Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Programmable Logic Controller Hardware and Software Architecture

Caricato da

Kantharaj ChinnappaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Programmable Logic Controller Hardware and Software Architecture

Caricato da

Kantharaj ChinnappaCopyright:

Formati disponibili

Electronic hygrometer (capacitive type) Structure and composition Electronic hygrometers detect the change in the electrostatic capacity

or electric resistance of a sensor when it absorbs moisture. In this section, the electrical capacitive hygrometer is described. The electrical capacitive hygrometer uses a dielectric material made of high polymer membrane, as a sensor.

Figure 3.4 shows the basic structure of the high polymer membrane humidity sensor, and Figure 3.5 shows the appearance of the electronic hygrometer used by the Japan Meteorological Agency. The sensor is fitted with a filter which protects the sensor from contaminants, such as toxic gases, and has pores to tale moisture in it. Figure 3.6 shows an example of such a filter.

(2) Characteristics of the sensor

The measurement range of the electrical capacitive hygrometer is from 0 to 100%, and its accuracy can be improved by calibration. By calibrating with the standard hygrometer, the electrical capacitive hygrometer attains the error of 1% or less in the range from 0 to 90% and error of 2% or less in the range from 90 to 100%. The hysteresis becomes large when the humidity changes from high to low. It is within 1% at relative humidity of 60-80%. when relative humidity increases from 0 to 90% and the sensor absorbs moisture, the time constant of the sensor is about six seconds. On the other hand, when relative humidity decreases from 90 to 0% and the sensor releases moisture, the time constant is about 10 seconds. For meteorological purposes, the sensor is put in a ventilation shelter to protect the sensor from precipitation and sunlight with the aspiration speed of 2 to 4 m/s around the sensor. The time constant with the shelter from the saturation to the room humidity is about 20 minutes, which is longer than that without the shelter, because of the shelters large thermal capacity. A high polymer membrane humidity sensor has temperature dependence of about 0.1%/ for the temperature range from 5 to 30 and 0.2%/ for the temperature range from 30 to 0. Therefore, a temperature sensor is installed together with the humidity sensor to compensate its temperature dependency. (3) Sources to cause errors a) Any difference between the ambient temperature and the sensor temperature causes an error. For example, at 20 and 50%RH, a difference of 1 between the ambient temperature and the sensor temperature results in an error of about 3%. At 90%RH, the error becomes up to about 6%. When the sensor temperature is lower than the ambient temperature in a low humidity condition, dew may form on the surface of the sensor. This will make a large measurement error. The sensor is housed in an ventilation shelter to reduce or eliminate the difference of temperature between the sensor and the ambient air to prevent dew formation. b) The electronic capacitive hygrometer can be used in any environment where the human can live. However, do not use the hygrometer in the atmosphere containing oil mist, flammable gas, dust, organic solvents, acid, alkaline or ammonia. Using the hygrometer in the atmosphere may cause its sensor electrodes to corrode, thus the sensor life is shortened. To prevent the sensor electrode from corrosion, a protection filter is used to keep out dust or organic solvents. (4) Maintenance Routine maintenance

Routine maintenance is not needed. Periodic maintenance a) Compare the electrical capacitive hygrometer with the aspirated psychrometer once three months to observe time-dependent changes. b) Replace the protection filter with a new one twice a year. In rural areas where little soot is found , the interval between replacements may prolonged to a maximum of once a year. 15 (5) Calibration If a humidity generator chamber is available, an electrical capacitive hygrometer is calibrated in the same way as the hair hygrometer. The sensor of the electrical hygrometer can be separated from display and recording units. This enables the calibration in a small humidity generator chamber, in which it is easy to attain various humidity. Use aspirated phychrometer or chilled-mirror dewpoint hygrometer as standard instrument. (6) Repair Because most of parts of the humidity sensor cannot be repaired, they must be replaced with new ones if they become defective. Refer to the instruction manual of the hygrometer on the method to identify defects and to replace parts. (7) Transportation and installation Ask the manufacturer of the hygrometer for information about transportation, because precautions for transportation differ by the type of the hygrometer. The method of installation of the hygrometer sensor is basically the same as that of the aspirated psychrometer

Programmable logic controllers: Hardware, software architecture

Editors Note: This is the first part of a two-part article on the main distinguishing characteristics of the PLC: its basic hardware and software architecture. The second part will cover how the program and input/output (I/O) modules are scanned, and it will be available as a web exclusive in December (www.isa.org/link/Basics_main). In many respects, the architecture of the programmable logic controller (PLC) resembles a general-purpose computer with specialized input/output (I/O) modules. However, some important characteristics distinguish a PLC from a general-purpose computer. Most important, a PLC is much more reliable, designed for a mean time between failures measured in years. Second, a PLC can be placed in an industrial environment with its

substantial amount of electrical noise, vibration, extreme temperatures, and humidity. Third, PLCs are easily maintained by plant technicians. Basic PLC hardware architecture The basic architecture of a PLC consists of main components the processor module, the power supply, and the I/O modules. The processor module consists of the central processing unit (CPU) and memory. In addition to a microprocessor, the CPU also contains at least an interface to a programming device and may contain interfaces to remote I/O and other communication networks. The power supply is usually a separate module, and the I/O modules are separate from the processor. The types of I/O modules include discrete (on/off), analog (continuous variable), and special modules like motion control or high-speed counters. The field devices are connected to the I/O modules.

Depending on the amount of I/O and the particular PLC processor, the I/O modules may be in the same chassis as the processor and/or in one or more other chassis. Up until the late 1980s, the I/O modules in a typical PLC system were in chassis separate from the PLC processor. In the more typical present-day PLC, some of the I/O modules are present in the chassis that contains the processor. Some PLC systems allow more than one processor in the same chassis. Smaller PLCs are often mounted on a DIN rail. The smallest PLCs (often called micro-PLCs or nano-PLCs) include the power supply, processor, and all of the I/Os in one package. Some micro-PLCs contain a built-in operator interface panel. For many micro-PLCs, the amount of I/O is limited and not expandable.

Basic software, memory architecture (IEC 61131-3) The IEC 61131-3 standard defines a memory and program model that follows modern software engineering concepts. This model incorporates such features as top-down design, structured programming, hierarchical organization, formal software interfaces, and program encapsulation. Fortunately, extensive training in software engineering techniques is not necessary to become a proficient programmer. If fully implemented, the model is reasonably complicated. The main disadvantages of the model are its complexity and its contrast to the simplicity of the early PLCs. The overall IEC 61131-3 memory program and memory model are described. (For various implementations of the standard, visit www.isa.org/link/Erickson_PLC.) The IEC 61131-3 memory model (what the standard calls the software model) is layeredeach layer hides many of the features of the layers beneath. Each of the main elements is now described. The configuration is the entire body of software (program and data) that corresponds to a PLC system. Generally, a configuration equates with the program and data for one PLC. In large complex systems that require multiple cooperating PLCs, each PLC has a separate configuration. A configuration communicates with other IEC configurations within the control system through defined interfaces, called access paths. The choice of the term configuration conflicts with the historic use of this term in the controls industry. Generally, configuration refers to the process of specifying items such as the PLC processor model, communication interfaces, remote I/O connections, memory allocation, and so on. Therefore, the vendors producing IEC-compliant PLCs that use the term configuration in the historic sense refer to the entire body of software with some other term, such as project. A resource provides the support functions for the execution of programs. One or more resources constitute a configuration. Normally, a resource exists within a PLC, but it may exist within a personal computer to support program testing. One of the main functions of a resource is to provide an interface between a program and the physical I/O of the PLC.

A program generally consists of an interconnection of function blocks, each of which may be written in any of the IEC languages. A function block or program is also called a program organization unit. In addition to the function blocks, the program contains declarations of physical inputs/outputs and any variables local to the program. A program can read and write to I/O channels, global variables, and communicate with other programs. Access paths provide the means to transfer information between configurations. Tasks control the execution of the program or parts of a program. A task controls one or more programs and/or function blocks to execute. The execution of a program implies that all of the function blocks in the program are processed once. The execution of a function block implies that all of the software elements of the function block are processed once. There are no implied mechanisms for program execution. In order for a program to be executed, it must be assigned to a task, and the task must be configured to execute continuously, periodically, or with a trigger. Variables are declared within the different software elements of the model. A local variable is defined at the software element and can only be accessed by the software element. Local variables can be defined for the function block, program, resource, or configuration. A global variable defined for a configuration, resource, or program is accessible to all elements contained in it. For example, a global configuration variable is accessible to all software elements in the configuration. A global program variable is accessible to all function blocks in the program. Directly represented variables are memory and I/O locations in the PLC. IEC 61131-3 defines formats for references to such data. However, many implementers of the standard use their own formats, which are not consistent with the IEC standard.

PLC Architecture consists of two core assemblies, internal and external. Designing a complete system will require exploring the many architecture options available

Arguably the most important thing to decide while designing a system, is the type of external architecture. The application needs, along with the desired location plays a large part on what technology is available to your design.

A fixed PLC is usually small, has little memory, and a limited number of inputs and outputs, or I/O as typically referred to. The CPU, power supply, and I/O system are all constructed as a single entity, therefore any options desired must be included. This PLC architecture is usually inexpensive, and has very basic functionality that is not expandable. An ideal choice for small compact machines, with limited space and functionality. However very powerful, specialty fixed systems are a small part of the industry for emergency or safety circuits.

Today the industry seems to use the terms modular, and rack mounted PLC interchangeably quite often, it's purely from a marketing standpoint. In a technical sense they are related, however there are a few major differences that need to be understood.

Modular PLCs are adaptive systems that can be changed easily and simply. They consist of a chassis, rail, or back plane upon which a collection of modules are built into an interfaced system. Required components for a complete system are CPU, power supply, and I/O modules. The main advantage of a modular PLC architecture, is the ability to choose individual specifications as required, such as the quantity and type of I/O modules. Other options can include network interface cards, to almost endless specialty modules. A system of this size will require a control cabinet for mounting and wiring.

Rack mounted PLCs go beyond modular PLCs in that multiple racks (within the same enclosure or remote enclosure) are connected with a network or comm link of some sort. Distributed I/O and Remote I/O modules can eliminate point-to-point wiring by networking process signals to one digital communication link. Data acquisition is performed with field mounted sensors and transmitters, as with any standard I/O interface. Using this method allows for sending control signals over very long distances, with the flexibility to use twisted pair, fiber optic cabling and some wireless methods. The other advantage with this PLC architecture is the

ability to distribute signal conditioning, and convert otherwise weak sensor signals to digital signals, avoiding problems in electronically noisy settings. While the external components are important for the layout and design, internal PLC architecture, from processing power, memory consumption, current load, and the number of I/O devices, will impact the size and cost of a system.

The CPU in a PLC is a microprocessor based, central processing unit. The type of CPU module required will depend on the needs of the designer, such as arithmetic and logic operations, memory block moves, user interface, local area network accessibility, and other functions. Whether the CPU is mounted in a rack, chassis or a fixed unit, data is sent across the data bus in the back plane. A typical scan time cycle, will start scan, perform internal checks, scan inputs, execute program logic, and finally update outputs. The functions and options available will vary based on the make and model used. There are two standard types of memory the CPU will use, load and work memory. Load memory is storage for the user program. Depending on the specific module this can be RAM, ROM, or EPROM. Work memory is integrated RAM, used to store parts of the user program required for processing. Typically any blocks of memory not required for start up will be stored in the load memory.

With the many I/O modules available, a designer can mix and match the modules to fit application needs. I/O devices can consist of digital or analog signals. Digital I/O is a discrete signal that is simply on or off, such as a limit switch for input or relay on output. Analog I/O converts a voltage or current into an equivalent value by the CPU, such as an input thermocouple, or an output pressure regulator. Most modular systems allow for I/O expandability, only restricted by the CPU capabilities. PLC power supplies typically have an input ranging from 24 VDC to 240 VAC, and will fit most designed power requirements. Depending on the manufacturer, power supplies can be a separate unit, or integrated into the chassis. The power supply should match the load requirements of the PLC system. Since development of the first PLC in 1968, the world has depended on the unmatchable abilities, and nearly nonstop operation offered by this technology. The original unit from 1968 operated for 25 years uninterrupted, it is possible with todays PLC architecture and technology, to see systems operating for a lifetime.

Potrebbero piacerti anche

- Design and Fabrication of Plastic Bottle and Can Crusher For Recycling PurposeDocumento3 pagineDesign and Fabrication of Plastic Bottle and Can Crusher For Recycling PurposeInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Design Plastic Bottle CrusherDocumento4 pagineDesign Plastic Bottle CrusheragungNessuna valutazione finora

- What Are Different Types of Brakes?Documento9 pagineWhat Are Different Types of Brakes?Japhet Charles Japhet Munnah100% (1)

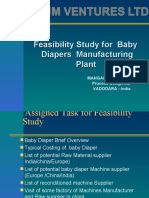

- Feasibility Study For Baby Diapers Manufacturing PlantDocumento76 pagineFeasibility Study For Baby Diapers Manufacturing PlantMangal DevNessuna valutazione finora

- Analysis of Tool Geometry for Screw Extrusion MachinesDocumento12 pagineAnalysis of Tool Geometry for Screw Extrusion MachinesdjklikaNessuna valutazione finora

- Load Estimation: Types of LoadsDocumento5 pagineLoad Estimation: Types of Loadsanupnaskar naskarNessuna valutazione finora

- M Bayu Irpan F 4EBDocumento5 pagineM Bayu Irpan F 4EBBayu Jarai100% (1)

- Introduction to Mechatronics SystemsDocumento86 pagineIntroduction to Mechatronics SystemsSt. Anne's CET (EEE Department)Nessuna valutazione finora

- Aravind Panasa Research Paper Transformer Thefts PDFDocumento7 pagineAravind Panasa Research Paper Transformer Thefts PDFaravind panasa100% (1)

- Control DC Motor Speed Using Field FluxDocumento11 pagineControl DC Motor Speed Using Field FluxTwisha100% (1)

- Online Lab - Me Lab1 Expt 2 Area MeasurementDocumento5 pagineOnline Lab - Me Lab1 Expt 2 Area MeasurementDessa GuditoNessuna valutazione finora

- RacDocumento26 pagineRacgurunakhale123Nessuna valutazione finora

- Thermodynamics 2Documento29 pagineThermodynamics 2S Tunkla EcharojNessuna valutazione finora

- Brayton CycleDocumento5 pagineBrayton CycleDanang Wahdiat Aulia IshaqNessuna valutazione finora

- Project TopicsDocumento16 pagineProject TopicsVasu VermaNessuna valutazione finora

- Frog Leg WindingDocumento9 pagineFrog Leg WindingAbhijeet RedekarNessuna valutazione finora

- MEng 198 Proposal FormatDocumento12 pagineMEng 198 Proposal FormatBilly JhunNessuna valutazione finora

- Fdocuments - in Otto Cycle PresentationDocumento97 pagineFdocuments - in Otto Cycle PresentationUTSAV KUMARNessuna valutazione finora

- Mechatronics Unit III and IV Question and AnswersDocumento6 pagineMechatronics Unit III and IV Question and AnswersSaravanan MathiNessuna valutazione finora

- Instrumentations / Energy Conversion / Others: Moving-Iron InstrumentDocumento9 pagineInstrumentations / Energy Conversion / Others: Moving-Iron InstrumentJermaine Lachica100% (1)

- Generate Power by Walking with Foot Step Non-Conventional Energy SystemDocumento4 pagineGenerate Power by Walking with Foot Step Non-Conventional Energy SystemGeeta VermaNessuna valutazione finora

- Lecture 5 CondenserDocumento37 pagineLecture 5 CondenserWalid MohammedNessuna valutazione finora

- Refrigeration and Air Conditioning Course OverviewDocumento9 pagineRefrigeration and Air Conditioning Course OverviewAsif jabarNessuna valutazione finora

- Can CrusherDocumento11 pagineCan CrusherElakkiya KarthicNessuna valutazione finora

- Marking Scheme of MST-I AST-308Documento3 pagineMarking Scheme of MST-I AST-308Ranjit Kour0% (1)

- ME432 Power Plant Engineering May Jun 2007 PDFDocumento3 pagineME432 Power Plant Engineering May Jun 2007 PDFBala MuruganNessuna valutazione finora

- Cooling Towers & Dryers ExplainedDocumento18 pagineCooling Towers & Dryers ExplaineddaanNessuna valutazione finora

- Machine Design Lab ManualDocumento28 pagineMachine Design Lab ManualEr Raghvendra Singh100% (1)

- Multipurpose Air Flow Duct PDFDocumento11 pagineMultipurpose Air Flow Duct PDFHabtie GetinetNessuna valutazione finora

- Blade Less Wind TurbineDocumento6 pagineBlade Less Wind TurbinePavan ReddyNessuna valutazione finora

- Southern Luzon State University: College of Engineering Mechanical Engineering DepartmentDocumento8 pagineSouthern Luzon State University: College of Engineering Mechanical Engineering DepartmentRosalyNessuna valutazione finora

- BoardDocumento8 pagineBoardJerald ManlangitNessuna valutazione finora

- AHMT Assignment 01Documento7 pagineAHMT Assignment 01shubham0% (1)

- Module II - Lecture Notes 1 - Isentropic Flow - Area Variation With Mach NumberDocumento4 pagineModule II - Lecture Notes 1 - Isentropic Flow - Area Variation With Mach NumberSakthivel MunirajanNessuna valutazione finora

- Magneto Hydro Dynamic Power Generation: EEE Dept The Vazir Sultan College of EnggDocumento23 pagineMagneto Hydro Dynamic Power Generation: EEE Dept The Vazir Sultan College of EnggAzghar Ali0% (1)

- Design and Fabrication of Single Phase Induction Motor For Numerical Machine ComplexDocumento55 pagineDesign and Fabrication of Single Phase Induction Motor For Numerical Machine Complexmugisa aloysiousNessuna valutazione finora

- Solar-Powered Fishpond Feeder With Real-Time Water Quality Monitoring SystemDocumento6 pagineSolar-Powered Fishpond Feeder With Real-Time Water Quality Monitoring SystemInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- c4 Tutorial TurbineDocumento2 paginec4 Tutorial TurbinehahahaNessuna valutazione finora

- NTPC Project ReportDocumento105 pagineNTPC Project Reportgauravatnet_92Nessuna valutazione finora

- Project Study 2Documento41 pagineProject Study 2James AlcariaNessuna valutazione finora

- Split-Phase Motor GuideDocumento11 pagineSplit-Phase Motor Guidewensley jethrou guzmanNessuna valutazione finora

- 604 I.c.engine (Me-604) Exp. ManualDocumento35 pagine604 I.c.engine (Me-604) Exp. Manualnavaneet gupta100% (1)

- Generation of Electric Power McqsDocumento10 pagineGeneration of Electric Power McqskeerthikaNessuna valutazione finora

- Vapour Power Cycles Reheat Rankine CycleDocumento12 pagineVapour Power Cycles Reheat Rankine CycleWilliam J ThompsonNessuna valutazione finora

- ELE 2314 - Course Project Description and Rubrics (1) - 1588187297Documento7 pagineELE 2314 - Course Project Description and Rubrics (1) - 1588187297sjNessuna valutazione finora

- Gas Leakage Alarm With Power Failure SystemDocumento64 pagineGas Leakage Alarm With Power Failure Systeminfo8103Nessuna valutazione finora

- PAMANTASAN NG LUNGSOD NG MAYNILA Experiment No.1Documento12 paginePAMANTASAN NG LUNGSOD NG MAYNILA Experiment No.1ManuelitoBorjaNessuna valutazione finora

- H&MT - Lesson 6. Numericals On ConductionDocumento18 pagineH&MT - Lesson 6. Numericals On ConductionadimeghaNessuna valutazione finora

- Assignment 2Documento1 paginaAssignment 2dhrumilNessuna valutazione finora

- Scrap Collecting Robot Using IR Sensor and MicrocontrollerDocumento53 pagineScrap Collecting Robot Using IR Sensor and Microcontrollerkumarravishankar100% (3)

- Energy Conservation & Audit AssignmentDocumento2 pagineEnergy Conservation & Audit AssignmentKnowledge JunctionNessuna valutazione finora

- Orifice, Nozzle and Venturi Flow Rate Meters: Water & Air FlowmetersDocumento4 pagineOrifice, Nozzle and Venturi Flow Rate Meters: Water & Air Flowmeterssiva_nagesh_2Nessuna valutazione finora

- Experiment 5 - On-Off ControllerDocumento7 pagineExperiment 5 - On-Off ControllerJitender YadavNessuna valutazione finora

- Conceptual Questions: Unit 2: Electricity and Magnetism Chapter 10: Direct-Current CircuitsDocumento25 pagineConceptual Questions: Unit 2: Electricity and Magnetism Chapter 10: Direct-Current CircuitsDaniel AntonioNessuna valutazione finora

- Earthquake AlarmDocumento11 pagineEarthquake AlarmDILIP KUMARNessuna valutazione finora

- Portable Electric Power Tilling Machine Project ReviewDocumento8 paginePortable Electric Power Tilling Machine Project ReviewP KalaivaniNessuna valutazione finora

- Street Light Control System:By MaheshrajDocumento67 pagineStreet Light Control System:By MaheshrajMaheshraj Birajdar80% (5)

- Embedded systems introductionDocumento7 pagineEmbedded systems introductionMuhammad Anaz'sNessuna valutazione finora

- AUTOMATIC ENGINE LOCKING With BuzzerDocumento79 pagineAUTOMATIC ENGINE LOCKING With BuzzersankeerthanreddyNessuna valutazione finora

- Emissions and Performance Evaluation of DI CI - VCDocumento8 pagineEmissions and Performance Evaluation of DI CI - VCKantharaj ChinnappaNessuna valutazione finora

- Panas LebihDocumento51 paginePanas LebihRinggo Reog100% (1)

- Yoga Kundalini UpanishadDocumento26 pagineYoga Kundalini UpanishadSunil LokeNessuna valutazione finora

- Data & Observations: BrassDocumento4 pagineData & Observations: BrassKantharaj ChinnappaNessuna valutazione finora

- Strength of Material-Shear Force and Bending MomentsDocumento25 pagineStrength of Material-Shear Force and Bending MomentszakeriyaNessuna valutazione finora

- SFD and BMDDocumento278 pagineSFD and BMDRama KumarNessuna valutazione finora

- Strength of Materials Jan 2018 (2015 Scheme)Documento2 pagineStrength of Materials Jan 2018 (2015 Scheme)Kantharaj ChinnappaNessuna valutazione finora

- ME 260 Spur Gear ProfileDocumento8 pagineME 260 Spur Gear ProfileKantharaj ChinnappaNessuna valutazione finora

- Student Progress Check FormDocumento1 paginaStudent Progress Check FormKantharaj ChinnappaNessuna valutazione finora

- Materials Testing TensileDocumento2 pagineMaterials Testing TensileKantharaj ChinnappaNessuna valutazione finora

- Data & Observations: BrassDocumento4 pagineData & Observations: BrassKantharaj ChinnappaNessuna valutazione finora

- Auto CADDocumento61 pagineAuto CADThiru MuruganNessuna valutazione finora

- Data & Observations: BrassDocumento4 pagineData & Observations: BrassKantharaj ChinnappaNessuna valutazione finora

- Gear Calculations Rev3Documento5 pagineGear Calculations Rev3ghostghost123Nessuna valutazione finora

- Brief ContentsDocumento7 pagineBrief ContentsKantharaj ChinnappaNessuna valutazione finora

- Worked Examples 1 Induction MotorDocumento2 pagineWorked Examples 1 Induction MotorKantharaj ChinnappaNessuna valutazione finora

- Elec 1Documento4 pagineElec 1Kantharaj ChinnappaNessuna valutazione finora

- Santhosh Wind Energy Resource Evaluation in A Site of Central Italy by CFD SimulationsDocumento1 paginaSanthosh Wind Energy Resource Evaluation in A Site of Central Italy by CFD SimulationsKantharaj ChinnappaNessuna valutazione finora

- DC MachineDocumento3 pagineDC MachineKantharaj ChinnappaNessuna valutazione finora

- Applications of Induction MotorsDocumento2 pagineApplications of Induction MotorsKantharaj ChinnappaNessuna valutazione finora

- Lee N DuffyDocumento1 paginaLee N DuffyKantharaj ChinnappaNessuna valutazione finora

- Fluorescent LampDocumento1 paginaFluorescent LampKantharaj ChinnappaNessuna valutazione finora

- FuseDocumento3 pagineFuseKantharaj ChinnappaNessuna valutazione finora

- DC MachinesDocumento1 paginaDC MachinesKantharaj ChinnappaNessuna valutazione finora

- Three Phase Induction Motor ADocumento2 pagineThree Phase Induction Motor AKantharaj ChinnappaNessuna valutazione finora

- EarthingDocumento7 pagineEarthingKantharaj ChinnappaNessuna valutazione finora

- Gauss SeidalDocumento3 pagineGauss SeidalKantharaj ChinnappaNessuna valutazione finora

- 3.2 Criteria For Curve FittingDocumento5 pagine3.2 Criteria For Curve FittingKantharaj ChinnappaNessuna valutazione finora

- Protective DevicesDocumento4 pagineProtective DevicesKantharaj ChinnappaNessuna valutazione finora

- DesignDocumento1 paginaDesignKantharaj ChinnappaNessuna valutazione finora

- Explain The Functions of An Operating SystemDocumento5 pagineExplain The Functions of An Operating Systemapi-247871582100% (2)

- Config Idevice Standard DOCU V20 en PDFDocumento44 pagineConfig Idevice Standard DOCU V20 en PDFAutomation WorksNessuna valutazione finora

- GPIO Terminal BlockDocumento28 pagineGPIO Terminal BlockAlejandro MolinaNessuna valutazione finora

- Data Bits (Word Length) It Can Handle at A Time. Initial Prototypes Had 4-Bit Capability. AfterDocumento10 pagineData Bits (Word Length) It Can Handle at A Time. Initial Prototypes Had 4-Bit Capability. AfterUiNessuna valutazione finora

- Help On Kodak MachineDocumento150 pagineHelp On Kodak MachinejonokorbabaNessuna valutazione finora

- BC0040 Computer Organization and Architecture Paper 2Documento15 pagineBC0040 Computer Organization and Architecture Paper 2SeekEducationNessuna valutazione finora

- D2-250-1 Key Features: DL250-1 CPUDocumento3 pagineD2-250-1 Key Features: DL250-1 CPUVladimir Aliro Quezada CidNessuna valutazione finora

- Manual Book RTKLIBDocumento81 pagineManual Book RTKLIBDwi Aji HariyantoNessuna valutazione finora

- The Unix Time SharingDocumento11 pagineThe Unix Time SharingjorgitoSolNessuna valutazione finora

- Bay Control & Monitoring System: Digital EnergyDocumento535 pagineBay Control & Monitoring System: Digital EnergyBurak ÖzsoyluNessuna valutazione finora

- Introduction To Computing SystemsDocumento629 pagineIntroduction To Computing SystemsDaniel C. Suh100% (6)

- QuantumDocumento116 pagineQuantumleangel hernandezNessuna valutazione finora

- GPU 2 Manual de InstalaciónDocumento75 pagineGPU 2 Manual de InstalaciónjjcanoolivaresNessuna valutazione finora

- 7SR5 Engineering Guide Version 2.20 en USDocumento154 pagine7SR5 Engineering Guide Version 2.20 en USAlexandre MandettaNessuna valutazione finora

- RM14 User ManualDocumento19 pagineRM14 User ManualrifaiNessuna valutazione finora

- Some Features of MicroprocessorDocumento10 pagineSome Features of MicroprocessorAjitKumarNessuna valutazione finora

- Touch Typing Lesson 2 - The Top Row - How To Type - Free Typing Lessons, Typing Practice and Typing Tests.Documento3 pagineTouch Typing Lesson 2 - The Top Row - How To Type - Free Typing Lessons, Typing Practice and Typing Tests.Dinesh KushwahaNessuna valutazione finora

- RS3785 - Grade - 10 MicroprocessorDocumento104 pagineRS3785 - Grade - 10 MicroprocessorAshish Banstola90% (10)

- COMPUTER KNOWLEDGE FOR EPFO EXAMDocumento15 pagineCOMPUTER KNOWLEDGE FOR EPFO EXAMAtul DelhiNessuna valutazione finora

- GSM Interface Module: Product OverviewDocumento11 pagineGSM Interface Module: Product OverviewGitesh MisalNessuna valutazione finora

- Ip Project Class 11 2021-2022Documento31 pagineIp Project Class 11 2021-2022Julie George100% (1)

- Keyboard Processing With Control Flow: Julius BancudDocumento30 pagineKeyboard Processing With Control Flow: Julius BancudRed StreakNessuna valutazione finora

- Information Processing: Main Aims of The UnitDocumento10 pagineInformation Processing: Main Aims of The UnitTanaka ChivutaiseNessuna valutazione finora

- 271.148 580.HBMDocumento39 pagine271.148 580.HBMcastelNessuna valutazione finora

- E560 RP570-71 SubDocumento49 pagineE560 RP570-71 SubTuan Dung LuNessuna valutazione finora

- 16kbit and 8kbit Serial SPI Bus EEPROM With High Speed ClockDocumento40 pagine16kbit and 8kbit Serial SPI Bus EEPROM With High Speed ClockDanny EversonNessuna valutazione finora

- Manual WT9501M03Documento11 pagineManual WT9501M03rodrigoxavieroenNessuna valutazione finora

- DataEase Quick Reports GuideDocumento40 pagineDataEase Quick Reports Guidecarlos_saNessuna valutazione finora

- Modbus Manual - Saia Burgess PCD3Documento43 pagineModbus Manual - Saia Burgess PCD3Mayank Singh BaiswarNessuna valutazione finora

- Portable Data Recorder: 5.7" Colour Touchscreen Up To 38 Sensors Can Be Connected Automatic Sensor RecognitionDocumento4 paginePortable Data Recorder: 5.7" Colour Touchscreen Up To 38 Sensors Can Be Connected Automatic Sensor RecognitionMoodNessuna valutazione finora