Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Weir Slurry Classification Method

Caricato da

Juan Pablo ApazaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Weir Slurry Classification Method

Caricato da

Juan Pablo ApazaCopyright:

Formati disponibili

Index

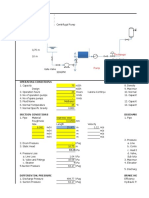

Pumping heterogeneous slurries (Type A Weir slurry clasification)

Application according Warmans empirical method [1]

Sheet N

1

2

3

4

5

6

7

8

9

Rev. cjc 30.01.2014

Pumping heterogeneous slurries (Type A Weir slurry clasification)

Application according Warmans empirical method [1]

Name

Resume. Resumed application of Weir method

" Weir type A " heterogeneous slurry. Definitions

Input data

Pressure losses (water as fluid)

Pressure difference betwen slurry and water as flow media

Theory of Warman's empirical method

Application

Limit deposition velocity

Resistance curves for different weight concentrations

The pressure correction indicated by Warman [1], has a real contribution when the

fluid velocity v > = v

L

and, in addition, when this fluid velocity is near this

limit deposition velocity.

According Warman, for v / v

L

> 1.3, the calculated pressure drop on

water has same value as the slurry pressure drop expressed in meters of slurry

column [1], page S6-3.

On the other hand, to avoid deposition, the system shal be designed for

v >= 1.1 v

L

Thus, the Warman application rage is

1.1 v

L

< v < 1.3 v

L

Note. From the theory, the maximum value is around 1.4 v

L

v

L

: limit deposition velocity

1.- Resume The slurry pressure drop is calculated,

according Weir [1], as the sum of the water

Weir empirical method for slurries type A pressure drop and the calculated pressure

difference. See below an explanation paragraph

Weir A-type slurries are defined by the following ranges from [1].

of the weight concentration "Cw" and average particle For a calculated water pressure drop

size "d

50

": (example)

0 % <= Cw <= 40 %

AP

w =

28.56

50 m < d

50

< 300 m the slurry pressure would be

AP

s =

AP

w

+ AP

s-w

The weir method gives the pressure difference "AP

s-w

" AP

w =

28.6

between the actual slurry pressure loss "AP

s

" and the AP

s_w

= 1.47

water pressure loss "AP

w

" for the the same flow rate. AP

S =

30.02

Pressure difference "AP

s-w

" The corecction factor has to be applied if

The calculation can be done by means of Q / Q

L

< 1.4

following Excel function The rage is also limited to

Q / Q

L

> 1.1

Required input data (Example. Note 1)) to ensure no deposition can occur.

Thus the application rage is

Input data for the function 1.1 < Q / Q

L

<

DeltaP = Slurry_Weir_A_DeltaP_d50_Cw_dn_Ss_Pw

d

50

= 145 m

For Q/Q

L

> 1.4, the value of the slurry pressure

Cw = 40 % drop in [mpc] has to be considered equal to

d

n

= 4 in

the value of the water pressure drop expressed

S

s

= 2.65 -

in [mwc]. (Ref. 1).

Q = 0.0104 m/s

P

w

= 28.6 mwc

Figure 2-6 [5] (below) shows the basics of

s

lining

= 9 mm

Warman method. For a flow rate Q > 1.4 QL

the slurry and water curves merge. For lower

AP

s_w

=Slurry_Weir_A_DeltaP_d50_Cw_dn_Ss_Pw flow rates, there is a difference, and the Weir

AP

s_w

= 1.47 msc method calculates it with an empirical method.

Note 1. The method will be explained in base of a numerical example, with a pipe of uniform size (for suction and discharge) and using carbon stell pipes

with standard shedule. If a different material is to be used, the values obtained (automatically) with the pipe dimension functions shall be replaced manually

by the values of the corresponding material and schedule.

[1]

4 . 1 ~

L

Q

Q

Rev. cjc 30.01.2014

The slurry pressure drop is calculated, d

50

: Average particle size [m]

according Weir [1], as the sum of the water Cw : Weight concentration [%]

pressure drop and the calculated pressure d

n

: Carbon steel pipe nominal diam. [in]

difference. See below an explanation paragraph (Standard shedule will be used)

S

S

: Solids specific gravity [-]

For a calculated water pressure drop Q : Slurry flow rate [m/s]

P

w

: Calculated pressure drop using

mwc water as fluid [mwc] (Ref. 1)

s

lining

: Lining (and deposition) thickness [mm]

Q

L

: limit deposition flow [m/s]

mwc Q

L

= v

L

* A

msc v

L

: Limit deposition velocity [m/s]

msc A : Area of interior pipe section [m]

The corecction factor has to be applied if

Index

s :solids

p . pulp

to ensure no deposition can occur. w : water

n : nominal

1.4 L : related to the limiting deposition velocity

For Q/Q

L

> 1.4, the value of the slurry pressure

drop in [mpc] has to be considered equal to Fig. 6.2, in sheet 7, (page 3) explains

the value of the water pressure drop expressed graphically the Weir method.

Figure 2-6 [5] (below) shows the basics of

Warman method. For a flow rate Q > 1.4 QL

the slurry and water curves merge. For lower

flow rates, there is a difference, and the Weir

method calculates it with an empirical method.

Note 1. The method will be explained in base of a numerical example, with a pipe of uniform size (for suction and discharge) and using carbon stell pipes

with standard shedule. If a different material is to be used, the values obtained (automatically) with the pipe dimension functions shall be replaced manually

To calculate the pressure drop of a "Weir type A slurry", the system is to be calculated as if the fluid were water. Sheet 3 presents a usual input data sheet and sheet 4 presents a usual water pressure

drop calculation. Finaly, sheet 5 presents the calculation of the pressure difference that in defined cases has to be added to the in sheet 4 calculated pressure drop.

2.- " Weir type A " heterogeneous slurry, by the Weir empirical method

Rev. cjc 30.01.2014

To calculate the pressure drop of a "Weir type A slurry", the system is to be calculated as if the fluid were water. Sheet 3 presents a usual input data sheet and sheet 4 presents a usual water pressure

drop calculation. Finaly, sheet 5 presents the calculation of the pressure difference that in defined cases has to be added to the in sheet 4 calculated pressure drop.

2.- " Weir type A " heterogeneous slurry, by the Weir empirical method

Rev. cjc 30.01.2014

To calculate the pressure drop of a "Weir type A slurry", the system is to be calculated as if the fluid were water. Sheet 3 presents a usual input data sheet and sheet 4 presents a usual water pressure

2.- " Weir type A " heterogeneous slurry, by the Weir empirical method

1.- Input data 2.- Help variables Volume concentration

Solids mass flow rate Internal diameter of CS pipe Cv = Cw*L*(s-((Cw/100)*(s-L)))

ms = 20 ton/h di = Pipe_Imp_CS_Dint_dn_sch(dn,sch) Cw = 40 %

Weight concentration of solids in slurry dn = 4 in L = 1000 kg/m

3

Cw = 40 % sch = STD S = 2650.0 kg/m

3

di = 102.3 mm Cv 20.1 %

Liquid density

L= 1000 kg/m3 Inside diameter with lining and depo- Pulp density (Index p: pulp)

Specific gravity of solids sition thicknesses p = L /(1-(Cw/100)*((s-L)/s)

Ss = 2.65 - slining = slng + sdep L = 1000 kg/m

3

Maximum allowed velocity slng = 9 mm Cw = 40.0 %

vmax = 4 m/s sdep = 0 mm s = 2650.0 kg/m

3

Minimum velocity (to avoid deposition) slining = 9 mm p = 1332 kg/m

3

vmin = 1.1 * vL m/s di = d - 2 * slining

(vL : Limit deposition velocity) d = 102.3 mm Pulp mass flow rate

Pipe nominal diameter (Note 1) slining = 9 mm Cw = ms / mp

dn = 4 in di = 84.26 mm mp = ms / Cw

Schedule di = 0.08426 m ms = 20 ton/h

SCH = STD - Cw = 0.4 -

Particle diameter d50 Pipe section mp = 50.0 ton/h

d50 = 145 m A = (t/4) * d^2

Slurry temperature d = 0.08426 m Pulp volumetric flow rate

t = 10 C A = 0.0056 m

2

QP mP / P m

3

/h

Pipe absolute rugosity mp = 50.0 ton/h

Rabs = 0.15 mm Water properties p = 1.33 ton/m

3

Pipe lengths t = 10 C QP = 37.55 m

3

/h

Lsucc = 5 m Absolute viscosity of water QP = 0.0104 m

3

/s

Ldisch = 400 m = SaturatedWaterAbsoluteViscosity_t QP = 10.43 L/s

Interior lining thickness = 1.3E-03 Pa s

slng = 9 mm Density of water

Deposition thickness L = SaturatedWaterDensity_t Pumping slurries [1], S6.2, see Note 1

sdep = 0 mm L = 1000 kg/m

3

Froth factor Kinematic viscosity of water Empirical method for Warman's "A" type

FF = 1 - v = / of slurries, defined as:

Security factor on pressure losses v = 1.3E-06 m/s

2

Particles essentially coarser than 50 m

SFlosses = 1.2 - and finer than 300 m and with a weight

Height above sea level Solids density concentration 0% < Cw <= 40%

HASL = 24 m.a.s.l. S = Ss * L

S = 2650 kg/m

3

g = 9.81 m/s

2

Note 1. For this method, only the discharge pipe is considered

Suction pipe can be changed, but it will afect only the suction

pressure drop

Cw <= 40%. Correct for this method

4.- Pressure loss calculation routine for water

Input data for pressure loss calculation routine

Particle diameter d

50

d

50

= 145

Volumetric concentration C

v

= 20.10

Pipe nominal diameter (CS) dn 4

Pipe schedule sch = STD

Solid's specific weight S

S

= 2.65

Lining and deposition thickness s

lining

9

Nominal diameter

Shedule dn in

Exterior diameter de mm

Pipe thickness s mm

Total lining thickness s

lining

mm

Interior diameter di mm

di m

Area A m

Absolute rugosity Rabs mm

Rugosidad relativa Rrel -

Extracted flow rate Q

extracted

m/h

Volumetric flow rate Q

i

= Q

i-1

- Q

extracted

Q m/h

Flow velocity v m/s

Limit deposition velocity v

L

m/s

Reynolds Re -

Friction coefficient (Darcy) f -

Velocitties ratio v/v

L

-

Kinematic pressure h

v

= v/(2*g) h

v

m

Unit pressure loss. Darcy. J = f*(1/d)*hv J m

Length L m/m

fFriction losses

AP

f m

Singularities K

Average friction factor

f

av

=

0.024

Standard straight tee [12] L/d = 20 0.484

Satandard tee (90) [12] L/d = 60 1.452

Curve 90 (5D) [12] L/d = 15 0.363

Curve 45(5D) [12] L/d = 7.5 0.181

Curve 90 (3D) [12] L/d = 11 0.266

Curve 45(3D) [12] L/d = 6.4 0.155

Elbow 90 standard [12] L/d = 30 0.726

Codo 45 estndar [12] L/d = 16.0 0.387

Reduction | = d

1

/d

2

(Nota 1) [12]

| =

0.75 0.42

Enlargement | = d

1

/d

2

(Nota 1) [12]

| =

0.75 0.60

Diaphragm valve (Weir K = f(dn) [6] dn = 4 2.35

Diaphragm valve (Thru) K = f(dn) [6] dn = 4 0.27

Pinch valve K = f(dn) [5] dn = 4 0.28

Gate/knife valve K = f(dn) [3] dn = 4 3.38

Vlvula de cono K = f(dn) [10] dn = 4 N/A

Ball valve K = f(dn) [1] dn = 4 0.05

Butterfly V. Bray 20/21 K = f(dn) [2] dn = 4 0.14

Butterfly V. Bray 30/31 K = f(dn) [2] dn = 4 0.33

Globe valve K = f(dn) [4] dn = 4 8.48

Angular valve (90) K = f(dn) [9] dn = 4 14.84

Check valve K = f(dn) [8] dn = 4 1.94

Y-filter K = f(dn) [11] dn = 4 2.92

Pipe inlet (r/D = 0) [12] - 0.50

Pipe outlet [12] - 1.00

Other 0.34

Other 0

Nota 1. d2 is the largest diameter

Total singular coefficient K

sing_tramo

=

Singular losses. AP

s_tramo

= K

sing_tramo

*h

v

= AP

s_tramo

Friction losses AP

f_tramo

Other losses (mca) AP

otras

Sum of losses AP

tramo

= EAP AP

tramo

Suction losses AP

succion

Discharge losses AP

impulsion

Total losses AP = APsuction + APdischarge

g = 9.80665 m/s

Constant of the water parabola

Ap =

C =

AP =

Q =

C =

60

70

F

r

i

c

t

i

o

n

h

e

a

d

l

o

s

s

H

f

[

m

]

Figure 6.2.- Heterogeneous slurry

0

10

20

30

40

50

60

0.00 0.01

F

r

i

c

t

i

o

n

h

e

a

d

l

o

s

s

H

f

[

m

]

B

A

Rev. cjc 30.01.2014

mm Pipe absolute rugosity Rabs = 0.15 mm

% Kinematic viscosity v = 1.3E-06 [m/s]

in Water flow rate Q = 37.5 m/h

- (In this method, slurry flow rate is usedin the initial calculation)

- Pipe lengths L

succ

= 5 m

mm L

disch

= 400 m

1 2 3 4 5 6 7

4 4

STD STD

114.3 114.3

6.02 6.02

9.00 9.00

84.26 84.26

0.0843 0.0843

0.00558 0.00558

0.15 0.15

0.0018 0.0018

0 0

37.5 37.5

1.87 1.87

1.61 1.61

121,430 121,430

0.0242 0.0242

1.16 1.16

0.178 0.178

0.051 0.051

5.00 400.00

0.26 20.49

1 3

4 26

1

Discharge SUCTION

Number of singularities in each section

0

2 2

3

1

1

1

1

13.99 0 29.79 0 0 0 0

2.50 0.00 5.31 0.00 0.00 0.00 0.00

0.26 0.00 20.49 0.00 0.00 0.00 0.00

2.75 0.00 25.80 0.00 0.00 0.00 0.00

2.75 mwc

25.80 mwc

28.56 mwc

Constant of the water parabola

C * Q^2

Ap / Q

28.56 mwc

0.0104 m/s

262,505

Heterogeneous slurry

0.01 0.02

Flowrate Q [m

3

/s]

A

C

Input data for pressure difference A calculation resume is going to be made

calculation routine (Note 1) with the use of the function

From sheet 3 DeltaP = Slurry_Weir_A_DeltaP_d50_Cw_dn_Ss_Pw

Particle diameter d50 d

50

= 145 mm

Weight concentration C

w

= 40 % Input data for the function

Volumetric concentration C

v

= 20.10 % DeltaP = Slurry_Weir_A_DeltaP_d50_Cw_dn_Ss_Pw

Pipe nominal diameter

dn 4 in d

50

= 145 m

Pipe schedule sch = STD - Cw = 40 %

Solid's specific weight S

S

= 2.65 - d

n

= 4 in

Lining and deposition thickn. s

lining

9 mm S

s

= 2.65 -

Pipe absolute rugosity Rabs = 0.15 mm Q = 0.0104 m/s

Kinematic viscosity v = 1E-06 [m/s]

P

w

= 28.56 mwc

Water flow rate Q = 37.5 m/h

s

lining

= 9 mm

From sheet 4

Water pressure drop AP

w =

28.56 mwc DPs_w = Slurry_Weir_A_DeltaP_d50_Cw_dn_Ss_Q_Pw_Slining

AP

s_w

= 1.47 msc

The slurry pressure drop is the sum

of the water pressure drop, expressed in

meters of slurry column plus the

calculated difference APs-w [msc]

AP

s =

AP

w

+ AP

s-w

AP

w =

28.6 msc

Note 1 AP

s_w

= 1.47 msc

The routine calculates the presure difference

between the slurry and the water curves, AP

s =

30.0 msc

for a given flow rate, as described in [1].

OK. Cv within range

OK. d50 within range

5.- Pressure difference betwen slurry and water as flow media

Checking of ranges

Rev. cjc 30.01.2014

Range of application Internal diameter of CS pipe

When using the function DeltaP, the limit

d

i

= Pipe_Imp_CS_Dint_dn_sch(dn,sch)

flow "Q

L

" has to be calculated to know d

n

= 4 in

whether the correction factor has to be sch = STD

considered or not. d

i

= 102.3 mm

The corecction factor has to be applied if

Inside diameter with lining and depos.

Q / Q

L

< 1.4 di = d - 2 * s

lining

For heigher values of of the ratio Q/Q

L d = 102.3 mm

the slurry presure drop is the same as s

lining

= 9 mm

the water pressure drop, but expressed di = 84.26 mm

in meters slurry column.

di = 0.08426 m

To avoid deposition the minimum velocity Pipe section

shall be A = (t/4) * d^2

v

L_min

= 1.1 * v

L d = 0.08426 m

thus, the correction "AP

s-w

" is to be A = 0.0056

m

2

applied only if

1.1 < Q/Q

L

<= 1.4 Limit flow rate

Q

L

= v

L

* A

Limit deposition velocity v

L

= 1.61 m/s

This velocity is calculated according A = 0.0056

m

2

JRI [3] Q

L

= 0.0090 m/s

v

L

= Slurry_Limit_Deposition_Velocity_Lining_JRI_Imp_d50_Cv_dn_Ss_Slining

d

50

= 145

m

Ratio Q/QL

C

v

= 20.1 % Q = 0.0104

m

3

/s

d

n

= 4 in Q

L

= 0.0090

m

3

/s

S

S

= 2.65 - Q / Q

L

= 1.16 -

s

Lining

=

9.00 mm

v

L

= 1.61 m/s Q/Qc< 1.4. Correction shall be applied

5.- Pressure difference betwen slurry and water as flow media

Curves construction

Determination of the pulp resistance The water curve, shown in sheet 4,

curve

The limit flow rate is (sheet 5)

The pulp friction height in [mpc],

will be numerically greater than the

Q

L

= 0.0090

m

3

/s

water friction loss [mwc] for the same

flow. [1], p. S6-3 and [2], page 59 Point "A" of the water resistance

curve

In this development it will be asumed that

the static height is zero. Draw a vertical line Q = QL until it

Z = 0.0 m cust the water resistance curve. This

point in the curve is the point "A"

If "Z" is positive (or negative), a parallel Q

A

= Q

L

line to the graphic base shall be drawn, Q

A

= 0.009

m

3

/s

at a distance "Z" above (or below) of this

base.

The pressure drop at this point is

So, the left most point of the curve will Ap

A

= C * Q

A

^2

start at this line and not in the origin. C = 262505

Q

A

= 0.009

m

3

/s

Ap

A

= 21.21 mca

First, calculate the pressure losses as

the fluid were water (done in sheet 4) From point "A" draw an horizontal line

The water resistance curve has been until it cuts the ordinate axe. This point

claculated in sheet 3. is the pressure corresponding to the

The parabel has the form limit flow QL.

Ap = C * Q^2

and the "C" value is

C = 262,505 Sheet 4)

Points "A", "B" and "C" of the curves

Pulp resistance curve Point "B"

Point "B" isdefined with a pressure

equal to the pressure at point "A" and

Water resistance curve with a flow equal to 70% of the limit flow

6.- Theory of Warman's empirical method

Pumping heterogeneous slurries

t Q s Q r P + + =

2

Pressure at point "B"

Punto "A" P

B

= P

A

P

A

= 21.2 m ca

Point "A" is defined as a point of the P

B

= 21.2 m ca

water curve, where the flow has the value

of the limit flow

Flow at point "B"

Flow at point "A"

Q

A

= Q

L

Experience data indicates that the pulp

Q

L

= 0.009

m

3

/s

resistance curve has his minimum at a

Q

A

= 0.009

m

3

/s

point determined by a value

Pressure at point "A" C

b

= 0.7

where

P

A

= C * Q

A

^2 Q

b

= C

b

* Q

L

C = 262505 C

b

= 0.7

Q

A

= 0.009

m

3

/s

Q

L

= 0.009

m

3

/s

P

A

= 21.2 m ca Q

b

= 0.006

m

3

/s

The system is defined by four equations. b) Tangente de la curva de

These equations allow the three curve resistencia del agua en el punto "c"

parameters (r, s and t) of the slurry

curve and the flow at point "C" to be Water resistance curve

determined.

Pulp resistance curve The pressure derivative is

Evaluationg the slope at point "C"

a) Tangente nula en "b"

(Ec. b1)

The pulp resistance curve is defined

with an horizontal tangent in point "B"

The pressure derivative is

s Q r

dQ

dp

+ = 2

t Q s Q r P + + =

2

2

Q C P =

2

Q C P

w

=

Q C

Q

P

w

=

c

c

2

C

C

w

Q C

Q

P

=

c

c

2

t Q s Q r P

P

+ + =

2

C

P

C

w

Q

P

Q

P

c

c

=

c

c

Condition for tangent zero at point "b"

(Ec. a)

(Ec. a) From equations (a) y (b)

(Ec. b)

Replacing (a) in (c)

(Ec. c)

Replacing (a) in (d)

(Ec. d)

.(e)

(f)

(g)

s Q r

dQ

dp

+ = 2

b

Q r s = 2

c c

Q r Q C s = 2 2

c c c

Q s Q r Q C t =

2 2

b

Q r s = 2

) ( 2 r C Q s

c

=

t Q s Q r p

b b b

+ + =

2

b c

Q r r C Q = 2 ) ( 2

( ) t Q Q r Q r p

b b b b

+ + = 2

2

( )

c b c c

Q Q r Q r Q C t = 2

2 2

( )

c b c

Q Q r r C Q t + = 2

2

t Q r p

b b

+ =

2

b c

Q r r C Q = 2 ) ( 2

2

b b

Q r p t + =

( )

c b c

Q Q r r C Q t + = 2

2

0 =

B

dQ

dp

0 2 = + = s Q r

dQ

dp

B

B

0 2 = + s Q r

B

C

P

C

w

Q

P

Q

P

c

c

=

c

c

s Q r Q C

C C

+ = 2 2

.(e)

Replacing (e) en (h), one obtain a 3th degree equation, that enables to obtain "Qc"

This equation is solved with the function Function Qc_C_Qb_Pb(C,Qb,Pb)

Checking the required slopes

Slope at point "B" (must be equal zero)

dP/dq|b = 2 r * Q

b

+ s

r = 514,716

Q

b

= 0.006

s = -6477.3

dP/dq|b = 0 OK

Checking of slopes at point "C", that shall be equal for both curves

Slurry curve slope at point "C" Water curve slope at point "C"

Ap = C * Q^2

2* r * Q

c

+ s 2 * C * Q

C

r = 514,716 C = 262,505

Q

c

= 0.013 m/s Q

c

=

0.0128 m/s

s = -6477

6742 6742

b c

Q r r C Q = 2 ) ( 2

b c c

Q r r Q C Q = 2 2 2

b c c

Q r r Q C Q = 2 2 2

( ) ( ) ( )

0 2

2 2

=

(

+

|

|

.

|

\

|

(

b b

b c

c

b

b c

c

c

b c

c

c

p Q

Q Q

C Q

Q

Q Q

C Q

Q

Q Q

C Q

C Q

t Q s Q r P

P

+ + =

2

s Q r

Q

P

P

+ =

c

c

2

0 =

c

c

Q

P

P

s Q r

Q

P

C

C

P

+ =

c

c

2

=

c

c

C

P

Q

P

=

c

c

C

P

Q

P

C

C

w

Q C

Q

P

=

c

c

2

=

c

c

C

w

Q

P

=

c

c

C

w

Q

P

=

c

c

c

c

C

P

C

w

Q

P

Q

P

t Q s Q r P

P

+ + =

2

0 OK

=

c

c

c

c

C

P

C

w

Q

P

Q

P

Rev. cjc 30.01.2014

1

A simple way to solve the problem is to

provide a "Cc value" taken from the

Point "B" of the resistance curve experience, which is known to originate

results, very similar to those obtained in

Experience data indicates that the pulp the real life.

resistance curve has its minimum at Warman uses the value

approximately a value C

c,W

= C

c,Warman

C

B

= 0.7 C

c,W

= 1.43

where Using this value, the two curves

Q

B

= C

B

* Q

L intersect at point "C", with very similar

C

B

= 0.7

slopes (no tangency).

Q

L

= 0.009

m

3

/s The flow corresponding to this point is

Q

B

= 0.006

m

3

/s

Q

c,W

= C

c,W

* Q

L

C

c,W

= 1.42857203

The pressure loss corresponding to this Q

L

= 0.009

m

3

/s

point is Q

c,W

= 0.0128

m

3

/s

AP

B

= AP

A

AP

A

= 21.21 mca The pressure loss corresponding to this

AP

B

= 21.21 mca point is

Ap

c,W

= C * Q

c,W

^2

Thus, point "B" is defined by C = 262505

Q

B

= 0.006

m

3

/s

Q

c,W

= 0.0128

m

3

/s

AP

B

= 21.21 mca Ap

c,W

= 43.3 mca

When enforced the requirement

Point "C" of the resistance and water of tangency (indicated by Warman),

curves point "C" scrolls as shown

Experince data indicates that these in the following table

two curves merge from a point "C" to Q H

be determined. m

3

/s

m ca

The flow at point "C" will be "A" 0.009 21.21

Q

C

= C

C

* Q

L

"B" 0.006 21.21

with "Cc" a value to be determined. "C" 0.0128 43.29

2

Point "C"

Point "C" is defined as the point where

both curves have a common point and

where they ar tangent as well.

6.- Theory of Warman's empirical method

Pumping heterogeneous slurries

Flow at point "C"

Flow at point "C" is defined as

Q

C

= C

C

* Q

L

where C

C

is a value determined by the

conditions impose to the system.

Pressure at point "C"

Point "C" is determined as follow

3

c) Tangente de la curva de e) Curvas de resistencia se cortan

resistencia de la pulpa en punto "c" en "C"

Pulp resistance curve

The pressure derivativeis

(Ec. c1)

Evaluating at point "C" Water resistance curve

(Ec. b2)

(Ec. c2)

d) Condition of common tangent at Equating equations c1 y c2

point "c"

2

Q C p =

t Q s Q r p

c c c

+ + =

2

t Q s Q r p + + =

2

2

c c

Q C p =

t Q s Q r Q C

c c c

+ + =

2 2

t Q s Q r P

P

+ + =

2

s Q r

Q

P

P

+ =

c

c

2

s Q r

Q

P

C

C

P

+ =

c

c

2

C

P

C

w

Q

P

Q

P

c

c

=

c

c

(Ec. c)

f) Pulp resistance curve

goes through point "b"

Curva de resistencia de la pulpa

(Ec. b)

(Ec. d)

4

.(e)

(g)

(f)

Equating equations (g) y (f)

(h)

(f)

(g) (h)

c c

Q r Q C s = 2 2

) ( 2 r C Q s

c

=

t Q s Q r p

b b b

+ + =

2

t Q s Q r p + + =

2

t Q s Q r Q C

c c c

+ + =

2 2

c c c

Q s Q r Q C t =

2 2

( ) t Q Q r Q r p

b b b b

+ + = 2

2

( )

c b c c

Q Q r Q r Q C t = 2

2 2

t Q r Q r p

b b b

+ =

2 2

2

t Q r p

b b

+ =

2

( )

c b c

Q Q r r C Q t + = 2

2

( )

2 2

2

b b c b c

Q r p Q Q r r C Q + = +

( ) 0 2

2 2

= +

b b b c c

p Q r Q r Q r C Q

C

P

C

w

Q

P

Q

P

c

c

=

c

c

s Q r Q C

C C

+ = 2 2

.(e)

(i)

5

Results for the pulp resistance

curve

r = 514,716

s = -6,477

t = 42

Flows

Q

A

= 0.009 m/s

Q

B

= 0.006 m/s

Q

C

= 0.0128 m/s

b c c

Q r r Q C Q = 2 2 2 ( )

b c c

Q Q r C Q =

( )

b c

c

Q Q

C Q

r

=

( ) ( ) ( )

0 2

2 2

=

(

+

|

|

.

|

\

|

(

b b

b c

c

b

b c

c

c

b c

c

c

p Q

Q Q

C Q

Q

Q Q

C Q

Q

Q Q

C Q

C Q

Water and slurry curves. Durand limit velocity

According Weir empirical method [10]

For validity range, see Note 1

Mc Ewans and Cave correction factor

F

L

= Pipe_Fl_McElvain_d50_Cv(d50,Cv)

Input data d

50

= 145 m

Following data is required to draw the

curves

C

v

= 20.1 %

dn 4 in

sch = STD - Limit deposition velocity according JRI [3]

d

50

= 145 mm d

50

= 145 m

C

v

= 20.1 % C

v

= 20.1 %

S

S

= 2.65

-

dn 4 in

s

lining = 9 mm Ss = 2.65 -

Q =

0.0104

m/s

s

lining

= 9 mm

AP = 28.56 mwc

v

L

= Slurry_Limit_Deposition_Velocity_Lining_JRI_Imp_d50_Cv_dn_Ss_Slining

v

max

= 4 m/s v

L

= 1.61 m/s

Inside diameter with lining Slurry flow velocity

di = d - 2 * s

lining

v = Q

P

/ A

m

3

/s

where s

lining

is the sum of the lining pipe Q

P

= 0.0104

m

2

and the deposition film

A = 0.0056 m/s

Inside pipe diameter

v = 1.87

d = Pipe_Imp_CS_Dint_dn_sch

d = 102.3 mm

s

lining

= 9 mm

di = 84.26 mm Limiting flow rate

di = 0.08426 m Q

L

= v

L

* A

v

L

= 1.612 m/s

Area of pipe section A = 0.0056

m

2

A = (t/4)*di^2 Q

L

= 0.0090

m

3

/s

di = 0.08426 m

A = 0.005576129 m Note 1. The method is valid for the Weir defined type-A fluids. See sheet Ref. 10 & 11

Water system curve constant From pages 3 to 5, sheet 6, [3]

The system curve for water is the pulp curve is

for H

estat.tot

= 0

H = r*Q^2 + s*Q + t

AP = C * Q^2 with

Velocity enough to avoid settlement

7.- Weir method for slurry pump selection for A-type fluids

OK. d50 within range

OK. Cv within range

OK. v < vmax

( )

(

=

b c

c

Q Q

C Q

r

thus, the water system constant is

C = AP / Q^2

From input data, the water pressure drop is r = C * Qc / (Qc - Qb)

Ap = 28.56 mwc C = 262,505

and the flow rate (Q

P

= Q

w

) is Qc = 0.0128410

Q

P

= 0.0104

m

3

/s

Qb = 0.006

then r = 514,716

C = 262,505 -

From page 4 of Sheet 6, the flow rate at point "c" is s = - 2 * r * Qb

calculated from equatio (i)

[3]

r = 514716

(Ec. i) Qb = 0.006

s = -6477

This equation is solved with the function

Function Qc_C_Qb_Pb(C,Qb,Pb) t = Qc^2*(C - r) - s*Qc

Using an auxiliar variable Qc = 0.0128410

z = (Qc*C)/(Qc-Qb) C = 262505

The equation to be solved is r = 514716

Zero = Qc^2*(C-z) +2*Qc*Qb*(z) - Qb^2*(z)-Pb s = -6477

The equation is solved using the function t = 41.6

Qc = Qc_C_Qb_Pb(C,Qb,Pb)

C = 262,505 Thus, the parabola constants for the

Q

b

= 0.0063

m

3

/h

slurry curve are:

P

b

= 21.2 mca r = 514,716

Qc = 0.0128

m

3

/h

s= -6,477

t = 41.6

( ) ( ) ( )

0 2

2 2

=

(

+

|

|

.

|

\

|

(

b b

b c

c

b

b c

c

c

b c

c

c

p Q

Q Q

C Q

Q

Q Q

C Q

Q

Q Q

C Q

C Q

( )

(

=

b c

c

Q Q

C Q

r

b

Q r s = 2

c c

Q s r C Q t = ) (

2

40

50

60

70

F

r

i

c

t

i

o

n

h

e

a

d

l

o

s

s

H

f

[

m

]

Figure 6.2.- Heterogeneous slurry

Pulp resistance curve [mpc]

H = r*Q^2 + s*Q + t

C = 262505 C = 262505

Limiting flowrate

Q

a

= Q

L

Q Ap Q Ap Ap

m

3

/s

m fc

m

3

/s

m fc m fc

0 0.00 0.0090 0.00 0.00

0.001 0.26 0.0090 10.00 0.00

0.002 1.05 0.0090 20.00 20.00

0.003 2.36 0.0090 24

0.004 4.20 0.0090 28

0.005 6.56 0.0090

0.006 9.45 0.0090

0.007 12.86 0.0090

0.008 16.80 0.0090

0.009 21.26

0.01 26.25

0.012 37.80

0.014 51.45

0.016 67.20

C = 262505

r = 514716

s= -6477

t = 42

Limiting flow rate

Q

L

= v

L

* A

Water curve QL * 1.1

Ap = C * Q

0

10

20

30

40

0.00 0.01

F

r

i

c

t

i

o

n

h

e

a

d

l

o

s

s

H

f

[

m

]

Flowrate Q [m

B

A

Minimum pressure

v

L

= 1.61 m/s

A = 0.01

m

2

Q

L

= 0.00899

m

3

/s

1.1 * Q

L

= 0.0099 m/s

Subroutine for the pressure loss, for the actual flow in metres of pulp column

For Q < 1.1 * Q

L

,

deposition will occur Q

L

= 0.0090

m

3

/s

For 1.1 * Q

L

< Q <= Q

c

Pulp curve is to be used P = r * Q^2 + s * Q + t

For Q > Q

c

Water curve is to be used P = C * Q^2

Flow "1.1 * Q

L

"

1.1 * Q

L

= 0.0099

m

3

/s

Q >= 1.1 *QL

Flow at point "c"

Q

c

= 0.0128

m

3

/s

Actual flow

Q = 0.0104

m

3

/s

Slurry curve

P =

r * Q^2 + s * Q + t, C *Q^2

r = 514,716

s = -6,477

t = 42

C = 262,505

P = SI( Q<=Q

c

, r * Q^2 + s * Q + t, C *Q^2)

P = 30.02 mpc

Flow enough to avoid deposition

1.1*QL < Q < Qc. Flow to be calculated

using the slurry curve

Ratio Q

P

/Q

L

Q

B

= C

B

* Q

L

whith C

B

= 0.7

Q

P

= 0.0104

m

3

/s Thus, with

Q

L

= 0.0090 m

3

/s

C

B

= 0.7

Q /Q

L

= 1.16 Q

L

=

0.0090

the value of the limit flow is

Q

L

= 0.0090

and Q

B

= 0.006

Points "A" y "B"

Pressure in point "B"

Flowe rate and pressure in point "A" According "Weir" asumption, it should be

Point "A" is defined as the point in the

P

B

= P

A

Water curtve, where the flow rate

coincides with the limiting flow rate. If the total static height is not zero, the

v

L

= Slurry_Limit_Deposition_Velocity_Lining_JRI_Imp_d50_Cv_dn_Ss_Slining

Thus parabola equation shall be

Q

A

= Q

L

P = H

stat_tot

+ C * Q^2

.

Q

L

=

0.0090 m/s

Q

A

=

0.0090 m/s

Total static height

Since the water curve is a parabola EL

suc

= 0.0

and in this case the total static E

lpump

= 0.0

height has been defined as zero, the EL

disch

= 0.0

parabola equation is

H

stat.tot

= EL

desc

- El

suc

. P = C * Q^2 H

stat.tot

= 0.000

For the point "A"

P

A

= C * Q

A

^2

Weight concentration

Cw = Ss*Cv / ( 1 + Ss*Cv - Cv )

Flow rate in point "B" S

s

= 2.65

Experience data indicates that the pulp C

v

= 0.20

resistance curve has its lowest point at Cw = 0.40

a flow rate defined by a value "CB",

Cw = 40

Note 1. The method is valid for the Weir defined type-A fluids. See sheet Ref. 10 & 11

From pages 3 to 5, sheet 6, [3] Pressure at point "A" The ratio Q

c

/ Q

L

is

Q

A

= Q

L

Q

c

/ Q

L

=

Q

A

= 0.0090

m

3

/s

Q

c

=

P

A

= C * Q

a

^2 Q

L

=

C = 262,505 Q

c

/ Q

L

=

7.- Weir method for slurry pump selection for A-type fluids

No settling, but increase diameter if possible

Q

A

= 0.0090

m

3

/s

P

A

= 21.2 m Warman indicates a value

Q

c

/ Q

L

=

C * Qc / (Qc - Qb) Pressure at point "B" as an approximate value

P

B

= P

A

=

The reason being that up a value of 1.3,

P

A

= 21.2 m ca

both water and slurry curves are

P

B

= 21.2 m ca practically the same (see Fig. 6.2)

The constant "C

c

" For this application, the ratio Q / Q

L

is

Relating the flow at point "C" to the Q / QL =

limiting flow "Q

L

" with the pameter "C

C

" Q =

Q

c

= C

c

* Q

L

QL =

C

c

= Q

c

/ Q

L

Q / QL =

Q

c

= 0.0128

m

3

/s

Q

L

= 0.009

m

3

/s

According Weir, at flows over "Qc" the

C

c

= 1.43 slurry curve and the water curve should

be similar. Thus, for Q > Q

C

, the pressure

Qc^2*(C - r) - s*Qc Pressure at point "C" can be calcualted using the water curve,

P

C

=

r*Q^2 + s*Q + t expressed in metres of slurry column and

Q

c

= 0.0128

m

3

/s no correction is required.

r = 514716

s= -6477 On the other hand, the flow should not

t = 42 be lower than the limiting value "1.1*QL"

P

C

=

43.29 m to ensure no deposition will occcur.

Thus, the parabola constants for the

Thus, a correction will be only required

in the range

1.1 * Q

L

< Q < 1.4 * Q

L

c c

Q s r C Q t = ) (

2

Heterogeneous slurry

Qa= QL

DP=C*Q

Qb=Cb*QL

Qc=Cc*QL

C

Water

resistance curve

2

Q C P

w

=

Actual flow rate

Graphic is for static height equal zero

C = 262505

Flow rate at point"B" Actual flow rate

0.0104

QL * 1.1 Q Ap Q Ap

m

3

/s

m fc

m

3

/s

m fc

0.0099 0.0063 0.00 0.0104 0.00

0.0099 0.0063 10.00 0.0104 25.00

0.0099 0.0063 20.00 0.0104 50.00

0.0099 0.0063 0.0104 75.00

0.0099 0.0104 100.00

0.0099 0.0104 125.00

0.0099 0.0104 150.00

0.0099 0.0104 175.00

0.0099 0.0104 200.00

0.0104 225.00

0.0104 250.00

0.0104 275.00

0.0104 800.00

Minimum pressure drop

Ap = Apa

Q P

a

Q Pactual

m

3

/s

mpc

m

3

/s

mpc

0.000 21.2 0.000 30.02

0.010 21.2 0.010 30.02

0.015 21.2 0.015 30.02

0.020 21.2 0.020 30.02

QL * 1.1

Q

b

=C

b

* Q

L

Actual pressure drop

0.01 0.02

Flowrate Q [m

3

/s]

Qb=Cb*QL

Qc=Cc*QL

Slurry resistance

Q

QL*1.1

Pa

Pactual

C

Limiting flowrate Q

L

Flowrate Q

b

= 0.7 * Q

L

Q = 1.1 * Q

L

Q

c

= 1.43 * Q

L

Actual flow rate

Actual pressure

0.025 21.2 0.025 30.02

0.030 21.2 0.030 30.02

0.035 21.2 0.035 30.02

0.040 21.2 0.040 30.02

0.042 21.2 0.042 30.02

0.045 21.2 0.045 30.02

0.050 21.2 0.050 30.02

Slurry_Weir_A_DeltaP_d50_Cw_dn_Ss_Pw_Slining(d50, Cw, Dn, Ss, Q, P, Slining)

Use of function DeltaP

The shown subroutine calculation can be repalced by the function DeltaP

Input data for the function DeltaP The slurry pressure is then,

DeltaP = Slurry_Weir_A_DeltaP_d50_Cw_dn_Ss_Pw_Slining(D368, D369, D370, D371, D372, D373,D374)

. P = P

w

+ DeltaP

d

50

= 145 m with

Cw = 40 % P

w

: the pressure calculated as the fluid

d

n

= 4 in

was water

S

s

= 2.65 - P

w

= 28.56

Q = 0.01043

m

3

/s and

P

w

= 28.56 mwc

DeltaP: the difference between the

s

lining

= 9 mm pressures for slurry and water,

measured in metres of pulp column,

Function result (Note 1) corresponding to the actual flow

DeltaP = 1.47 msc DeltaP = 1.47

Note 1. Correction "DeltaP" required Thus, the slurry pressure is

to be applied only if P = 30.02

1.1 * Q

L

< Q <= 1.4 * Q

L

Checking of ranges:

This condition is equivalent to

1.1 < Q/Q

L

<= 1.4

These ranges correspond to the by Weir

In this application defined type-A fluid

Q = 0.0104 m/s

Q

L

= 0.0090 m/s Note.

Q/Q

L

=

1.16 When using the standard method (sheet 2)

the pressure head is

P = 29.23

Between both methods there is a difference of

AP

difference

= 0.791

2.6

OK. Cv within range

Correction is to be applied

OK. d50 within range

Rev. cjc 30.01.2014

1

and

m/s

m

3

/s

m

3

/s

According "Weir" asumption, it should be

If the total static height is not zero, the

H

stat_tot

+ C * Q^2

m

m

m

m

Ss*Cv / ( 1 + Ss*Cv - Cv )

-

-

-

%

2

The ratio Q

c

/ Q

L

is

0.0128

0.0090

1.43

7.- Weir method for slurry pump selection for A-type fluids

0

10

20

30

40

50

60

70

0.00

F

r

i

c

t

i

o

n

h

e

a

d

l

o

s

s

H

f

[

m

]

Figure 6.2.

B

Warman indicates a value

1.3

as an approximate value

The reason being that up a value of 1.3,

both water and slurry curves are

practically the same (see Fig. 6.2)

For this application, the ratio Q / Q

L

is

0.0104

m

3

/s

0.0090

m

3

/s

1.16

m

3

/s

According Weir, at flows over "Qc" the

slurry curve and the water curve should

be similar. Thus, for Q > Q

C

, the pressure

can be calcualted using the water curve,

expressed in metres of slurry column and

no correction is required.

On the other hand, the flow should not

be lower than the limiting value "1.1*QL"

to ensure no deposition will occcur.

Thus, a correction will be only required

3

1.1 * Q

L

< Q < 1.4 * Q

L

Qa= QL

DP=C*Q

Qb=Cb*QL

Qc=Cc*QL

Graphic is for static height equal zero

C = 262505 4

Q

c

=C

c

* Q

L

262505

Q Ap

m

3

/s

m fc

0.0128 0.00

0.0128 10.00

0.0128 20.00

0.0128 30.00

0.0128 35.00

0.0128 40.00

0.0128 45.00

Q H

m

3

/s

m cf

0.002 30.69

0.004 23.91

0.006 21.25

0.008 22.71

Flow rate at point"c"

Slurry resistance curve

H = r*Q^2 + s*Q + t

Qb=Cb*QL

Qc=Cc*QL

Slurry resistance

QL*1.1

Pactual

0.010 28.29

0.012 37.98

0.014 51.79

0.016 69.72

cjc.Rev. 1213.11.2012

5

P

w

: the pressure calculated as the fluid

mwc

DeltaP: the difference between the

pressures for slurry and water,

measured in metres of pulp column,

corresponding to the actual flow

msc

msc

These ranges correspond to the by Weir

When using the standard method (sheet 2)

msc

Between both methods there is a difference of

msc

%

OK. Cv within range

OK. d50 within range

0.01 0.02

Flowrate Q [m

3

/s]

Figure 6.2.- Heterogeneous slurry

B

A

C

8.- Depositation limit velocity, according JRI

1. JRI Formula [1] [Eq. b] 2. JRI Formula

For coarse-grained solids with wide d50 >= 200 m For coarse-grained solids with wide

particle size range and small diameter particle size range and large diameter

tubes d, cualquiera tubes

[Ec.1]

v

L

= F

L

* (2* g * d * (S

S

-1))^0.5 v

L

= 1.25 *F

L

* (2* g * d * (S

S

-1))^0.25

Applicacin Applicacin

d

50

= 250

m d50 >= 200 m

d

50

= 150

C

v

= 20.1 % C

v

= 20.1

d

n

= 200 mm d, cualquiera d = 200

S

S

= 2.65 - S

S

= 2.65

Mc Elvain y Cave correction factor Mc Elvain y Cave correction factor

F

L

= Slurry_Fl_McElvain_d50_Cv(E19;E20) F

L

= Slurry_Fl_McElvain_d50_Cv(E19;E20)

d

50

= 250

m

10 <= d

50

<= 3000 d

50

= 150

C

v

= 20.10 % 5% <= C

v

<= 40% C

v

= 20.1

F

L

= 1.089 - F

L

= 0.988

Limit deposition velocity Limit deposition velocity

v

L

= F

L

* (2* g * d * (S

S

-1))^0.5 v

L

= 1.25 *F

L

* (2* g * d * (S

S

-1))^0.25

F

L

= 1.089 - F

L

= 1.005

g = 9.81 m/s

2

g = 9.81

d

n

= 200 d

n

= 200

Sch = STD Sch = STD

d

i

= 202.74 d

i

= 202.74

d

i

= 0.20274 m d

i

= 0.203

S

S

= 2.65 - S

S

= 2.65

v

L

=

2.790 m/s

v

L

=

2.011

v

L

= Slurry_Limit_Deposition_Velocity_JRI_Imp_d50_Cv_dn_Ss Also, there is a function that allows consideration of a

d

50

= 250

m

lining thickness.

C

v

= 20.1 %

d

n

= 8 in v

L

= Slurry_Limit_Deposition_Velocity_JRI_Imp_d50_Cv_dn_Ss_Slining

S

S

= 2.65 -

v

L

= 2.790 m/s

) 1 ( 2 =

S L L

S d g F v | |

25 . 0

) 1 ( 2 25 . 1 =

S L L

S d g F v

19

[1] [Eq. c] 3. JRI Formula [1] [Eq. a]

For coarse-grained solids with wide d50 < 200 m For fine-grained solids with narrow d50 < 200 m

particle size range and large diameter particle size range and small diameter

d >= 150 mm tubes d < 150 mm

[Ec.2]

1.25 *F

L

* (2* g * d * (S

S

-1))^0.25 v

L

= 1.1 *F

L

* (2* g * d * (S

S

-1)^0.6)^0.5

Applicacin

m d50 < 200 m

d

50

= 100

m d50 < 200 m

% C

v

= 20.1 %

mm d >= 150 mm d = 100 mm d < 150 mm

- S

S

= 2.65 -

Mc Elvain y Cave correction factor Mc Elvain y Cave correction factor

Slurry_Fl_McElvain_d50_Cv(E19;E20) F

L

= Slurry_Fl_McElvain_d50_Cv(E19;E20)

m

10 <= d

50

<= 3000 d

50

= 100

m

10 <= d

50

<= 3000

% 5% <= C

v

<= 40% C

v

= 20.1 % 5% <= C

v

<= 40%

- F

L

= 0.920 -

Limit deposition velocity

1.25 *F

L

* (2* g * d * (S

S

-1))^0.25 v

L

= 1.1 *F

L

* (2* g * d * (S

S

-1)^0.6)^0.5

- F

L

= 0.920 -

m/s

2

g = 9.81 m/s

2

d

n

= 100

Sch = STD

d

i

= 102.26

m d

i

= 0.102 m

- S

S

= 2.65 -

m/s

v

L

=

1.665 m/s

Also, there is a function that allows consideration of a

v

L

= Slurry_Limit_Deposition_Velocity_JRI_Imp_d50_Cv_dn_Ss_Slining

6 . 0

) 1 ( 2 1 . 1 =

S L L

S d g F v | |

25 . 0

) 1 ( 2 25 . 1 =

S L L

S d g F v

10.- Water un pulp resistance curves

Warman's empirical method

Application range

50 m < d < 300 m

% < C

w

<= 40 %

The graphic represents the case of a

solids mass flow rate

m

s

= 40 ton/h

with four different weight concentrations

C

w 15 %

C

w 20 %

C

w 30 %

C

w 40 %

To each concentration corresponds

a specific pulp mass flow rate and

a pulp volumetric flow rate

The table shows a resume of the

four cases

C

w % 15 20 30 40

m

p ton/h 267 200 133 100

Q

P m

3

/s 0.0672 0.0486 0.0301 0.0209

The curves for cases with water as fluid, are the four parabolas that start from the

origin of coordinates. This is because it is considered the case in which the height

difference between the suction and the discharge is zero.

If this difference were not zero, the origin of these curves would move upwards or

downwards.

The four curves for the case of pulp, are the four parabolas with minimum flow rates

corresponding to the limit deposition flow rate QL for each case.

[1] Slurry pumping manual

Warman International Ltd.

1st edition, 2002

[2] Warman Slurry Pumping Handbook - AU

Warman International Ltd.

Feb. 2000

[3] JRI

'Curso de transporte hidrulico de slidos

'Tecnex. Ingenieros ltda. (JRI)

'Octubre 1993

'pginas 20 y 21

[4] Slurry systems handbook

[5] Warman slurry pumping handbook

http://www.pumpfundamentals.com/slurry/Warman_slurry_pumping.pdf

1.- Ball valves

http://info.jamesbury.com/public/publicdocs/Docs/T120-1.pdf

2.- Butterfly valves Bray 2021

http://www.bray.com/docs/brochures/20.pdf

2.- Butterfly valves Bray 3031

http://www.bray.com/docs/brochures/30.pdf

3.- Knife valves

http://www.sureflowequipment.com/pdf/Knife-Gate-Valves-Catalog-2008-SureFlow.pdf

4.- Globe valves

http://www.fnwvalve.com/FNWValve/assets/images/PDFs/FNW/FlgGGC_tech-Cv.pdf

5.- Pinch valves

http://www.jecwoodland.com/pinch_valve_CV.html

6.- Diaphragm valves

http://www.thevalveshop.com/pdf/saunders9.pdf

6.- Diaphragm valves

http://www.thevalveshop.com/pdf/saunders9.pdf

6.- Diaphragm valves

http://www.thevalveshop.com/pdf/saunders17.pdf

6.- Diaphragm valves

http://www.thevalveshop.com/pdf/saunders17.pdf

7.- Round plug valve

http://www.gaindustries.com/MProducts/Bulletins/EccentricPlugValves/GAI_PV517.pdf

7.- Rectangular plug valve

http://www.gaindustries.com/MProducts/Bulletins/EccentricPlugValves/GAI_PV517.pdf

8.- Check valves

http://www.acuster.com/files/documentos/FC-69-PVV-10_es.pdf

9.- Angle valves

http://www.controlvalves.com/series/125/125_sizing.html

10.- Cone valve

http://www.detroitcontracting.com/documents/Cone-Valve-1.pdf

11.- Strainers

http://www.coltonind.com/file_library/products/33_STR990-1_Pressure%20Drop%20Data%20Y.pdf

12.- Expansion/reduction, fittings

Crane A-46 [1]

[2], 57-59

Cw

100

90

80

70

60

50

40

30

20

10

0 0 10 20 30 40 50 60

Particles essentially

all finer than 50 m

[1], page S6-3

Homogeneous slurries

At sufficiently low concentrations Hf will be close to that for clear water and may be estimated by the empirical method as applied to Category "A" Heterogeneous slurries

At sufficiently high concentrations, The Yield Stress characteristic largely influernces the value of Hf.

A Heterogeneous slurries Category "A"

Particles essentially all coarser than 50 m and finer then 300 m, and with Cw from Zero to 40%

Head losses can be calculated by means of the empirical method propossed by Warman in [2]

The most economical slurry velocity is a velocity a little in excess of the limit velocity " v

L

"

This is an empirical method, that provide estimates considered to be rasonable accurate for many practical slurry pimping applications.

B Heterogeneous slurries Category "B"

Particles essentially all coarser than 50 m and finer then 300 m, and with Cw greater than 40%

Generally, friction losses for this category are much higher than for Category "A" due largely to the increased friction effect of the more closed-packed solids content upon

the pipe wall. This effect generally increases with increasing Cw and is so greatly influenced by a number of variables, for example, Cw, S

s

, S

Liq

, d

50

and actual sieve analysis

of solids present that is not possible to provide a simple empirical method of estimating slurry Hf.

See [2], 59

C Heterogeneous slurries Category "C"

Particles essentially all coarser than 300 m, and with Cw from Zero to 20%

Generally, friction head losses for Category "C" slurries are also much higher than for Category "A"

See [2], 59

D Heterogeneous slurries Category "D"

Particles essentially all coarser than 300 m, and Cw greater than 20%

Generally, friction head losses for Category "D" slurries are also much higher than for Category "A"

See [2], 59

Homogeneous slurries

Heterogeneous

slurries

Weir slurry clasification

A-type 0 % <= Cw <= 40 %

50 m < d

50

< 300 m

70 80 90 100 110 120 130 140

At sufficiently low concentrations Hf will be close to that for clear water and may be estimated by the empirical method as applied to Category "A" Heterogeneous slurries

At sufficiently high concentrations, The Yield Stress characteristic largely influernces the value of Hf.

Particles essentially all coarser than 50 m and finer then 300 m, and with Cw from Zero to 40%

Head losses can be calculated by means of the empirical method propossed by Warman in [2]

The most economical slurry velocity is a velocity a little in excess of the limit velocity " v

L

"

This is an empirical method, that provide estimates considered to be rasonable accurate for many practical slurry pimping applications.

Particles essentially all coarser than 50 m and finer then 300 m, and with Cw greater than 40%

Generally, friction losses for this category are much higher than for Category "A" due largely to the increased friction effect of the more closed-packed solids content upon

the pipe wall. This effect generally increases with increasing Cw and is so greatly influenced by a number of variables, for example, Cw, S

s

, S

Liq

, d

50

and actual sieve analysis

of solids present that is not possible to provide a simple empirical method of estimating slurry Hf.

Generally, friction head losses for Category "C" slurries are also much higher than for Category "A"

Generally, friction head losses for Category "D" slurries are also much higher than for Category "A"

Heterogeneous

slurries

B

0 % <= Cw <= 40 %

50 m < d

50

< 300 m

150 160 170 180 190 200 210 220

Heterogeneous

slurries

230 240 250 260 270 280 290 300

Heterogeneous

slurries

D

310 320 330 340 350 360 370 380

Heterogeneous

slurries

C

390 400 410 420 430 440 450 460

Heterogeneous

slurries

470 d [m]

Heterogeneous

Potrebbero piacerti anche

- Technical Bulletin 1Documento8 pagineTechnical Bulletin 1RANAIVOARIMANANANessuna valutazione finora

- WPG 50MP10: For Contact Details - Visit WWW - Warman.co - Za For Contact Details - Visit WWW - Warman.co - ZaDocumento22 pagineWPG 50MP10: For Contact Details - Visit WWW - Warman.co - Za For Contact Details - Visit WWW - Warman.co - ZaMamiherintsoa Issaia RanaivoarimananaNessuna valutazione finora

- Notice: I Have: Engineering CalculationDocumento34 pagineNotice: I Have: Engineering CalculationAlexandre GelsiNessuna valutazione finora

- Mathcad - 2Documento4 pagineMathcad - 2Desejo SozinandoNessuna valutazione finora

- Liquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340Documento10 pagineLiquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340pablodugalNessuna valutazione finora

- Linear Screen Technical Data SheetDocumento4 pagineLinear Screen Technical Data SheetHARIPRASADNessuna valutazione finora

- Froth Pump Power EstimationDocumento40 pagineFroth Pump Power EstimationJuan Pablo Apaza100% (3)

- Mega - Operating Instructions PDFDocumento12 pagineMega - Operating Instructions PDFAshish TIwariNessuna valutazione finora

- Pump System Hinsom Bore PumpDocumento78 paginePump System Hinsom Bore Pumpsaroat moongwattanaNessuna valutazione finora

- TECHNICAL Layne Engineering ManualDocumento34 pagineTECHNICAL Layne Engineering ManualAnonymous CMS3dL1TNessuna valutazione finora

- Pump. Froth Selection WarmanDocumento77 paginePump. Froth Selection WarmanEmre ÖZDEMİRNessuna valutazione finora

- Agitator Power Requirement and Mixing Intensity CalculationDocumento27 pagineAgitator Power Requirement and Mixing Intensity CalculationElizabeth Allende CéspedesNessuna valutazione finora

- Keto Slurry 101Documento23 pagineKeto Slurry 101ShooeibNessuna valutazione finora

- CP100i STD Pump Build & Service Manual Revision 1Documento10 pagineCP100i STD Pump Build & Service Manual Revision 1ISRAEL GONZALESNessuna valutazione finora

- ESP Excel PAD Rev01 - 5628121 - 01Documento37 pagineESP Excel PAD Rev01 - 5628121 - 01Geraldo Soemaschris SoewarnoNessuna valutazione finora

- Pump Line Calculation SheetDocumento1 paginaPump Line Calculation SheetEsapermana RiyanNessuna valutazione finora

- American Manufacturing Aw1122bcd Parts BookDocumento6 pagineAmerican Manufacturing Aw1122bcd Parts BookFelipe MalleaNessuna valutazione finora

- Tugas MekfluDocumento21 pagineTugas MekfluriloaddNessuna valutazione finora

- Dv300 STD MMDocumento40 pagineDv300 STD MMjacklyn ade putraNessuna valutazione finora

- WPG 151AH31: 14 MM 14 MMDocumento24 pagineWPG 151AH31: 14 MM 14 MMMamiherintsoa Issaia RanaivoarimananaNessuna valutazione finora

- 1PF1R4 Ra 11263Documento8 pagine1PF1R4 Ra 11263Dias EliNessuna valutazione finora

- Thicken Er Design and ControlDocumento20 pagineThicken Er Design and ControlHarshalNessuna valutazione finora

- Catalogo TownleyDocumento12 pagineCatalogo TownleyVladimir SepulvedaNessuna valutazione finora

- GX Catalogue2013Documento32 pagineGX Catalogue2013Leobardo DiazNessuna valutazione finora

- Sump PumpDocumento1 paginaSump PumppinkypachoNessuna valutazione finora

- Burst & Collapse Presure FormulaDocumento4 pagineBurst & Collapse Presure FormulaDigger Downhole ToolsNessuna valutazione finora

- Performance Curve Notes: Viking Universal Seal PumpsDocumento2 paginePerformance Curve Notes: Viking Universal Seal PumpsErick GoyesNessuna valutazione finora

- Camisas Refrigeracion Flowsleeves Pi-058 GB 2013-06-12Documento38 pagineCamisas Refrigeracion Flowsleeves Pi-058 GB 2013-06-12daniel2rialNessuna valutazione finora

- Kemix Interstage Screen BrochureDocumento8 pagineKemix Interstage Screen BrochureFernandim SoaresNessuna valutazione finora

- KSB Pumps CatalogDocumento208 pagineKSB Pumps CatalogMuhammad Faheem ShahbazNessuna valutazione finora

- Pump OnlineDocumento62 paginePump OnlineAlWaleed KhalidNessuna valutazione finora

- Warman International LTD: Intake FlangeDocumento3 pagineWarman International LTD: Intake FlangerickNessuna valutazione finora

- Pump Performance Test Results and DataDocumento6 paginePump Performance Test Results and DataZul ZulhilmiNessuna valutazione finora

- Slurry pump sizing and selectionDocumento41 pagineSlurry pump sizing and selectionyuli_o2100% (7)

- CIP CIL Interstage Screening SolutionsDocumento4 pagineCIP CIL Interstage Screening SolutionsevalenciaNessuna valutazione finora

- Slurry Pumps MCU Introduction (English)Documento33 pagineSlurry Pumps MCU Introduction (English)Jose Antonio RojasNessuna valutazione finora

- Characteristic Curve - KSBDocumento7 pagineCharacteristic Curve - KSBmawooaNessuna valutazione finora

- Calculating pump head and specific speed using Euler's equationDocumento9 pagineCalculating pump head and specific speed using Euler's equationspdhimanNessuna valutazione finora

- Pump CurveDocumento3 paginePump CurveAnton PaneNessuna valutazione finora

- Sump Pump Critical Speeds WDS 101Documento3 pagineSump Pump Critical Speeds WDS 101RANAIVOARIMANANA0% (1)

- Analysis of LimeDocumento5 pagineAnalysis of LimeToni VilayNessuna valutazione finora

- WI - 7 5 022 Warman Pump Tolerances - r7Documento2 pagineWI - 7 5 022 Warman Pump Tolerances - r7munhNessuna valutazione finora

- HD150 Pump Maintenance ManualDocumento35 pagineHD150 Pump Maintenance Manualjacklyn ade putraNessuna valutazione finora

- Warman WGR Pump BrochureDocumento8 pagineWarman WGR Pump BrochureJOKO WIKARNANessuna valutazione finora

- Slurry Piping DesignDocumento11 pagineSlurry Piping DesignDipanjan ChakrabartiNessuna valutazione finora

- Slurry Pump CalculationsDocumento46 pagineSlurry Pump Calculationslavascudo100% (2)

- Katalog STP Red Jaket All PDFDocumento198 pagineKatalog STP Red Jaket All PDFwarung1bensin100% (1)

- Basic Pump SizingDocumento50 pagineBasic Pump SizingRizaldiSaputraNessuna valutazione finora

- ELMO-F Vacuum Units with Vacuum Pumps, Range 2BE Selection GuideDocumento17 pagineELMO-F Vacuum Units with Vacuum Pumps, Range 2BE Selection GuideDSdds0% (1)

- Affinity Laws: Centrifugal PumpsDocumento2 pagineAffinity Laws: Centrifugal PumpsPrudhvi RajNessuna valutazione finora

- Predict Friction Lossin Slurry Pipes Darbyetal 1992Documento5 paginePredict Friction Lossin Slurry Pipes Darbyetal 1992Baris YeltekinNessuna valutazione finora

- Normalizing NPSH: Calculating Suction Specific SpeedDocumento5 pagineNormalizing NPSH: Calculating Suction Specific Speedorchids28Nessuna valutazione finora

- Hand PumpsDocumento224 pagineHand PumpsKarin AndersonNessuna valutazione finora

- Bomba Galigher Horizontal - InglésDocumento7 pagineBomba Galigher Horizontal - Ingléslilium2816100% (1)

- Data Well CalculationsDocumento6 pagineData Well Calculationsfaraj100% (1)

- EI6603 - Industrial - Instrumentation - II - University - QP - Answer - KeyDocumento16 pagineEI6603 - Industrial - Instrumentation - II - University - QP - Answer - KeyMadhusudhanan Ramaiah100% (1)

- Drilling Hydraulics ADocumento63 pagineDrilling Hydraulics Asryn89100% (3)

- Solved Problems in Fluid MechanicsDocumento19 pagineSolved Problems in Fluid MechanicsPrincess Janine CatralNessuna valutazione finora

- Physical Properties of WaterDocumento4 paginePhysical Properties of WaterAshokNessuna valutazione finora

- Fluid Mechanics Tutorial 8C Pumped Piped Systems: Let's Start by Examining The Meaning of Specific Speed of PumpsDocumento17 pagineFluid Mechanics Tutorial 8C Pumped Piped Systems: Let's Start by Examining The Meaning of Specific Speed of Pumps12Nessuna valutazione finora

- Tolerance - E.O.T CranesDocumento3 pagineTolerance - E.O.T CranesSriraghuraman Gopal RathnamNessuna valutazione finora

- Steel Pipe Vessel1Documento272 pagineSteel Pipe Vessel1Juan Pablo ApazaNessuna valutazione finora

- Energy Efficient Compressed AirDocumento25 pagineEnergy Efficient Compressed AirocchityaNessuna valutazione finora

- A 501 - 01 Qtuwmq - PDFDocumento6 pagineA 501 - 01 Qtuwmq - PDFJuan Pablo ApazaNessuna valutazione finora

- Pneumatic ConveyingDocumento8 paginePneumatic ConveyingAstri NgentNessuna valutazione finora

- Simulations of Dense-Phase Pneumatic ConveyingDocumento7 pagineSimulations of Dense-Phase Pneumatic ConveyingMadan YadavNessuna valutazione finora

- Petroleum Wax in Paper: Standard Test Method ForDocumento3 paginePetroleum Wax in Paper: Standard Test Method ForJuan Pablo ApazaNessuna valutazione finora

- Quicklime For Structural PurposesDocumento2 pagineQuicklime For Structural PurposesAlejandro Valdés RojasNessuna valutazione finora

- Sampling and Accepting A Single Lot of Paper, Paperboard, Fiberboard, and Related ProductDocumento5 pagineSampling and Accepting A Single Lot of Paper, Paperboard, Fiberboard, and Related ProductfrostestNessuna valutazione finora

- D 5628 - 96 R01 - Rdu2mjg - PDFDocumento10 pagineD 5628 - 96 R01 - Rdu2mjg - PDFJuan Pablo ApazaNessuna valutazione finora

- C 5 - 79 R97 - Qzutukve PDFDocumento4 pagineC 5 - 79 R97 - Qzutukve PDFJuan Pablo ApazaNessuna valutazione finora

- E 527 - 83 R97 Rtuyny04m1i5n0ux PDFDocumento7 pagineE 527 - 83 R97 Rtuyny04m1i5n0ux PDFJuan Pablo ApazaNessuna valutazione finora

- Engineering Letter: Fanperformance-ThesystemeffectDocumento4 pagineEngineering Letter: Fanperformance-ThesystemeffectJuan Pablo ApazaNessuna valutazione finora

- Cal. Dew PointDocumento1 paginaCal. Dew PointJuan Pablo ApazaNessuna valutazione finora

- Hydro-Flo Technologies DAF Sizing CalculatorDocumento6 pagineHydro-Flo Technologies DAF Sizing CalculatorJuan Pablo ApazaNessuna valutazione finora

- Engineering Letter: SystemcalculationDocumento4 pagineEngineering Letter: SystemcalculationjmartinezmoyNessuna valutazione finora

- Pipe Dimensions and Friction FactorDocumento24 paginePipe Dimensions and Friction FactorJuan Pablo ApazaNessuna valutazione finora

- Psychrometric Functions - Resume: Max Max Max MaxDocumento5 paginePsychrometric Functions - Resume: Max Max Max MaxJuan Pablo ApazaNessuna valutazione finora

- El 25Documento8 pagineEl 25Juan Pablo ApazaNessuna valutazione finora

- Selection Criteria For DampersDocumento4 pagineSelection Criteria For Dampersmarlon168Nessuna valutazione finora

- FANS AND BLOWERS FOR COMBUSTIONDocumento4 pagineFANS AND BLOWERS FOR COMBUSTIONnedduc20Nessuna valutazione finora

- Chap1 2Documento60 pagineChap1 2Juan Pablo ApazaNessuna valutazione finora

- Engineering Letter: IntegralmotorsforcentrifugalfansDocumento4 pagineEngineering Letter: IntegralmotorsforcentrifugalfansjameeloNessuna valutazione finora

- El GDocumento8 pagineEl GJuan Pablo ApazaNessuna valutazione finora

- Engineering Letter: ElectricmotorcodesandstandardsDocumento4 pagineEngineering Letter: Electricmotorcodesandstandardsnedduc20Nessuna valutazione finora

- Psychrometric Functions - Resume: Max Max Max MaxDocumento5 paginePsychrometric Functions - Resume: Max Max Max MaxJuan Pablo ApazaNessuna valutazione finora

- Fundamentals of Steam Heating Systems ExplainedDocumento2 pagineFundamentals of Steam Heating Systems ExplainedJuan Pablo ApazaNessuna valutazione finora

- Ideal gas law application to air propertiesDocumento12 pagineIdeal gas law application to air propertiesJuan Pablo ApazaNessuna valutazione finora

- EL-00 IndexDocumento1 paginaEL-00 IndexJuan Pablo ApazaNessuna valutazione finora

- Cal. Dew PointDocumento1 paginaCal. Dew PointJuan Pablo ApazaNessuna valutazione finora

- Oscilator KeramičkiDocumento7 pagineOscilator Keramičkiacodr83Nessuna valutazione finora

- Is It Time For Industrial UPS Systems in Data Centers?: White Paper PCS100 UPSDocumento2 pagineIs It Time For Industrial UPS Systems in Data Centers?: White Paper PCS100 UPSAhmedNessuna valutazione finora

- HSC Physics PDFDocumento202 pagineHSC Physics PDFLawrence Lim Ah Kow100% (1)

- SH - No. Description: Power Control Equipments, B'LoreDocumento31 pagineSH - No. Description: Power Control Equipments, B'LoreBalamurugan ArumugamNessuna valutazione finora

- Power Systems Analysis - Bee 21 & Bew 21Documento3 paginePower Systems Analysis - Bee 21 & Bew 21zy44cwfjjgNessuna valutazione finora

- Modeling Accelerometers as Spring-Mass-Damper SystemsDocumento4 pagineModeling Accelerometers as Spring-Mass-Damper SystemsKillburnNessuna valutazione finora

- Grouped Conductor Surface Voltage GradientsDocumento1 paginaGrouped Conductor Surface Voltage GradientsRichard Andi Kanta TariganNessuna valutazione finora

- S10332200-3001 Electrical Engineering StandardDocumento64 pagineS10332200-3001 Electrical Engineering Standardappril26Nessuna valutazione finora

- Shielding PDFDocumento49 pagineShielding PDFgilbertomjcNessuna valutazione finora

- ManualDocumento38 pagineManualEl Condor CondorNessuna valutazione finora

- Cat AirpaxDocumento244 pagineCat AirpaxinggavNessuna valutazione finora

- I. V. R Operation Manual PDFDocumento20 pagineI. V. R Operation Manual PDFR Jay FranNessuna valutazione finora

- IEEE Standard Application Guide For Low-Voltage AC Nonintegrally Fused Power Circuit Breakers (Using Separately Mounted Current-Limiting Fuses)Documento12 pagineIEEE Standard Application Guide For Low-Voltage AC Nonintegrally Fused Power Circuit Breakers (Using Separately Mounted Current-Limiting Fuses)ukritNessuna valutazione finora

- Simply Smart Circuit BreakersDocumento12 pagineSimply Smart Circuit BreakersRajiv ChaudhariNessuna valutazione finora

- The Sound of Silence: Designing and Producing Silent TransformersDocumento5 pagineThe Sound of Silence: Designing and Producing Silent TransformersRezaNessuna valutazione finora

- Explore Resistors and CapacitorsDocumento108 pagineExplore Resistors and CapacitorsGurpreet KaurNessuna valutazione finora

- Relative Lowering of Vapour Pressure - 1524262518Documento4 pagineRelative Lowering of Vapour Pressure - 1524262518PavitraNessuna valutazione finora

- On The Class F Power Amplifier DesignDocumento21 pagineOn The Class F Power Amplifier DesignAmador Garcia IIINessuna valutazione finora

- GP1 Q1 Week-6 PDFDocumento9 pagineGP1 Q1 Week-6 PDFmar liaNessuna valutazione finora

- VTU-22-12-2018 08:29:13am: TG - TG - TG - TG - TG - TG - TG - TG - TGDocumento9 pagineVTU-22-12-2018 08:29:13am: TG - TG - TG - TG - TG - TG - TG - TG - TGPâvâñ NagarajNessuna valutazione finora

- Low-Voltage Hydrogen Peroxide Electrolyzer For Highly Efficient - Power-To-Hydrogen ConversionDocumento8 pagineLow-Voltage Hydrogen Peroxide Electrolyzer For Highly Efficient - Power-To-Hydrogen ConversionShangli HuangNessuna valutazione finora

- Stored Energy in CapacitorsDocumento25 pagineStored Energy in CapacitorsJennifer MagangoNessuna valutazione finora

- Switching Impulse Flashover Performance of Different Types of Insulators at High Altitude Site of Above 2800 MDocumento6 pagineSwitching Impulse Flashover Performance of Different Types of Insulators at High Altitude Site of Above 2800 MdaaanuNessuna valutazione finora

- Actividad 4. Derivación de Funciones Algebraicas: Calculo DiferencialDocumento8 pagineActividad 4. Derivación de Funciones Algebraicas: Calculo Diferencialprimitivo58Nessuna valutazione finora

- U18CE404 Hydraulics EngineeringDocumento2 pagineU18CE404 Hydraulics EngineeringPENDLI SAI SATHWIKNessuna valutazione finora

- A Presentation On 'Maxwell's Demon'Documento27 pagineA Presentation On 'Maxwell's Demon'luciferlightNessuna valutazione finora

- Kramers-Kronig Relations and Sum Rules: 10.1.1 A Notch FilterDocumento23 pagineKramers-Kronig Relations and Sum Rules: 10.1.1 A Notch FilterIvan Hernádez GutierrezNessuna valutazione finora

- Model: THG1365YLS: Technical Data SheetDocumento3 pagineModel: THG1365YLS: Technical Data SheetAndres VargazNessuna valutazione finora

- 1SBL397001R1300 Af80 30 00 13 PDFDocumento5 pagine1SBL397001R1300 Af80 30 00 13 PDFFilip KrižanNessuna valutazione finora

- Heat and Mass Transfer: "Solved Problems"Documento16 pagineHeat and Mass Transfer: "Solved Problems"qiritical99Nessuna valutazione finora