Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

QuickGuide Micrometers

Caricato da

torjaniceTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

QuickGuide Micrometers

Caricato da

torjaniceCopyright:

Formati disponibili

6 Quick Guide to Precision Measuring Instruments

Quick Guide to Precision Measuring Instruments

Micrometers

Frame

Anvil

Measuring faces

Spindle

Outer sleeve

Inner sleeve

Adjusting nut

Ratchet stop

Heat insulator

Spindle lock

Index line on sleeve

Thimble

Heat insulator

Measuring faces

Frame

Anvil

Thimble

Spindle lock

Outer sleeve

Output connector (for data output type only)

Ratchet stop

ZERO (INC)/ABS set key

Origin key

HOLD key

Standard Outside Micrometer

Nomenclature

Digimatic Outside Micrometer

Special Purpose Micrometer Applications

Spindle

Blade micrometer Inside micrometer, caliper type Spline micrometer Tube micrometer

Point micrometer Screw thread micrometer Disc type outside micrometer V-anvil micrometer

For diameter inside narrow

groove measurement

For small internal diameter, and

groove width measurement

For splined shaft diameter

measurement

For pipe thickness measurement

For root diameter measurement For effective thread diameter

measurement

For root tangent measurement on

spur gears and helical gears

For measurement of

3- or 5-ute cutting tools

7 Quick Guide to Precision Measuring Instruments

Detailed Shape of Measuring Faces How to Read the Scale

Micrometer with standard scale (graduation: 0.01mm)

The scale can be read directly to 0.01mm, as shown above, but may

also be estimated to 0.001mm when the lines are nearly coincident

because the line thickness is 1/5 of the spacing between them.

Micrometer with vernier scale (graduation: 0.001mm)

The vernier scale provided above the sleeve index line enables direct

readings to be made to within 0.001mm.

Micrometer with digital display (resolution: 0.001mm)

Sleeve reading 6. mm

Thimble reading .21mm

Reading from the vernier scale marking

and thimble graduation line .003mm

Micrometer reading 6.213mm

Audible in

operation

One-handed

operation

Remarks

Ratchet stop

Yes Unsuitable

Audible clicking operation causes

micro-shocks

Friction thimble

(F type)

No Suitable

Smooth operation without shock or

sound

Ratchet thimble

(T type)

Yes Suitable

Audible operation provides conrma-

tion of constant measuring force

Ratchet thimble

Yes Suitable

Audible operation provides conrma-

tion of constant measuring force

Constant-force Devices

Potential Reading Error Due to

Parallax

When a scale and its index line do not lie in the same plane it is possible

to make a reading error due to parallax, as shown below. The viewing

directions (a) and (c) will produce this error, whereas the correct reading

is that seen from direction (b).

Difference in Thermal Expansion

between Micrometer and Standard

Bar

The graphs above show the change in size of a standard length bar

when held in the hand at palm temperatures of 21C, 27C and 31C.

Standard Bar Expansion with

Change of Temperature (for 200mm bar initially at 20C)

These drawings above are used for explaration and they are not to scale

Sleeve reading 7. mm

Thimble reading + .37mm

Micrometer reading 7.37mm

(b)

(c)

(a)

Thimble

Sleeve

Sleeve index line Sleeve index line

Thimble graduation line Thimble graduation line

Approx. +1m Approx. +2m

125

-3

-2

-1

0

+1

+2

+3

225 325

0C

20C

10C

425 525

D

i

f

f

e

r

e

n

c

e

i

n

e

x

p

a

n

s

i

o

n

(

m

)

Nominal length (mm)

31C

27C

21C

Lapse of time (minutes)

T

h

e

r

m

a

l

e

x

p

a

n

s

i

o

n

(

m

)

10 9 8 7 6 5 4 3 2 1 0

20

15

10

5

0

Third decimal place

Second decimal place

First decimal place

Millimetres

Tens of mm

0 2 9 9

mm

6

4

5

0

45

2

0

0.01

+

2.994mm

.004mm

.09 mm

.9 mm

2. mm

00. mm

Third decimal place on vernier scale ( 0.001 mm units)

Vernier reading 0.004mm

Counter reading

Index line

6

.

3

5

6

.

3

30

8

30

7

.

9

5

Carbide tip

s

p

i

n

d

l

e

s

p

i

n

d

l

e

8 Quick Guide to Precision Measuring Instruments

Quick Guide to Precision Measuring Instruments

Supporting point Supported at the bottom and center Supported only at the center

Attitude

Maximum

measuring

length (mm)

325 0 5.5

425 0 2.5

525 0 5.5

625 0 11.0

725 0 9.5

825 0 18.0

925 0 22.5

1025 0 26.0

Measurement Error Depending on

Attitude and Supporting Point (Unit: m)

Supporting point Supported at the center in a lateral

orientation.

Supported by hand downward.

Attitude

Maximum

measuring

length (mm)

325 +1.5 4.5

425 +2.0 10.5

525 4.5 10.0

625 0 5.5

725 9.5 19.0

825 5.0 35.0

925 14.0 27.0

1025 5.0 40.0

Abbes Principle

Abbes principle states that maximum accuracy is obtained when the

scale and the measurement axes are common.

This is because any variation in the relative angle (q) of the moving

measuring jaw on an instrument, such as a caliper jaw micrometer

causes displacement that is not measured on

the instruments scale and this is an Abbe error

(e= L in the diagram). Spindle straightness error,

play in the spindle guide or variation of

measuring force can all cause q to vary

and the error increases with R.

Hertz's Formulae

Hertzs formulae give the apparent reduction in diameter of spheres and

cylinders due to elastic compression when measured between plane

surfaces. These formulae are useful for determining the deformation of

a workpiece caused by the measuring force in point and line contact

situations.

Effective Diameter of Thread

Measurement

Three-wire Method of Thread Measurement. The effective diameter

of a thread can be measured by using three wires contacting

the thread as shown in gure below. Effective diameter E can be

calculated by using formula (1) or (2).

For metric or unifed screw threads (60 thread angle)

E=M3d+0.866025P .......(1)

For Whitworth screw threads (55 thread angle)

E=M3.16568d+0.960491P .......(2)

Where, P: Screw thread pitch (A pitch in

inches is converted to its metric

equivalent for unied screw threads.)

d: Mean diameter of the three wires

E: Effective diameter of the thread

M: Measurement over the three wires

Micrometers

Anvil

Spindle

Odd-fluted tap

Wire

Screw thread type Best wire size

Metric screw thread (60) 0.577P

Whitworth screw thread (55) 0.564P

Single-wire Method of Thread Measurement. An Odd-futed tap can be

measured using a V-anvil micrometer and a single wire in contact with

the thread fanks as shown. This method uses two measurements and

a calculation to obtain an equivalent value for M as was obtained by

direct measurement in the `three-wire method.

Where, M1: Maximum micrometer reading over the single wire (at

cutting edge)

D: Maximum diameter of tap (at cutting edge)

For a three-fute tap: M = 3M1 2D

Or for a fve-fute tap: M = 2.2360M1 1.23606D

Then, the effective diameter E can be calculated by substituting this M

in formula (1) or (2)

Assuming that the material is steel and units are as follows:

Modulus of elasticity: E=196 GPa

Amount of deformation: (m)

Diameter of sphere or cylinder: D (mm)

Length of cylinder: L (mm)

Measuring force: P (N)

a) Apparent reduction in diameter of sphere

1 =0.82

3

P

2

/D

b) Apparent reduction in diameter of cylinder

2 =0.094P/L

3

1/D

L

R

P

SD

2

2

P

2

2

L

D

(a)

Sphere between

two planes

(b)

Cylinder between

two planes

Since the measurement value is changed by the supporting point and

maximum measuring length, it is recommended to use the instrument

by performing zero-setting with the same orientation as it will be used

in practice.

9 Quick Guide to Precision Measuring Instruments

Hooke's Law

Hookes law states that strain in an elastic material is proportional to the

stress causing that strain, providing the strain remains within the elastic

limit for that material.

Testing Parallelism of Micrometer

Measuring Faces

Parallelism can be estimated using an optical parallel held between the

faces. Firstly, wring the parallel to the anvil measuring face. Then close

the spindle on the parallel using normal measuring force and count

the number of red interference fringes seen on the measuring face of

the spindle in white light. Each fringe represents a half wavelength

difference in height (0.32m for red fringes).

In the above gure a parallelism of approximately 1m is obtained from

0.32m x 3=0.96m.

Testing Flatness of Micrometer

Measuring Faces

Flatness can be estimated using an optical fat (or parallel) held against

a face. Count the number of red interference fringes seen on the

measuring face in white light. Each fringe represents a half wavelength

difference in height (0.32m for red).

Measuring face is curved by

approximately 1.3m. (0.32m x 4

paired red fringes.)

Measuring face is concave (or

convex) approximately 0.6m deep.

(0.32m x 2 continuous fringes)

Fringes on the spindle side

Optical parallel reading direction on the spindle side

Optical parallel

Anvil

Optical at Optical at

Anvil

Interference fringe

reading direction

Potrebbero piacerti anche

- Battery Cross RefDocumento130 pagineBattery Cross ReftorjaniceNessuna valutazione finora

- Perkins Light SetDocumento1 paginaPerkins Light SettorjaniceNessuna valutazione finora

- SopananrithamDocumento4 pagineSopananrithamtorjaniceNessuna valutazione finora

- CAN DictionaryDocumento2 pagineCAN DictionarytorjaniceNessuna valutazione finora

- Engine Interface ModuleDocumento3 pagineEngine Interface Moduletorjanice89% (46)

- MEP UNIT Service ScheduleDocumento2 pagineMEP UNIT Service ScheduletorjaniceNessuna valutazione finora

- Amperage ChartDocumento1 paginaAmperage ChartWage KarsanaNessuna valutazione finora

- Qsk60 - Service ScheduleDocumento1 paginaQsk60 - Service ScheduletorjaniceNessuna valutazione finora

- Vcaliper How ToDocumento2 pagineVcaliper How TotorjaniceNessuna valutazione finora

- Sdmo Telys 1 Control Panel ManualDocumento40 pagineSdmo Telys 1 Control Panel ManualAlberto Celleri Bravo86% (28)

- Automatic Transfer SwitchesDocumento4 pagineAutomatic Transfer Switchestorjanice100% (1)

- 1300 Series PerkinsDocumento1 pagina1300 Series Perkinstorjanice80% (5)

- VolvoDocumento2 pagineVolvotorjaniceNessuna valutazione finora

- Remote AnnunciatorsDocumento2 pagineRemote AnnunciatorstorjaniceNessuna valutazione finora

- Fuel - Consumption - Chart - Standard Diesel EngineDocumento1 paginaFuel - Consumption - Chart - Standard Diesel EngineCaptIsqanNessuna valutazione finora

- Exide Fitment Guide2010Documento72 pagineExide Fitment Guide2010torjaniceNessuna valutazione finora

- SwitchgearDocumento32 pagineSwitchgearistenicNessuna valutazione finora

- Laser Printer: Reliable, High-Quality Black and White Laser OutputDocumento2 pagineLaser Printer: Reliable, High-Quality Black and White Laser OutputtorjaniceNessuna valutazione finora

- EIG H LV SwitchgearDocumento28 pagineEIG H LV SwitchgeartorjaniceNessuna valutazione finora

- 1000 Series PerkinsDocumento1 pagina1000 Series PerkinstorjaniceNessuna valutazione finora

- Power Generation Service ChecklistDocumento1 paginaPower Generation Service ChecklisttorjaniceNessuna valutazione finora

- MEP UNIT 250 Service ScheduleDocumento3 pagineMEP UNIT 250 Service ScheduletorjaniceNessuna valutazione finora

- 1000 Series PerkinsDocumento1 pagina1000 Series PerkinstorjaniceNessuna valutazione finora

- VolvoDocumento2 pagineVolvotorjaniceNessuna valutazione finora

- Amperage ChartDocumento1 paginaAmperage ChartWage KarsanaNessuna valutazione finora

- ESP Pricelist May 2013Documento80 pagineESP Pricelist May 2013torjaniceNessuna valutazione finora

- Anuroop Switchgear Company Price ListDocumento2 pagineAnuroop Switchgear Company Price ListtorjaniceNessuna valutazione finora

- Dual-Fuel ARTEMIS CaseStud eDocumento17 pagineDual-Fuel ARTEMIS CaseStud etorjaniceNessuna valutazione finora

- ABB SwitchDocumento6 pagineABB SwitchtorjaniceNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5782)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Efficient Production of Mannosylerythritol Lipids With High Hydrophilicity by Pseudozyma Hubeiensis KM-59Documento10 pagineEfficient Production of Mannosylerythritol Lipids With High Hydrophilicity by Pseudozyma Hubeiensis KM-59sushidombeNessuna valutazione finora

- Materials of Engineering Lecture Unit 1 Pptmaten22Documento24 pagineMaterials of Engineering Lecture Unit 1 Pptmaten22Ignacio Flores CaballeroNessuna valutazione finora

- The Development Cultural Studies in BritishDocumento6 pagineThe Development Cultural Studies in BritishIeie HollyNessuna valutazione finora

- Civil TechnologyDocumento2 pagineCivil TechnologyLeonicia MarquinezNessuna valutazione finora

- Anatomy of an AI SystemDocumento23 pagineAnatomy of an AI SystemDiego Lawliet GedgeNessuna valutazione finora

- Answer Following Questions: TH THDocumento5 pagineAnswer Following Questions: TH THravi3754Nessuna valutazione finora

- Today's Court Decision on Land Registration AppealDocumento6 pagineToday's Court Decision on Land Registration AppealJohn Lester TanNessuna valutazione finora

- Thomas McPherson Brown MD Treatment of Rheumatoid DiseaseDocumento29 pagineThomas McPherson Brown MD Treatment of Rheumatoid DiseaseLidia Lidia100% (1)

- Housing Typologies & Development in The PhilippinesDocumento5 pagineHousing Typologies & Development in The Philippinesmaria lourdes bautista100% (1)

- Assertive CommunicationDocumento5 pagineAssertive CommunicationAditi VaidNessuna valutazione finora

- Songs For The Deaf: Parental Advisory EdDocumento5 pagineSongs For The Deaf: Parental Advisory EdTinta CafeNessuna valutazione finora

- El 114 The-Adventures-of-Tom-Sawyer-by-Mark-TwainDocumento11 pagineEl 114 The-Adventures-of-Tom-Sawyer-by-Mark-TwainGhreniel V. Benecito100% (1)

- Sports Project BbaDocumento10 pagineSports Project Bbadonboy004Nessuna valutazione finora

- CostingDocumento3 pagineCostingAarti JNessuna valutazione finora

- 3I'S (Week 7-8)Documento15 pagine3I'S (Week 7-8)AldrinJosephLacuarinNessuna valutazione finora

- Bells and WhistlesDocumento2 pagineBells and Whistlesapi-265536295Nessuna valutazione finora

- Fake News Detection PPT 1Documento13 pagineFake News Detection PPT 1Sri VarshanNessuna valutazione finora

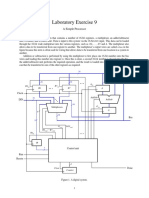

- Laboratory Exercise 9: A Simple ProcessorDocumento8 pagineLaboratory Exercise 9: A Simple ProcessorhxchNessuna valutazione finora

- Einstein & Inconsistency in General Relativity, by C. Y. LoDocumento12 pagineEinstein & Inconsistency in General Relativity, by C. Y. Loicar1997100% (1)

- Iso 11783 3-2018Documento72 pagineIso 11783 3-2018vax1100% (1)

- Speech To Third Form English.Documento1 paginaSpeech To Third Form English.maxNessuna valutazione finora

- Nina Weighed A Random Sample of 50 Carrots From Her Shop and Recorded The Weight, inDocumento20 pagineNina Weighed A Random Sample of 50 Carrots From Her Shop and Recorded The Weight, inHalal BoiNessuna valutazione finora

- Spec 120knDocumento2 pagineSpec 120knanindya19879479Nessuna valutazione finora

- 2011-YPG Plan Activity Book FINAL 4-17-11Documento27 pagine2011-YPG Plan Activity Book FINAL 4-17-11Dan CompitelloNessuna valutazione finora

- Zoomorphology: Morphology and Function of The Tube Feet of (Echinodermata: Crinoidea)Documento13 pagineZoomorphology: Morphology and Function of The Tube Feet of (Echinodermata: Crinoidea)Indra SatriaNessuna valutazione finora

- All India Post Graduate Medical Entrance Exam ForumsDocumento57 pagineAll India Post Graduate Medical Entrance Exam ForumsabhishekbmcNessuna valutazione finora

- Indian EthosDocumento43 pagineIndian EthosKarishma ChaudharyNessuna valutazione finora

- Labprograms 1A2A3ADocumento11 pagineLabprograms 1A2A3ARajiv SethNessuna valutazione finora

- DLL - Science 5 - Q3 - W2Documento10 pagineDLL - Science 5 - Q3 - W2Eihcra SubacNessuna valutazione finora

- HIlbro SurgicalDocumento70 pagineHIlbro Surgicalshazay_7733% (3)