpressure sides, in wet and dry suction lines, and in liquid lines without phase change (i.e. where no expansion takes place in the valve). The function of a PM valve depends solely on the pilot pressure applied to the valve, either from pilot valves or in the form of externai pilot pressure. PM 1 has one connection for pilot pressure/ pilot valve, while PM 3 has three pilot pressure/pilot valve connections. The associated Danfoss pilot valves can either be screwed direct into the main valve or be connected via an externai pilot line.

Several pilot valves can be used on one main valve to give a large number of different functions. The PM valve top cover has a pressure gauge connection so that the inlet pressure can be measured when, for example, main valve function must be set or adjusted in relation to the system regulation performed by the pilot valves. The spindle in the top cover of the main PM valve can be used to manually open and close the valve (although PM 65-125 cannot be opened fully in this way). The main valve bottom plug can be replaced by an AKS 45 electronic position indicator so that the position of the regulating cone can be read electronically.

Features

Can be used for all normal, non-flammable refrigerants, including R 717, and non- corrosive gases/liquids - assuming seals of the correct material are used. * Large range of flanges with connection dimensions in accordance with standards: DIN. ANSI, SOC, SA and FPT. a Performs as a multifunction valve when several pilot valves are connected to the same main valve. All pilot valves can be used on all sizes of PM main valves. They can be screwed direct into the main valve so that there is no need for weld or solder connections, or separate pilot lines.

The valve has a pressure gauge connection so that inlet pressure can be measured. * The valve has a built-in filter and a teflon seat to give excellent tightness. The PM main valve top cover can be oriented in any direction without the function of pilot valves being affected. The valve can be equipped with an AKS 45 electronic position indicator as an accessory.

Danfoss a/s (rc-cm/mwa), 09-2002 Technical

leaflet - RD4XA402

Pilot operated main valves for regulating pressure and temperature, type PM

Design

Connections There is a very wide range of connection possibilities with PM main valves: Welding, DIN (2448) Welding, ANSI (B 36.10) Welding socket, ANSI (B 16.11) Solder connection, DIN (2856) Solder connection, ANSI (B 16.22) FPT internai thread, NPT (ANSI/ASME B 1.20.1) PM main valves are designed as pilot operated valves that can be fully opened with a very small differential pressure (0.2 bar/ 2.9 psi). The valve design means that it will only fully close in the direction of flow. Pressure Equipment Directive (PED) The PM-valves are approved in accordance with the European standard specified in the Pressure Equipment Directive and are CE marked. For further details / restrictions - see Installation Instruction

PM 1 will accept one pilot valve mounted direct on the valve, while PM 3 will accept three pilot valves. Two of the PM 3 pilot valve connections (S1 and S2) are series connected while the third pilot connection (P) is connected in parallel. Thus, with different combinations of pilot valves it is possible to obtain a very large number of different functions from one PM main valve. The PM main valve has a logarithmic or v-shaped throttle cone that ensures optimum regulating accuracy. The PM main valve top cover can be oriented in any direction without the function of pilot valves being affected. Valve body EN-GJS-400-18-LT or cast iran GG 25 Seals Do not contain asbestos.

Ci

Technical data

PM valves Nominal bore Classified for Category DN< 25 (1 in.) Article 3, paragraph 3 DN32-125 mm (1 1/4 - 5 in.) Fluid group I II DN 150 mm (6 in.) III

Refrigerants Can be used for all normal, non-flammable refrigerants, including R 717, and non- corrosive gases/liquids - assuming seals of the correct material are used. Use with flammable hydrocarbons cannot be recommended; please contact Danfoss. Temperature range 60/+120X (-76/+248T). * Surface PM 5 - 65: The externai surface is zinc-chromated to give good protection against corrosion. PM 80- 125: The surface of the PM 80 - 125 is treated with a multi-layer painting.

Pressure range The valve is designed for: Max. working pressure: 28 bar g (406 psig) Test pressure: 42 bar g (609 psig) Opening differential pressure: Fully open: Min. 0.2 bar g (min. 2.9 psig) Max. (MOPD), solenoid valves only (10 W a.c. and 20 W d.c.): 21 bar g (305 psig) Built-in filter PM 5 - 40 mesh: 950 ji (18 mesh/in.) PM 50- 125 mesh: 1500 n (10 mesh/in.)

Technical leaflet - RD4XA402

Danfoss MS (RC-CM / MWA), 09 - 2002

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Matsusada DC-DC ConvertersDocumento4 pagineMatsusada DC-DC ConvertersAP SinghNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Application Letter For Promotion T2 T3Documento24 pagineApplication Letter For Promotion T2 T3FGacadSabadoNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Stress: Problem SetDocumento2 pagineStress: Problem SetDanielle FloridaNessuna valutazione finora

- NiftDocumento3 pagineNiftMegha Nair PillaiNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

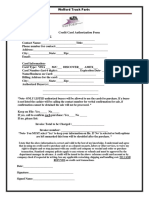

- Credit Card Authorization Form WoffordDocumento1 paginaCredit Card Authorization Form WoffordRaúl Enmanuel Capellan PeñaNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Hydrology Report at CH-9+491Documento3 pagineHydrology Report at CH-9+491juliyet strucNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- ISO-50001-JK-WhiteDocumento24 pagineISO-50001-JK-WhiteAgustinusDwiSusantoNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Per Dev Dlp-1-2 - 3 SelfDocumento6 paginePer Dev Dlp-1-2 - 3 SelfMonisa SocorinNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Angle ModulationDocumento26 pagineAngle ModulationAtish RanjanNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- 1st Unseen Passage For Class 5 in EnglishDocumento7 pagine1st Unseen Passage For Class 5 in EnglishVibhav SinghNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- ToiletsDocumento9 pagineToiletsAnonymous ncBe0B9bNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Zener Tester: by MedhatkoDocumento6 pagineZener Tester: by Medhatkosaran gulNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- TransistorDocumento3 pagineTransistorAndres Vejar Cerda0% (1)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- GATE Chemical Engineering 2015Documento18 pagineGATE Chemical Engineering 2015Sabareesh Chandra ShekarNessuna valutazione finora

- SoundsDocumento61 pagineSoundsJemabel RosarioNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Typical Cable Laying Details For Direct Buried, Low Tension CablesDocumento9 pagineTypical Cable Laying Details For Direct Buried, Low Tension CableslataNessuna valutazione finora

- Sustainable Development Precautionary PR 2Documento12 pagineSustainable Development Precautionary PR 2PramodNessuna valutazione finora

- PH-01 (KD 3.1) Filling Out Forms (PG20) - GFormDocumento4 paginePH-01 (KD 3.1) Filling Out Forms (PG20) - GFormLahita AzizahNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Turbine Start-Up SOPDocumento17 pagineTurbine Start-Up SOPCo-gen ManagerNessuna valutazione finora

- 2018-2019 Annual Algebra Course 1 Contest: InstructionsDocumento2 pagine2018-2019 Annual Algebra Course 1 Contest: InstructionsNaresh100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Natal Chart Report PDFDocumento17 pagineNatal Chart Report PDFAnastasiaNessuna valutazione finora

- Code of Federal RegulationsDocumento14 pagineCode of Federal RegulationsdiwolfieNessuna valutazione finora

- Caroline G Babin: Undergraduate Degree at Louisiana State University in Baton Rouge, Louisiana - Currently EnrolledDocumento2 pagineCaroline G Babin: Undergraduate Degree at Louisiana State University in Baton Rouge, Louisiana - Currently EnrolledCaroline BabinNessuna valutazione finora

- Summative Test in Foundation of Social StudiesDocumento2 pagineSummative Test in Foundation of Social StudiesJane FajelNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Lab 3 Report Fins RedoDocumento3 pagineLab 3 Report Fins RedoWestley GomezNessuna valutazione finora

- E Voucher Hotel en 1241564309Documento2 pagineE Voucher Hotel en 1241564309taufksNessuna valutazione finora

- Research Project Presentation of Jobairul Karim ArmanDocumento17 pagineResearch Project Presentation of Jobairul Karim ArmanJobairul Karim ArmanNessuna valutazione finora

- Swenson 1 Dan Swenson Printing Press: Part One (Timeline)Documento6 pagineSwenson 1 Dan Swenson Printing Press: Part One (Timeline)Dan SwensonNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- EEE301 Digital Electronics Lecture 1 Part 3: Dr. A.S.M. MohsinDocumento6 pagineEEE301 Digital Electronics Lecture 1 Part 3: Dr. A.S.M. MohsinAaa AaaNessuna valutazione finora

- SAP Solution Manager - CHARM - Retrofit - Change Request Management Enhanced RetrofitDocumento61 pagineSAP Solution Manager - CHARM - Retrofit - Change Request Management Enhanced RetrofitARPITA BISWASNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)