Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

3516 BPDF

Caricato da

jlmunozvDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

3516 BPDF

Caricato da

jlmunozvCopyright:

Formati disponibili

Generator

Set

3516B

1800 rpm

2000 kW 60 Hz

Shown with

Optional Equipment

FEATURES

CAT DIESEL GENERATOR SETS

Factory designed, certified prototype tested

with torsional analysis. Production tested and

delivered to you in a package that is ready to

be connected to your fuel and power lines.

EPG Designer computer sizing available.

Supported 100% by your Caterpillar dealer

with warranty on parts and labor. Extended

warranty available in some areas. The

generator set was designed and manufactured

in an ISO 9001 compliant facility. Generator

set and components meet or exceed the

following specifications: ABGSM TM3,

AS1359, AS2789, BS4999, BS5000, BS5514,

DIN6271, DIN6280, EGSA101P, IEC 34/1,

IS03046/1, IS08528, JEM1359, NEMA MGl-22,

VDE0530, 89/392/EEC, 89/336/EEC.

CATERPILLAR SR4B GENERATOR

Type Brushless, revolving field,

sol id-state exciter

Construction Single bearing, close coupled

Three phase Wye connected

Insulation Class H with tropicalization

and anti abrasion

Enclosure Drip proof IP 22

Alignment Pilot shaft

Overspeed capability 150%

Wave form Less than 5% deviation

Paralleling capability standard with

adjustable voltage droop

Voltage regulator 3-phase sensing with

VOlts-per-Hertz

Voltage regulation Less than 1/2%

Voltage gain Adjustable to compensate

for engine speed droop and line loss

Standby Power

CATERPILLAR ENGINE SPECIFICATIONS

V-16, 4-Stroke-Cycle Watercooled Diesel

Bore - mm (in) 170 (6.7)

Stroke - mm (in) 190 (7.5)

Displacement - L (cu in) 69 (4210)

Compression ratio 14:1

Oil CF-4

RELIABLE, FUEL EFFICIENT DIESEL

The compact, four-stroke-cycle diesel engine

combines durability with minimum weight

while providing dependability and economy.

The fuel system operates on a variety of fuels.

CATERPILLAR SR4B GENERATOR

Single bearing, wye connected, static

regulated, brushless self excited generator

designed to match the performance and

output characteristics of the Caterpillar diesel

engine that drives it.

EXCLUSIVE CATERPILLAR

VOLTAGE REGULATOR

Three-phase sensing and Volts per Hertz

regulation give precise control, excellent block

loading, and constant voltage in the normal

operating range.

TIF Less than 50

THF Less than 3%

CATERPILLAR CONTROL PANEL

24 Volt DC Control

Terminal box mounted

Vibration isolated

NEMA 1IIP 23 enclosure

Electrically dead front

Lockable hinged door

Generator instruments meet ANSI C-39-1

Voltages Available

60 Hz

380, 480, 600, and 4160

(Adjustable a minimum of 10%)

Other voltages available - consult your Caterpillar dealer.

Some voltages require derating.

C.l.TERPILLAR&

STANDARD EQUIPMENT

3516B GENERATOR SET

STANDBY POWER ATTACHMENTS

Engine

Aftercooler

Air cleaner

regular duty

Breather,crankcase

Cooler, lubricating oil

Exhaust fitting and

flange

Filters, right hand

fuel and lubricating

oil

Flywheel housing

SAE No. 00

standard rotation

Fuel system

electronic controlled

unit injectors

Governor

ADEM electronic

control

Manifold, exhaust. dry

Oil pan, shallow

Pumps,

fuel transfer;

aftercooler water,

jacket water, and

lubricating oil -

gear driven

Radiator

Rails, mounting

Shutoff, manual

Starting, electric,

24 Volt DC

Turbochargers

Vibration damper

Generator

SR4B brushless

permanent magnet

excited with VR3

voltage regulator

Space heaters

ElECTRONIC MODULAR

CONTROL PANEl (EMCP)

Standard generator

controls and monitoring:

Ammeter/voltmeter

phase selector switch

Digital ammeter,

voltmeter, and

frequency meter

Voltage adjust rheostat

Standard engine controls

and monitoring:

Automatic/manual

start-stop control

Engine control switch

for:

off/reset. auto start.

manual start. stop,

cooldown timer,

cycle cranking,

emergency stop

pushbutton

Safety shutoff protection

and LED indicators for:

High coolant temp.

Low oi I pressure

Overcrank

Overspeed

Emergency stop

pushbutton

Engine

Air cleaners

Charging systems

Cooling systems

fan drives, radiators,

fans, expansion tanks

Control systems

governor, Woodward

2301A load share

Exhaust system

fittings, elbows,

flanges, muffler

Lube system

Mounting systems

Protection devices

Starting system

Generator

Oversized generators

Manual voltage control

RFI Filters -

N level (VDE 875).

BS800, MIL Std 461B

Digital voltage regulator

2:1 volts per hertz VR3

Control Panel

Auxiliary relay

Enclosure,

NEMA 1211P 44

Governor speed switch

Illuminating lights

Installed speed sensing

governor (Woodward)

Low coolant level

Provision for:

alarm module -

NFPA 99

alarm module -

NFPA 110

Reverse power relay

Starting aid switch

Synchronizing lights

Caterpillar" EMCP II

Electronic Modular Control Panel

The Electronic Modular Control Panel (EMCP II) is a

generator-mounted control panel, available on all

Caterpillar packaged generator sets. It utilizes

environmentally sealed, solid-state, microprocessor-

based modules for engine control and AC

metering. This new application of mature, high-

tech electronics to generator monitoring provides

more features, accuracy, and reliability than

present electromechanical and many competitive

panel systems.

The EMCP II provides these standard control and

monitoring features, many of which are options on

other panels:

Automatic/manual start-stop engine control

with programmable safety shutdowns and

associated flashing LED indicators for low oil

pressure, high coolant temperature, overspeed,

overcrank, and emergency stop

Cycle cranking - adjustable 1-60 second

crank/rest periods

Cooldown timer - adjustable 0-30 minutes

Energized to run or shutdown fuel control

systems

LCD digital readout for: engine oil pressure,

coolant temperature, engine rpm, system DC

volts, engine running hours, system diagnostic

codes, generator AC volts, generator AC amps,

and generator frequency

Engine control switch

Ammeter-voltmeter phase selector switch

Emergency stop pushbutton

Indicator/display test switch

Voltage adjust potentiometer

Rugged NEMA 111P 23 cabinet

3516B GENERATOR SET

TECHNICAL DATA

C..lTERPILLAR

3516B Standby Power Generator Sets -1800 rpm

Power Rating @ 0.8 PFwith Fan ekW 2000

kVA 2500

Engine Rating without Fan bhp 2876

Generator Frame Size 825

Engine Lubricating Oil Capacity - Requires CF-4 Oil qts 440

Engine Coolant Capacity without Radiator gal 62

System Backpressure (Max Allowable) in water 27

Exhaust Flange Size - (Internal Diameter) (Dual) in 8

Low Emissions Version Lo BSFC

Coolant to Aftercooler Temperature (Max) F 85 140 195 195

Length in 223 223 223 224

Width in 82 82 82 92

Height in 97 97 97 102

Shipping Weight Ibs 32550 32550 33550 33100

Engine Coolant Capacity with Radiator gal 107 107 107 121

Separate Circuit Aftercooler

Aftercooler Cooling Circuit gal 11 11 11 N/A

Aftercooler Pump Coolant Flow gal/min 159 159 159 N/A

at 9.5 feet water head

100% Load

Fuel Consumption (100% load) with Fan gal/hr 141 139 138 132

per IS03046/1: +5%, -0% tolerance

*NOx emissions at ISO standard conditions: Ib/hr 28.1 33.7 42.3 54.5

+ or - 15% tolerance g/hr 12765 15290 19200 24700

75% Load

Fuel Consumption (75% load) with Fan gal/hr 103 101 102 99

per IS03046/1: +5%, -0% tolerance

*NOx emissions at ISO standard conditions: Ib/hr 20.5 25.0 28.9 40.7

+ or - 15% tolerance g/hr 9310 11 345 13095 18480

50% Load

Fuel Consumption (50% load) with Fan gal/hr 70 70 70 68

per IS03046/1: +5%, -0% tolerance

*NOx emissions at ISO standard conditions: Ib/hr 13.7 16.8 20.9 28.4

+ or - 15% tolerance g/hr 6220 7605 9475 12870

Combustion Air Inlet Flow Rate ft3/min 6850 6620 6505 6150

Exhaust Gas Flow Rate ft3/min 17375 17245 17495 16230

Heat Rejection to Jacket Water BTU/min 44650 44300 44130 42825

Heat Rejection to Aftercooler BTU/min 35430 31 620 25480 22410

Heat Rejection to Exhaust (total) BTU/min 123 580 124035 128 185 118460

Heat Rejection to Atmosphere from Engine BTU/min 7735 7735 7735 7735

Heat Rejection to Atmosphere from Generator BTU/min 4380 4380 4380 4380

Exhaust Gas Stack Temperature Deg F 900 936 981 953

Deration for Engine ft 2300 2215 2130 6730

Altitude - 3% per 1000 feet above

* Note: For permitting see TMI data.

C..lTERPILLAR

3516B GENERATOR SET

STANDBY POWER GENERATOR SET PACKAGE - TOP VIEW

[QD Centerline of Engine @Oil Filter

[QD Rear Face of Cylinder Block 8 Air Inlet

@Exhaust

@Control and Power Panel

@Conduit Entrance

S Customer Mounting Holes

For overall length see technical data section (page 3). Note: General configuration not to be used for

installation. 5ee general dimension drawings for detail.

CONDITIONS AND DEFINITIONS

Standby - Output available with varying load for

the duration of the interruption of the normal

source power. Fuel stop power in accordance

with 1503046/1, A52789, DIN6271, and B55514.

Ratings are based on 5AE J1349 standard

conditions. These ratings also apply at 1503046/1,

DIN6271, and B55514 standard conditions.

Fuel rates are based on fuel oil of 35 API (16C

or 60 F) gravity having an LHV of 42 780 kJ/kg

(18 390 Btullb) when used at 29C (85F) and

weighing 838.9 glliter (7.001 Ibs/U.5. qal.),

Lubricating oil - requires CF-4 oil.

Additional ratings may be available for specific

customer requirements. Consult your Caterpillar

representative for details.

Materials and specifications are subject to change without notice.

LEHX6758 1996 Caterpillar Inc.

Supersedes LEHX5428

The International System of Units (Sl) is used in this publication.

Printed in U.S.A.

All rights reserved.

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- 2012 ARCTIC CAT 450 ATV Service Repair Manual PDFDocumento30 pagine2012 ARCTIC CAT 450 ATV Service Repair Manual PDFjksmmmddNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Cessna421c HandoutDocumento25 pagineCessna421c Handoutjiminyf16100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Volvo - D16F, H, J Cylinder Head, ReplacementDocumento39 pagineVolvo - D16F, H, J Cylinder Head, ReplacementprescottNessuna valutazione finora

- Mud Pump GTS FinalDocumento77 pagineMud Pump GTS FinalSanjiv Pathak0% (1)

- Cameron Um Bop RamDocumento55 pagineCameron Um Bop Ramjlmunozv50% (2)

- Home Power Magazine Issue 031Documento116 pagineHome Power Magazine Issue 031Bogdan Dragan100% (1)

- Generator Protection CBIP - 28-01-2016 PDFDocumento74 pagineGenerator Protection CBIP - 28-01-2016 PDFRamphani Nunna100% (2)

- 002 Prime-G+ Commercial PerformanceDocumento18 pagine002 Prime-G+ Commercial Performancesameerjp50% (2)

- MOD 15 en EditavelDocumento704 pagineMOD 15 en EditavelJoao Santos100% (10)

- Tesco 750 ESIDocumento2 pagineTesco 750 ESIjlmunozvNessuna valutazione finora

- Tesco 500 ESIDocumento2 pagineTesco 500 ESIjlmunozv0% (1)

- Einstelldaten Kubota 03-M-Serie (EU Stage IIIA, EPA Int - Tier 4)Documento24 pagineEinstelldaten Kubota 03-M-Serie (EU Stage IIIA, EPA Int - Tier 4)Alex AyalaNessuna valutazione finora

- Auxiliary Steam SystemDocumento15 pagineAuxiliary Steam SystemSwaroop KumarNessuna valutazione finora

- IPCC ConceptDocumento24 pagineIPCC ConceptTapadev DasNessuna valutazione finora

- Methanol ProductionDocumento6 pagineMethanol ProductionGovind KumarNessuna valutazione finora

- Compresor TITAN 130 (Solar)Documento86 pagineCompresor TITAN 130 (Solar)Martínez Rodriguez DiegoNessuna valutazione finora

- KTA19Documento2 pagineKTA19Carlos César100% (4)

- Water Flooding: Buckely-Leverett TheoryDocumento23 pagineWater Flooding: Buckely-Leverett Theoryبشير الزامليNessuna valutazione finora

- MHD55148 BOP Catalog 052008Documento20 pagineMHD55148 BOP Catalog 052008jlmunozv100% (4)

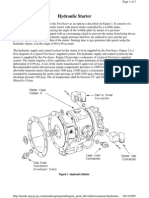

- Figure 1. Hydraulic StarterDocumento3 pagineFigure 1. Hydraulic StarterDenis JimenezNessuna valutazione finora

- Cummins KTA50-G3Documento16 pagineCummins KTA50-G3Teodoro Cornelius AltuveNessuna valutazione finora

- Ficha Gerador Caterpillar 3406C 400Documento6 pagineFicha Gerador Caterpillar 3406C 400jlmunozvNessuna valutazione finora

- Qsi-012 0413Documento12 pagineQsi-012 0413jlmunozvNessuna valutazione finora

- H 3 1 Third Generation FA5ADocumento6 pagineH 3 1 Third Generation FA5AjlmunozvNessuna valutazione finora

- Model A32P / A32SDocumento6 pagineModel A32P / A32SjlmunozvNessuna valutazione finora

- Quincy Qsi 245I-500I Rotary Screw Air Compressor 50-100 HPDocumento8 pagineQuincy Qsi 245I-500I Rotary Screw Air Compressor 50-100 HPjlmunozvNessuna valutazione finora

- DL 01069Documento24 pagineDL 01069jlmunozvNessuna valutazione finora

- Winch and Hoist Solutions Ingersoll Rand Company 20017 72 Ave. S. Kent, WA 98032Documento1 paginaWinch and Hoist Solutions Ingersoll Rand Company 20017 72 Ave. S. Kent, WA 98032jlmunozvNessuna valutazione finora

- 3516 BPDFDocumento4 pagine3516 BPDFjlmunozvNessuna valutazione finora

- Ezyt Install Oper Manual - PDF - Adobe Acrobat Professional OcrDocumento4 pagineEzyt Install Oper Manual - PDF - Adobe Acrobat Professional OcrjlmunozvNessuna valutazione finora

- Winch and Hoist Solutions Ingersoll Rand Company 20017 72 Ave. S. Kent, WA 98032Documento1 paginaWinch and Hoist Solutions Ingersoll Rand Company 20017 72 Ave. S. Kent, WA 98032jlmunozvNessuna valutazione finora

- Polea Viajera 3000 HP Trad. SimpleDocumento1 paginaPolea Viajera 3000 HP Trad. SimplejlmunozvNessuna valutazione finora

- QM-101 IVRev 1 4-Quality - ManualDocumento21 pagineQM-101 IVRev 1 4-Quality - ManualjlmunozvNessuna valutazione finora

- ABCO Complete CertificatesDocumento7 pagineABCO Complete CertificatesjlmunozvNessuna valutazione finora

- CAD Product Brouchure 2010Documento11 pagineCAD Product Brouchure 2010jlmunozvNessuna valutazione finora

- Deadline Anchors BrochureDocumento3 pagineDeadline Anchors Brochurejlmunozv100% (2)

- ABCO Complete CertificatesDocumento7 pagineABCO Complete CertificatesjlmunozvNessuna valutazione finora

- HT000 - Spec SheetDocumento4 pagineHT000 - Spec SheetJoseph MaamahNessuna valutazione finora

- Zurich WarrantyDocumento15 pagineZurich WarrantyEnos LewisNessuna valutazione finora

- Type of EnginesDocumento4 pagineType of EnginesIman SadeghiNessuna valutazione finora

- Detroit Failure AnalysisDocumento12 pagineDetroit Failure AnalysisCris LozoyaNessuna valutazione finora

- NaphthaDocumento9 pagineNaphthaLasal RNessuna valutazione finora

- SS-9236197-18396528-019 SS Page 1 of 5: Page: M-1 of M-3 © 2018 Caterpillar All Rights Reserved MSS-IND-18396528-019 PDFDocumento5 pagineSS-9236197-18396528-019 SS Page 1 of 5: Page: M-1 of M-3 © 2018 Caterpillar All Rights Reserved MSS-IND-18396528-019 PDFRizky UtomoNessuna valutazione finora

- BPCL CSR 2011 - 2012Documento6 pagineBPCL CSR 2011 - 2012Dimple DuggalNessuna valutazione finora

- Mine Foreman Study GuideDocumento363 pagineMine Foreman Study GuidemapykNessuna valutazione finora

- Powermyride BG FinalDocumento22 paginePowermyride BG FinalMario ManciaNessuna valutazione finora

- 2008 ARCTIC CAT 366 Service Repair Manual PDFDocumento40 pagine2008 ARCTIC CAT 366 Service Repair Manual PDFfuksekfmmd100% (1)

- Acl Company ProfileDocumento70 pagineAcl Company Profileashishkhare2008Nessuna valutazione finora

- KL HazopDocumento4 pagineKL HazopSalahBouzianeNessuna valutazione finora

- TMP - 18102 6CTAA8.3 G1 1017870363Documento2 pagineTMP - 18102 6CTAA8.3 G1 1017870363Aung MhNessuna valutazione finora

- MMD Ap0094bh eDocumento2 pagineMMD Ap0094bh eNadolu MarianNessuna valutazione finora