Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Lime Mortar

Caricato da

Sree Harsha PenugondaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Lime Mortar

Caricato da

Sree Harsha PenugondaCopyright:

Formati disponibili

Traditional Lime Mortar:

Also known as Natural Lime Mortars, mortars of this type are made with sand and use lime as a binder. They should not be confused with sand, lime and Portland cement mortars, regardless of the relative proportions of the lime and Portland cement. There are two basic types of lime for traditional lime mortars those that set and harden by the reaction with air and those that do so by reaction with water !non hydraulic and hydraulic limes respectively". Non-hydraulic limes : Lime made from relatively pure forms of calcium carbonate !e.g. chalk or limestone" burned in a kiln produce calcium o#ide !$uicklime". %hen this is then reacted !slaked" with water it produces calcium hydro#ide !hydrated lime". &alcium hydro#ide reacts !carbonates" with carbon dio#ide in the air to reform calcium carbonate, i.e. the composition of the raw material originally used to make the lime. 'n a mortar mi# it is this (setting( that binds together particles of sand and bonds it to the masonry units. The setting process is slow, taking several weeks to gain a basic working strength, and many months, or even years, to reach ultimate strength throughout. The setting is entirely dependent on air and not on water) indeed lime putty, a moist, plastic form of the hydrated lime, will keep for years in an airtight container or under water. Hydraulic limes Naturally occurring deposits of calcium carbonate can include impurities, i.e. small amounts of other minerals, very often clay or silt. %hen burned in a kiln the calcium carbonate forms calcium o#ide, but the (impurities( form calcium silicates and aluminates that will chemically react with water to set and harden regardless of the presence of air. 'n the manufacturing process *ust sufficient water is added to the kiln product to hydrate the calcium o#ide to form calcium hydro#ide in a dry powder form, but not enough to promote setting of the calcium silicates and aluminates. The material is bagged and stored dry to prevent the commencement of a set by atmospheric moisture. The composition of raw materials from different sources varies greatly and this relative content of (impurities( influences the setting and hardening characteristics of the lime produced. 'n practice hydraulic limes are graded according to the rate and ultimate strength of their set and they are described as (feebly hydraulic(, (moderately hydraulic( and (eminently hydraulic( limes.

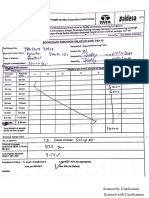

'n geographical areas where available natural limes were not sufficiently hydraulic for some purposes, traditional practice included the use of additives to produce a set !Po++olans", e.g. brick dust from a kiln or furnace ashes, to improve the setting and ultimate strength of mortars made with non hydraulic, feebly hydraulic, or moderately hydraulic limes. Mortars made with eminently hydraulic limes and,or Po++olan additives can be $uite strong and hard and, in these characteristics, resemble those of Portland cement mortars. -sing hydraulic lime in mortar mi#es gives a very nice workability, good elasticity, high permeability, e#cellent resistance to salts and self healing properties. .ydraulic lime can be used to produce different products such as) bedding or repointing mortars, renders, in*ection grouts, lime paint, etc. The hydraulic lime is available in three grades according to their hydraulicity) higher hydraulicity means that the lime will develop higher strength. N.L / 0 1eebly hydraulic N.L 2.3 0 Moderately hydraulic N.L 3 0 4minently hydraulic Also available are the moderately and eminently hydraulic lime with an air entraining agent that will considerably increase free+e thaw resistance. N.L 5/0 Moderately hydraulic lime !N.L 2.3" with air entraining agent. N.L 520 4minently hydraulic lime !N.L 3" with air entraining agent. MORTARS M$% RAT$O * +A,S "- +A,S . MONTHS &" MONTHS "/ MONTHS Consumption 0or &m) # o0 mortar 1g' 2!- &34# /:6 //8 57: Compressive strength - N!mm"# &:" 6.7/ 5.8: 2.:8 8.66 8./3 &:"'( 6.32 5.27 2.66 /.;6 2.66 &:) 6.89 5./3 /.:: /.;6 /.93

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Scanned With CamscannerDocumento2 pagineScanned With CamscannerSree Harsha PenugondaNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Book 1Documento2 pagineBook 1Sree Harsha PenugondaNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- CMD - (M35 PQC With 350kg Vikram Ulteratech Cement & Sikament 280 (1) )Documento6 pagineCMD - (M35 PQC With 350kg Vikram Ulteratech Cement & Sikament 280 (1) )Sree Harsha PenugondaNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Ballast Test ReportDocumento4 pagineBallast Test ReportSree Harsha PenugondaNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- 40 Ways To Better Health in 2013Documento1 pagina40 Ways To Better Health in 2013Rashid MahmoodNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Staad and WordbbDocumento1 paginaStaad and WordbbKheldz Picache100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Scanned With CamscannerDocumento1 paginaScanned With CamscannerSree Harsha PenugondaNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Scan Doc with CamScanner AppDocumento2 pagineScan Doc with CamScanner AppSree Harsha PenugondaNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- 18 11 19 PDFDocumento1 pagina18 11 19 PDFSree Harsha PenugondaNessuna valutazione finora

- ReadMe enDocumento4 pagineReadMe enSree Harsha PenugondaNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Scan Doc with CamScanner AppDocumento1 paginaScan Doc with CamScanner AppSree Harsha PenugondaNessuna valutazione finora

- BeliefsDocumento4 pagineBeliefsSree Harsha Penugonda100% (1)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Scanned With CamscannerDocumento1 paginaScanned With CamscannerSree Harsha PenugondaNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- New Microsoft Word DoxcumentDocumento1 paginaNew Microsoft Word DoxcumentSree Harsha PenugondaNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- A Bbs FormulaDocumento20 pagineA Bbs FormulaSree Harsha PenugondaNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Is 875 3 1987Documento67 pagineIs 875 3 1987Sree Harsha Penugonda100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Online Mock Test Download for Govt. Jobs & ExamsDocumento5 pagineOnline Mock Test Download for Govt. Jobs & ExamsSree Harsha PenugondaNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- SailDocumento10 pagineSailSree Harsha PenugondaNessuna valutazione finora

- SailDocumento10 pagineSailSree Harsha PenugondaNessuna valutazione finora

- Design Data:: Maharani PalaceDocumento4 pagineDesign Data:: Maharani PalaceSree Harsha PenugondaNessuna valutazione finora

- A Bbs FormulaDocumento20 pagineA Bbs FormulaSree Harsha PenugondaNessuna valutazione finora

- HinduismDocumento1 paginaHinduismSree Harsha PenugondaNessuna valutazione finora

- Design of Water Tanks-CE 05014 p3 6Documento65 pagineDesign of Water Tanks-CE 05014 p3 6engineerkranthi4055100% (1)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Design of Water Tanks-CE 05014 p3 6Documento65 pagineDesign of Water Tanks-CE 05014 p3 6engineerkranthi4055100% (1)

- Beam ForcesDocumento3 pagineBeam ForcesSree Harsha PenugondaNessuna valutazione finora

- MeclDocumento7 pagineMeclSayan PalNessuna valutazione finora

- AbstractDocumento1 paginaAbstractSree Harsha PenugondaNessuna valutazione finora

- Tabel Konversi SatuanDocumento1 paginaTabel Konversi SatuanSutopo AhmadNessuna valutazione finora

- Santhosh ResumeDocumento2 pagineSanthosh ResumeSree Harsha PenugondaNessuna valutazione finora

- Cheaper Alternatives to Conventional Solar Water HeatersDocumento19 pagineCheaper Alternatives to Conventional Solar Water HeatersErickMartinSNessuna valutazione finora

- Nov 2019 Paper 1 MSDocumento11 pagineNov 2019 Paper 1 MSYapo Daniel N'GUESSANNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Photosynthesis under stress overviewDocumento28 paginePhotosynthesis under stress overviewnaufal samiNessuna valutazione finora

- Rejuvenation of Qarun FieldDocumento12 pagineRejuvenation of Qarun FieldPeter JamesNessuna valutazione finora

- Storm Tech - Design - Manual PDFDocumento32 pagineStorm Tech - Design - Manual PDFPepe2095Nessuna valutazione finora

- REVIEW OF AGRICULTURE: An Alternative Draft for ConsiderationDocumento14 pagineREVIEW OF AGRICULTURE: An Alternative Draft for ConsiderationAsha ShivaramNessuna valutazione finora

- Shell Spirax S4 CX 30: Performance, Features & Benefits Main ApplicationsDocumento2 pagineShell Spirax S4 CX 30: Performance, Features & Benefits Main ApplicationsDarmawan PutrantoNessuna valutazione finora

- ION ANALYSIS - Thin-Layer (Planar) ChromatographyDocumento17 pagineION ANALYSIS - Thin-Layer (Planar) Chromatographydeni ebit nugrohoNessuna valutazione finora

- Solar Energy History All BeganDocumento30 pagineSolar Energy History All Beganmar_ouqNessuna valutazione finora

- Don Bosco School EVS Class 2 Water RevisionDocumento26 pagineDon Bosco School EVS Class 2 Water RevisionChristo JeniferNessuna valutazione finora

- Characterization of Abattoir WastewaterDocumento12 pagineCharacterization of Abattoir WastewaterAG-Metal /Tretman Otpadnih Voda/Wastewater Treatment40% (5)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Photosynthesis QuestionsDocumento65 paginePhotosynthesis QuestionsForm 4B100% (1)

- Grundfosliterature 5501Documento68 pagineGrundfosliterature 5501Mykola Titov100% (1)

- Offshore Marginal Field - 23.05.2014 (Ver2)Documento38 pagineOffshore Marginal Field - 23.05.2014 (Ver2)moechamad_aditiaNessuna valutazione finora

- Percussion Drilling: A 3000-Year-Old Technique for Drilling WellsDocumento21 paginePercussion Drilling: A 3000-Year-Old Technique for Drilling WellsMudassar KhanNessuna valutazione finora

- Sika® Ceram-100P Tile AdhesiveDocumento2 pagineSika® Ceram-100P Tile Adhesivedep_vinNessuna valutazione finora

- PERFORMANCE CHECKLIST With Oral Questioning ToolDocumento3 paginePERFORMANCE CHECKLIST With Oral Questioning ToolChonaMarieEstellinaNessuna valutazione finora

- Drawback of Plastic Industry Cipet Final Report PDFDocumento32 pagineDrawback of Plastic Industry Cipet Final Report PDFSavi sharmaNessuna valutazione finora

- Third. Summative Test in Industrial Arts 6Documento2 pagineThird. Summative Test in Industrial Arts 6Joecel A Polinag100% (1)

- Environmental LawDocumento4 pagineEnvironmental LawManohar RNessuna valutazione finora

- Readings Upper IntermediateDocumento7 pagineReadings Upper Intermediatepiopio123475% (4)

- Minnesota vs. 3MDocumento37 pagineMinnesota vs. 3MBrett BachmanNessuna valutazione finora

- Introduction To WASPDocumento23 pagineIntroduction To WASPblacklist_number9Nessuna valutazione finora

- Lab Manual for Environmental EngineeringDocumento186 pagineLab Manual for Environmental EngineeringVamshi ChaitanyaNessuna valutazione finora

- Tales of Battle CreekDocumento177 pagineTales of Battle CreekTaylor A. Warsop100% (1)

- Tekmar 284 Multi Boiler Control p9450 02Documento2 pagineTekmar 284 Multi Boiler Control p9450 02api-221502147Nessuna valutazione finora

- Site Appraisal Form: Ministry of Basic, Higher and Technical EducationDocumento3 pagineSite Appraisal Form: Ministry of Basic, Higher and Technical EducationJohaima HaronNessuna valutazione finora

- Air Cooler and Chiller Types and Applications Ben214 Fluid MechanicsDocumento14 pagineAir Cooler and Chiller Types and Applications Ben214 Fluid MechanicsMahmoud M.AbdelalimNessuna valutazione finora

- Saber and Shadow - S. M. StirlingDocumento518 pagineSaber and Shadow - S. M. StirlingPeter McLaughlin100% (1)

- ГОСТ 533-2000 inglDocumento19 pagineГОСТ 533-2000 inglviacheslavverdeshNessuna valutazione finora

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationDa EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationValutazione: 4 su 5 stelle4/5 (18)

- Guidelines for Developing Quantitative Safety Risk CriteriaDa EverandGuidelines for Developing Quantitative Safety Risk CriteriaNessuna valutazione finora

- Fish School 101: A Step-by-Step Guide for Fish OwnersDa EverandFish School 101: A Step-by-Step Guide for Fish OwnersValutazione: 5 su 5 stelle5/5 (16)

- Guidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisDa EverandGuidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisNessuna valutazione finora

- Chemical Process Safety: Learning from Case HistoriesDa EverandChemical Process Safety: Learning from Case HistoriesValutazione: 4 su 5 stelle4/5 (14)

- Advanced Process Control: Beyond Single Loop ControlDa EverandAdvanced Process Control: Beyond Single Loop ControlNessuna valutazione finora

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDa EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNessuna valutazione finora